It’s hard to argue with anything about the GM LS engine. Traditional Chevy vs. Ford vs. Mopar guys can bicker all they want about the old-school engines, but no sane person can say that the LS does not have the most power potential of any engine out there, especially on a cost-per-horsepower basis. But as good as the factory hardware is, it can always be made better with some good old fashioned hot rodding ingenuity, and when you want to start making truly stupid power with one, like up into the 1,000 horsepower range and beyond, you need to look to an aftermarket block to withstand the stress.

Some time ago we did a story on the various aftermarket LS engine blocks, but as time goes by, engineers refine and improve their designs, so we thought it would be good to refresh readers on what’s out there in the way of aftermarket LS blocks. We went back to the well and included the pieces from Dart Machinery, Bill Mitchell and World Products (which used to be one company but are now two separate entities), Racing Head Service (RHS), ERL Performance, and of course GM Performance Parts, which underwent a brand change to Chevrolet Performance.

Regardless of which block you choose, each of them have huge advantages over stock blocks, and a few can handle well over 2,000 horsepower. If you’re wanting to build more power than that, you need to start looking into buying HEMI parts and drums of nitro-methane!

Dart Machinery – LS Next

Richard Maskin and Dart have been at the forefront of the hardcore racing and high-end street performance scenes for decades, including during the glory days of NHRA Pro Stock in the ’70s and later, alongside the likes of Jenkins, Dyno Don, Bill Glidden, as well as the big stages of circle track racing like Indy and World of Outlaws sprint cars. This hardcore racing bent has evolved into a huge line of performance engine parts for both racing and the street use (at roughly 15,000+ sold per year, they are the largest producer of engine blocks in the aftermarket), and when it comes to blocks they’ve figured out what works and what doesn’t. They apply this to every Dart block, especially their new LS parts.

Far removed from most people who fawn over GM for the design of the LS, Maskin said that in his 50+ years of working on engines, “The LS is the most pathetic engine I’ve ever worked on.” Those are strong words for sure, but he bases it on several things, including the block’s strength and oiling issues. Regarding the oiling problems, Maskin points to the enormous amount of internal oil “leakage” with the LS. “The Gen 1 small-block Chevy, which they built 100 million of, takes 5 gallons per minute of oil at 6,000 RPM to lubricate everything. Our modern Pro Stock engines use 3 gallons at 11,000 RPM. The LS uses 18 gallons. What’s wrong with this picture?” The excessive oil use and the resulting issues associated with it are due to GM’s design of the oiling system, which Maskin points out has numerous problems that are eliminated by Dart’s LS Next cast-iron block.

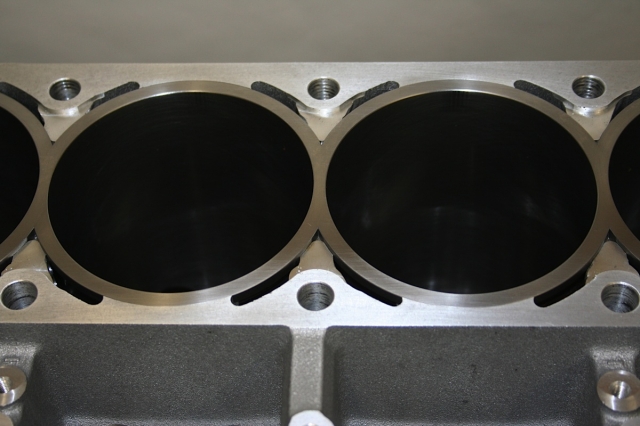

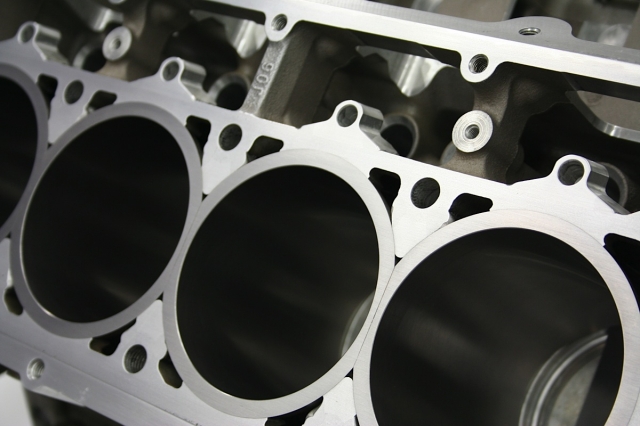

Compare this shot of Dart’s LS Next to the other blocks shown in this story and you can see non-skirted design of the block. Moroso has also made up pan rail spacers that allows a stock LS oil pan to fit, with a modified pickup bracket due to the revised main stud location.

