When we thought about putting together a project car with some excitement, we decided to build a 2014 Camaro SS. One that could handle 8-second drag strip duty and be driven to and from the track. While a stock Camaro is perfectly safe for everyday street use, the safety factor is much higher on the track for full-throttle runs down the strip.

When it comes to safety, we’re not oblivious to those differences. Mama didn’t raise any fool (but if she did it’s our brother at Street Muscle Magazine), so we opted to make some much-needed safety upgrades to our street/strip warrior. To make the car as safe as possible, we reached out to the pros at Impact Racing and JEGS for support.

Safety First

Ok, we know what you’re thinking. Racing restraints as seatbelts makes a lot of sense if you’re going to be partaking in all-out competition at the drag strip, but why racing seats? First…it’s smart! Safety first. Let’s also mention, if you are going to enter organized race events, the rules will probably require you to have safety equipment installed in your car. These rules vary by class, but even cars competing in “street-legal” classes have safety requirements.

“What we’ve learned about biomechanics has progressively changed things a little bit,” explains Ben O’Connor, VP of sales at Impact. “We’re really understanding how the human body works in relation to the restraints. There is actual science to it.” As the safety systems get better, the rules eventually catch up.

Sometimes, these daily-driver classes have regulations that are tougher than required on some purpose-built, track-only cars. It is best to do your homework and know which class you intend to compete. Then build your car to meet the safety rules of that class. You can expect the rules to be more stringent as the speeds of the different classes increase.

Let’s be honest here. Nobody is fooled by the “street legal” designation. Sure, the car might have a title and a license plate, but there has never been a racer on this planet that has not spent everything he/she could to make a purpose-built race car in any class. Sometimes they even get caught spending too much in certain classes. Trying to cast a slower and less dangerous light on these cars by calling them “street legal” is somewhat deceiving. They are still cars built for the purpose of racing and appropriate safety measures should be taken.

Rules And Common Sense

From the inception of this project, we focused on competing in NMCA’s True Street class. NMCA events are held at National Hot Rod Association (NHRA) or the International Hot Rod Association (IHRA) member race tracks. Since these tracks fall under the purview of the NHRA and IHRA, racers competing in the True Street class have to follow the NHRA/IHRA safety guidelines in the official rulebooks (at a minimum) to ensure they can compete.

The regulations that cover driver and passenger seats for street legal classes are pretty straightforward. They must be properly braced and framed. They must be supported and constructed of carbon fiber, aluminum, or steel. They must also be equipped with seat belts. Full-bodied cars that run 135 mph or faster, or turn 7.5 to 9.99 quarter-mile e.t.’s must have an approved window net. The common-sense approach to restraints is this: If you are installing an aftermarket seat and the car is required to have a roll bar or roll cage, buy and use a racing harness.

For most classes, the rules are clear. A quick-release, 3-inch shoulder harness meeting SFI-Spec 16.1, including a crotch strap, is mandatory in all cars required by the rules to have a roll bar or a roll cage. The driver restraint system must be clearly labeled as meeting SFI-Spec 16.1 and be dated by the manufacturer. This type of restraint system must be updated at two-year intervals from the date of manufacture.

Always Done It That Way

Racing shoulder and lap belts have seemingly always been 3-inches wide. “The origin of the 3-inch restraint we use today was that someone, at some point, had taken a set of restraints out of a military aircraft and put them in a race car.” This was a case of “we’ve always done it that way.”

“The 3-inch belts worked great for what they were doing, and the textile industry being what it was back then, the belts weren’t as strong as they are today. So the 3-inch width was really considered a necessity to gain the strength they needed,” O’Connor explained.

