Project Track Addict is back for the final phase of the build. When we announced this project at the beginning of this year, the goal was straightforward. We aimed to find out how much quicker we could make the C8 Corvette LT2 engine on a road course over a showroom stock machine. The mid-engine American supercar is an excellent track-day choice in stock form when it leaves the Bowling Green, Kentucky, plant. But we can’t leave anything alone, and a planned course of action was already in place before we even got our C8 in the shop. We aim to turn our stock C8 Corvette into a track-day-terror with increased durability, braking, grip, handling, and straight-away speed.

As we progressed through each phase of the build, we returned to the Big Willow road course at Willow Springs International Raceway to let our professional driver, Allen Ward, rip around the 2.5-mile road course and measure how much quicker the lap times were. Ward typically spends his days testing and setting up Porsche race cars as the manager and driving instructor for GMG Racing. He has decades of racing experience behind the wheel and on motorcycles. Having Ward in the pilot seat of Project Track Addict immensely helped get every ounce of performance from the C8.

The build of Project Track Addict was to be performed in three phases consisting of many carefully thought-out modifications chosen with input from manufacturers specializing in C8 performance. Phase one included prepping the C8 for track duty by installing a harness bar from Pietz Performance and Sparco harnesses. We also installed upgraded axle bolts from Cicio Performance. After Ward set a baseline for track times with Track Addict in stock form, we pulled the factory wheels and tires to make way for lightweight forged monoblock wheels from Forgeline wrapped in Continental 200 treadwear tires. The weight savings and increased strength of the Forgeline wheels combined with the sticky Continental rubber immediately dropped Track Addict’s times. Ward improved from a best lap time of 1:38.37 in stock form to a best of 1:34.63 with the new wheel and tire package. To see the full story in phase one, click here.

ALCON brakes and Forgeline wheels wrapped in Continental rubber made a big difference with this track terror.

Phase two of Project Track Addict was divided into two stages. The first stage involved improving upon the already good factory brakes. For this upgrade, we contacted the experts at Lingenfelter Performance Engineering, who have extensive hands-on experience with the C8 platform. Alcon Brakes was the recommendation from Lingenfelter’s VP/COO, Mark Rapson, so the Alcon Pro-System performance brake package was chosen.

The Pro-System package includes new front and rear rotors and calipers. Additionally, we chose to install track-focused HAWK DTC-60 brake pads. The new brakes allowed Ward to drive harder into turns and brake much later. To see the Alcon brake installation and the G meter data we were able to get when testing the new brake package, check out the full story here.

