When we decided to piece together our stroker mill we could have chosen the venerable 454ci big-block using a traditional 4-bolt main Gen IV foundation. This setup would have provided us with lots of low-end grunt at a fraction of the cost. However, we were after something more unique to set this build apart from the rest.

We chose the 502ci foundation because of its proven potential on the dyno, LS-style reliability and although not the most affordable, definitely worth the extra cost and street cred. “The 502 CID LSX engine build exemplifies the design criteria that we set out at RHS for the LS block. It provides a long-arm friendly, large cubic inch combination that incorporates the features of an all-out race block but is suitable for street,” added Kevin Feeney, Product Manager for RHS.

While the majority of our cost went into the short-block alone, we were far from done. When we last left you, we had just finished putting together our big-inch, LME-built RHS 502 short block. We began with RHS‘s new LS tall-deck block, fortified the bottom end with a Lunati rotating assembly and locked it all together using ARP fasteners. We even added as set of high-compression Wiseco slugs to the mix for potent and reliable means for battling the constant high rpm and abuse.

Unfortunately, we couldn’t fit the entire build into one complete story. If you missed the first part of the build, be sure to check it our right HERE. For ease of viewing, we split the build into two parts. This month, we are finishing up by completing the top-end assembly.

While this specific engine embodies a ton of late-model race components, it’s not a race engine. Instead, we plan to put this gem on the street. That said, drivability needed to be key with this particular combination.

Coming Together

To achieve this, we finished our build with a set of heavy-breathing RHS aluminum LS7 cylinder heads. Our set was CNC-machined and was equipped for a hydraulic roller camshaft from COMP and came complete with oversized, Ferrera valves (2.20/1.61-inch intake/exhaust valves) and 69cc chambers.

We then matched it with a FAST 102mm LSXR manifold to maximize low- and mid-range torque. Of course, The FAST manifold has also proven itself to carry the horsepower through the upper powerband, making it ideal for our needs.

To see how we did, we headed over to LME and continued our work with Brian Neelan who hooked up our mill to their Superflow 902 engine dyno. We knew it wasn’t going to be record breaker, but we were still impressed by the final numbers. You’ll have to read on to get the complete breakdown of what it made and how we built it.

COMP Lifters

When it came to our long-stroker generating an ample amount of rpm without much work, we went with a hearty set of COMP’s, short travel race hydraulic lifters. COMP Cams has taken a strong foothold within the LS market and produces an abundant supply of LS-related parts and components. We chose these hydraulic lifters because they have been specifically engineered from a patent-pending design which allows them to perform at higher engine speeds.

When it came to our long-stroker generating an ample amount of rpm without much work, we went with a hearty set of COMP’s, short travel race hydraulic lifters. COMP Cams has taken a strong foothold within the LS market and produces an abundant supply of LS-related parts and components. We chose these hydraulic lifters because they have been specifically engineered from a patent-pending design which allows them to perform at higher engine speeds.

How is this possible? COMP has designed each lifter to limit the movement of the internal piston from each lifter. Limitations within the internal piston of the lifter cuts down on loss of power and limits valvetrain failure at sustained, high rpm. For a durable and long-lasting life, each lifter is REM-finished and then black oxide coated. We dropped each set into the lifter bores with the T-bars and began assembly of our LS7 cylinder heads.

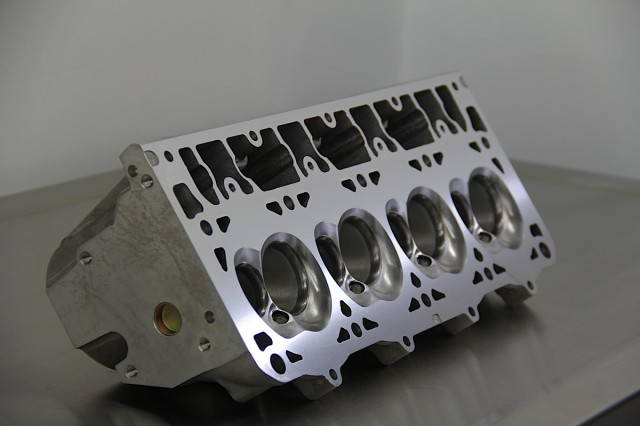

RHS Pro Elite LS7 CNC-Ported Cylinder Heads

With so many cylinder heads claiming superiority in the LS-market, it was hard to choose a set of heavy breathing lungs with the capability and R&D backing what we were looking for. We not only needed a set of cylinder heads to flow well but wanted something that could go on just like a factory cyinder head. We decided on a set of RHS’s new Pro Elite LS7 CNC-ported cylinder heads.

