When it comes to repowering your ride with a crate engine, there are always considerations and challenges that will arise during the final installation. In this case, stuffing GM’s beastly LT5 crate engine into Larry Dixon’s 1966 Nova brought on some specific challenges. Dixon’s Nova is a true, old-school ride in the sense that it’s never had air conditioning or power steering, and Dixon likes it that way. But, GM’s super-powerful Gen-V LT5 engine comes with all the accessories you would expect from a modern automobile and then some.

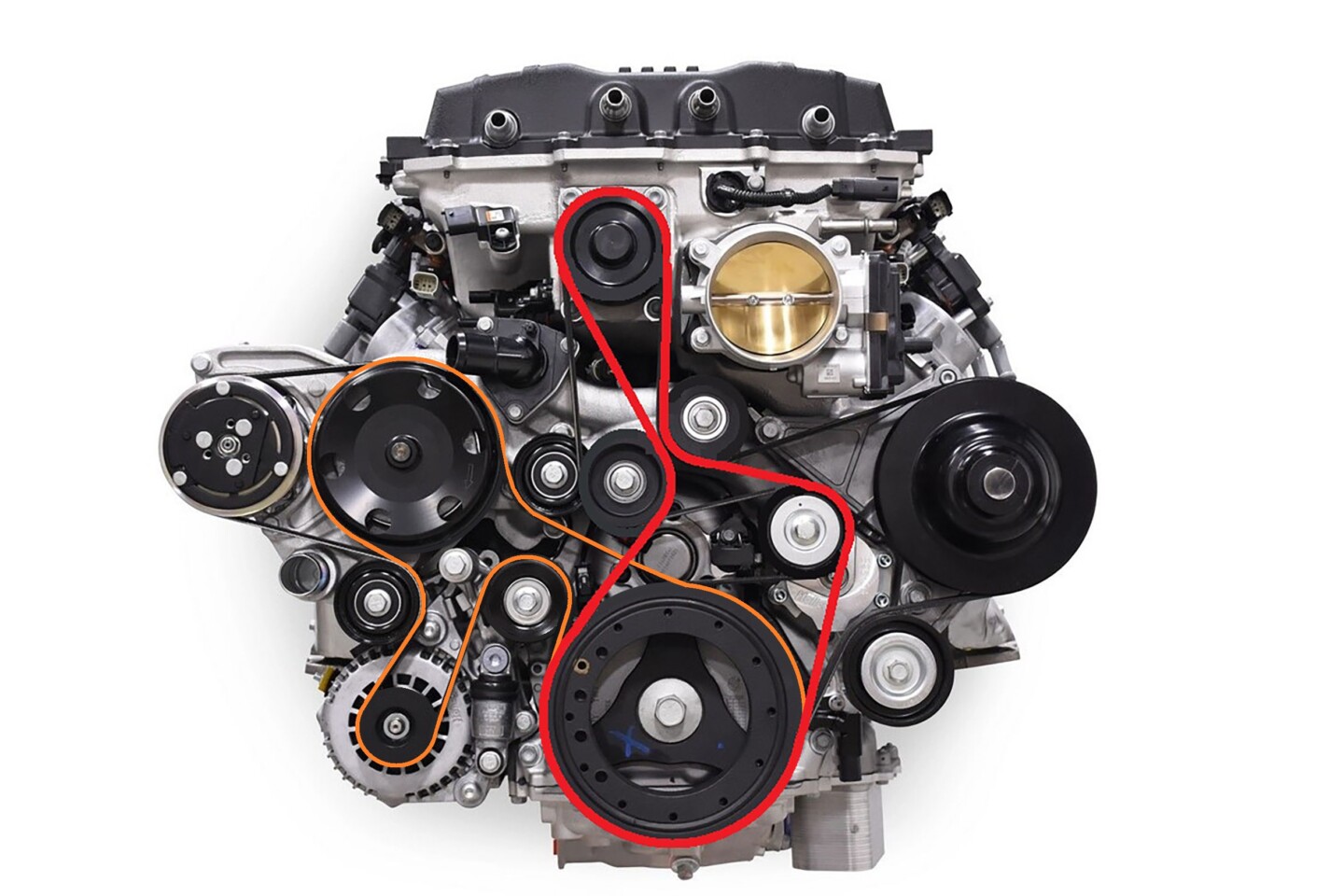

The OEM drive belt routing on the LT5 utilizes two belts along with several idler and tensioner pulleys.

