In the world of hot rodding, function is king – performance takes priority when the main goal is going fast. But that doesn’t mean we always have to ignore the form in order to get there. Edelbrock’s new cross-ram LS intake manifold seeks to address both sides of the equation with a design that is not likely to be overlooked on cruise nights that also leverages the power advantages of a cross-ram layout.

“Simply put, we wanted to build the best-performing 1500-6500 rpm intake on the market,” says Brent McCarthy of Edelbrock Performance. “We’ve developed carbureted manifolds, XT Style EFI, and four-barrel LS manifolds in the past, but it felt like we needed something more in that EFI manifold space.”

Gearheads tend to fixate on peak horsepower and torque numbers to benchmark performance potential. That makes a lot of sense in a purpose-built racing application, where the engine is expected to be on boil most of the time. But the reality is that most hot rod projects spend the majority of their life out on the street, where low-end power and mid-range torque are far more useful – and noticeable – on a day-to-day basis.

“With the tunnel rams and our XT manifolds, you give up torque in order to get the horsepower,” McCarthy explains. “And for a lot of applications, that’s totally fine. But if you’ve got, for instance, an LS swap in a ’57 Chevy, you probably want to drive it. And you’d probably like having that torque.”

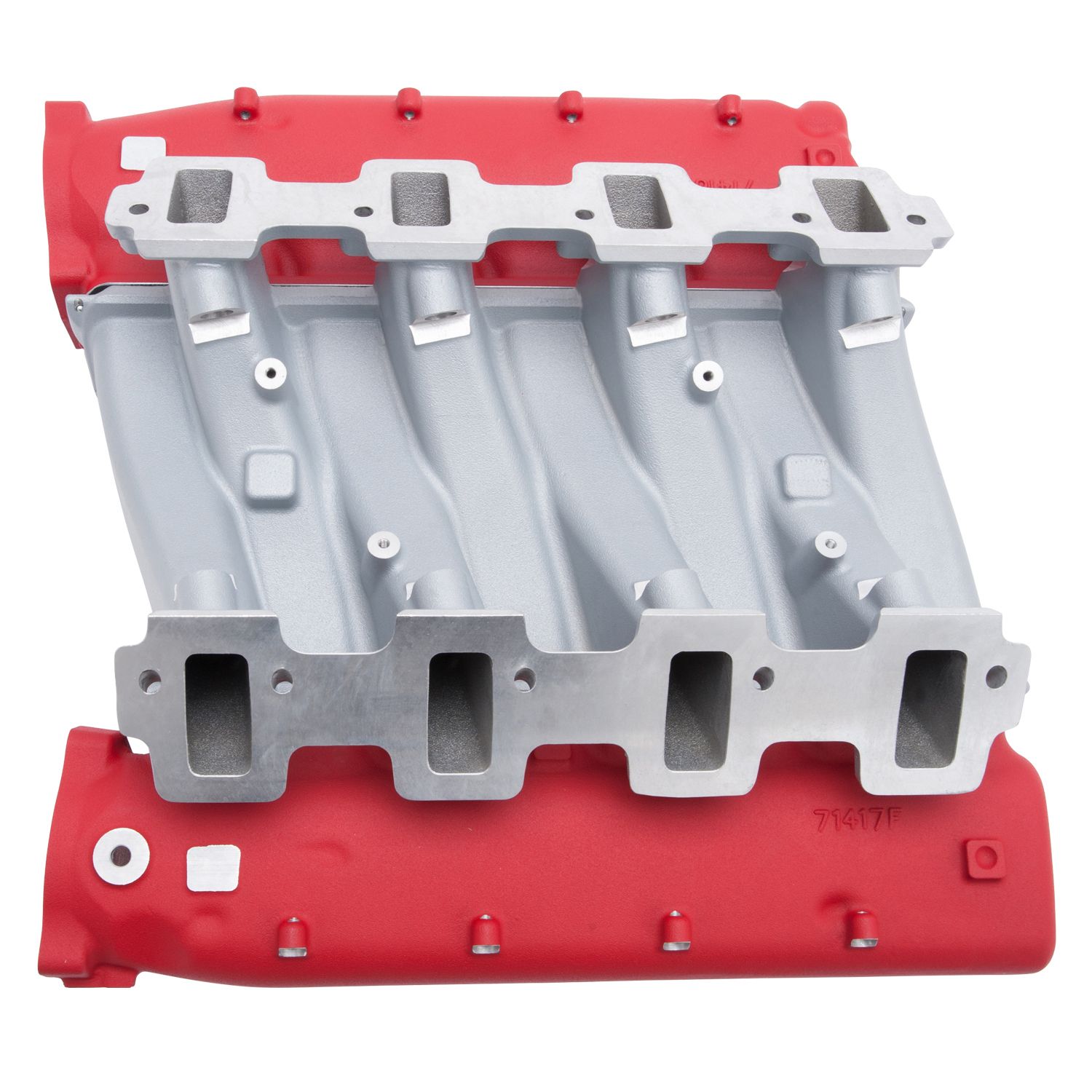

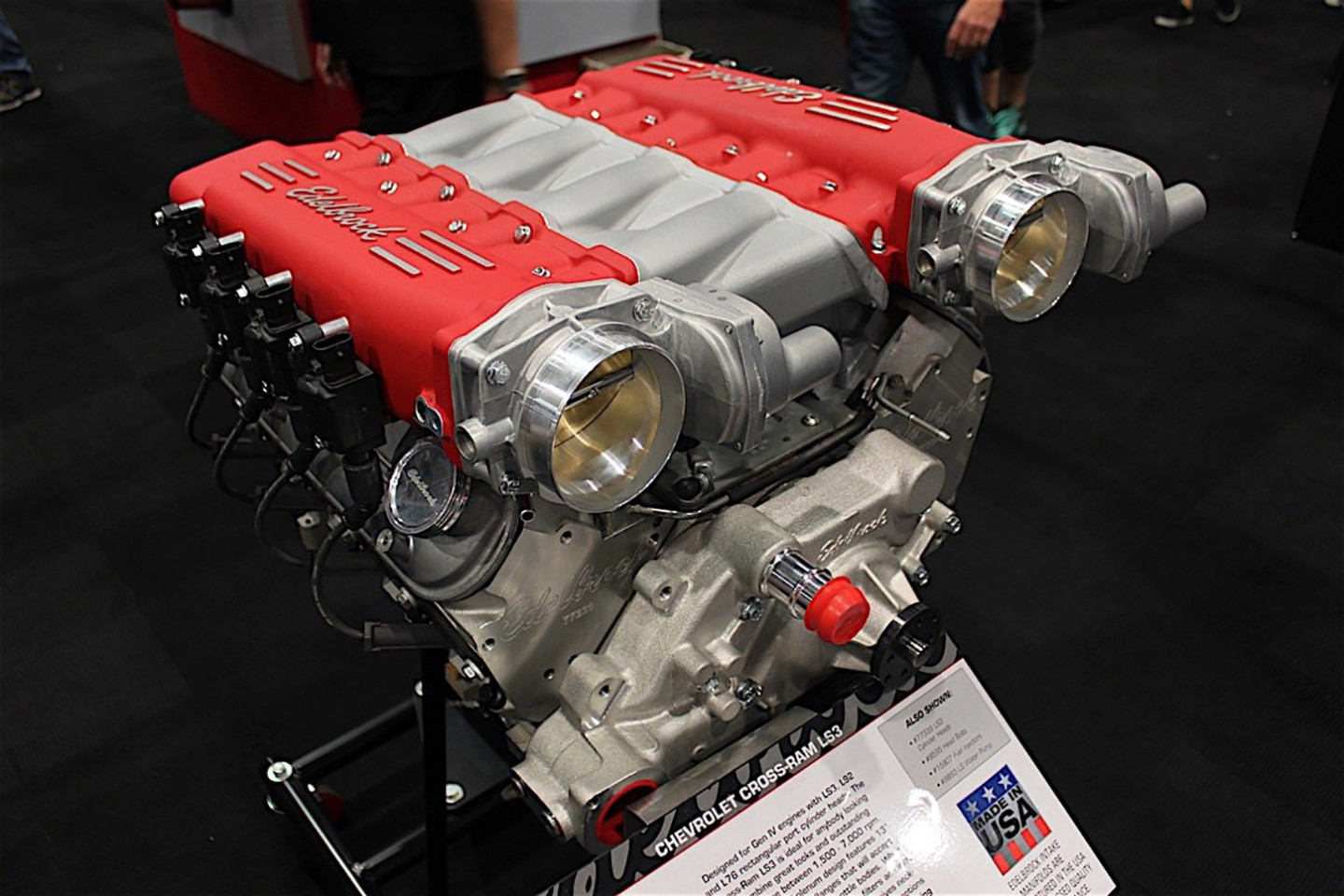

Edelbrock’s eye-catching three-piece cross-ram intake design has a killer look and delivers some big improvements in mid-range power over traditional single-plenum designs.