These are truly the aftermarket’s first high performance, LS-style head. These gems also feature a 12-degree valve angle and unique, 0.220-inch raised intake runner design, which provides a better line of sight into the cylinders and allows for an improved short turn. The best part, these cylinder heads also facilitate both the stock and aftermarket LS7 intake manifolds and nearly any aftermarket valvetrain setup.

When speaking with Kevin Feeney over at RHS about our options he gave us the skinny, “The use of our LS7 head is just another testament to how hard our engineers work. They provide the engine builder with the power they expect while leaving them with the convenience of using factory rocker arms and intake manifolds.”

Bryan Neelan, engine builder at Late Model Engines shared this sentiment and added, “The RHS heads showed strong flow numbers with a nice port shape. I like the volume of the intake runner for the bigger cubic inches the RHS tall deck block accommodates. The RHS cylinder head is a nice clean casting that machines well and was very nice to work with.”

Each cylinder head utilizes the popular LS 6-bolt head design which allows these cylinder heads to be compatible with both the RHS LS race block like we’re using or the GM LSX blocks. The 6-bolt design provides strength and an increased ability to clamp at high capacities, which greatly improves head gasket retention. Most notably, the raised runner and rolled valve angle increases overall flow capability while an improved water jacket design improves thermal conductivity.

While we’re getting eager to get this set of cylinder heads installed, it’s also important to note that these RHS Pro Elite LS7 CNC-ported lungs can be used in small or large cubic-inch hardcore street applications.

For the correct compression, LME knocked off 0.018-inch of material for 63cc chambers.

LS7 Quick Notes

- 100% CNC-machined runners optimize volume, atomization, and velocity

- Increased clamping capacity greatly improves head gasket retention in high horsepower and boosted applications

- 0.750-inch thick deck surface increases integrity; reinforced solid rocker rail increases rigidity and stability

- 355-T6 aluminum withstands race conditions

- 0.400-inch raised rail works with aftermarket rockers

- 0.100-inch raised exhaust port allows use of stock and aftermarket manifolds

- Can be used in both small and large cubic-inch hardcore street/strip applications

Intake & Exhaust

Although we opted out of receiving a completed set of cylinder heads, completed versions are still available and highly recommended from RHS. To control our intake and exhaust flow to our exact specifications, we relied on a custom set of Ferrea titanium intake and stainless steel exhaust valves.

The Ferrea titanium intake valves measured in at 2.200- x 0.313-inch stem with a 5.565 x 0.290-inch tip (hard tip with no lash cap).

The quality of our Ferrea custom titanium and stainless steel intake/exhaust valves compliment the rest of this high-end build.

The titanium benefits our valvetrain from shedding unnecessary weight, essentially freeing up more power for a rev-happy engine. For the exhuast side of things, Ferrea built us a custom stainless steel set which measured in a 1.615- x 0.313-inch stem with a 5.595- x 0.290-inch tip rounding out a complete Ferrea utopia for our intake/exhaust setup.

Engine valves exert enormous influence on engine airflow, mixture quality and the ability to run higher engine speeds. -Zeke Urrutia

“Engine valves exert enormous influence on engine airflow, mixture quality and the ability to run higher engine speeds,” says Zeke Urrutia of Ferrea Racing Components. Less mass inertia allows a reduction in valve-spring rates and puts less strain on the entire valvetrain. Titanium valves must be used with bronze valve guides.

Ferrea valves have a proprietary Chrome Nitride coating (CrN) or a diamond-like coating (DLC) to provide rapid heat dissipation and wear reduction while reducing delaminating and flaking from valve flex. Titanium valves generally do not have hardened tips, so they must be used with steel lash caps to prevent damage.

To assemble the rest of our cylinder heads, we used a complete set of COMP components, which included dual springs, titanium retainers, locks, Viton seals with steel jackets and machine steel cups. Install height was 1.820-inch with 145 lb seat pressure with 485 lb at 0.660-inch lift. LME also utilized a 0.150-inch retainer for seal clearance.

