It is easier than ever to generate significant horsepower with modern engines, however, you’ll need a clutch capable of handling all the power if you plan on using any of it. With modern muscle cars easily producing 500 and 600 lb-ft of torque, and more, you’ll require substantial more power-holding capability, and a twin-disc clutch might just be what you need.

We all desire to experience the enhanced power output behind the wheel, but we must also consider that our cars, unless they are ground-up race car builds, were originally designed to meet OE specifications, and their components operate within certain design parameters. Modifying the vehicle to improve performance often necessitates pushing components beyond their intended limits, leading to potential failures — unless you upgrade them beforehand.

Coming In Clutch

In a manual-transmission application, the clutch assembly is often the first component to exhibit an inability to cope with the newfound power. Bolt-on components can add up to 100 horsepower in some cases, while supercharger and turbocharger systems can offer 200-plus. Considering that newer cars are increasingly heavier and traction has improved, it’s easy to understand that a stock clutch won’t last nearly as long as it could have in a completely stock situation. Aftermarket companies like SPEC Clutch have risen to the challenge of designing and manufacturing performance clutches, and the go-to unit for many modern muscle cars is the twin-disc clutch assembly.

Singles Only

In a standard clutch assembly, a flywheel is bolted to the crankshaft, and a pressure plate is fastened to the flywheel. Between the two is a single clutch disc that spins on the input shaft of the transmission. This clutch disc has friction material on it that grips the flywheel surface when the pressure plate applies force on the disc. Engaging the clutch pedal releases the pressure, allowing the engine to spin freely and independently of the transmission, facilitating gear changes. The clutch pedal is used to modulate the pressure, gradually engaging the clutch disc and initiating vehicle movement.

A typical aftermarket, single-disc clutch assembly can be equipped with a variety of friction materials, usually selected based on the application. In a street application, the goal is to balance the engagement profile with power-holding capability, while a racing application prioritizes power-holding capability above all else. However, a single clutch disc, regardless of the friction material, has a limit to its power-holding capability. In the past, the solution was to increase the pressure provided by the pressure plate. Although this improved power holding, it came at the cost of a heavier pedal feel. While many enthusiasts chose to tolerate this compromise over the years, they eventually sought a better solution, and clutch companies like SPEC were already engineering one.

Twins For Twice The Win

With a twin-disc clutch assembly, you still have the same three assemblies: a flywheel bolted to the crankshaft, a pressure plate fastened to the flywheel, and a disc – or discs, in this case.. Additionally, there is a floater plate, typically a steel plate, sandwiched between the friction discs, acting similarly to the surface of the flywheel. In this multi-disc approach, the two friction plates effectively double the friction material and, consequently, the power-holding capability. The improved performance is achieved through the additional friction surface, eliminating the need to increase pressure in the pressure plate. This is advantageous for street applications, allowing for smooth engagement, an easy pedal pressure, and the necessary extra power-holding capability.

Twin and other multi-disc clutch assemblies are popular in racing applications because the additional friction discs and floater plates enhance power-holding performance. The multi-disc approach also effectively reduces heat in the friction materials, since the friction is distributed across multiple surfaces rather than just one. This becomes critical when hot-lapping the car at the dragstrip or completing laps on the road course, where there’s a need for numerous gear changes in a short amount of time.