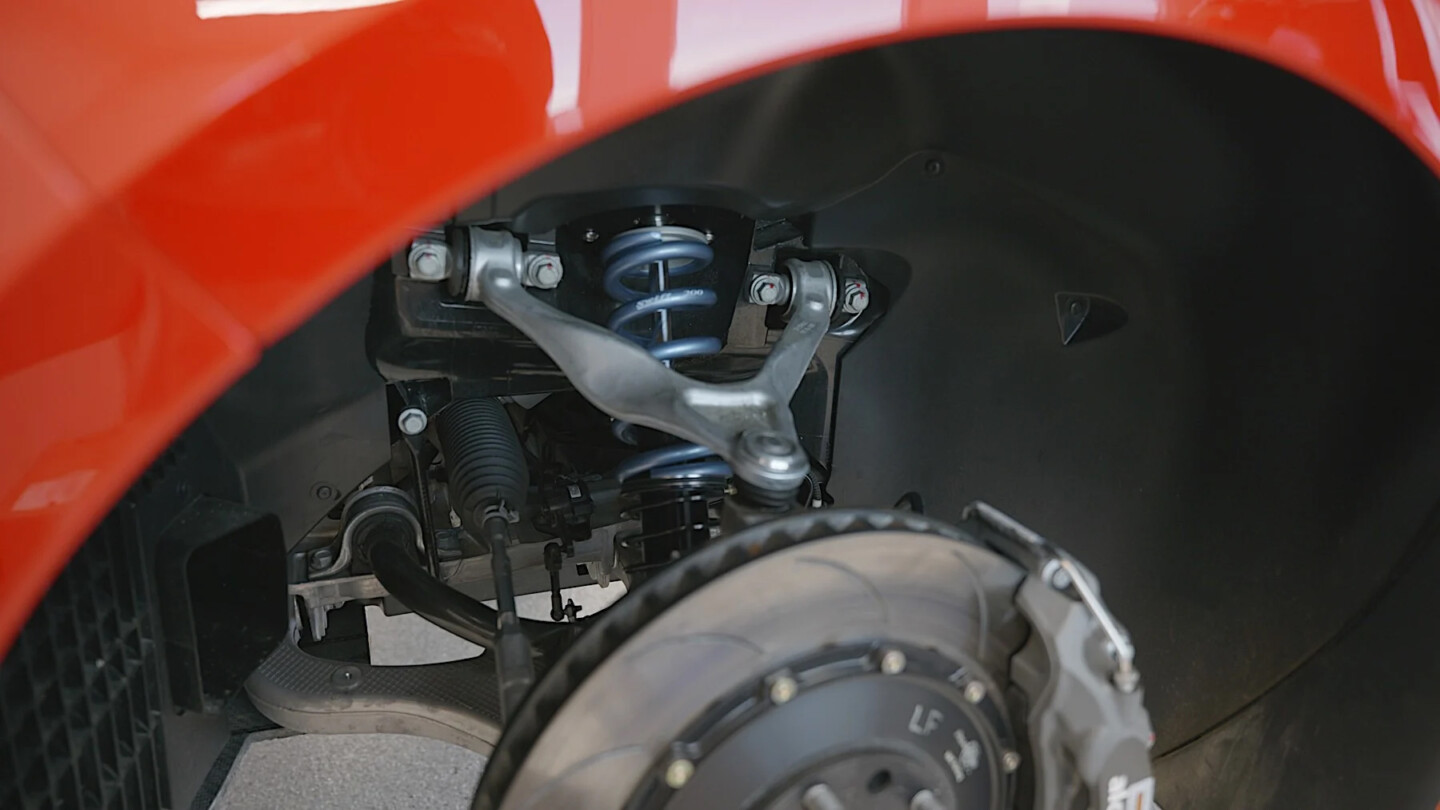

MCS and CICIO Performance came to the rescue by ditching the factory C8 suspension giving Track Addict tuned coilovers.

The second stage of phase two added an all-new suspension and an aero package. The new suspension setup included front and rear MCS coilovers from Cicio Performance. The aero package consisted of a carbon fiber rear wing and front splitter from LG Motorsports. These two upgrades combined to improve the grip and handling of Project Track addict drastically. In fact, Ward reported that he felt we had possibly reached the limits of Track Addict’s 200 treadwear tires due to how much faster he could drive into Big Willow’s turns with the upgraded MCS coilovers and increased downforce from LG’s aero components. To read the full story on the installation of the wing, splitter, and coilovers, including the test results, go here.

The carbon fiber intake manifold form Performance Designs is a nice touch in the engine compartment, and allows the LT2 engine to breath easier.

Adding Power To The Corvette LT2

For the final phase of Project Track Addict, we felt that a boost in power was the icing on the cake. Installing components to increase the C8’s power only made sense once the rest of the car had been upgraded and dialed in on the track. Many people choose to improve a car’s power first before modifying the rest of the car, which can get drivers in trouble on a big, fast, open road course like Big Willow.

