When swapping out a chassis, you want to maximize your investment and get the most performance available today. When looking for a chassis upgrade utilizing the latest technology, geometry, and components, a suspension from Art Morrison Enterprises (AME) is one of the easiest ways to put cutting-edge, modern-day performance under your car or truck.

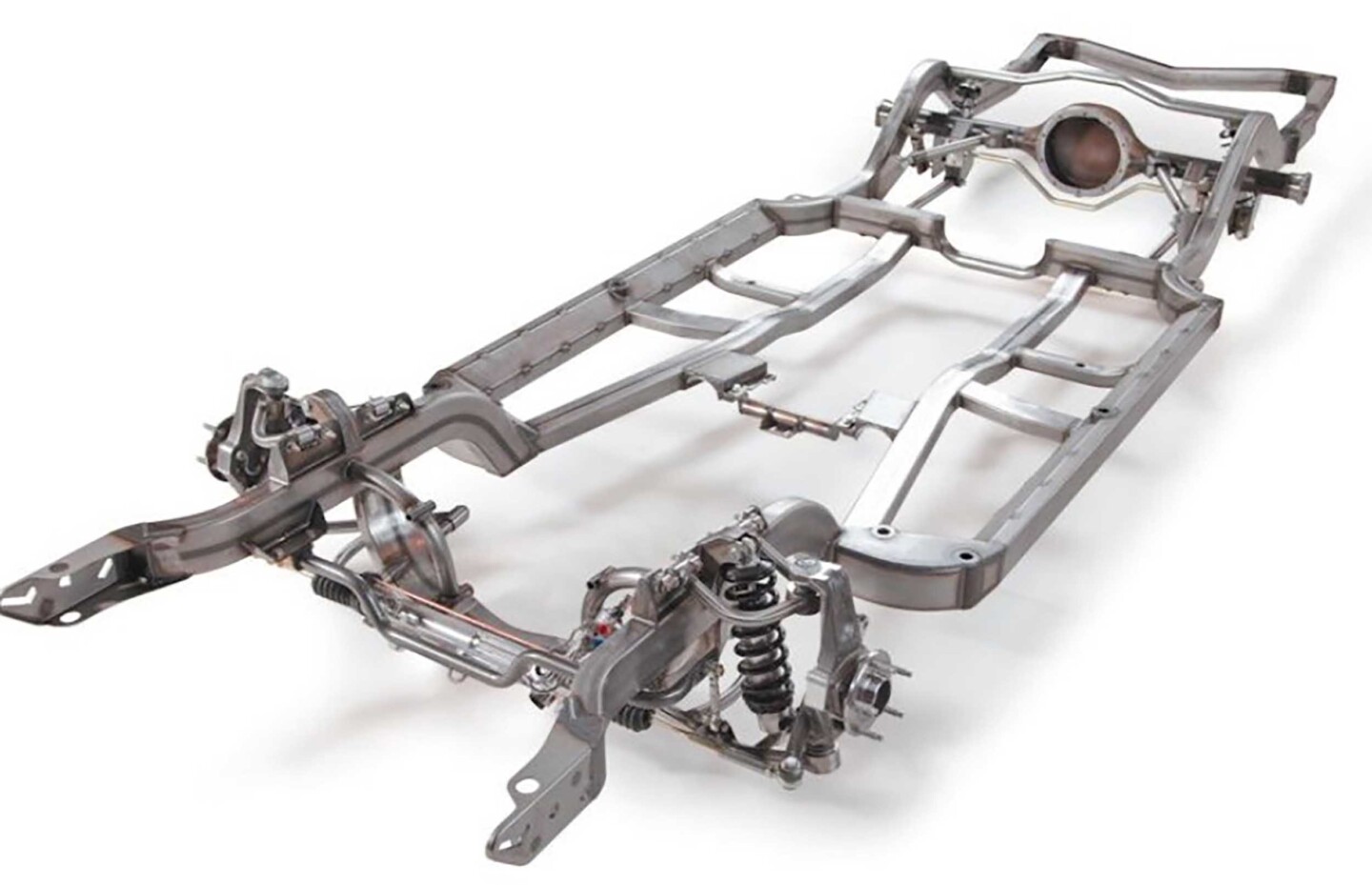

An AME chassis comes in the door of the fabrication shop as raw metal and leaves as a complete chassis upgrade for the intended vehicle. AME’s in-house frame jigs, along with all the data AME has recorded over the years ensure repeatability and a perfect fit.

