A couple of years back, we brought you EFI University’s project Spinal Tap. That was an adventure in getting an LS-platform engine to spin safely and reliably to 11,000 rpm with a production-style cylinder head. While that was an unmitigated success, as the engine ended up spending a considerable amount of time at or above 11,000 rpm, the critics were quite vocal about the combination’s power production at that elevated RPM.

“We were starting the dyno pulls past the horsepower peak,” explains Ben Strader. “The goal was never to make big power at 11,000, but rather, to prove that it could be done safely and reliably — and we accomplished that without a doubt.” Many people, ourselves included, asked Strader what the plans for the next iteration of the engine were. Well, after some serious discussions and collaboration, Strader is finally ready to discuss what he’s calling “Spinal Tap 2.0: The Reckoning”.

A Journey Of A Thousand Miles…

As with most projects like this, Spinal Tap 2.0 started with a conversation. While no bar napkins were involved this time, it was a simple phone call that somehow meandered down the right path. “One evening I was chatting with John Konstandinou from Competition Induction Designs, about a variety of things,” Strader says. “Somehow the conversation turned to Spinal Tap, and the idea of 1,100 horsepower came up.” Now 1,100 horsepower N/A is no small feat, but it’s also a number that isn’t foreign to Strader… until you add in the caveat of “from an LS.”

“I’ve been close with N/A LS platforms before — I think about 1,080 — but I’ve never had the induction system to get to that full 1,100 horsepower number,” Strader explains. However, during the course of the conversation, Konstandinou mentioned that Tony Bischoff had used a set of CID Inline 12-Degree LS heads and matching CID BA LS cast single four manifold to break that rarified mark” almost as if to goad Strader into the Spinal Tap 2.0 project. Then, he suggested something that really caught Strader’s attention — he offered to connect the two to try and get the project rolling.

