Optima Search For The Ultimate Street Car and SCCA racer Feras Qartoumy of Texas was on his way to an autocross event when he heard ticking under the hood of his ’08 Z06 Corvette; after pulling over, digging out the tools, and checking under the valve cover, he was devastated to find a loose rocker arm on top of his freshly-installed cylinder head. But that wasn’t all.

“I was driving to a local autocross, just cruising in sixth gear, and all of a sudden I heard ticking under the hood. I crossed my fingers, hoping it was just a loose rocker arm, and when I tried to re-torque it down, the bolt snapped in half. We got the car onto the trailer, took it home, pulled the head off, and then found that the lifter wouldn’t come out,” he says.

So he pulled out the camshaft, then discovered that the wheel from the lifter was gone, and then needle bearings from inside the roller were scattered throughout the engine. The parts failure even took a huge chunk out of the sleeve in the block, and cracked a piston in the process. It’s safe to say that the Z06’s 427 ci powerplant had reached the end of its life, after 35,000 miles–3,000 of which he had put on the car as ‘race miles’ since he purchased it back in December.

“I thought I was done. With brand-new heads, it was putting down 560 horsepower to the wheels, and I had decided the engine was solid for the rest of the year. Then here comes this huge expense out of nowhere,” says Feras.

With unknown usage of the car prior to his purchase, he was in a precarious situation regarding what to do. His initial thought was that his racing season was finished, but a well-placed phone call to Anthony Forney, Erik Koenig, Terry Fair, and the team at Horsepower Research (HPR) in McKinney, Texas changed his mind quickly.

“We did not get to see the lifters or the cam from the damage done, but from the parts found in the oil pan and pickup, it had a locked up axle/wheel to the lifter and the lifter let go. There were bits and pieces of the roller bearings from the lifter axle in the pan along with pieces of the roller on the lifter. Few nice small pieces of the engine block as well,” says Forney.

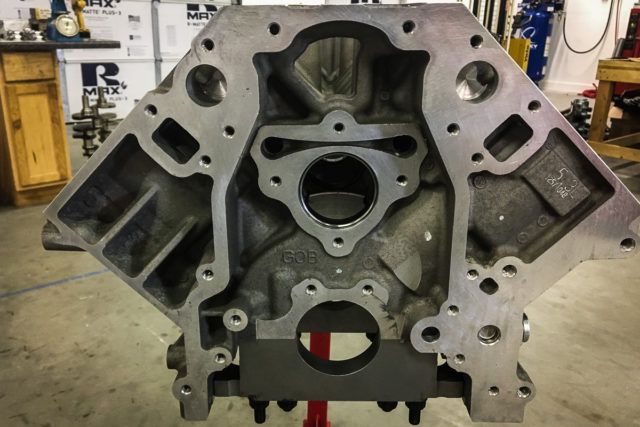

A new 5.3-liter block became the foundation for a new 468ci engine. A solid plan devised with help from Erik Koenig and Anthony Forney at Horsepower Research in Texas got Feras back on the right track.

As Feras–who usually does all of his own work– had recently installed a set of Stage 2 LS7 cylinder heads from West Coast Cylinder Head, the top end of the engine was already sorted out, but the failed shortblock needed a resurrection–and fast.

He consulted with Forney and Koenig, and the choice was made to step up to a stout 468ci bottom end.

“We had three weeks until my next event. It just so happened that they had everything on the shelf to build it except the block, and as of the following Monday they had the block in-hand, so I pulled the trigger. They got it built in a week-and-a-half,” Feras says.

“It was absolutely crazy. In sixteen days we had the car from broken and not working to ‘We’re ready to race.’ It was an unbelievable timeframe that all of this happened.”

Using the larger-displacement bottom end will provide Feras with a great foundation to improve performance as money and time permits.

“The 468 is the largest we can do within the dimensions of a stock LS/LT engine block currently. Using a tall deck RHS, or Dart block we can go as large as 527ci,” says Forney.

