It can be tempting to overlook the brake system when deciding where to invest one’s hard-earned ducats on performance upgrades. But at the end of the day, all the horsepower in the world isn’t worth much if you don’t have confidence in your ability to bring the vehicle back down from speed. And as a vehicle’s output and performance capability go, so do the demands asked of the braking system.

Such is the case with our LSA-swapped 2008 Chevrolet TrailBlazer SS, a truck which came from the factory with 390 horsepower and now sends roughly 720 ponies to all four corners. An 85 percent increase in power has a tendency to illustrate the other areas of a build that aren’t really on the level, and in the case of this TBSS, it had become clear that the stock brake components weren’t holding up their end of the bargain anymore.

When it comes to performance – particularly in street-driven and road course setups – striking a balance in performance capability is crucial. After swapping out the 390hp 6.0-liter mill for a warmed over LSA engine, this Trailblazer’s ability to pile on speed in short order had the stock brakes working overtime. But with the stopping power unable to keep pace with the engine, we were becoming hesitant to use the loud pedal as much as we wanted to, so we reached out to Baer for a way to bolster the factory brake system.

“My TrailBlazer SS has had noticeably poor brake performance since I changed the pads and rotors to stock about a year ago,” says Power Automedia’s Scott Parker. “It lost its bite and has been downright sketchy at times going through the canyons in SoCal where, on roads like Ortega Highway, you can sometimes ride the brakes going downhill for several miles at a time. When I bought the truck, it had some unknown aftermarket brake parts on it from the previous owner, which included rotors that were drilled and slotted.”

In the interest of keeping Scott from careening off of CA-74 into the open arms of oblivion, we got in touch with the folks at Baer Brakes for a new set of discs and pads that would work with the factory hardware while providing improvements in stopping power, heat management, pedal feel, and visual aesthetics. Here, we’ll take a closer look at the hardware we selected for the truck with some insight from the experts at Baer and go over some of the finer points of the install and bedding procedure.