The new cross-ram manifold comes with either black (PN 71413) or red plenums (PN 7141), the latter of which can provide a Ferrari-like aesthetic to the engine bay of your street rod or LS-swap project. While there’s no doubt it’s a cool-looking piece, we wanted to get a better sense of how this dual plenum design would respond using a 6.0-liter LS we had hanging out on the dyno and get some insight from McCarthy on what combinations will work best with a cross-ram.

Show ‘n Go

Designed for Gen IV engines with LS3, L92, and L76 rectangular port cylinder heads, McCarthy notes that this cross-ram intake is aimed mainly at traditional street machine builds, sharing, “a person who’s got a cam, headers, and perhaps aftermarket cylinder heads; builds that are in that naturally-aspirated and in the 500-650 horsepower range.”

And while its characteristics make it ideal for daily drivers, McCarthy points out that there are motorsport disciplines where this intake could pay dividends as well. “Of course, it really depends on your setup, but I could see this being a good option for autocross, where you’re on and off the throttle a lot. You might like having that improved throttle response and more torque in that 3,500-5,000 rpm range.”

The straight, 13-inch runners provide a meaty torque curve that benefits the rev ranges where street machines operate most of the time.

The intake gets its distinctive appearance thanks in part to its 13-inch runners with flanges that will accept two 90mm GM LS3 throttle bodies. “By moving the plenums out, we were able to package those straight runners,” McCarthy explains. “Traditional manifolds that wrap around and have single plenum on the bottom are normally in the 9- to 11-inch range, so this gives you more of an ideal runner length for that mid-range torque.”

And of course, the twin throttle body setup has advantages of its own. “With two 90mm throttle bodies, you have essentially twice the airflow to work with – or half the pressure drop, you might say — to get the air into the engine,” he says. “Any time air has to pass through an orifice, you give up some pressure in order to make it move. So in a traditional system, you’ve got atmospheric pressure of, let’s say, 14.7-pounds, and now you’re trying to feed an engine through a restricted opening – the throttle body – and in that scenario, you might lose 7/10ths of a psi. So now in your plenum, you only have 14psi at the top of the runner, and when the valve opens, you’ve got that reduced amount of pressure pushing air into the engine.”

Because the Cross-Ram intake sits so close to the valve covers, the coils needed to be relocated. To fix this problem, Edelbrock incorporated coil mounts on the sides of the plenums. This design makes installation a breeze since you don’t need to worry about remote mounting the coils to the firewall, inner fenders, or the frame.

And reducing that pressure drop with the dual throttle body setup has several performance advantages. “You’ll feel it in throttle response because you’re uncovering so much more throttle area now, so it definitely has more of a kick to it,” McCarthy tells us. “So while the 90mm throttle body isn’t totally lacking for throttle response, now it’s twice as much!”

