We are back with the team from Performance Systems Integration (PSI for short) for part two of our mini-series of LS and LT throttle bodies. This is the second feature in a three-part series of articles on comparing drive-by-cable and drive-by-wire throttle bodies to help clear the air on which parts play nice with each other and some common confusion with components and controlling them to dispel some online myths and inaccuracies. Last month was on drive-by-wire throttle bodies on the early Gen-III LS engines. For this month, we’re covering drive-by-cable throttle body options for Gen-III and Gen-IV LS engines.

A Cable-Driven Throttle Body

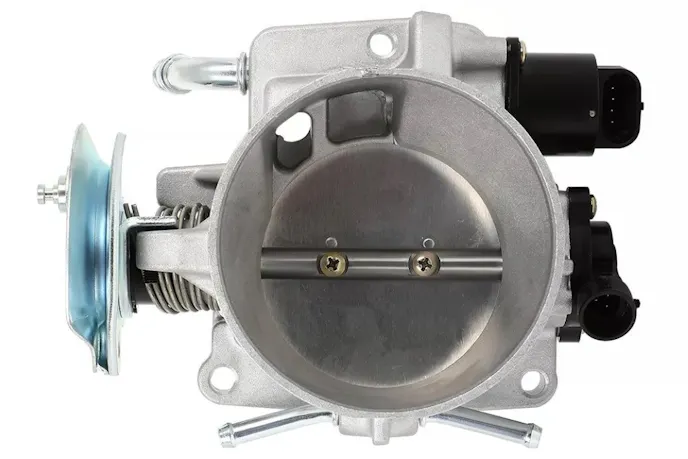

Just as the name implies, a drive-by-cable throttle body (often referred to as DBC) is a throttle body that is controlled by a cable attached to the gas pedal, much in the same way the throttle linkage is actuated with a carburetor. Cable-driven throttle bodies require a throttle position sensor (TPS) to tell the PCM what the exact throttle position is between idle and wide open throttle, and an idle air control valve (IAC) which is a solenoid that finely controls the amount of air allowed into the intake manifold to maintain engine speed at idle. Both sensors are mounted directly to the Throttle Body.

While a drive-by-cable throttle body is the style commonly thought of when it comes to LS engine swaps, it actually had a brief and limited production life. The cable throttle bodies were only used on the 1998 to 2002 model-year LS1-powered Camaros and Firebirds, the 1999 to 2002 model-year pickups, 2003 to 2006 model-year vans, and 2004 GTOs. While the C5 Corvette was produced during this same time period, it only received a drive-by-wire throttle body.

Since the early LS-swaps commonly used an engine pullout from an F-Body or truck going into a classic car or truck, drive-by-cable setups were very common. These throttle bodies are universally interchangeable between the F-Body and truck applications and feature a 78mm throttle blade diameter, the early-style three-bolt mounting pattern, and use the same TPS and IAC. GM did not offer a drive-by-cable throttle body with the later-style four-bolt mounting pattern or in a larger size.

Compatibility: ECM vs PCM

You might be inclined to install a DBC Throttle Body on your intake and call it a day, but unfortunately, it’s not that simple! The engine controller and tune need to be compatible with the throttle body and engine harness or you can end up with a project that won’t run or is stuck in limp mode (no throttle). Let’s take a step back and look at the compatibility differences.

Early Gen III (24x) LS engines used a powertrain pontrol module (PCM) because they control the engine and transmission functions. However, later Gen IV (58x) LS engines used an engine control module (ECM) and a separate transmission control module (TCM) for proper drivetrain function. What’s important to note is that only the Gen III PCMs had the capability of running DBC throttle bodies and of these PCMs, not all had IAC driver hardware installed. For the sake of commonality and availability, the guys at PSI recommend using a PCM with service number 12200411. Furthermore, having the proper tune installed on the PCM is just as critical as it will allow the PCM to actuate the IAC correctly.

The LS engine can be like Legos, with lots of interchangeability with certain parts, which is what makes the platform so popular. But if you mix and match your ECM/PCM incorrectly with your engine, throttle body, and harness, you can end up with headaches and a project that won’t run or a throttle body that is stuck in limp mode.

As stated above, GM used several different PCM service numbers during production. The 12200411 PCM was made by Delphi for General Motors for the ’99-’02 trucks and F-body cars and is identified by the “RED” and “BLUE” written on the connectors to tell you which harness it pairs with. It is important to note that you can also find these 411 PCMs in ’99-’03 Corvettes, but they will need to be reprogrammed, as the C5 Corvettes only came with drive-by-wire throttle bodies.

Also, the ’97-’98 Corvettes and ‘98 LS1-powered Camaros and Firebirds utilized a PCM that also used red and blue connectors for its engine harness, which can be mistaken as a viable PCM option. These computers can be identified by a service number ending in “212” and a body that looks different than the 411 PCMs. These are not wired the same as the ’99-’02 PCMs, are not reliable or tuner-friendly, and should be avoided.

DBC On A Gen-IV LS

Since the cable-driven throttle bodies were only used on the early Gen-III LS engines with a 24x crankshaft reluctor wheel from the factory, running a Gen-IV LS engine with a cable throttle body and an OEM PCM can be a tricky endeavor. It is not as simple as wiring the TPS and IAC to a GEN-IV PCM and some retuning, the computer is not capable of doing that. But there are a couple of options when doing a swap with a Gen-IV LS.

The first option would be to completely disassemble the engine and have the 58x crankshaft reluctor wheel swapped out for a 24x version, a job that has to be completed at your local machine shop to be done right. Combining this intrusive engine surgery with a 1x upper timing gear would allow you to use a PSI Gen-III drive-by-cable harness, 411 PCM, and cable throttle body. This route is rarely chosen due to the time, expense, and labor to get the job done. Also, the last thing anyone wants to do is tear apart the engine you spent a lot of money on just to swap the reluctor wheel.

PSI offers a far less intrusive, time-consuming, and costly solution to this conundrum. PSI’s engine harness package that utilizes a PSI Gen-III drive-by-cable harness, 411 PCM, and Lingenfelter’s signal conversion box. This specially-engineered signal conversion box converts the 58x crankshaft and 4x camshaft signal to the 24x and 1x signal a 411 PCM computer wants to see. This means you can take an LS like an LS3, LS7, ’07-’13 Vortec LS out of a truck or SUV, etc., and run it with a cable-driven throttle body without the cost and labor to open up your engine like the first option above.

For the throttle body, you also have two options, one obviously better than the other. Since GM never made a cable-driven throttle body with a four-bolt mounting pattern that Gen-IV intake manifolds have, you could use the three-bolt, 78 millimeter throttle body off the ’99-’02 truck and F-Bodies with an adapter. While this could potentially be a cheap solution, you certainly don’t want to take an engine made for a 90 millimeter throttle body and choke it down. The second option is best for ease of fitment and performance, and that would be to grab an aftermarket throttle body from a company like Nick Williams that uses the necessary four-bolt mounting pattern but is cable-actuated with provisions for TPS and IAC.

Clearing The Air

If you choose to keep the old-school mechanical gas pedal in your project versus converting to a drive-by-wire setup, there are plenty of options to get whatever LS engine you’re swapping into your build running and on the road right. Keep an eye out for our conclusion to this series next month as we tackle Gen-IV and Gen-V drive-by-wire throttle bodies!

You might also like

Getting Aligned: Honey Badger Gets aFe's Camber Kit And Tow Hooks

Step one in getting our C5 Corvette ready for the road course is to get the suspension settings dialed in with the help of aFe's camber kit