In order to provide additional bottom-end strength, the LS is a skirted block, which creates excessive crankcase windage. To address it, GM used “communication ports” or windows between the cylinders, above the main bores, but that leaves very little metal to hold the main bores and cam tunnels in place and can lead to wear problems. As Maskin said, “All cams flex a little and it’s no big deal, but in the LS the cam and crank are like noodles in there, and it wipes out bearings and lifters.”

As things progressed in the LS market, Maskin knew he had to do something about it, and after five years of work said, “It finally came out right.” Looking at the production and existing aftermarket blocks, he decided he didn’t want to just do more of the same thing, so he chucked a stock block in a mill and cut the oil pan skirt off, then incorporated all the critical features he’s learned in his years of block science into a brand new casting that is very similar to generation 1 small-block Chevy.

As Maskin says, “Dart’s LS Next block is the first significant change in the architecture of the LS engine platform. By eliminating the Y-block design and utilizing conventional-style main caps and oil pans, Dart has addressed the problems resulting from the LS engine’s separated crankcase bays. Windage is greatly reduced, resulting in increased power along with a much stronger main web area.” He also said they fixed the oiling and main-webbing problems with the stock block, and extended the cylinder barrels by .375-inches at the bottom, providing better piston support (from the factory, the piston skirts extend out of the cylinder sleeves at the bottom of their travel).

Dart has a billet block for the LS (as we addressed in the last story) but the LS Next is their new affordable block for the masses. According to company owner/founder Richard Maskin, the LS Next is far stronger and has much better oiling than the factory piece. The current block is cast-iron but an aluminum version should be out in early 2014.

Additional features are 4-bolt main caps with 7/16-inch bolts, full main webbing for the utmost in bottom-end strength, 9.240-inch deck height (an option of 9.450-inches is available, which allows for a possible effective barrel length of a 9.825 deck height), extra-thick siamesed cylinder bores (which allow for large displacement capacity, and a max bore size of at least 4.200-inches), a 5/8-inch thick full deck design with a 9.240 deck height, four 7/16-inch head bolts per cylinder (with blind holes that don’t go into the water jacket) and a 3/8-inch and metric stud for the inner valley bolt, increased capacity in the #1 cylinder water jacket, provision for oil restrictors in the lifter valley, revised low-restriction priority main oiling system, Pro-Stock/Pro-Mod big-block-style stepped main oil galley, and dual starter mounts. An external oil filter must be used with stock or aftermarket oil pumps, and LSX-style lifter bosses and dog bone provision are provided.

ERL Performance

ERL’s dry sleeve block ($2,250 with the customer’s block or core) uses ductile iron sleeves in place of the stock cast iron sleeves from GM that are also longer for more piston support with stroker cranks and short rods.

Though this story is about aftermarket blocks, we had to include ERL’s entry into the LS market even though they start with a production block. With nearly 45 years in business and a ton of experience in all sorts of performance (and not just automotive either), ERL has figured out how to machine and modify a stock block to handle as much power as you can throw at it. They state that there are “quite a few” racers making well in excess of 2,000 horsepower with their blocks.

ERL uses GM’s LS castings and does the modifications to them with three different sleeving options depending on your application. Street use, road race, autocross, drag race, and even drifting, they can cover your needs. The “entry level” block, if you can call it that, uses dry, ductile iron sleeves with .107-inch sleeve thrust wall thickness (on a 4.125 bore, 4.185 if desired) and at 5.800 inches deep, the sleeves offer more piston support with stroker cranks.