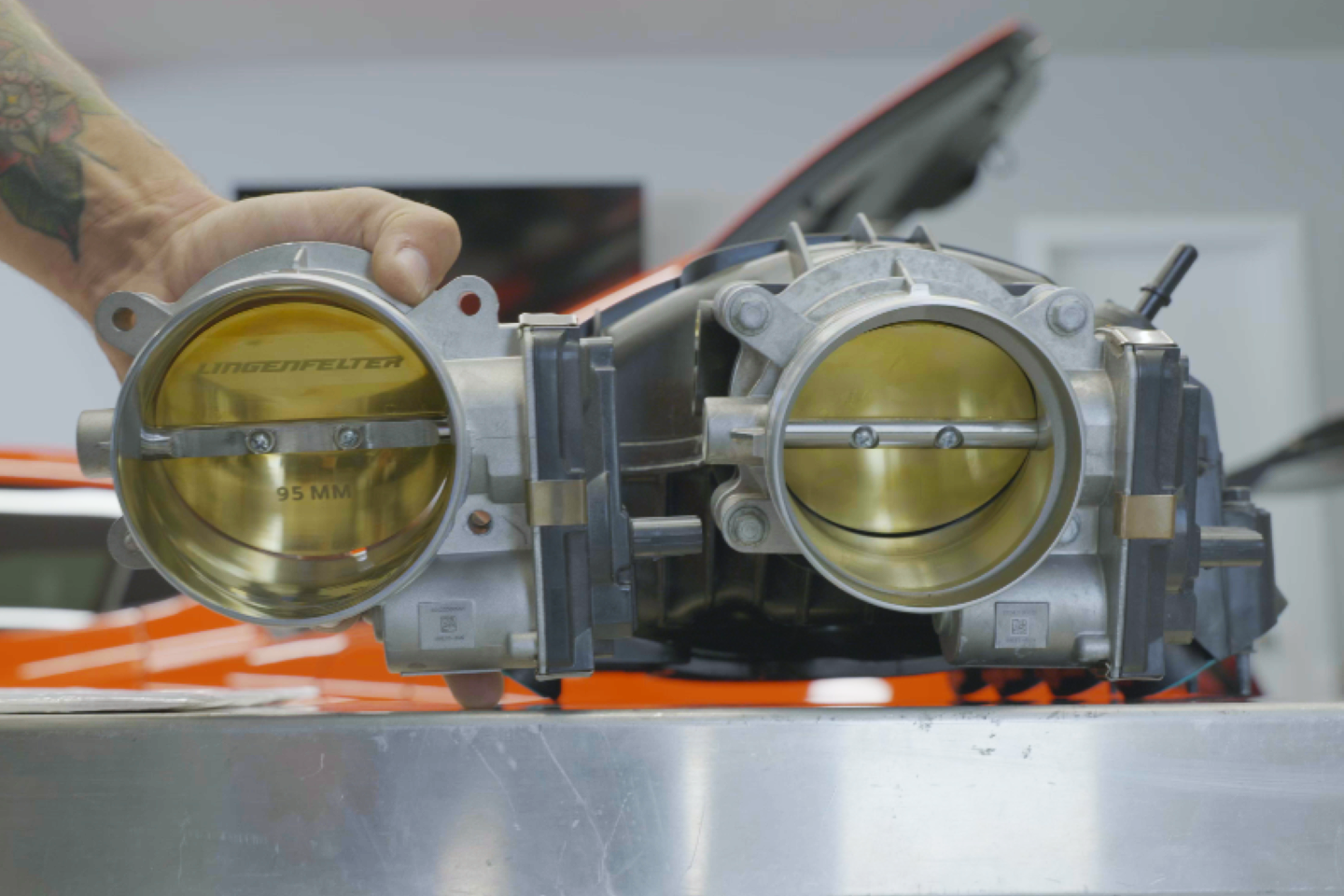

The differences between the stock intake and throttle body and the Performance Design Carbon pTR intake and Lingenfelter throttle body are profound! The intake offers more plenum volume as well as a larger opening for the 95mm throttle body versus the stock 87mm unit.