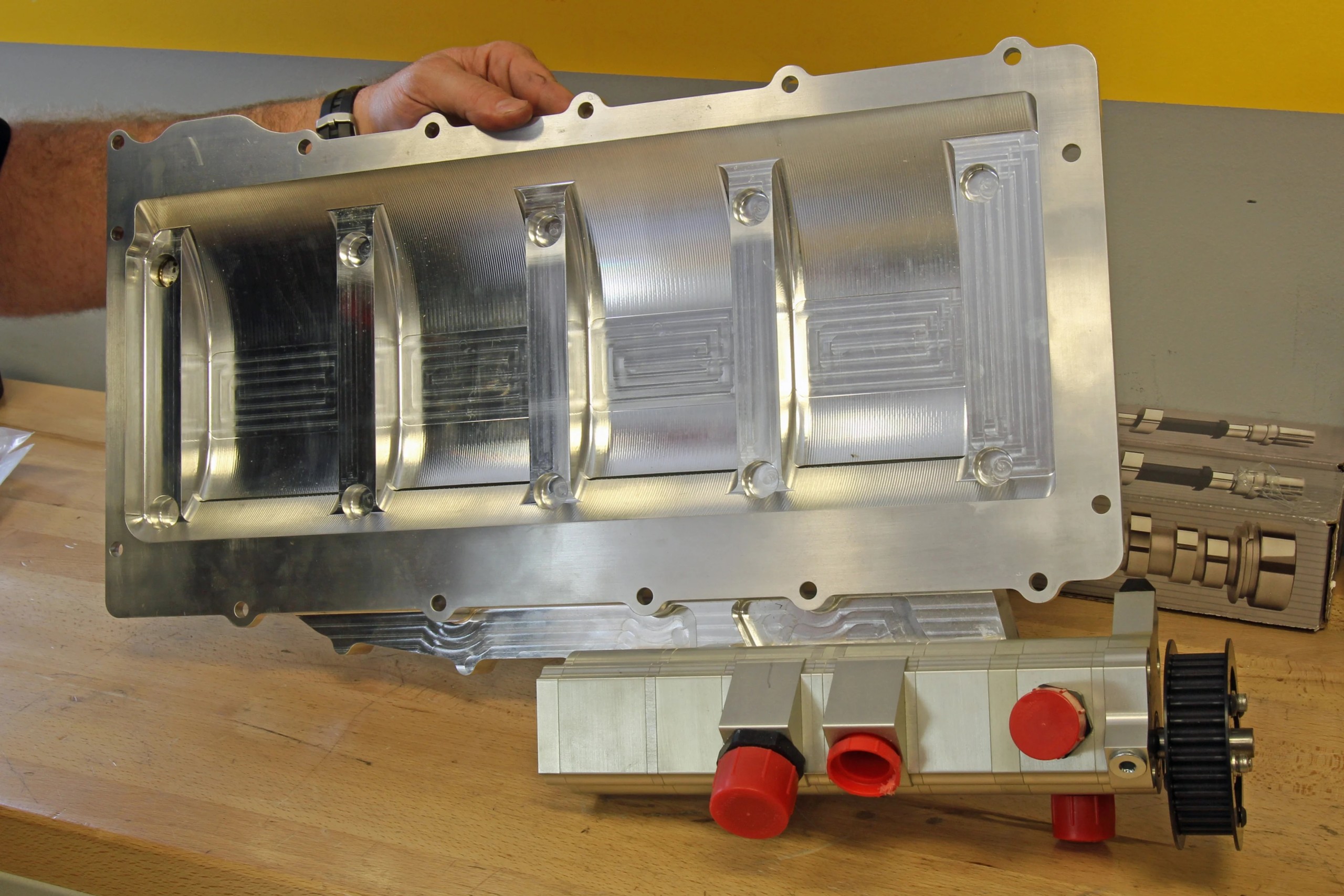

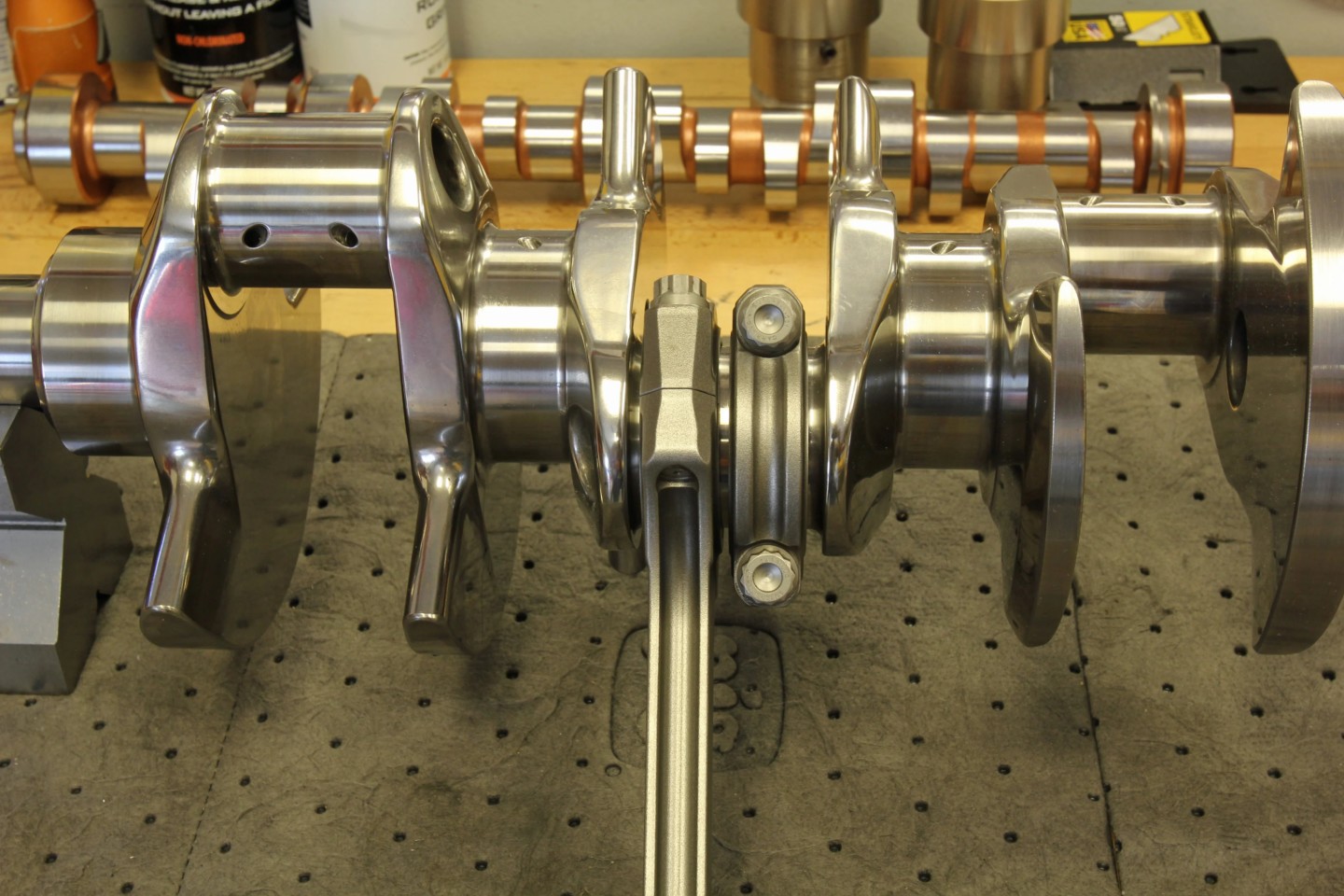

Spinal Tap 2.0 will reuse several of the parts which proved their prowess in the original Spinal Tap project. That includes the Dart LS Next iron block, the Winberg billet 4330V crankshaft, and the Dailey Engineering dry sump system.

“I loved the idea, but I didn’t really know Tony on a personal level, and we sort of compete over in N/A10.5,” says Strader. “John called Tony, and put us in touch. As we chatted, Tony said, ‘if you want to make 1,100 horsepower out of a 360 cubic-inch engine, that’s exceeding 3 horsepower per cube, and I’m the guy who has always said that can’t be done. But, When I heard you were working on this, my thought was, maybe I’m missing an opportunity to learn something. So heck yeah, I’m in.’ And that’s how it all got started.”

A Brief Layout of the Project

For those who somehow missed the original Project Spinal Tap article, at its core was a Dart LS Next iron block, punched out to 4.185 inches. Coupled with a billet Winberg 3.250-inch-stroke crankshaft, the short-block measured in at 358 cubic inches. For this project, those two components will be reused.

“We’re using the exact same crankshaft, so all of the bearing sizes are the same,” Strader reveals. “We’ll be running just a few thousandths larger bore, as we honed it out and cleaned up the walls. So roughly a 4.200-inch bore with the 3.250-inch stroke for 360 cubic inches. It’ll have the same Jesel belt drive, and the same Dailey Engineering dry-sump system. Really, from the deck up is what’s changing.” However, with a new top end will be the need for new pistons.

One of the coolest things we saw in the original Spinal Tap was the piston-guided rods. That side clearance is excessive by design, and doesn’t affect oil pressure, as was once thought.

We’re using one of MAHLE Motorsport’s NASCAR Cup forgings as the basis for the piston design,” Strader reveals. “Having the engineering backing of MAHLE really gives me confidence in the project. Total Seal is on board to help design some rings for the project, A new company called Point One Manufacturing, who makes incredible fasteners, is making some custom rod bolts for the custom connecting rods that Nick Norris at Callies is designing for us, made out of something like 300M but on steroids.”

While the specs of the short-block might be quite similar, Strader is making sure that the foundation of the engine is as unshakable as possible. “I’m not taking any chances, says Strader. “I’ll be using extremely high-end materials on this project, because I don’t want to have all these really amazing people working their asses off, and then I do something wrong that compromises the engine. I’ve reached out to every connection I have to get the absolute best components, price be damned. From the Winberg billet crank to these fancy one-off connecting rods and pistons. Exotic materials? Cool, I’ll pay for it.”