The ERL Superdeck I blocks are the next step up the scale of seriousness, with 4- and 6-bolt versions available. What makes the Superdeck blocks incredibly strong is ERL’s special truss that connects each pair of head bolts through an aluminum structure, which allows the load to be shared across the deck surface minimizing deck deflection.

The Superdeck I system also allows for larger bores than dry sleeves. The block is available as a 443 cubic inch engine with a 4.200 bore and 4.000 stroke, with a 25% greater sleeve wall thickness at 4.200 bore than the others have with a smaller 4.125 bore.

As ERL states, “We have incorporated the superior stability of the deck with optional 1/2 inch head studs to provide uniform clamping over the entire gasket surface – a clamping force of nearly 80,000 pounds is provided by the 1/2 inch studs to reduce the potential of lifting the head. Traditional aftermarket race blocks increase deck thickness and reduce water access to the deck to aid in head gasket retention. The Superdeck I does not restrict water access to the deck surface. In fact, it extends the water cavity floor and emphasizes upper cylinder cooling through the trusses which are short-poured. This lowers the potential for detonation caused by hot spot in the combustion chamber. An additional advantage of the truss system is that it ties the main saddles in the block to the deck. This greatly increases the strength of the main saddles by changing the load path.”

As ERL’s Jeff Liebert explained, “Once we get the block, we machine out the factory sleeves and a portion of the aluminum ‘can’ that the sleeve sits in, machine the area around the head bolts, and radius a portion of the water jacket area.” Then, the truss blank is installed, pressed down into place, and welded up.

As we said, ERL offers two Superdeck I LS blocks. The Superdeck I four-bolt block uses the truss as well as ductile iron sleeves, which are much stronger than standard cast-iron sleeves, and a 4.200 bore capacity. The Superdeck I comes finish-machined and ready for assembly with ARP main studs and ERL’s doweled billet main caps.

Finally, there’s the Superdeck I 6-bolt block, which ERL says, “…takes our Superdeck I 4-bolt system to the next level for extreme applications. The addition of two head bolt bosses per cylinder creates a block that is specifically designed to handle extremely high boost or nitrous. Our Superdeck I 6-bolt blocks have run successfully with over 30 PSI of boost and over 1,500 horsepower.”

The prices for ERL’s blocks range from $2,250 for the Dry Sleeve unit to $3,500, based on the customer supplying the core block for ERL to sleeve or exchange.

ERL Performance built the LS engine in Mark Koehler’s (Ohio Boys) Trans Am, seen here at the 2013 Holley LS Fest. Koehler and another ERL-built car finished #1 and #2 at this year’s LS Fest in the Drag Radial class.

Chevrolet Performance

When you want to know all about the LS engine, the original group that developed it is your best source, and that’s not just for the production piece either. GM Performance Parts, now renamed Chevrolet Performance, took their world-beating LS1, re-engineered the weak parts of the block for racing, and debuted the first LSX Bowtie iron block in 2007. So even though it’s from the original manufacturer, it’s still considered an “aftermarket” block since it was never intended for a production line car.

The LSX block was the first LS block to offer six bolts per cylinder for head retention—note the extra bolt bosses cast into the top and bottom sides of the deck surface. If you’re running high boost or a load of spray, the extra bolts help keep the head gasket from blowing out.

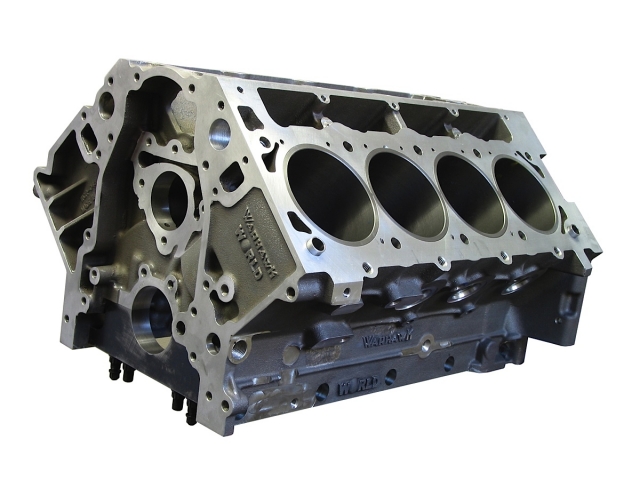

There are three non-production LS blocks from Chevy Performance: the C5R race block and both short- (9.260 inch) and tall-deck (9.720 inch) versions of the LSX. The C5R block has seen its share of extreme racing success at the 24 Hours of LeMans and Daytona, but at over $8,000 and manufactured in very limited supply, it’s out of range of what we’re talking about here. Besides, the LSX block is just as strong, if not stronger, and is less than a third of the cost of the C5R.