“The standard-deck 468 is something of our own design, and we do sell them separate as short blocks, long blocks, or finished engines.”

The short-block consists of a Darton-sleeved 5.3L Gen IV block, filled with one of K1‘s forged, long-post 4.250-inch stroke crankshafts, a set of Wiseco‘s 6.125-inch forged H-beam connecting rods finished to HPR’s specifications, and HPR-designed Wiseco forged pistons. They also use their own proprietary ring pack, which has been developed as a result of the research performed by Koenig on some of the Houston area’s quickest LS/LT powered machines.

Since the valvetrain from the 0ld engine was wrecked, a new package was selected to work with the existing WCCH cylinder heads. HPR spec’d out one of their custom camshafts, which features .655-inch lift on both intake and exhaust lobes to go with 254 degrees of duration on the intake side and 260 degrees on the exhaust.

Although more power likely could have been had with different camshaft specifications, the HPR team made the decision to use this bumpstick for a reason.

“This camshaft is going on a road race engine designed for reliability. When the customer isn’t using a bottomless bank account, you must pick your items wisely for both power and long lasting performance,” explains Forney.

Finishing off the valvetrain are a set of HPR’s double-taper pushrods, Morel link bar lifters with .750-inch wheels, and LS7 rocker arms. Feras re-used his existing cylinder heads–they are virtually new, after all–and added a Katech oil pump while everything was in process. Cometic MLS head gaskets were used to seal the heads to the block.

Overall, it’s a relatively simple build with respect to the components used inside. There is nothing exotic used in this engine, only proven, well-thought-out modifications which are designed to keep Feras on the track and out of the shop. Ultimately, the goal for the build was longevity and on-track performance in road-race and autocross conditions. Although the engine is not the highest-horsepower LS7-based powerplant out there, it offers plenty of performance for Feras to continue his Optima and SCCA seasons.

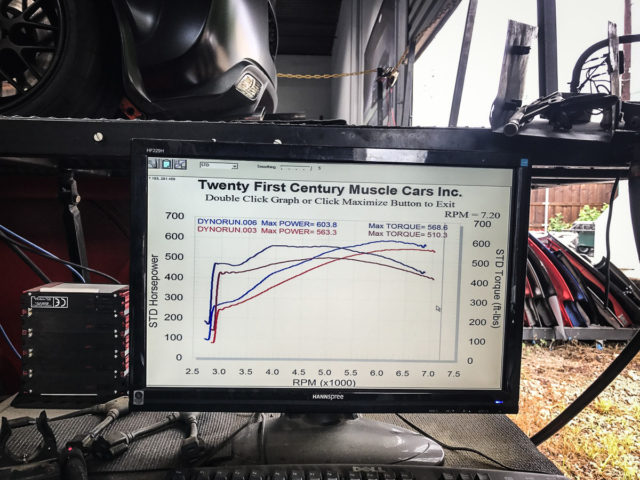

Once the engine was reassembled and back into the car, Feras had it on the chassis dyno to ensure the engine calibration was dialed in to maximize performance. When all was said and done, the car pounded out 603 rear-wheel horsepower and 568 lb-ft of torque.

The dyno tells the tale. Old versus new shows solid gains all around, with more on tap for the future as restrictions are removed from the induction system.

They also discovered that the headers–which were already on the car–use 1.750-inch tubes, which, when combined with the LS7 cylinder head castings, present a bit of a restriction with the engine in this configuration. Feras feels that he’ll pick up 20-30 rwhp just from changing the headers, and upgrading the heads yet again to a better option will also boost the horsepower numbers. Since this engine is already a better performer than what he started the season with, he’s already on the right track to quicker lap times.

“They are not crazy impressive numbers but with the heads we are running its pretty good. The heads are a major restriction here. If I wasn’t currently out of money, I would throw down for some giant heads but that will have to wait since all of this was a major unexpected cost in the first place,” says Feras.

“HPR did an amazing job.”

Feras on the track at the Optima event at Pikes Peak International Raceway. Photo Credit: Optima Ultimate Street Car Challenge