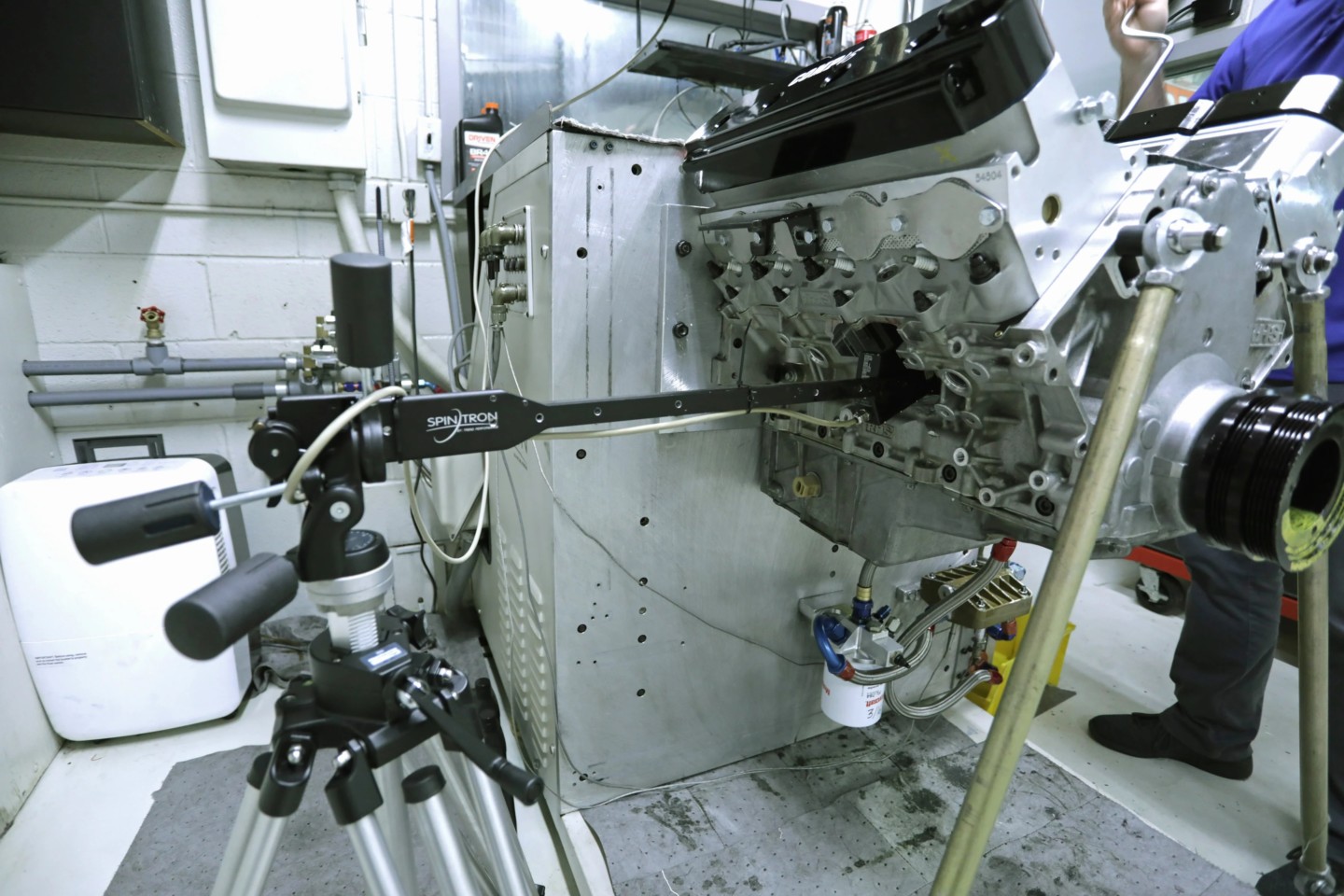

Like the original, Spinal Tap 2.0 will be extensively Spintron tested to ensure valvetrain stability at 11,000 rpm.

