Four-door vehicles are no stranger to the drag racing scene. Wagons, sedans, even minivans have made tire-burning launches from countless blacktops across the country.

Four-door vehicles are no stranger to the drag racing scene. Wagons, sedans, even minivans have made tire-burning launches from countless blacktops across the country.

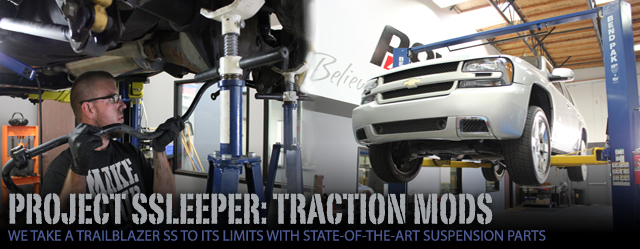

We decided that the time was right to get in on the action with the relatively fresh 2007 Trailblazer SS that plopped into our garage not but three months ago. But this was no ordinary Trailblazer.

They say that when you stare into the abyss, the abyss stares back at you. We stared into the aby-SS (see what I did there?), and staring back at us was a metallic midsize ready to blaze a fiery trail down the asphalt.

For this first stage of Trailblazer improvement, we set about making mods to the suspension, courtesy of a rear suspension kit from Spohn, a sway bar kit from Belltech, and a coilover conversion kit from KW Shocks. We also replaced the oil in the diff and engine thanks to some fresh lubricants from DRIVEN Racing Oil.

What’s so Super Sport-y about It?

Back in the early of the 2000s, General Motors introduced the world to the GMT (short for GM Truck) 360 platform, an evolution of the earlier GMT 325/330 line that included models like S10, Envoy, and Blazer. The first production model, the 2002 Oldsmobile Bravada, was debuted in February 2001.

Research and development of the Trailblazer SS fell upon the shoulders of two men: John Heinricy, renowned SCCA racer and former director of GM’s Performance Division, and Tom Wallace, former Corvette chief engineer. The Trailblazer SS was an exercise in speculation, merging kid-schlepping with hot-rodding. Or, put another way, it was the saving grace for dads everywhere forced to give up their coupe and studio flat for a four-door and house.

By far the biggest thing that makes this a real SS is the engine. Stock Trailblazers, Envoys, and Bravadas had an inline 4.2L 6-cylinder engine rated at an SAE 285hp and 276 lb.-ft. of torque, which was great for soccer moms. However the SS version received the SAE-rated 395hp, 400 lb.-ft., 364 cubic inch, 6.0L LS2 engine. From there the Trailblazer SS has lots of other upgrades to complement the engine.

The Nürburgring-tuned suspension is a key feature of the SS. Comprised of 25% stiffer springs and a 10% larger front sway bar, as well as a Stabilitrak electronic stability system, the suspension allows the car to handle corners like its slimmer Corvette cousin. And just like the Corvette, the engineers gave the Trailblazer its own special touches for braking: a custom-tuned ABS, 12.8-inch front rotors, and twin-piston calipers stuffed with C6 brake pads.

Carbuyers could slap on the SS package to the Trailblazer for a good chunk of change–$5,270–bringing the sticker price to around $35,000 for the 2WD LS model, or $40,000 for the AWD LT model. A pretty penny, but a worthwhile one if you ask us.

And when you look at them now, the prices on these four-doors have dropped off significantly. According to Kelly Blue Book, one with the options seen in our specimen can fetch between 10-12 grand in a private sale.

However, we had to settle the first big question: where to begin? We opted for some basic maintenance, suspension mods, and got our ducks in a row by ordering some swell new parts from the likes of Granatelli, Corsa, Airaid, and more.

Day 1: Fluids and Brakes and Dynos, Oh My!

We started with some initial maintenance on the fluids. Our good friends at Driven Racing Oil supplied us with some much-needed fluids to get everything lubed up and ready for the track.

The Driven gear oil maintains an excellent viscous quality throughout multiple levels of activity across hours of abuse.

For the rear differential, Synthetic Gear Oil–now called Racing Gear Oil (p/n 04231)–to improve operating temperatures and protect against the high shear we’d encounter when we took the car racing. The long-lasting viscosity stats were great, too; tests showed that the oil would last well for several hours, while still providing that same great level of lubrication and shear protection.