The staff at AME can create a chassis for a wide variety of vehicles, and when you order one of the company’s offerings, all the measuring and slide-rule heavy lifting has been done for you. The AME staff uses modern technology and proven, modern suspension components to create each complete chassis upgrade. Once AME’s team of fabricators finishes your chassis, it is shipped to you. Then, you just need to focus on finalizing the installation with the necessary plumbing, wiring, drivetrain, wheels, and tires.

Designing A Modern Chassis Upgrade For Vintage Rides

The first step in creating a modern, high-performing chassis involves designing a computer-generated version of the new frame. To do this, the team at AME begins by sizing up the vintage frame and body, if possible. These components are 3-D scanned, so clearances and dimensions can be accurately measured and easily replicated. This also ensures the new frame closely adheres to the shape of the original and fits into the required under-car space of the body. Even if the frame is not available, AME can scan the underside of a vehicle to get exact measurements and create a chassis to fit that body, sometimes better than the original.

AME uses 3-D scanning to create a computer-generated replica of the vehicle's body. This ensures proper fitment of body mounts and components and highlights areas for possible tweaking of the suspension for various upgrades or tucking the frame into the allowed under-body cavity for a lower ride.

Once these parameters are known, AME’s engineering team employs the latest suspension geometry to give each chassis a modern ride and handling characteristic. This computer-generated foundation precisely locates every mounting point, bracket, and component within the chassis. The engineering team adds each part to the computer-generated design to ensure compatibility with the car’s body and retain the proper geometry for modern performance and handling.

The triangulated inner face of the outer framerails on this GM A-body suspension allows it to recess up into the available space of the car’s body.

Through careful placement of mounting points, the team can utilize the available space to improve the car’s handling, such as increasing the suspension’s caster for better stability at speed. They can also design a suspension that will better control camber, keeping the tires pointed in the right direction throughout the suspension’s range of travel. Bump-steer was a huge issue with many vintage suspensions as components would move through their entire range of travel. By engineering a suspension with matching camber, caster, and bump-steer arcs as the suspension moves, AME has full control over bump-steer.

This frame is on a special table that precisely aligns the suspension during the assembly process. This allows AME to make adjustments to the camber, caster, and toe, to perfect the suspension's geometry!

One of the most notable benefits of precisely mapping the underside of a vehicle’s body is the ability to drop the overall stance without significantly affecting ground clearance. Due to AME’s exacting tolerances between the body and frame, and creating a path for the exhaust and driveshaft to pass through the frame, ground clearance can be optimized while still providing for a killer stance.

Same Space, Better Chassis

Much like architecture relies on a solid foundation, a quality built and engineered chassis is a crucial foundation for any great car build. At the heart of every AME chassis are exceptionally rigid rectangular-tube frame rails made of proprietary steel, which are mandrel-bent for a consistent wall thickness. Far more rigid than early pressed C-channel frame rails, the rectangular rails improve ride quality by minimizing body flex, and at the same time reducing squeaks and rattles. Using the latest technology, AME’s team of engineers applies scientific principles and advanced software to analyze and improve suspension geometry that brings the vehicle’s performance and handling into the modern era while maintaining its iconic appearance.

By 3-D mapping the underside of a vehicle, the AME engineers can design a chassis using the available space and greatly reduce the need for trimming of the body.

In certain instances, such as the AME GT Sport chassis designed to fit under GM’s A-body vehicles, the specially designed and TIG-welded outer framerails have an angled inner face designed to tuck up into the body just like the originals. This allows the much sturdier chassis upgrade to fit into the same space as the original and still provide for the utmost ground clearance.

Modern Technology With Modern Components

The AME staff can custom-build just about anything needed for a chassis upgrade but knows they don’t need to recreate the wheel. The technology to engineer an AME chassis joins seamlessly with proven, modern components such as the C6 Corvette-style aluminum knuckles to maximize the performance of the new chassis. There are also single- or double-adjustable coilovers and an adjustable anti-roll bar to help limit body roll and simplify the ability to tune the car’s handling for the intended driving style. This helps infuse all that improved geometry under vintage vehicles but also builds a chassis platform specifically designed for the installation of modern, performance-focused brakes, wheels, and tires.