The factory LT5 crate engine accessories layout is a unique blend of belts and pulleys. There are two drive belts, one for the typical accessories and another for the top-mounted supercharger. Also, the LT5 was only offered as a dry-sump system. All these factors meant that any accessory drive system we used would need to be based specifically on the LT5 engine.

Since Dixon didn’t have any use for power steering or A/C, we needed to find another way to drive only the components needed for this installation. Thankfully, Holley Performance offers a variety of aftermarket accessory drive systems, including a complete LT5 crate engine accessory drive system that is designed as a modular unit that we could modify for Dixon’s specific application.

We’ll still use the two-belt system, minus the power steering pump and air conditioning compressor, but as you’ll see, there are a few modifications along the way. This will not only help us put this 755-horsepower beast into a super-quick vintage ride, but also shows the versatility of the Holley design. Follow along and you’ll see that the hot-rodding spirit is still alive and well, even with all of today’s technology.

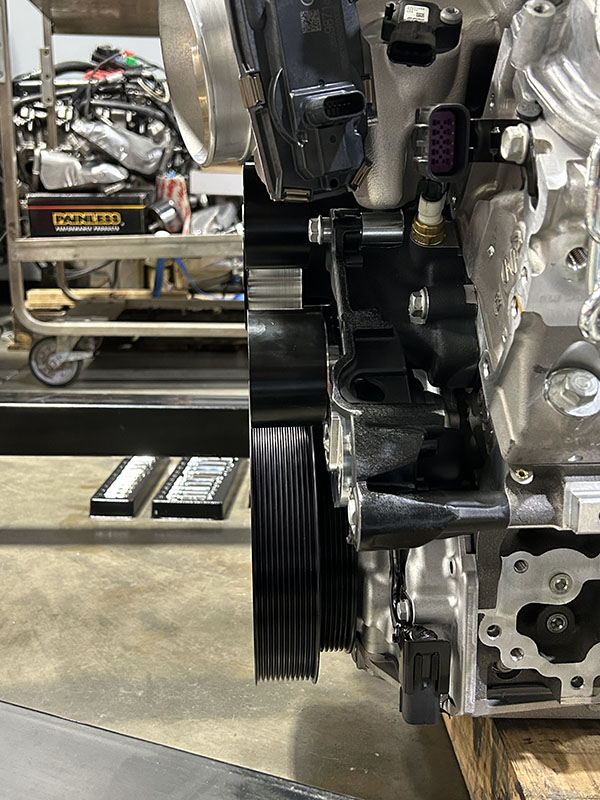

The Holley accessory drive kit comes with everything you’ll need to utilize all the factory accessories. We did just a few modifications to make it fit our application perfectly.

Differences Make All The Difference

We previously followed Dixon as he swapped another supercharged GM crate engine, the LT4, into his 1966 Chevy Nova. He explains, “The goal for the LT4 was to run ten-flat or high-nines with it and still have it fully drivable. I was more than thrilled that goal was achieved. Of course, it’s easy to understand how a multiple top-fuel championship winner such as Dixon would constantly be seeking an edge with his current ride. For the Nova, that meant swapping the LT4 for an even bigger hammer with GM’s LT5 crate engine. The goal with the new engine is to run 9.50s in the quarter-mile and still have the car completely drivable, as it will remain Dixon’s Drag and Drive contender.