Better Braking By Design

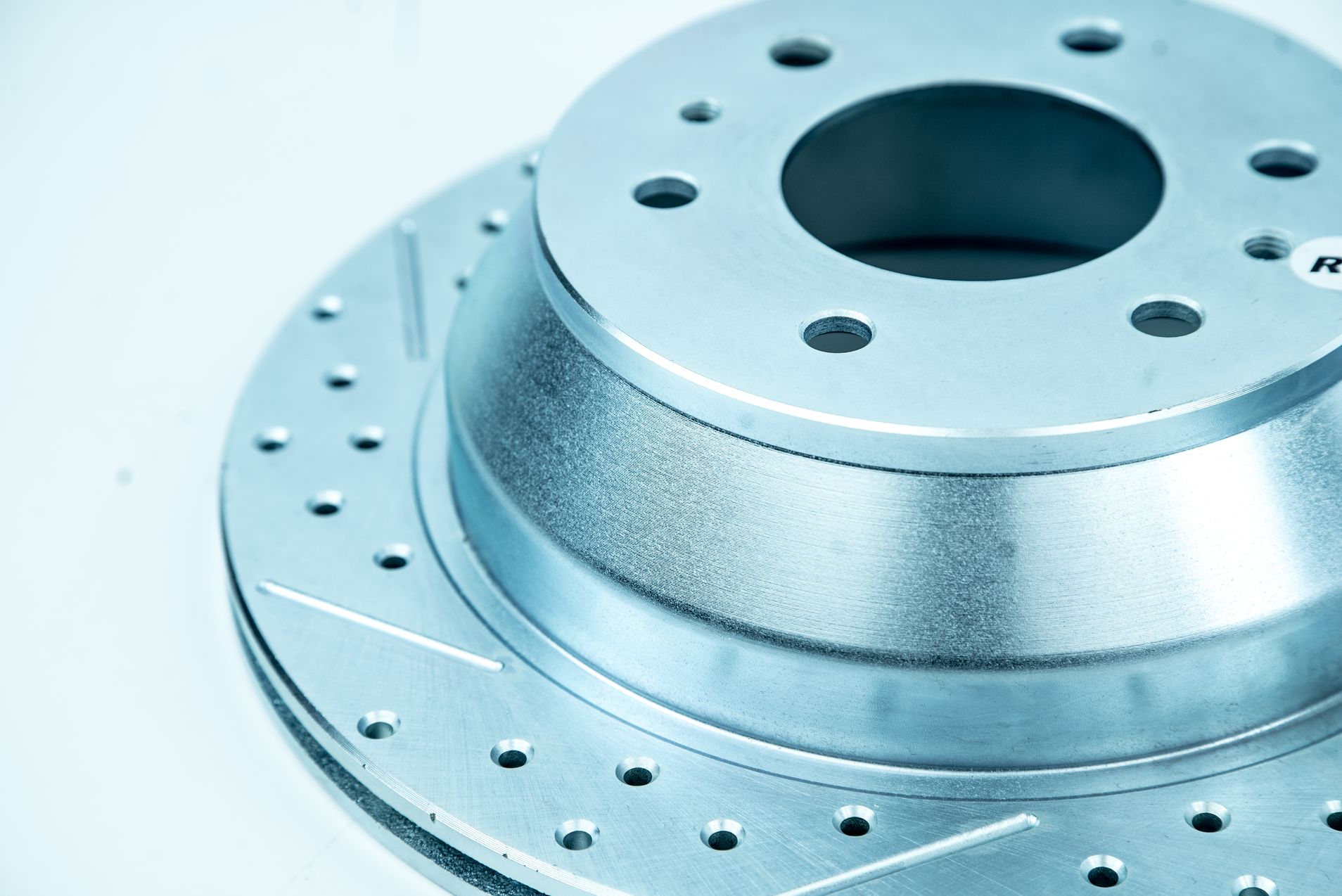

We selected a set of Baer Sport rotors for the job. Designed as direct-replacement parts, these discs and pads will work with all the associated OE brake components while providing more capability and a bit of eye candy behind the wheels.

“Baer Sport rotors are the first step up from stock or stock-replacement rotors for the driver looking to enhance appearance and improved and extended brake performance at the edge of the system capability,” explains Bill Fowler, VP of development for Baer. “They can be used for high-performance street, strip or short autocross events with sub-40 second lap times.”

With large diameters and open-spoke designs becoming increasingly popular in both OEM and aftermarket wheels, the brake system has become an integral part of a performance vehicle’s overall look. These sharp looking Baer Sport rotors will not only help bring the truck down from speed but also enhance its overall aesthetic.

Though the swept area remains identical to the factory hardware, Baer’s design enhancements yield a more efficient and effective brake disc. “Baer Sport rotors are dimensionally identical to stock but use higher grade cast iron for improved heat dissipation and increased frictional coefficient, also known as μ (“mu”) factor,” says Fowler. “All of our Sport line rotors feature a directional drill pattern for enhanced resistance to pad outgassing and are slotted to minimize pad transfer and improve foreign substance rejection, like the sand and silt you might pick up from driving through deep puddles.”

The rotors’ enhanced durability versus the factory discs goes beyond heat and debris management improvements, too. “All Baer Sport rotors are zinc plated to resist rust and corrosion,” Fowler adds. “The zinc coating will be worn off the rotor face as the rotor and pads are bedded in, however, the zinc plating will protect the rest of the rotor for its useful life.”

Baer Sport rotors also match the OEM design in terms of the internal cooling vanes, straight where OEM is straight, curved where OEM is curved, and the drilling pattern is optimized for each style of vane. These vanes act as a heat exchanger to push cooler air out from the center of the wheel and channel heat away from the rotor.