To help choose the right combination of horsepower-increasing components, we once again collaborated with Mark Rapson at Lingenfelter Performance Engineering. As much as we would have loved to turbocharge or supercharge our C8, we felt that installing several bolt-on components and tuning the car would be a better fit. To put together a simple bolt-on package for a naturally aspirated combination, Rapson knew exactly which parts to use, and in no time, we had several boxes from Lingenfelter Performance Engineering show up full of parts ready to be installed.

Lingenfelter’s exhaust kit is supplied with everything you need, including head pipes that connect to the factory cats that feature flex joints like OEM.

Starting at the top with out C8 Corvette LT2 engine, we installed a Performance Design Carbon pTR intake manifold along with a Lingenfelter Ported 95mm throttle body. Aside from looking fantastic, the pTR intake features a tunnel ram architecture, provisions for the addition of port fuel injectors, and has been tested to 50-pounds of boost for those wanting to run the Carbon pTR intake manifold on boosted engine combinations.

The Lingenfelter CORSA Xtreme-S cat-back exhaust system is made from stainless steel and features high-flow mandrel bends with an integrated X-pipe design. In total, this exhaust system saves over 13 pounds in weight.

To feed more air to the LT2 engine, we installed the Lingenfelter Hornet Cold Air Box by Halltech. We also wanted to give Track Addict a more aggressive tone and a free-flowing exhaust. The Lingenfelter CORSA Xtreme-S cat-back exhaust system fits the bill. It has an excellent tone without being annoyingly loud and offers increased exhaust flow over the factory system.

The exhaust system includes 4.5-Inch black chrome tips with laser etched logos that exit in the stock location.

The C8 Corvette LT2 And Global B

Once our resident tech, Seth Ward, got all the new parts in his hand, he went to work. All of the new parts bolted on with zero issues. With the latest performance parts installed on Track Addict, we wanted to get the C8 on a chassis dyno to have it calibrated. It should be noted that the components we installed on our C8’s engine do not require tuning when installing them individually. However, because we installed multiple components on the engine, we felt that to get Track Addict dialed in and performing at its best, it would be a good idea to have the car tuned. We set a date to take the C8 to A&C Performance in Murrieta, California, to use their chassis dyno. But there was still one problem: a software called Global B.

The Global B architecture in the C8’s ECM and TCM has been a problem for enthusiasts who want to modify their cars. That was until June of 2023 when industry leader HP Tuners launched the first comprehensive diagnostic and calibration software for vehicles running the Global B electronics. For this reason, we contacted Justin Burt at HP Tuners. Burt said, “2019 was the initial release of the C8 and we launched Global B support in June of 2023, so about 4 years to get to where we are today. Definitely a long and tedious process.”

General rule of thumb is, if you change the way the engine takes in, uses, or removes air, the vehicle will greatly benefit from a calibration change. – Justin Burt

After filling Burt in on the details of Track Addict’s build, he agreed that it would be a good idea to use the HP Tuners new software. “General rule of thumb is, if you change the way the engine takes in, uses, or removes air, the vehicle will greatly benefit from a calibration change,” Burt explained. “Sometimes, you can get away without one, but that doesn’t mean it’s the correct path forward.”