The LSX block uses six bolts to secure the crankshaft, four vertical and two horizontal (per main cap) for a solid bottom-end package. Improved over the stock block are vents between the main saddles to help reduce power-robbing windage.

The LSX Bowtie is a cast-iron block that has all of the improvements over the production block that you need to make big horsepower – Chevy Performance says it can handle over 2,500 horsepower, which has been done repeatedly so you know their marketing hype is true. Those upgrades include six head bolts per cylinder (if you want to use the various 6-bolt heads available for the LS), 6-bolt, dowel-located billet main caps, more beef around the main cam bearing holes, vents in the main webs to reduce windage, priority main oiling, wet or dry sump capability, and even holes to mount the engine to a front motor plate.

With seven years of development under their belts, over that time they’ve made some improvements to the LSX block compared to when it was first introduced. As pointed out by engineer Rocko Parker, “We stiffened the block in two ways. We changed the cast iron material from a 250 mPa tensile strength to a 400 mPa tensile strength. We also added radial supports within the casting at the top of each bore [to] allow the block to accept higher cylinder pressure.”

“One other improvement was in the camshaft bearing and oil feed to the bearing,” Parker continues. “The block was originally designed using 16mm wide camshaft bearings and the oil feed was a straight cut from the main bearing saddle to the camshaft bearing. The new feed hole is still straight from the main saddle to the cam bearing, but there is an added annulus cut behind the bearing. This allows the camshaft feed hole to be placed anywhere from a three o’clock position to a six o’clock position, with three o’clock position allowing the best oil wedge and load capability. Additionally, we changed the cam bearings from 16mm wide to 20mm wide, which reduces bearing load due to the larger surface area.”

Compared to the aluminum blocks shown here, the beefy iron LSX block is heavy, but like we said it’s been proven in competition time and time again, and at under $2,500 and with availability at any Chevrolet Performance dealer it’s a hard one to beat.

LSX Bowtie Blocks Available:

- PN 19260093 – 9.260 deck, 3.880 bore (semi-finished block)

- PN 19244059 – 9.720 deck, 3.880 bore (semi-finished block)

- PN 19260095 – 9.240 deck, 4.065 bore (fully machined)

- PN 19260099 – 9.240 deck, 4.185 bore (fully machined)

Racing Head Service has been in business since 1967, but they’re all modern with one of the most popular LS blocks on the market.

RHS LS Race Block

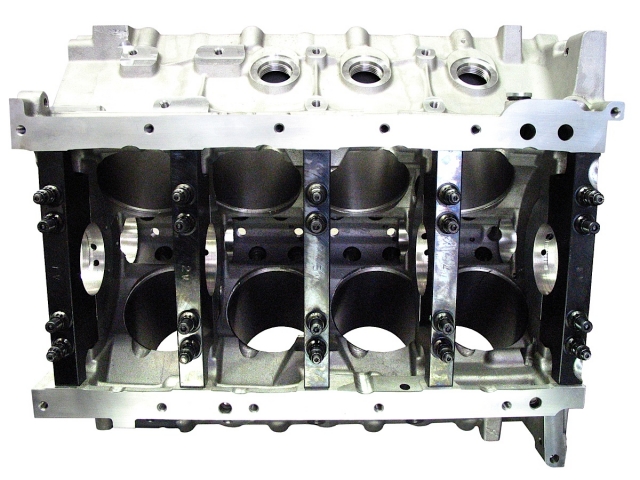

Responding to the exploding LS market, Racing Head Service, part of the COMP Performance Group in Memphis, Tennessee, developed a brand new block. Their goal was to design a block that could go up to 500 cubes and handle over 2,000 horsepower, but they didn’t want to knock the average guy with a street car out of the running in the process. The result is the RHS LS Race Block that comes to you fully machined and ready to build, or in unfinished form if you want to do the machine work yourself. Kevin Feeney, Product Manager at RHS, says, “The LS market is growing, and the LS components have been some of our biggest sellers – cams, lifters, heads. We chose to build a block because there simply was not a good alternative. Some guys are building 2000 horsepower-plus engines, so we especially focused on adding strength.”