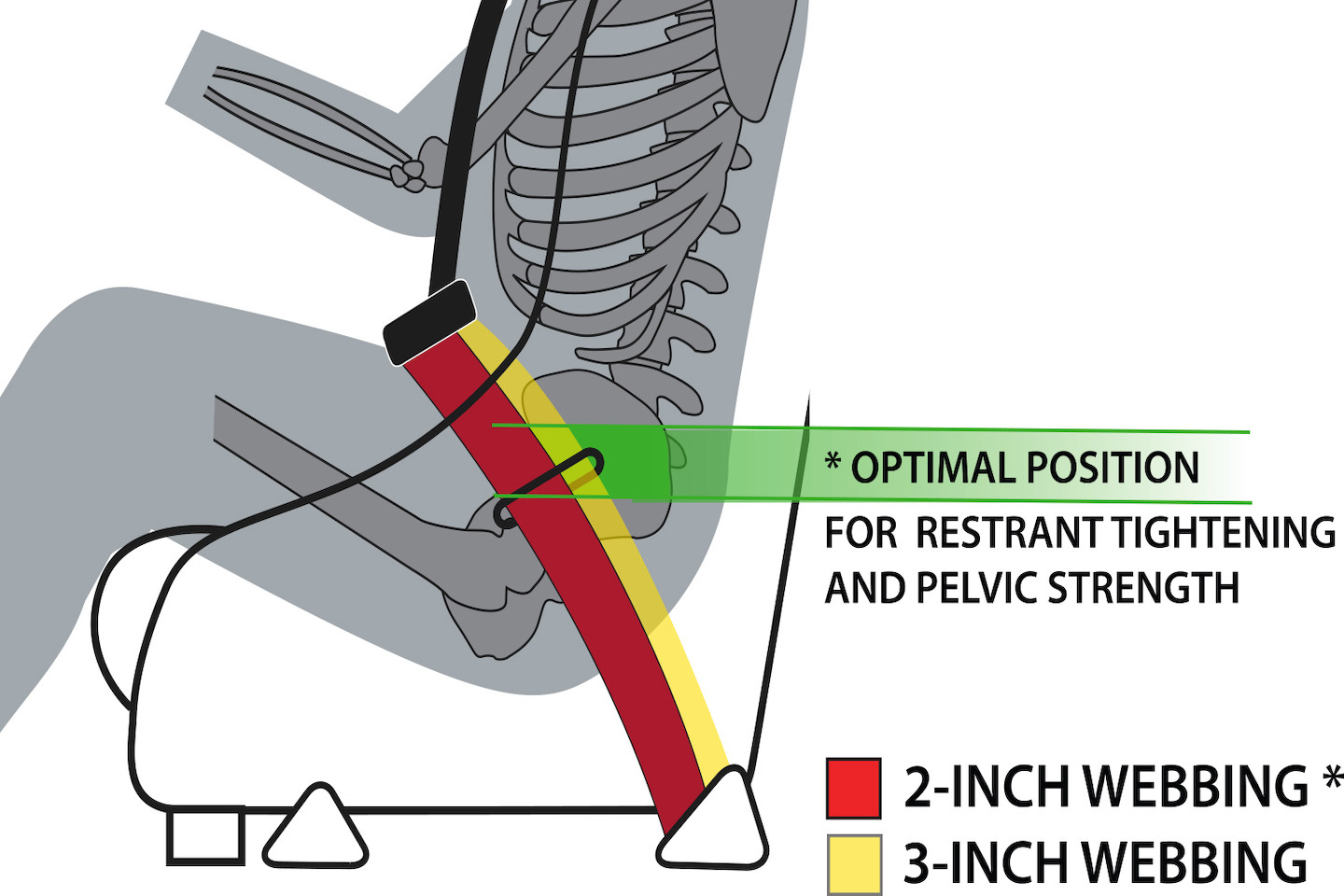

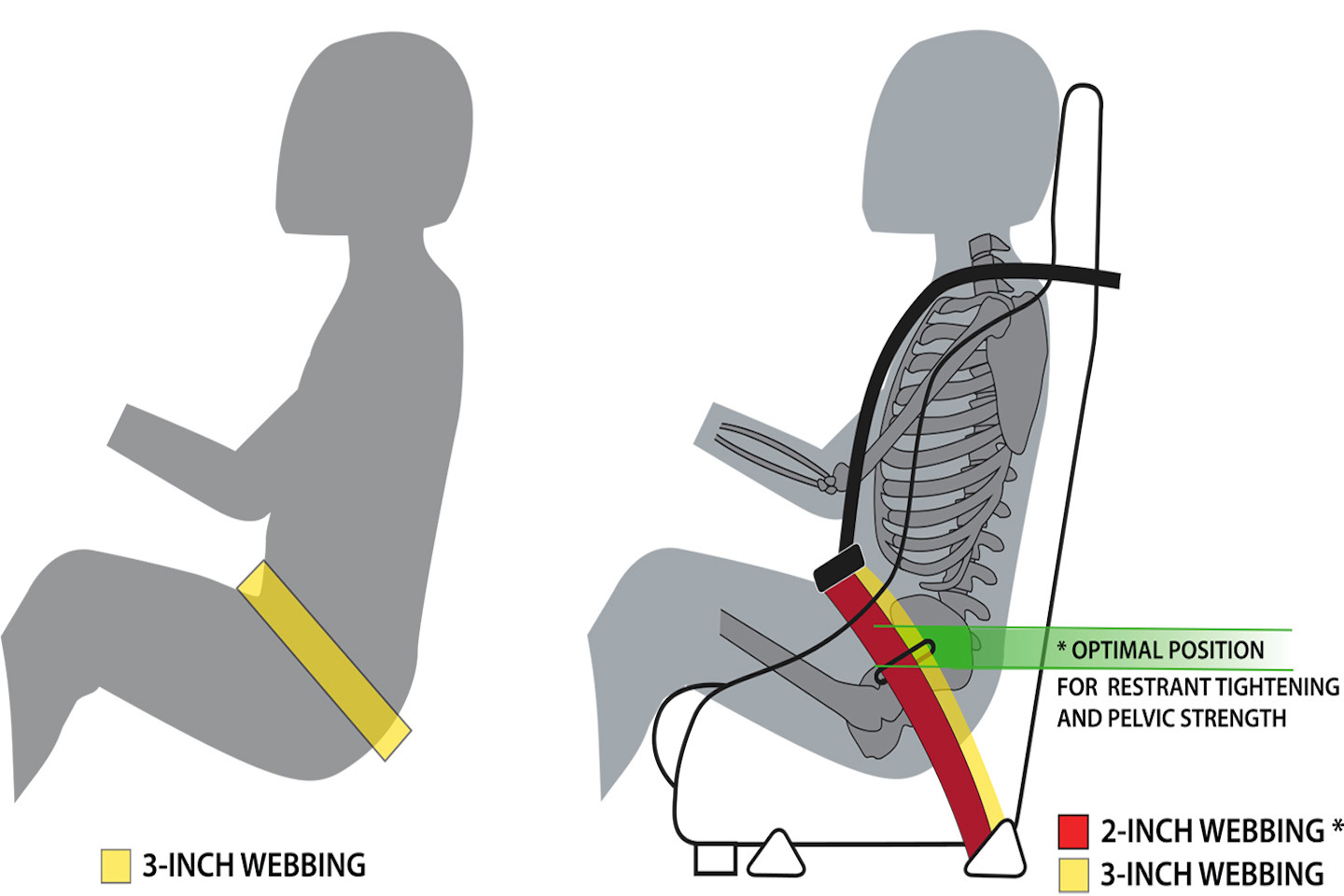

“Because of the way that the human body is structured, the strongest part of the body is the hip area. That’s the area you want to place all the restraint load. Getting the restraints as tight as possible is the number one criteria. And the way you do that is through brute force — pulling on the adjusters like crazy or even using ratchets — but one thing that makes it a lot easier to accomplish this is by decreasing the webbing size.”

About The 2-inch Harness

O’Connor pointed out that a 2-inch belt accomplishes the job much better than a 3-inch strap from the standpoint of body physiology. Plus, the 2-inch harness also meshes better with head and neck restraint (or frontal head restraint) devices, keeping them closer to the neck as the webbing narrows — this prevents sternum injuries because the load is placed closer to the center mass of the chest. For this purpose, we opted to go with Impact’s 3-inch lap belt with a 3-inch into 2-inch transition shoulder harness. This set keeps within the rules that also state: All seat belt and shoulder harness installations must be mutually compatible, originally designed to be used with each other, and produced by the same manufacturer.

The difference between 3-inch webbing and 2-inch webbing is significant. The 2-inch webbing is able to get into the ilium, or the hip pocket better than the 3-inch webbing.

O’Connor strongly recommends upgrading to the 2-inch belts when possible. “It was a strength issue decades ago, but as early as the 1990s, the textile industry advanced and the webbings got considerably stronger,” said O’Connor. “The amount of stretch, the overall strength of the webbing increased, and there was no longer a strength issue. From that standpoint, there was no need to continue with 3-inch belts.”

Like many project cars, our build has been delayed by a multitude of issues, like a global pandemic, and our belts were aged to a point where we were going to need to replace them before we ever hit the track. We will most likely replace the 3-inch set with the more stringent SFI 16.5 2-inch belts. For the purposes of getting the restraints and mounts correctly located in the chassis, we used the 3-inch belts.