An Incredible Top End

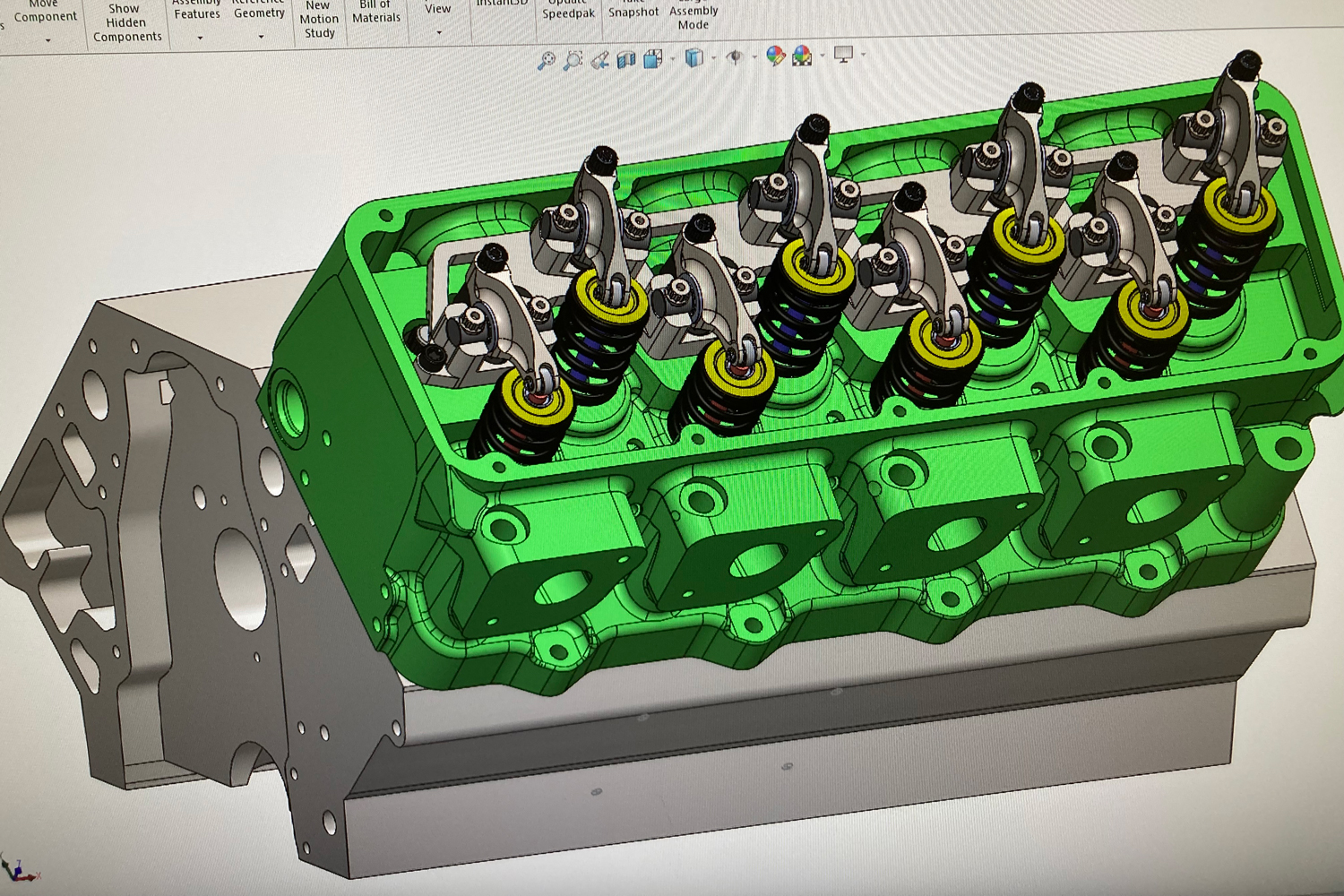

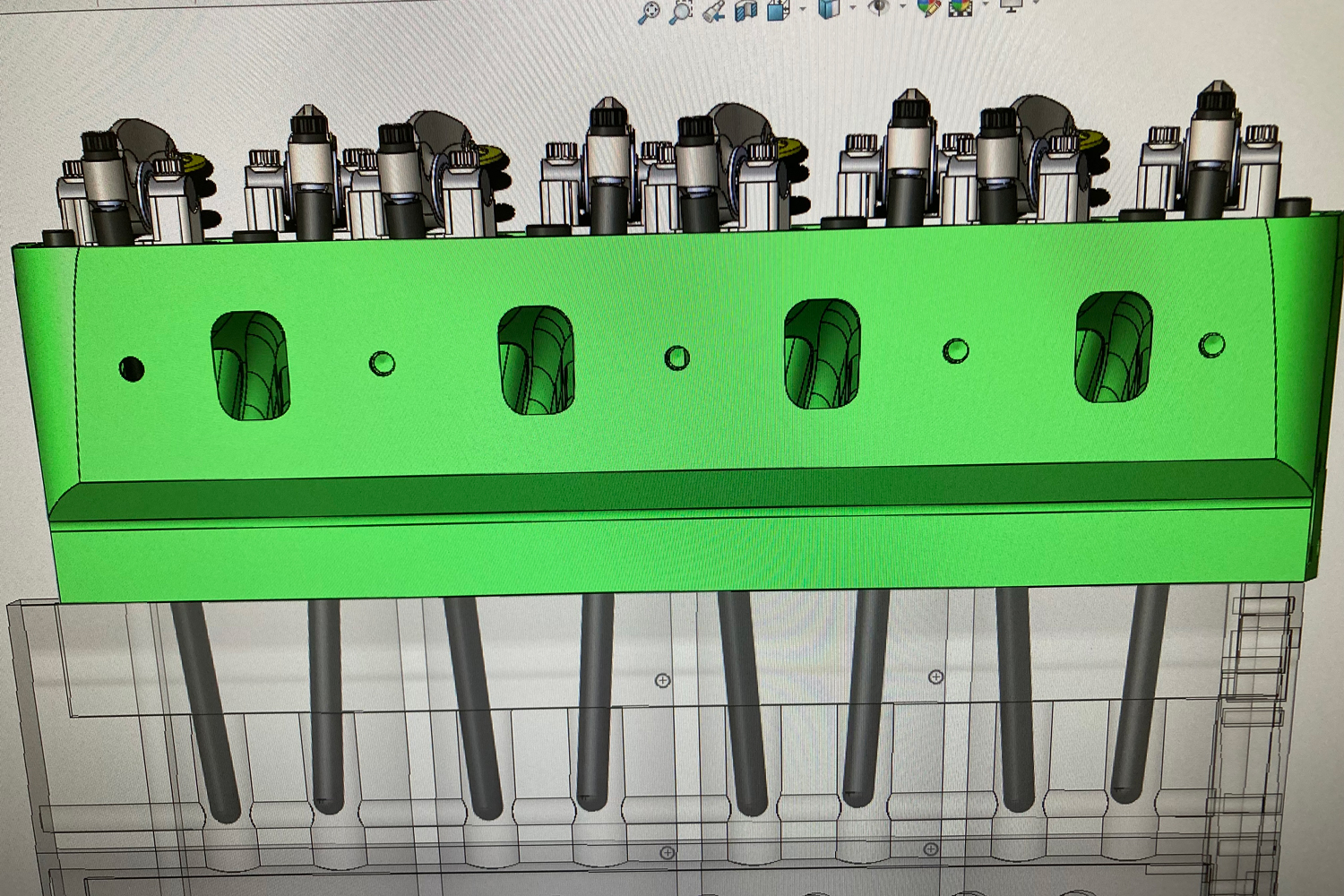

Moving to the upper half of the project, there is a ton of work being undertaken to build a top end that can move enough air for 1,100 horsepower. Based around a set of the CID Canted Valve LS-CR cylinder heads, the top-end development is being spearheaded by the crew at BES Racing Engines. It seems only fitting being that his cylinder head platform was originally developed by CID in conjunction with BES Racing Engines. “They’ve already completed the chamber design, made the mold, and sent it off to MAHLE Motorsport,” says Strader.