RHS not only has LS cylinder heads and the aluminum block, but accessories for the block as well. Shown here are the piston oiling kit (part #549120, $598.04) designed to keep the pistons lubricated for optimal performance even during the most demanding racing conditions. The oilers are built from a 100% billet alloy steel body, feature furnace-brazed construction, and are manufactured at an OEM-quality level to fit perfectly to the LS Race Block.

The LS Race Block is made of very strong A357-T6 aluminum alloy and is available in two deck heights, the standard 9.240 inch and taller 9.750 inch tall deck. It was designed to accept up to a huge 4.600 inch stroke crankshaft by raising the cam centerline by .388-inch and moving the priority main oil galley outboard of the cam bore. It also has siamesed bores (4.125 or 4.166 available), a thick deck surface (.500 inch on the standard-deck and .750 for the tall-deck), six head bolts, front and read -12 AN feeds for dry sump plumbing, and more meat in the lifter bores to accept a 1.060 inch bushing for keyed lifters). The RHS block also accommodates up to a 60mm camshaft, Gen I, II, III, and IV engine mounts, and a stock Gen IV knock sensor.

“We decided to raise the deck from the stock 9.240 to 9.750″ specifically to accommodate fitment in the new Corvette and Camaro without having to modify the cowl area of the vehicle,” said Feeney. “We also raised the camshaft .388″, which is the next limitation for a long stroke.” This, he points out, requires two more links in the cam chain. Not a big deal, but it’s good to know! “We also moved the main oil galley outboard to clear up to a 4.600″ stroke with a 2.100″ rod pin.”

RHS LS Aluminum Race Blocks are available in several different bores, deck heights, and level of finish machining required. RHS also has a bunch of accessories and tools for their LS block, including torque plates, main caps, piston oilers, seals, studs and hardware, MLS head gaskets, front covers, and gear drives. “However,” says Feeney, “we also wanted to ensure that it had all of the accessory bosses and motor mounts for a Gen III or Gen IV application and could bolt into a late model car.”

Finish-Honed Blocks

- PN54906 – 9.240 deck, 3.900 bore, 5.87 sleeve length

- PN54903 – 9.240 deck, 4.125 bore, 5.87 sleeve length

- PN54902 – 9.240 deck, 4.165 bore, 5.87 sleeve length

- PN54901 – 9.760 deck, 4.125 bore, 6.38 sleeve length

- PN54900 – 9.760 deck, 4.165 bore, 6.38 sleeve length

Bored, Ready to Hone

- PN54906U – 9.240 deck, 3.895 bore, 5.87 sleeve length

- PN54903U – 9.240 deck, 4.120 bore, 5.87 sleeve length

- PN54902U – 9.240 deck, 4.160 bore, 5.87 sleeve length

- PN54901U – 9.760 deck, 4.120 bore, 6.38 sleeve length

- PN54900U – 9.760 deck, 4.160 bore, 6.38 sleeve length

Unfinished

- PN54905 – 9.240 deck, 4.100 bore, 5.87 sleeve length

- PN54904 – 9.760 deck, 4.100 bore, 6.38 sleeve length

RHS has a bunch more accessories and tools, like the front cover plate (left) and even torque plates (right) if you want to do your own boring and honing.

BMP LS Aluminum

Since our last LS block story, one difference in the market is the divergence of World Products’ lines of aluminum and cast-iron products (blocks, cylinder heads, and intakes) into two separate companies. Bill Mitchell, Sr., the owner and patriarch of World Products, sold the aluminum line to his son, Bill Mitchell, Jr. at Bill Mitchell Products, while the cast-iron line and World Products brand is now being done by PBM Performance Products. We’ll address the BMP aluminum LS blocks first.