Racing Seats

It is not enough to select restraints and believe this is all the safety you need. Even in a street legal class, racing seats offer a lot of features that make this an easy choice. In the case of our project car, it will be running in a “daily driver” type racing class. But like the others in this division, it is also a dedicated race car. Dedicated race cars need racing seats — period. As with your restraints, seat certification is important. Look for SFI approved seats because they are up to the standards of safety for the type of racing you intend to do.

Make sure to check the SFI tag for specs and dates. These restraints need to be updated every couple of years.

O’Connor dropped some crucial knowledge on us about selecting seats and restraints: “Make sure your seat and harness work together,” he said. This has to be the most important safety instruction we’ve ever been given. This also goes for other devices as well. If you plan on wearing a HANS device, make sure the seat is HANS compatible.

Racing seats are designed for safety and are there to help protect the driver when things go wrong. A good racing seat will prevent or lessen injuries, and perhaps save the driver’s life. This is why many sanctioning bodies require racing seats.

Safety is a given, but let’s look at a couple of other factors when choosing racing seats. A well-designed seat will hold a driver in place – not only in the event of a crash but also in the cockpit itself. Installed correctly, the seat will put the driver in a position where they have more control, a positive grip on the steering wheel, proper placement on the pedals, and overall more confidence behind the wheel. As an added bonus, many racing seats offer weight savings. All these factors add up to quicker times and faster speeds.

We chose a great racing seat that offers a combination of safety while fitting into a modest budget at the same time. JEGS Lightweight Racing Seat (PN: 702260) is exactly what we were looking for in a race seat. Featuring tubular rolled edges with extra bracing and stiffening ribs and made out of thick (0.100-inch) 5052 aluminum for strength. The panels are CNC machine formed, precision cut, and TIG welded. The seat is designed with an 18-degree layback for comfort and works with any racing harness.

Driver Comfort

Factory OEM seats are built more for comfort and not for competition or racing safety. That does not mean you can’t have a little comfort added to a racing seat for the driver. JEGS racing seat design with the 18-degree layback helps, but adding the JEGS seat cover (PN: 555-702260-1) makes a ton of difference. Thick high-density foam adds leg, thigh, and rib support.

The seat cover features edge snaps that make removal and installation simplified. The cover is black tweed fabric with extra stitching and material around the belt openings and stress points, and the cover has an attractive JEGS logo. The concept and design behind these seat covers are to provide not only the benefit of comfort for racing but for daily driving on occasion.