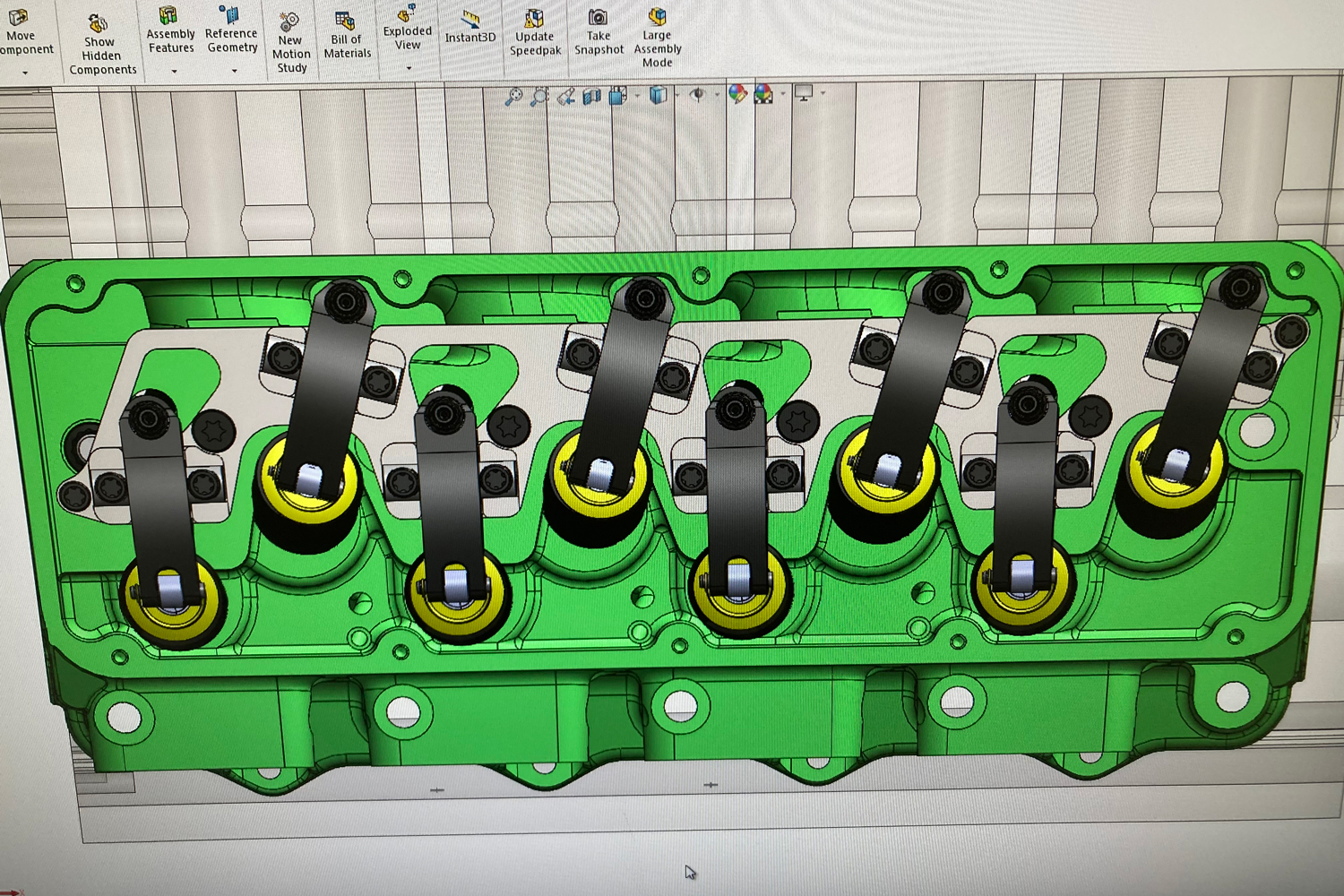

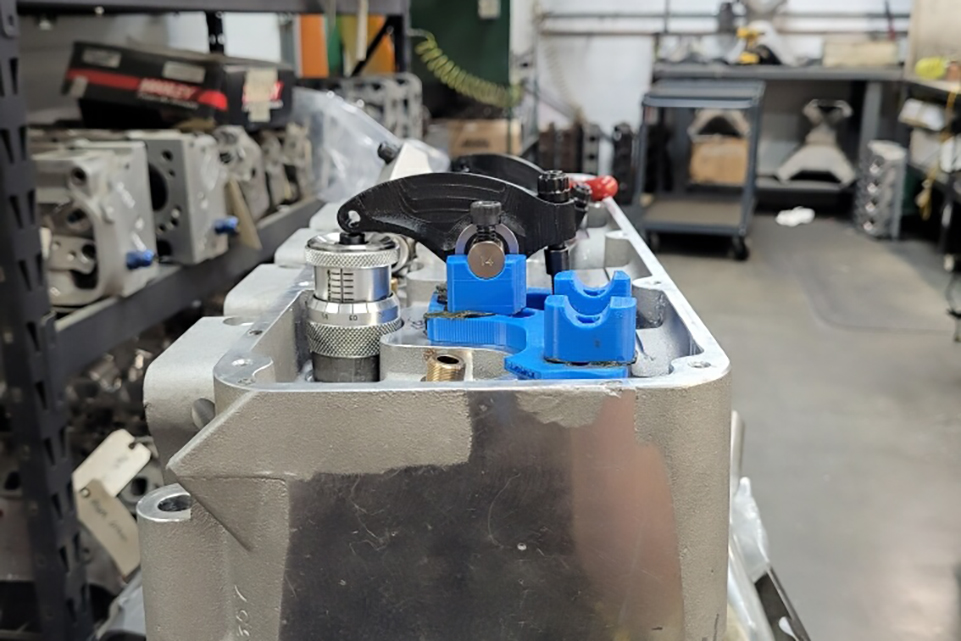

The design of the valvetrain is different than before, with the reverse order of the valves. “Jesel has 3D-printed some rocker arms and shafts for us,” Strader says.”We ended up cutting them up, epoxying them back together, and sending them back, and they are currently redesigning the rockers. The camshaft layout will be different as well. We had to reverse the lobe layout on the shaft, so Jesel is creating a new 63mm clamshell-bearing cam for us.”

Part of the R&D process is to rapid-prototype parts to check fitment and design. The parts can be easily modified and sent back to be redesigned and reprinted.

On the intake side, Spinal Tap 2.0 will benefit from something the original didn’t have available at the time. “We’ll be running a couple of Holley 4500 EFI throttle bodies,” shares Strader, which only makes sense since he was an avid proponent of the production all throughout its R&D.

“So much of this development is geometry based. Can we get the motion of the valve to behave so we can achieve the RPM we need? If we are able to, then, can Tony and the guys provide the airflow we need? If so, will my short-block be able to live? There are a lot of variables, and we’re all working as hard as we can. Keith Wilson of Wilson Manifolds is also interested in helping us with manifold design, which is awesome.”

Here you can see some of the CAD design work going into designing an 11,000 rpm-capable valvetrain. Things don't just happen by dumb luck, with every detail meticulously plotted out.