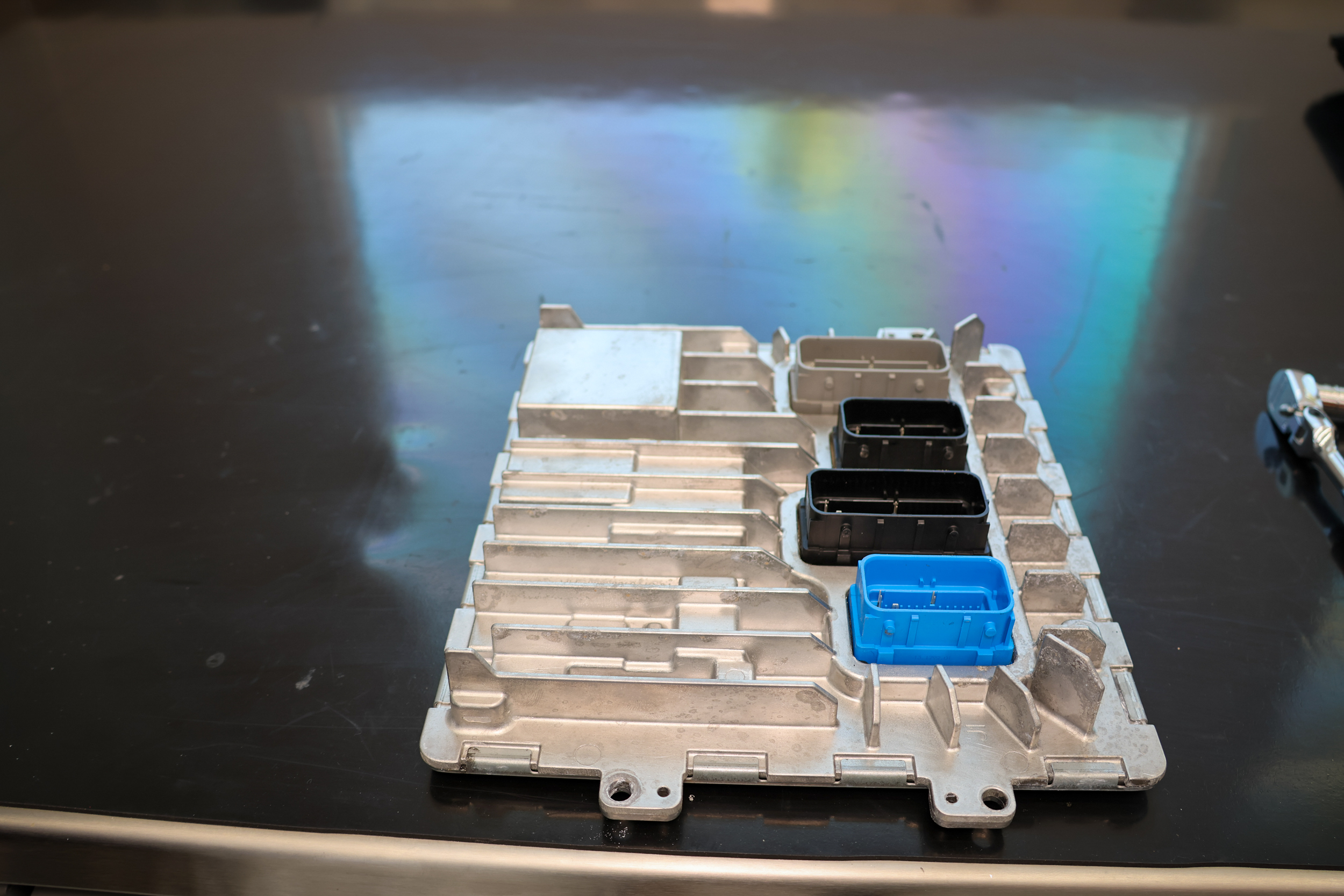

To unlock the C8’s ECM, it has to be removed from the car and shipped to HP Tuners for their technicians to perform the unlocking service. Before sending the unit off we were curious to how much time it would take for HP Tuners to work their magic. Burt said, “Our website states 1-3 business days not including shipping, but we generally have them knocked out in a day and on its way back to the customer.”

Getting the C8’s ECU out of the car is not that complicated if you take your time and know where to look. By the way, it’s in the driver’s side rear wheel well.

Getting the ECU out of the C8 was no easy task as the ECU lives behind the driver’s tire behind the bumper. First, Seth disconnected the battery. Then he removed part of the belly pan. Next, the rear wheel was removed before pulling out the inner fender well. Finally, we unplugged the computer and removed it from the car. All that was left was to ship the ECU off to HP Tuners and have them modify the unit so that it could be tuned.