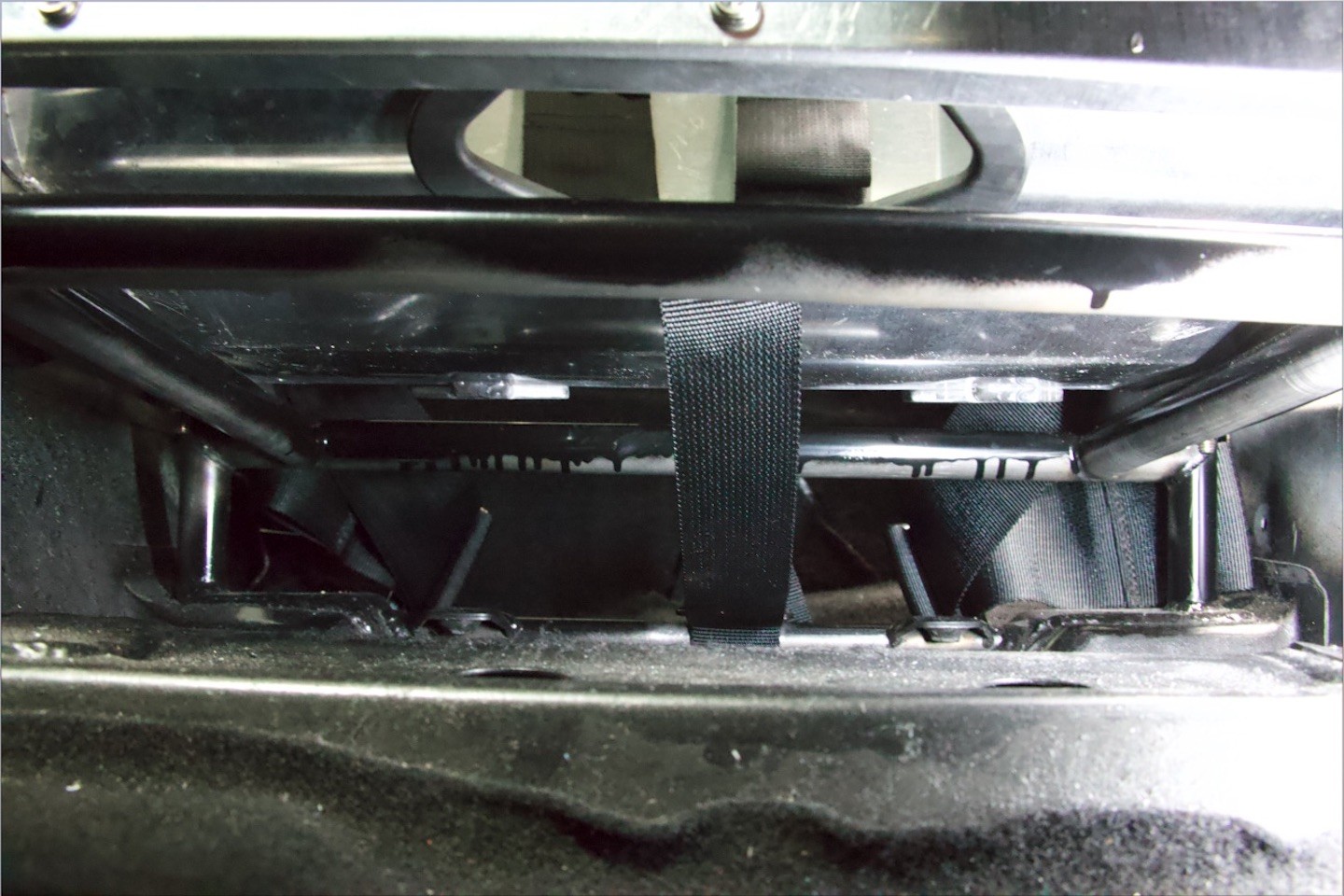

This is a view under the seat where the fifth point or crotch belt is mounted to the seat mounting bracket. The seat mounting bracket is securely mounted to the car’s body.

The final pieces of the racing seat puzzle involve mounting the seats into the cabin. We picked JEGS Aluminum Seat Mounting Brackets (PN: 555-70227) specifically for the height and tilt adjustment. Working with the principle of making the driver comfortable and held in the correct position, these mounting brackets allow for adjustments for body position.

Adjustable mounts are available but are considered a fixed mount for the seat. These brackets have options for height and tilt adjustments and are made of 6061-T6 aluminum. Ensure any seat mounting brackets used work with the seat you will be installing. Under no circumstances should anyone modify a racing seat to fit the mounts. Seat manufacturers usually offer the parts you need to properly mount the seat to your car.

Here is our seat-back brace attached to the roll cage. Note our restraints wrapped around the roll cage bar.

The last, and one of the most essential parts for safety, is the Seat Back Brace (PN: 555-70291). These 11-gauge steel mounts are adjustable, zinc-plated, and come with grade-5 mounting hardware and steel welding tabs. When properly mounted, the braces hold the racing seat firmly in position to help protect the driver. NHRA and IHRA rules require aftermarket seats, when used with a roll bar, must be braced. This kit allows the seat’s back to be braced and customized for body placement. Seven adjustment holes allow up to 4 inches of lateral movement.

Restraint Placement

You don’t want the webbing coming over the top of the hip bone, known as the iliac crest — in a forward event — the webbing can ride up over the hip bone and get into the abdomen, leading to internal injuries. O’Connor says you never want to be restrained around the stomach; the lap belt should always be as low and tight as possible. The shoulder restraints should help pull the driver down into the seat. This helps by limiting the driver’s body travel both upward and forward.

Ideally, you want the shoulder restraints pulling down. Once the seat cover is installed, the driver will be high enough to have the restraints pulling down toward their mounting point on the roll cage.

When it comes to restraints, the proper size and support will offer optimal body control and prevent and reduce fatigue. After the installation, the best thing you can do is sit in the seat. If you have followed the rules and everything lines up and feels right, you probably have a great installation. We were satisfied with the safety upgrades with our project car.

For more information on restraints, visit Impact Racing online at www.impactraceproducts.com. For more information on racing seats and mounting, visit JEGS at www.jegs.com.