With a veritable “who’s who” of high-performance naturally aspirated engine development on board, you might think a project like this is a slam dunk. That couldn’t be further from the truth, says Strader. “I don’t think this undertaking will be easy. I’ll even acknowledge that we might not get it on the first try. But, we have the right team of people who won’t give up just because it’s not easy.”

Spinal Tap’s original goal was to have an LS engine capable of running at 11,000 rpm safely and reliably, regardless of the power it made. Now, there is a finite power goal. “Really, all I have to make from this project is 1,080 horsepower to be able to break the 3 hp/ci mark that Tony thinks isn’t possible,” laughs Strader, who loves to poke at his friends. “But really, none of us will be happy until we break the 1,100 horsepower mark. There’s certainly a lot of responsibility and pressure on our shoulders here, but I don’t think any of us would have it any other way. We all thrive under pressure.”

As the project progresses, which it is doing at quite a rapid pace so far, we’ll be sure to bring you more details of the science behind the project that is turning LS engine performance up to 11, again. Because afterall, Strader is known for showing everyone the things that most engine builders hide and the lessons learned here are sure to make their way into the EFI U Competition Engine Development course curriculum.

Here is a good chunk of the Spinal Tap 2.0 dream team. Those look like the smiles of a group of people who know their goals are about to get crushed.