Once we removed the ECU, we sent it off to HP Tuners so that they could unlock it for us so it could be tuned at the dyno.

The ECU was boxed up and shipped off for the modification, and within a few days, we had the unit back in our hands. After reinstalling the unlocked ECM in the C8, tuning changes and diagnostic processes can be done using HP Tuners’ familiar MPVI3 device that connects to the car’s OBDII port. Additionally, after successfully connecting to the car’s ECM, the user has full access to the HP Tuner complete VCM suit.

Hitting The Dyno Remotely

To handle the tuning duties, we felt it only made sense to work with the guys at Elite Tuned. Mike Carnahan and Brandon Leeb would be the masterminds behind the keyboard and make the necessary adjustments to the C8 to compensate for the modified parts added to our Corvette. However, they would not be on site for the dyno pull. Instead, we had them remote in and make changes by looking at the data logs we can acquire from HP Tuners MPVI3.

The tuning process is straightforward mainly because Elite Tuning knows the ins and outs of HP Tuners, as the company teaches tuning classes on this very subject. Carnahan, Co-Onwer and Founder of Elite Tuned, said, “Using the latest remote tuning technologies from HP Tuners, we’re able to get very detailed with each aspect of the C8’s performance, from throttle response to fuel mapping. The goal is a seamless process that respects the car’s incredible engineering while pushing its performance to the next level with the given combination of parts.”

The C8’s advanced GM Global B electronics can be complex to modify remotely, but once you understand how to dial in the calibration, the results can be remarkable. – Mike Carnahan

And while we know a thing or two about tuning with HP Tuners, we have zero experience with Global B and the C8. Leaving this to the hands of experts was the best option for us. Carnahan agrees saying, “The C8’s advanced GM Global B electronics can be complex to modify remotely, but once you understand how to dial in the calibration, the results can be remarkable.”