But while the dual-plenum design is a defining visual characteristic of this cross-ram intake, it’s not its only unique attribute. If you compare it to other dual-plenum manifolds, you’ll notice that this one has four balance tubes across the plenums. With that long runner and the relatively small plenums, McCarthy says that there’s quite a bit of pressure pulsing going on in the plenums. If that’s not addressed, it can have an adverse effect on the powerband, creating unpredictable peaks and valleys in the torque vs RPM curve.

Black plenums are also available to provide a slightly more low-key aesthetic. (PN. 71413)

“If you don’t have balance tubes you might, for instance, get a spike at 2,500 rpm, and then the poor thing would fall into a hole at 3,500, only to come back at 5,000. That just wouldn’t be good for drivability. So in order to balance that out and make the engine run more evenly, you need to dampen the pressures in the plenum. We developed that by experimentation, 3D printing prototypes with different balance tube designs until we landed on the smoothest, most ideal torque curve. By balancing that out, you do lose some of those peaky torque spikes, but you’re also filling in those valleys too.”

Going Dual TB

Since we’re working with a twin throttle body system here, a few additional considerations must be taken into account when stepping up to a dual plenum intake like this cross-ram piece.

“People have had pretty good success with these using cable throttle bodies,” says McCarthy. “And that isn’t to say that we haven’t had success with the drive-by-wire throttle bodies, but in some ways, the cable throttle body can make your life a bit easier – it’s just one less thing you have to tune.”

Sniper EFI 92mm cable throttle bodies were used for these tests.

And with that in mind, it’s worth noting that drive-by-wire throttle bodies will require an EFI controller that supports a dual setup. “Our new Pro Flow 4+ is set to debut soon, and that will have the capability of running dual electronic throttle bodies,” McCarthy says. “And controllers like the AEM Infinity Series 8 will also do the job.”

Meanwhile, a key benefit of drive-by-cable throttle bodies with this setup is that more traditional EFI controllers are compatible, opening up a much wider range of options to choose from. Power should be more or less identical. But a drive-by-wire throttle body setup might look a bit cleaner and provide more tuning options, so choosing the right one for your particular project is largely subjective.