In fact, over the course of six hours of driving, testing showed that the oil would indeed maintain an ideal viscosity. Starting at about 19 centistokes, the oil would only degrade down to 18 at the test’s end.

It was an easy enough swap, too. All we had to do was drain the sludge out of the diff and pour in the appropriate amount of oil. We then shifted our attention to the front of the Trailblazer to check out how the engine oil was doing.

Driven’s LS30 engine oil was a sound choice, if for nothing else than the excellent viscous and sound-dampening qualities.

We drained the motor oil too, and in its place applied a few quarts of the DRIVEN LS30 oil (p/n 02907). Just like with the Racing Gear Oil, we expected that this product would deliver great performance, especially considering the research and development put into the oil.

Lake Speed Jr. of DRIVEN was able to share with us some of the added benefits of using the LS30 oil with our engine. “What makes LS30 different is its ability to work in synchrony with the LS motor. Other oils will eventually break down into a 5W-20 rating, but LS30 is engineered specifically not to break down,” said Speed Jr.

“This makes the oil maintain proper viscosity for longer. And it’s perfect for engine that will undergo internal changes too, like cams, lifters, and so on.”

That done, our last step was to slap on some fresh factory brake rotors to the front wheels. Finally, it was time for the dyno.

Day 2: Suspension Upgrades

From top left: Cody removes the in-link on the rear sway bar; the bolts holding in the control arms; and the Panhard bar itself.

Phase 2 of SSleeper’s evolution was now underway, as we moved on to installing the suspension upgrades. To be more specific, we were looking to upgrade the following: the Panhard bar, the control arms, the coil-overs up front, rear air bags, and the sway bar. Meanwhile, rubber bushings and bump stops would need replacing too. When all was said and done, we would need to inspect the steering as well.

We got SSleeper up on a lift and went to town on the suspension. We started removing the sway bar by unbolting the sway bar from the in-links and mounts on the chassis. The sway bar didn’t put up too much of a fight, requiring just a tad of finesse to remove the bar completely from the car.

Our replacement sway bar, made by Belltech (p/n 5530), was a great choice for a couple of reasons. First, we liked that the company used cold-formed solid steel construction and swaged ends, so we could trust the durability and reliability.

Cody removes the stock sway bar and installs the Belltech one.

Second, we liked that the bar came ready to install with performance polyurethane bushings, while also looking great with a powder coated silver to match the body’s paint. This sway bar just seemed like a sensible match.

The control arms and air bags were next. A few more nuts and bolts were removed, and they came off with a little finesse. With that done, we started to unpack our Spohn Rear Suspension Package (p/n TB-RSKIT) and examine the contents.

Chromoly steel are part of what make Spohn's control arms (left) and Panhard bar (right) so appealing.

Included in the kit is an adjustable Panhard bar, lower control arms, and upper control arms. We opted for the black ones with chromoly steel construction, and ordered our control arms to be adjustable as well.

Spohn’s own Dan Brown was able to answer some pressing questions about this kit, “Of course, the biggest benefit you’ll find is the improved handling. Reduced wheel hop will make for a more beneficial racing experience, thanks to the stiffer control arms and bushings offering the tires better traction.”

One thing we noticed right away was how much lighter these parts were than stock. They’d be far tougher too, owing to the chromoly construction.

Brown added, “We ran a lot of different tests as far as what material lasted the longest. We now offer the the kit in either mild steel or chromoly construction, but if you’re looking for improved durability and lighter weight, chromoly is the answer.”

The Panhard bar and control arms got a base adjustment, but we are going to hold off on installing them for a while. Meanwhile, we went about removing the factory-installed air bag suspension to make way for the new coil-overs that came as part of our KW Variant 3 coil-over kit (p/n 35261009), from KW Shocks.

Part and parcel of the SS’s performance options, these air bags were initially a major feature of the SS package when they were introduced back in the mid-2000s. They’ve since proven poor substitutes for the analog style, as they became prone to leaking and making excessive noise due to the compressor.