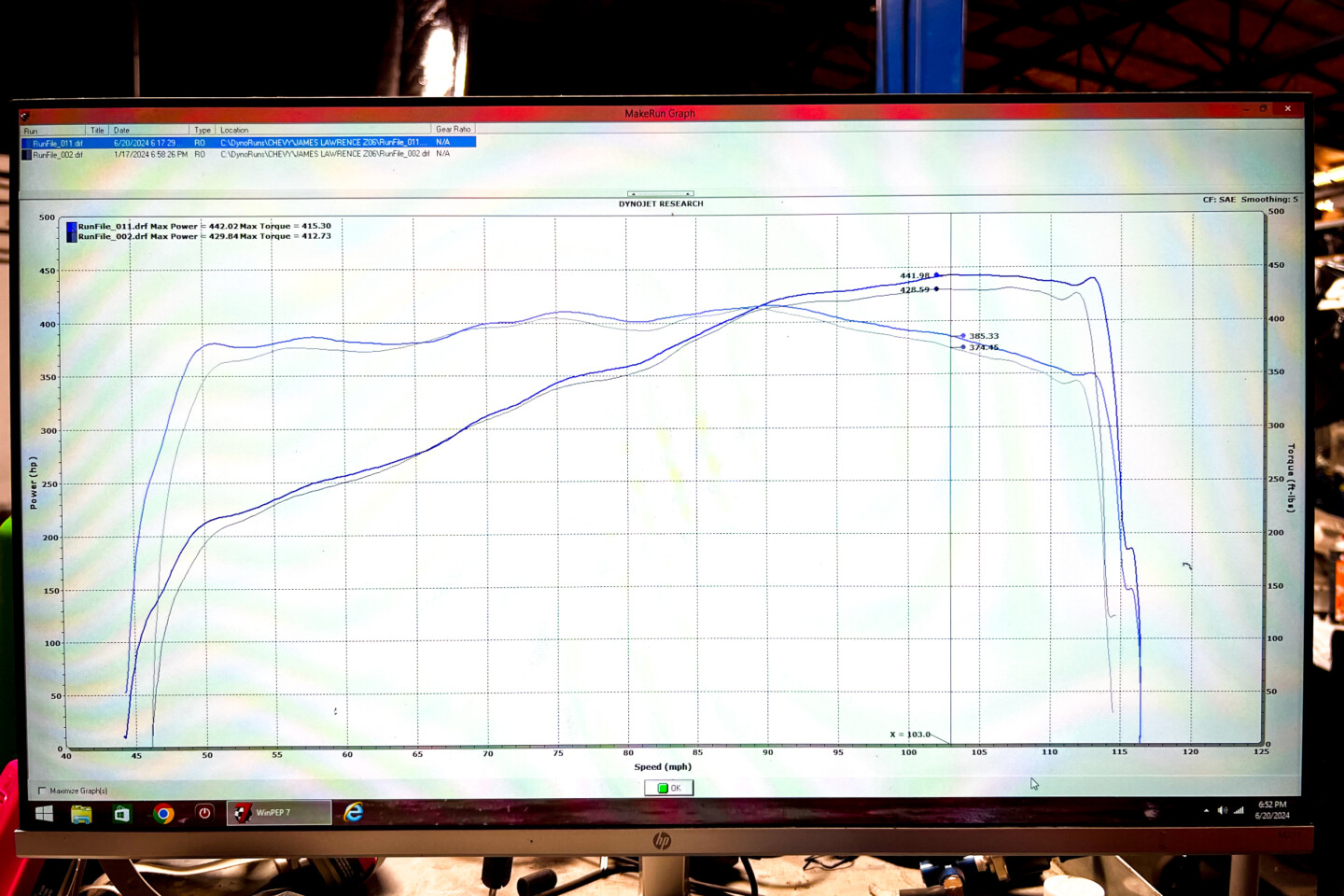

With the car strapped down on the dyno, it was time to make a rip. Our C8 put down 429 horsepower and 412 lb-ft of torque stock. With the stock tune and the new parts added to the car, the horsepower was upped to 440 and 411 lb-ft of torque, but we had a problem. We suffered from engine knock thanks to low-octane fuel from the great state of California. However, this was not an issue as Carnahan explained, “We prioritize communication throughout the remote tuning process, giving clients detailed updates and feedback on each calibration phase. This ensures they feel involved and informed, no matter the distance.”

With that said, Carnahan suggested an octane booster for the last dyno pull, so we added enough to get the number from 91- to 95-octane. It’s always better to have a little more octane than not enough. To prove this point, adding the octane booster not only added more protection to the engine as the engine knock went away, but it also came up a bit with the horsepower output. The final dyno number was 442 horsepower and 415 lb-ft of torque. Mike looked over the data one last time before confirming that everything was copacetic. With that notion, we unstrapped the C8 and rolled it off the dyno. We were done.

While the C8 picked up 13 horsepower and 3 lb-ft of torque, these numbers don’t tell the tale as the performance parts picked up power across the curve. Additionally, A&C Performance’s dyno is extremely stingy and infamously low with dyno numbers. To make matters worse, It was 22 degrees warmer than when we first dynoed the car, with 16- percent more humidity. Unfortunately, there was nothing we could do about the weather. However, you can tell by the graph that the new parts and tune picked up power across the board, great for road racing.

The C8 Corvette is a potent machine from the factory. However, once again, the performance aftermarket can take the best Corvette to date and step it up a notch in just about every area possible. One of the beauties of Project Track Attack is that this was a simple bolt-on project. It is all bolted on the car, from tires, wheels, and brakes to the engine, exhaust, and aero. No significant modifications were made to the vehicle, meaning anyone could copy this setup with minimum effort and have a mild-mannered streetcar that would be a terror on a track day. What’s not to love about that? It’s the best of both worlds.