Because the Sport rotors are OE replacements, and therefore use the same calipers and swept area as the stock components, you might be wondering how these discs can provide more effective braking capability than the factory stuff. Ultimately, it comes down to heat resistance, says Fowler.

Since they're direct OE replacement parts, the Baer Sport discs are dimensionally identical to the factory rotors, and that means the swept area remains the same. However, due to the slotting and cross drilling, these rotors manage heat more efficiently and are more resistant to debris gumming up the works. Higher grade cast iron versus the factory stuff equates to improved heat dissipation and increased frictional coefficient as well, while the Baer rotors' zinc plating is designed to stave off rust and corrosion throughout the life of the disc.

In wet conditions, or after multiple hard stops, the Baer Sport rotor will shed water more effectively and will resist pad fade longer. This is due to the drilling pattern that helps vent the stock pads outgassing as they give up under heavy use, delaying the onset of pad fade. This is why the combination of Baer Sport rotors and pads are critical to actually improving brake performance in all conditions and situations. – Bill Fowler, Baer Brakes

“In a single dry conditions panic stop situation the Baer Sport rotor will provide the same stopping distance as OEM,” he says. “But in wet conditions, or after multiple hard stops, the Baer Sport rotor will shed water more effectively and will resist pad fade (also referred to as brake fade) longer. This is due to the drilling pattern that helps vent the stock pads outgassing as they give up under heavy use, delaying the onset of pad fade. This is why the combination of Baer Sport rotors and pads are critical to actually improving brake performance in all conditions and situations.”

Fowler also points out that your brake system is not somewhere you want to skimp on quality. “It should be noted that many cheap offshore stock replacement rotors are made from highly questionable materials that do not meet OEM standards for mu factor, heat stability and wear,” he explains. “Those substandard products can wear out in a few thousand miles of ordinary driving, crack excessively, and present a real safety risk to the driver.”