Thus, the KW kit was a two-bird-one-stone solution; one we were happy to do if it meant better reliability and performance down the road, as well as a wide range of adjustability. This stems from the separate and independently adjustable rebound and compression damping integrated into the shock absorbers, easily modified with an Allen wrench.

Thus, the KW kit was a two-bird-one-stone solution; one we were happy to do if it meant better reliability and performance down the road, as well as a wide range of adjustability. This stems from the separate and independently adjustable rebound and compression damping integrated into the shock absorbers, easily modified with an Allen wrench.

Chris Marion from KW gave us some quick pointers on the kit’s standout features, “Our headquarters in Germany does all its testing in-house, and what we found with the SS was that it benefitted best from stainless steel shocks. We used a composite spring perch that’s self-lubricating to keep it from sticking, and had the springs coated and braided like all of our other fine products.”

“Since the SS is more for performance driving, we had to have a system to match. The problem was we needed to inspire confidence in driving–it’s all about consistency. And with this kit, we found the answer.”

Afterwards, we replaced the bump stops, which were noticeably well-worn and beginning to shred.

Out with the old, in with the new: we removed the stock air bags to install KW's springs.

We went up to the front of the Trailblazer and did a similar routine to the front struts. This was a bit more time-consuming, however, as we had to disassemble the strut from the car, the spring from the tower, and also the brake lines.

With the struts removed, we measured the adjustments we would have to make for the KW replacements. Since 40-70mm was the range of height we could choose from (measuring from the lower fastening screw to the spring seat), we opted to set them at the median: 55mm. We made sure the threads were clean, installed them, and hooked everything back up.

Seated perfectly up front, our KW struts made all the difference in ride quality and the handling performance.

Sadly, the post-op test drive would have to wait just a little while longer. We ended day two of our journey and went home to SSleep.

Day 3: Suspension Upgrades, Continued

Refreshed and reinvigorated, we tackled the task of removing and replacing the stock springs and Panhard bar. We made sure to do a final check on all our measurements for proper fitment.

With the Spohn bar and KW springs installed, we situated the shocks and control arms back into their proper place. But first, we had to find our true pinion angle.

We took our angle finder and accordingly found our vehicle would be better suited to -2° for its high performance intentions. As a helpful hint, Spohn recommends that you determine the direction and number of flats (1/6 of a turn) to figure out how many turns you make in order to adjust 1 degree of negative true pinion angle. That way, you’d be ready for making adjustments on the fly when you’re at the track.

Lowering SSleeper back on all fours, we busted out our trusty tape measure once again and measured from the floor to the edge of the fender. It turns out that we lowered the car by about an inch on both sides, and we were satisfied with the results.

Riding Impressions

A day after the installation was completed, we took the SS for a joy ride around the back streets of our hometown here in Murrieta, California. A barren eight-mile stretch of asphalt near the office, with a winding road leading to a dead end, should prove nicely just how well the ride has improved.

A day after the installation was completed, we took the SS for a joy ride around the back streets of our hometown here in Murrieta, California. A barren eight-mile stretch of asphalt near the office, with a winding road leading to a dead end, should prove nicely just how well the ride has improved.

Coming up on the eight-mile, and not a soul in sight, we gunned the engine down the road, eventually curving right into a 45-degree incline. Significantly reduced body roll was great to see, no doubt thanks to the Belltech sway bar, while the Trailblazer’s ability to absorb the crests and pits of the undulating road made us grateful for the KW suspension system keeping everything steady and comfortable.

We were surprised with the overall responsiveness of the ride, too. The stiffer front shocks were able to handle sudden braking better than before, allowing us to see the road ahead more clearly. If we wanted, we could make them softer too, and do it on the fly using a simple Allen tool.

At the end of the day, the differences were worlds apart: better handling, better response, and an all-around more comfortable ride were just a few of the thoughts that came to mind as we put the SS through its paces. These parts have made an incredible mark upon the ride comfort of this particular Chevy.

A substantial increase to the suspension, as well as boosting the life of our differential and engine, afforded us a great deal of confidence in the machine as we awaited our next phase: power mods! Stay tuned for our next chapter in Project SSleeper as we cover new parts including a full CORSA exhaust system, Granatelli coils, Airaid intake, and more.