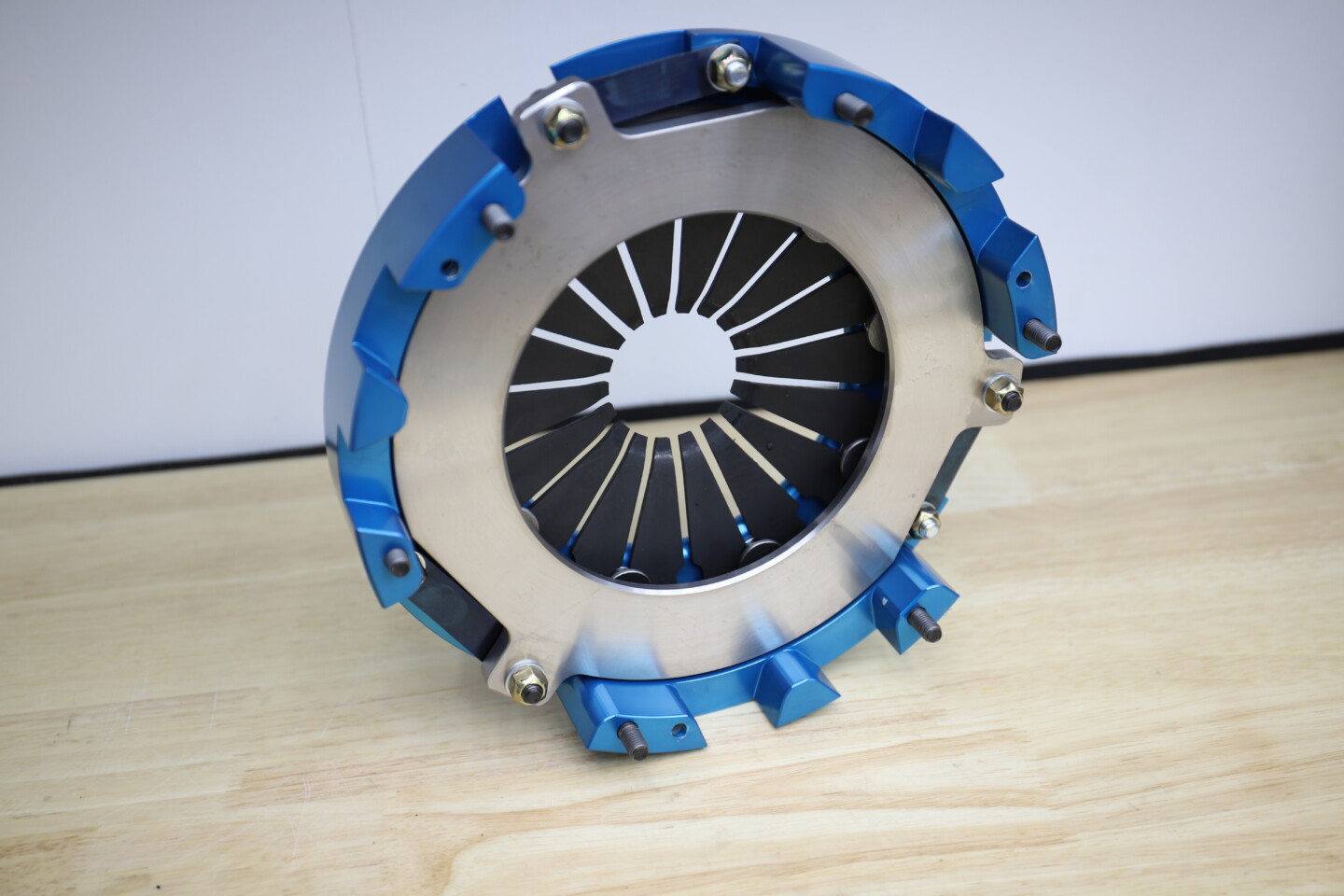

As there is now an added friction disc and a floater plate, the pressure plate is manufactured to encapsulate both discs and the floater. Here you can see how deep the twin-disc pressure plate is.

If there is a downside to the multi-disc clutch system, it’s the added rotational weight from the extra disc and floater plate. However, in some multi-disc clutches, smaller diameter friction and floater discs are used to offset this, reducing weight and more closely centering the remaining weight near the input shaft.

Super Twin Or Mini Twin

SPEC offers two styles of twin-disc clutch assemblies, with the company’s Super Twin being the choice for street cars and track use in extreme horsepower applications. They are rated for 750 to 1,500 lb-ft of torque, and SPEC states that they provide “near-stock drivability, tremendous life expectancy, a no-shimming setup with bolt-in installation, and maintenance-free operation.” This is likely the preferred option for most enthusiasts with street cars.