BMP claims its cast-aluminum (357-T6) LS block is, “the absolute strongest available with important improvements that even the factory race blocks don’t have.” The oiling system is priority-main, meaning that oil gets fed to the crank first and the top end last to prevent starving the main bearings of oil. Redesigned water jackets beef up the cylinder walls too. Ignore the World logo cast into this block—BMP doesn’t have any new photography of its redesigned block as of press time.

Available Deck and Bore Combinations

- 9.240” Deck, 3.990” Bore (Part #086505)

- 9.240” Deck, 4.115” Bore (Part #086515)

- 9.800” Deck, 4.115” Bore (Part #086525)

Growing up with his father’s tutelage, Bill Jr. knew the World Products Warhawk LS blocks inside and out, so when the chance came to purchase World’s aluminum line of parts it was the right thing for him to do. He knew he wanted to make some changes to the parts and jumped right to it, sending the foundry tooling back to the pattern shop for improvements and changing foundries completely. Bill said, “Trying to stay ahead of the curve in today’s high performance markets needs with the ever-increasing horsepower levels, the blocks needed to be even stronger. The LS was no exception in my mind. Although the BMP LS aluminum block was already made from the alloy 357-T6 and has already been on the dyno producing horsepower numbers in the neighborhood of 2,500 (which are in the range only a cast-iron or a billet version would normally be capable of), I wanted it stronger!”

The bottom end of BMP’s block has main caps made of 1045 alloy steel billet, which are claimed to be stronger than the 1020 steel used by some competitors. The caps are also located by ring dowels and secured with 200,000 PSI tensile strength, 7/16-inch ARP studs and 8mm cross-bolts.

The main changes to the previous World aluminum block are that there is now added material to the main webs to give it more strength, windows up in the valley to access the lifters without taking the heads off, and added shoulder bosses off the edge of the deck to allow a 6-bolt head. This is in addition to the previous advances over a production LS block, such as redesigned water jackets that put more material behind the sleeves that strengthen the cylinders. The ductile iron sleeves are pressed in and therefore replaceable, and since aluminum can be welded (if a rod goes flying or something) the block’s life span is nearly infinite.

Billy sums it up by claiming, “Our BMP LS aluminum block has proven itself to be the strongest of the cast-aluminum blocks available, mainly due to the water jacket area which gives the cylinder walls the strength they need in order not to balloon under extreme cylinder pressures. In addition to the casting changes, I have also changed machining centers, building all new machine fixtures for better accuracy and keeping up with today’s more advance machining methods.” The first of these new and improved LS blocks are scheduled to be available as you read this.

Stock LS motors only use four head bolts per cylinder, which can prove leaky when cylinder pressure gets extreme, so like GM’s LSX block, BMP added two bolt bosses to each cylinder. They are placed to work with BMP’s 12-degree LS7 heads, but are in slightly different spots as the GM block. However, standard 4-bolt GM heads will still fit.

PBM

Older readers will remember Erson Cams as one of the leaders in the ’60s and ’70s for racing camshafts, and the ease of availability afforded them when the company was purchased by Super Shops in the ’80s. Today, Erson is owned by PBM Performance Products, and we feel they are set for a big comeback in 2014, helped no doubt by PBM’s purchase of the World Products cast iron line of hard parts and brand name.

Older readers will remember Erson Cams as one of the leaders in the ’60s and ’70s for racing camshafts, and the ease of availability afforded them when the company was purchased by Super Shops in the ’80s. Today, Erson is owned by PBM Performance Products, and we feel they are set for a big comeback in 2014, helped no doubt by PBM’s purchase of the World Products cast iron line of hard parts and brand name.

Jack McInnis came to the company to help promote the World and Erson product lines. He told us that they are currently revising and ramping up production of the existing World line of cast-iron blocks and heads and don’t want to release any news until they have product ready to go. The target date is early 2014, so stay tuned. As a refresher, the World products line of iron blocks does not include an LS block per se, but rather a hybrid that allows you to have a standard Gen-1 small-block Chevy bottom-end with the LS heads and intake. This makes it easy to keep your factory mounts, accessories, and all that stuff yet take advantage of the high-flowing power of the new heads. As soon as PBM is ready to go with production, we’ll bring you all the juicy details.