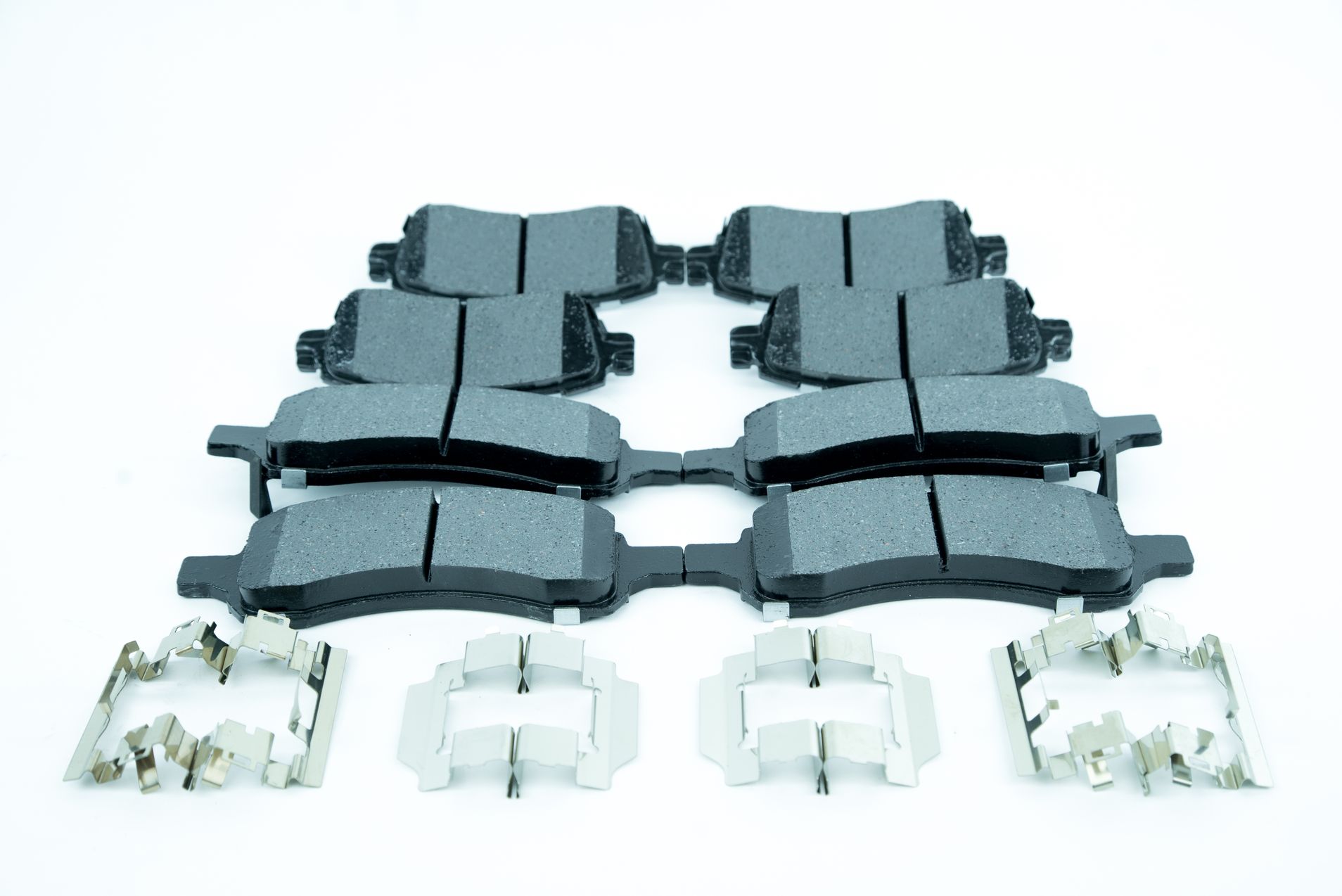

We paired the rotors up with a set of Baer Sport pads. These pads are a ceramic compound that’s designed to provide improved friction over an OEM spec pad with no increase in dust and little or no noise. They can also operate at considerably higher temperatures than OEM pads, which should result in longer lasting performance in spirited driving, at the strip, autocross or when towing.

Choosing the appropriate pad for the application is critical, as some compounds favor reduced noise over heat resistance and vice-versa, depending on a particular pad's intended use. These Baer Sport pads are designed primarily for street-driven vehicles, so they emphasize low brake dust and noise while providing enough heat resistance to make them appropriate for performance street cars that might see a bit of time at the autocross or drag strip.

“Like Baer Sport rotors, these proprietary ceramic formulation pads are a solid upgrade in all-around performance, that is: enhanced friction and stopping power over OEM, higher heat stability, low dust and low noise,” says Fowler. “They are suitable for any car or truck where the driver wants improved performance without sacrificing appearance.”

Installation And Bedding Process

Since these rotors and pads are direct OE replacement parts, the process of swapping out the factory stuff for the Baer Sport parts is about as hassle-free as a typical brake job.

“There are simply two bolts that hold the caliper to the caliper bracket, and two bolts that hold the caliper bracket to the front hub and rear axle,” Parker notes. “The rear caliper bolts were stubborn, but we managed to get them off.”

While the swap procedure is pretty straight-forward, it’s the brake system bed-in procedure that often proves to be a bit more nebulous, as there are a few different schools of thought on the exact process. It’s important to get this right though, as the bed-in process will establish a wear pattern between the rotor and pad.

Since they're direct-fit, installing the Baer rotors and pads is the same process as simply replacing the stock stuff with new factory replacements.

Fortunately, Baer provides this handy guide for the procedure. In a nutshell, you’ll begin by “seasoning” the rotors, then bedding the pads. To start, the recommended process is to drive the vehicle gently for five or six days, using the brakes as you would have before the upgrade. After this initial break-in period, find a safe location where the brakes can be run to temperature.