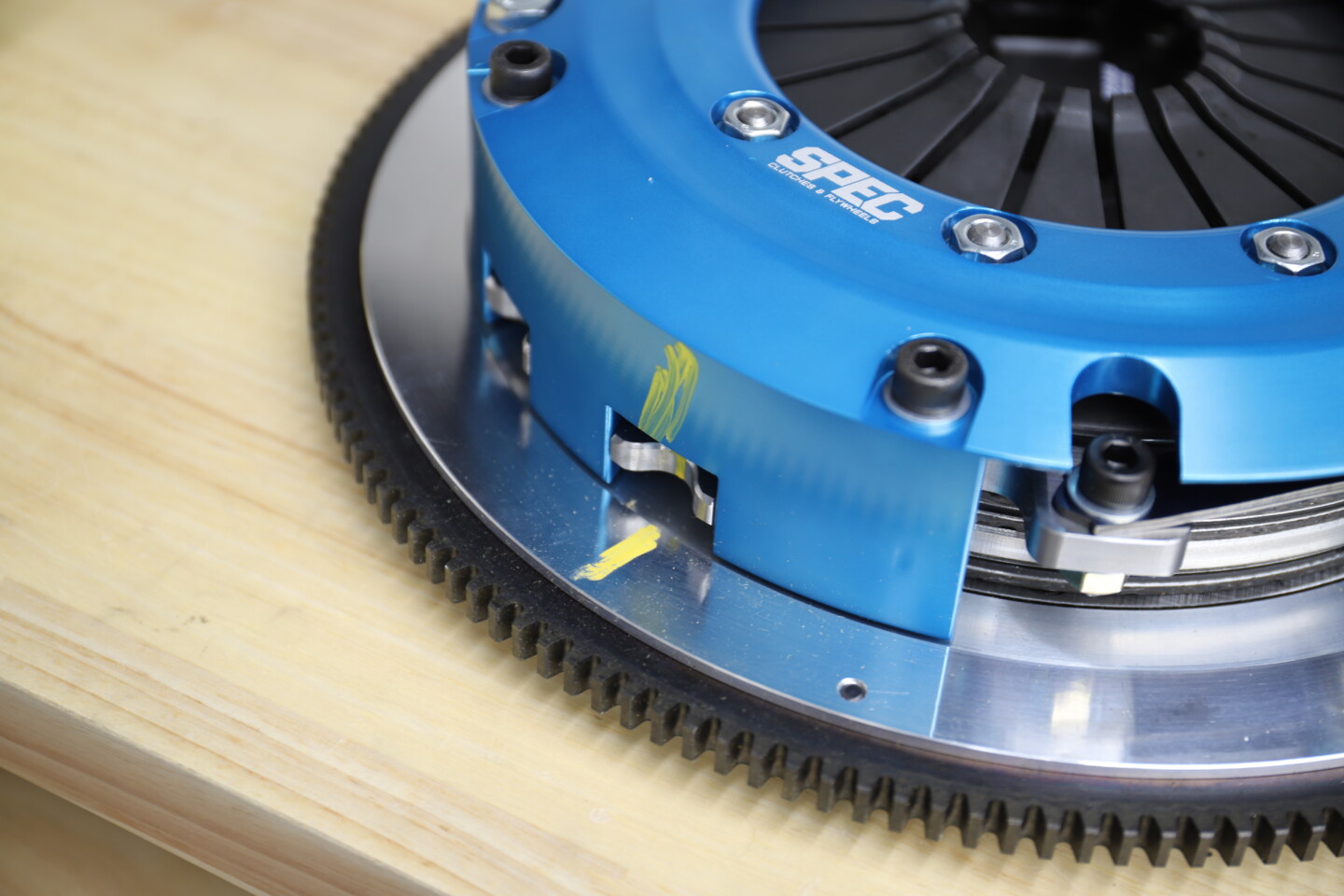

With the extra components and rotating mass of the twin-disc assembly, clutch manufacturers such as SPEC Clutch will balance the clutch assembly. It is important to look for the alignment marks on the pressure plate, floater plate, and flywheel when fastening them to your engine.

SPEC’s Mini Twin is designed for limited street use. It is aimed at drag racing and road racing applications. It is available in numerous configurations and diameters, with both factors determined by the vehicle’s usage and performance demands.

Friction For Days

Friction materials for clutch discs have evolved over the years. Most stock original equipment clutches use an organic compound that provides smooth engagement and sufficient wear and power-handling capability for the OE application. SPEC employs several friction materials in its clutch assemblies, including organic, carbon composite, carbon composite with Kevlar, and sintered iron.

Various friction materials are used in clutch assemblies and an organic, full-face friction disc such as the one pictured here are usually the first step above stock.

It’s important to note that depending on the chosen friction material, the design of the clutch disc can vary between full-face and individual-puck styles. This design works in conjunction with the specific friction material and how the friction disc engages with the flywheel and floater plate.

Hold The Power

Regardless of whether you have a restomod, high-performance classic, or a modern muscle car, equipped with any level of forced induction and traction capability, you’ll likely find yourself in need of a clutch soon. Explore the range of options SPEC offers, and be sure to consult with SPEC’s technical staff to determine the product that best suits your application.