The goal for the LT4 was to run ten-flat or high-nines with it and still have it fully drivable. I was more than thrilled that goal was achieved. – Larry Dixon, NHRA Top-Fuel Champion

Even though both engines are similar, several differences become obvious once you start matching up bolt holes. Firstly, the LT4 was offered as either a dry- or wet-sump system. The LT5 was only offered as a dry-sump system. We’ll deal with that when we focus on installing the LT5 into Dixon’s Nova.

The main difference that we’re focusing on here is that the LT5 is going in a car devoid of power steering and air conditioning. Why, you might ask, would anyone choose to do so? Dixon’s response tells it all, “My Nova never had them, and I never felt that I needed them in that car.” His car, his rules – right?

Dixon spent many an hour looking for ways to manipulate the belts and pulleys for the front of his LT5 to keep all the necessary bits while removing the unwanted components. Some old-school hot-rodding and a Sharpie laid out a path that would work and keep all the pulleys running in the right direction.

Dixon figured out a new route for each of the belts on his LT5 crate engine. He needed a shorter belt for the water pump and alternator belt (Orange route) after removing the A/C compressor. The supercharger belt (Red route) bypasses the power steering pump.

The next issue was finding belts that were the proper length. Removing pulleys makes room for routing the new belts, but they still need to fit. Dixon needed new belts to fit both the supercharger and the other necessities he wanted to keep. Even with the compactness of a modern aftermarket accessory drive and the limited travel of its spring tensioner, finding belts of the needed length wasn’t an issue. The belt for the water pump and alternator simply needed to be shorter. A short trip to the parts store netted a belt that was fit for the cause.

It took three belts to get the job done. The issue was finding belts the proper length that would fill each of the eleven grooves in the supercharger belt pulleys. Combining a five- and a six-rib belt solved the issue.

The problem arises when you consider that the supercharger atop the LT5 uses an 11-rib belt. The last thing you want is a supercharger belt slipping, and there’s a reason GM put that many ribs on this supercharger. Finding an 11-rib belt the proper length for an application that never existed is like putting socks on an octopus. Thankfully, the folks at Bando USA, a global leader in manufacturing world-class power transmission belts for both industrial and automotive OEMs, had the perfect solution. Dixon spoke with a representative and, using simple math, found a five- and six-rib solution that would fit the application and utilize every groove in that supercharger pulley for the best grip.

Modifying The Holley Accessories Drive

The beauty of Holley’s accessory drive kits is that they keep everything compact, making modern engines such as our LT5 fit into vintage engine bays. Since the power steering and A/C compressor went away, there wasn’t much reason to keep either mounting surface hanging on the front of the engine.

Both brackets were milled to remove the unwanted mounting surfaces and one pulley required removing the ribs since it would now be riding on the outside surface of the belt and we don't want the ribs to wear the belt unnecessarily.

The mount for the power steering pump is on its own bracket with bolts, but the A/C compressor mount is cast into the water pump housing. The power steering bracket also has a spring tensioner that we wanted to use, so a little bit of milling was in store for both cast pieces. There is also one pulley that is engineered to ride on the inside of the belt that was machined during the process. This was to better suit mating up with the belt’s flat, exterior surface, thanks to the new routing of the belt.

Another major consideration is making sure that all the pulleys are in plane with the crankshaft. Since our modifications only removed pulleys, everything lined up. But this is still a very valid concern when assembling any accessory drive system. Our modified Holley system bolted right on, and all the belts lined up as intended.

The new routing of the belts still allows for adequate wrap of all the driven pulleys, so there shouldn’t be any slippage issues. The modification also shows what can be done when thinking outside the box. The result was an even better-fitting accessory drive for our application, as Novas aren’t known for their cavernous engine compartments. And since the Holley accessory drive systems utilize the OEM hose routing, we were able to reuse all the hoses from the LT4 installation.

Now that the LT5’s accessory drive is ready, Dixon is already hard at it, installing the LT5 crate engine and eight-speed transmission into his 1966 Nova. There are still a few hurdles to overcome, but that’s a story for another time.