On The Dyno

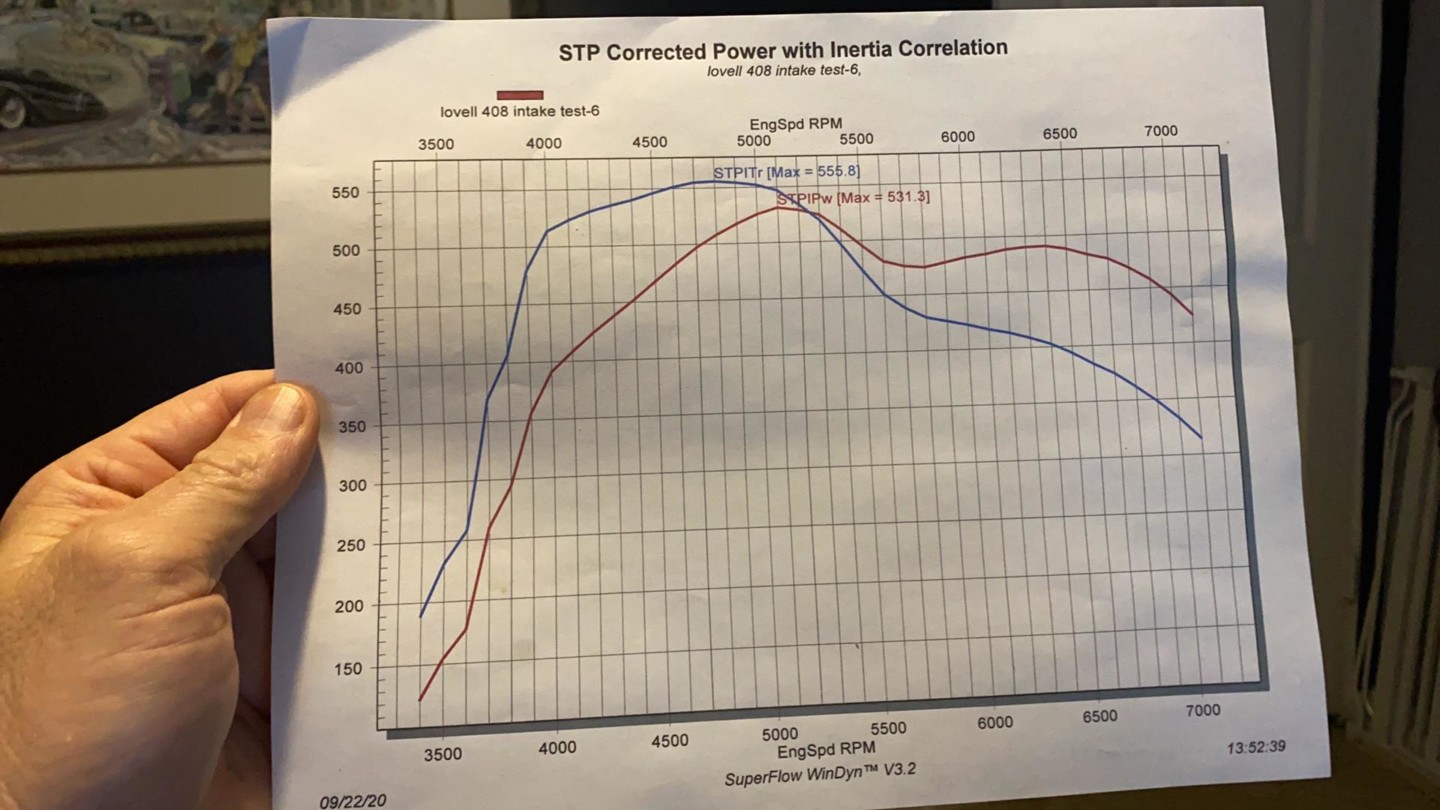

With our 6.0-liter-based iron block LS test subject on the dyno, it was time to make some pulls. Unfortunately, we made a few critical discoveries while testing with the Edelbrock dual plenum intake that only really revealed themselves in retrospect. Most importantly, we learned that an asymmetrical throttle body setup, where one is ostensibly pointing “up” while the other is pointing “down,” can cost you horsepower.

When we added the second Sniper EFI 92mm cable throttle body to the Edelbrock cross-ram tests, we flipped it upside down. We later learned that an inverted setup could cost you some power, so there’s a bit still left on the table here, but it’s clear that the amount of mid-range punch available is impressive.

“You need to make sure the throttle bodies match, and the openings should be going in the same direction,” McCarthy says. “That’s the ideal setup for this intake.”

Considering the fact that this intake isn’t designed to fit within the confines of a factory setup, he advises would-be engine swappers to spec out engine components that play to this intake’s strengths for maximum effect. Also, pay attention to what happens in front of the throttle bodies. Edelbrock found a 14-inch length between the filter and the throttle body was ideal. Even if the tube has a bend it ran better than no tube.

Nearly 520 lb-ft is available from 4,000 rpm with this intake, and it continues to ramp up on the way to 5,000 rpm, yielding peak numbers of 531.3 horsepower at 5,100 rpm and 555.8 pound-feet of torque at 4,800 rpm.

“You’re looking for a cam that’s really dialed in for that mid-range torque. Ultimately, the ideal application for this is someone who wants a cool manifold and likes to melt those tires.”

While this intake might not be perfect for every project out there, the design and powerband would most certainly fit the bill for 90-percent of the street cars on the road. The cross-ram design gives you a very beneficial power-band, gobs of tire-shredding torque, and unique looks that will be unrivaled at any local car show.