As the guide states, your goal is to gradually increase brake temperatures with progressively faster stops. To do so, start by performing four stops from 60 mph to 15 mph as you would in the normal course of driving. Next, perform four medium-effort pedal stops (about 50 percent of maximum stopping force) from 60 mph down to 15 mph. Follow this with a few minutes of freeway-speed driving with as little braking as possible to allow the rotors to cool.

Next, perform four medium-hard effort pedal stops (about 75 percent) from 60 mph down to 15 mph, and follow that up with another ten minutes or so of freeway-speed (with little/no braking) to allow the rotors to cool.

With 720 horsepower going to all four corners, and roughly 4,500 pounds of weight to contend with, the factory brake hardware just couldn’t keep up with the rest of the truck. While a rotor and pad swap won’t have a profound impact on the braking distance of a single panic stop, the Baer Sport components will improve the brakes’ resistance to fade and give the truck a more purposeful look.

Park the car overnight. The following day, head back to your designated brake test spot and perform four more medium-effort stops from 60 mph to 15 mph followed by five to ten minutes of freeway-speed driving to allow the brakes to cool. Next, perform the same procedure with medium-hard pedal effort, allowing a few extra minutes on the freeway for brake cooling. Lastly, perform six hard stops (100 percent pedal effort), followed by 10 minutes of freeway-speed driving with little-to-no braking to allow the brakes to cool.

That covers the rotor seasoning – after an over-night cool-down, we can move on to the pad bedding. This is a simpler process that consits of two light braking events from 65 to 10 mph, followed by two heavy stops (at the threshold of ABS intervention) back to back from 65 to 5 mph, followed by a 5-10 minute cool-down session. After that, three more light braking stops, then eight back-to-back heavy stops from 65 to 5 mph, and then 10 minutes of cool-down driving with no braking at all, if possible. After that, you’re all set.

After completing or pad bedding procedure, we were curious to see if the stopping distance had improved, even in a dry, panic-style stop. It certainly felt like it after we were done mounting them so we took to our favorite test grounds to find out. Keep in mind that before our upgrade whatever the previous owner had installed was very lackluster. In fact, testing before the Baer pads and rotors were installed showed a woefully inadequate 169.2-foot stopping distance from 60 mph. While the Trailblazer is definitely portly, this represents a fairly long stopping distance, even for an SUV.

As you can see on the left, our original setup brought the Trailblazer to a halt from 60 mph in 169.2 feet. Not exactly the performance we were hoping for and we could tell that the system needed help just by driving the vehicle normally. On the right, you can see that the Baer system substantially reduced our stopping distance and time. While these gains may have been available just by refreshing the stoppers with factory bits, the thermal management shown by the Baer brakes over the next consecutive emergency stop showed that they were far superior to factory equipment.

With the bedding procedure complete, we felt it was worth another test session, just to see if our assumption was right. As it turns out, the Baer pads and rotors are hauling in the Trailblazer’s considerable girth in 16.5 fewer feet, a considerable improvement by any standard. What’s more, the improvement was consistent over the next consecutive four 100-percent panic stops conducted for testing. This showed us that the pads are not only reigning in the vehicle’s inertia more effectively, the thermal efficiency offered by the new rotors and pads showed us that they were considerably less susceptible to fade.

And while we saw a vast improvement, the fact of the matter is, it was likely a combination of the improvement in materials provided by the Baer combination and the abuse our previous pads and rotors suffered through. A brand new set of standard pads and rotors would have likely decreased stopping distances as well, but the obvious improvements in thermal management provided by the Baer components would likely have become apparent as we repeated our test. That said, our experience showed us that the Baer setup has improved our TBSS’s stopping capabilities in every regard.

Looking to improve the stopping capability of your ride while retaining the factory brake system? The Sport line from Baer Brakes is a great way to improve the heat management, corrosion resistance, and overall look of your brakes at a budget-friendly price point. Give ‘em a shout and see what they’ve got for your application.