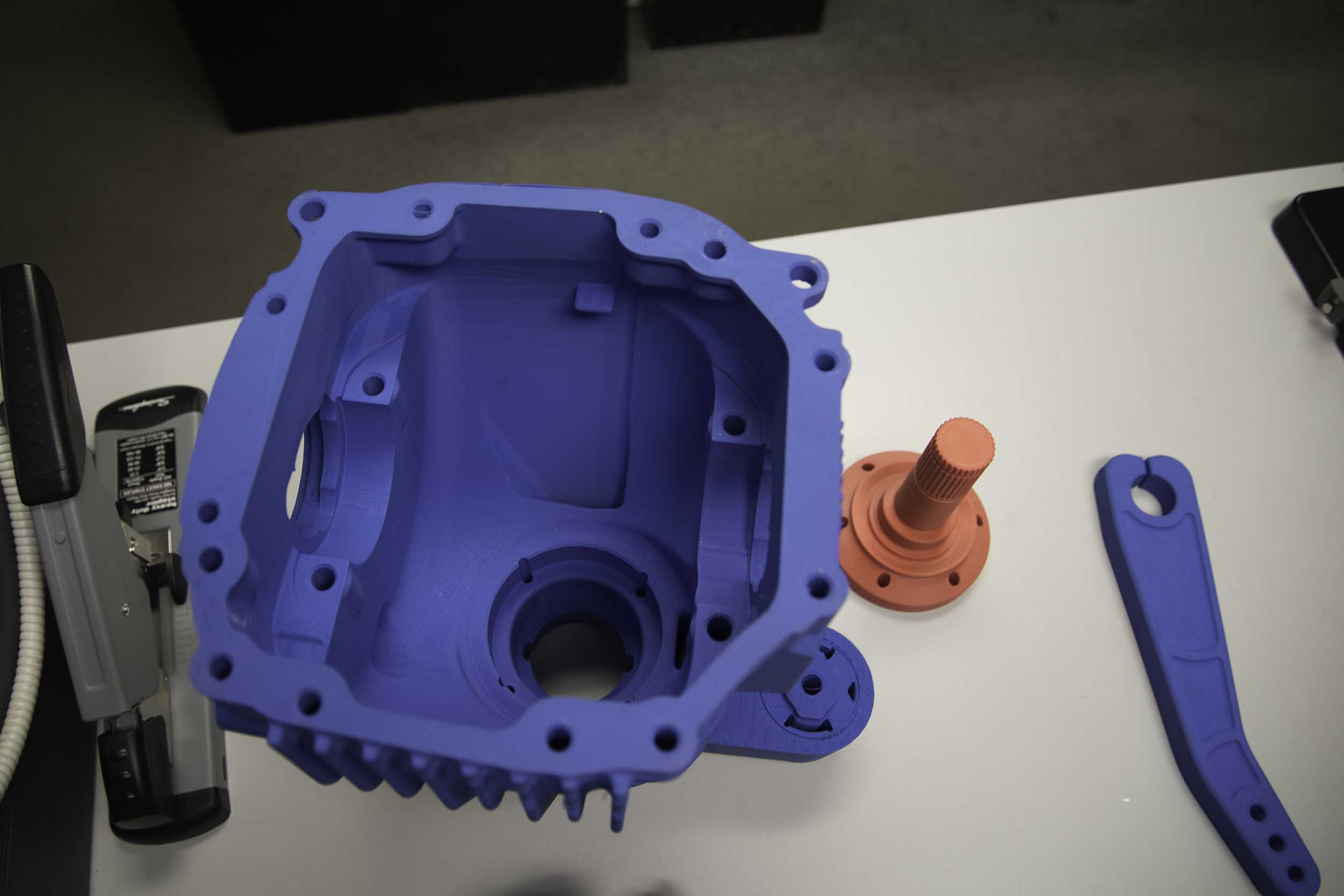

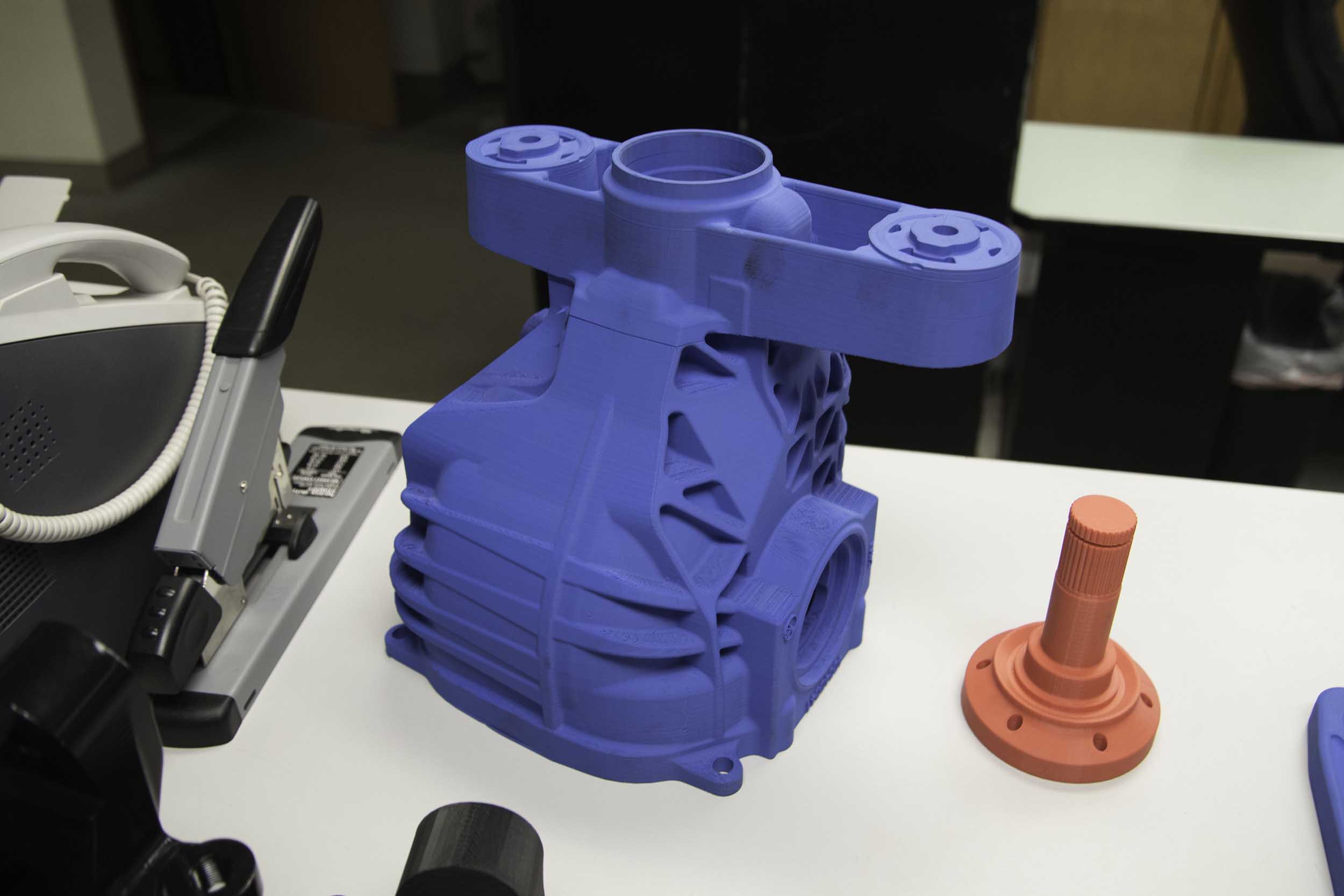

Engineers at AME have used 3-D scanning and printing to create many components specific to their needs. This reduces costs, limits supply chain issues, and shortens manufacturing times significantly.

The modern technology and chassis design built into every Art Morrison Enterprises suspension ensures that your ride’s chassis upgrade will perform just as a modern, performance-focused vehicle should. It is designed to give your ride that “just right” stance, and will maximize the drivability and comfort of your vintage automobile in the process. Exactly what you’re looking for in every aspect of a chassis upgrade!