Make sure to check out the build list below for all of the cylinder head part numbers. Once LME had each set of cylinder heads together, we could begin the process of installing each one over the ARP 2000 Pro Series head studs and Fel-Pro MLS-style 6-bolt, 0.040-inch head gaskets.

LME assembled our RHS Pro-Elite LS7 cylinder heads using a combination of Ferrea titanium intake with stainless exhuast valves. Additional COMP components were used to finalize the cylinder heads.

GM LS7 Intake & Exhaust Rocker Arms

Once the cylinder heads were locked into place, we could move on and begin installing the RHS rocker stands to each bank. With the RHS cylinder heads, the RHS rocker stands are a must. We installed those first and then moved onto dropping in our 8.400-inch COMP push rods.

From there, it was only a matter of installing each, GM LS7 rocker arm for the intake and exhaust valves. What makes using the GM LS7 rocker arm so unique, is the simple fact that these are off-the-shelf components. This not only cuts down on overall cost but it also makes them more available in the event of failure. What’s more, these rocker arms will install easily on our RHS cylinder heads without any modifications.

From there, it was only a matter of installing each, GM LS7 rocker arm for the intake and exhaust valves. What makes using the GM LS7 rocker arm so unique, is the simple fact that these are off-the-shelf components. This not only cuts down on overall cost but it also makes them more available in the event of failure. What’s more, these rocker arms will install easily on our RHS cylinder heads without any modifications.

We ordered up our sets separately since each set is specifically designed for the intake and exhaust valves. However, both come in the same, self-aligning, 1.8:1 ratio and narrow rocker arm body style.

Rocker Arm Trunion Modification

Since our application, again, isn’t the average build, the factory LS7 rockers won’t be able to sustain high-rpm abuse for the long haul. To combat this, we also modified each rocker arm with the COMP Cams GM LS series retrofit trunion kit. This modification was necessary to convert our stock LS series rocker arms into captured roller trunions for this specific application. It also keeps our valvetrain reliable throughout the entire rpm range. The kit includes all the necessary hardware including, the rocker arm trunions, rocker arm bearings, retaining rings and washers.

FAST Intake and RHS Intake Spacers

Continuing to fire away at the top-end of the engine, LME made quick work for the remainder of the installs before we hit the dyno cell. Next, making its way to the engine was the set of RHS intake spacers. RHS intake spacers will allow the use of standard style LS7-style intakes with tall-deck (9.750-inch) LS aluminum race blocks.

The spacers will work with FAST LSXR LS7 intakes, OEM GM LS7 intakes, or any other intake that is designed to work with LS7 heads. The spacers must also be used with LS7-style cylinder heads.

RHS Intake Spacers At A Glance

Fits LS7-style intakes

Fits LS7-style intakes- CNC-machined to strict tolerances to fit 9.750-inch deck height blocks

- CAD designed by engineers at RHS

- Lightweight scalloped design provides rigidity and function without adding significant weight

- Includes required hardware and spacer-to-head gasket (intake manifold gaskets are not included)

With the spacers installed, we could move on to moving some serious amounts of air. For this particular application, LME suggested we try out the FAST line of components. LME chose the FAST-developed, 3-piece, polymer intake manifold. This highly-advanced intake manifold means serious business and its constructed from a proprietary advanced polymer material that offers a host of benefits over aluminum aftermarket intakes, including lighter weight and improved strength and heat dissipating characteristics.

Up close and personal, the RHS intake spacers are truly a piece of art.

This intake also features a 102mm air inlet that is perfectly suited to the FAST Big Mouth 102mm throttle body, which we’ll be relying on. The intake is packed full of other features, too, including integrated nitrous bungs and perfect bolt-on fitment that allows for the use of factory accessories without modifications or clearance concerns.

FAST 102mm Intake Manifold At A Glance

FAST 102mm Intake Manifold At A Glance

- Fits LS7 raised Rectangle port cylinder head equipped applications (LS7)

- Drive-By-Cable throttle body options

- Big Mouth 102mm throttle body (PN# 54102)

- Big Mouth 92mm throttle body (PN#54092) for drive-by-cable applications

- Fuel Rail Options

The FAST LSXR intake manifolds’ 3-piece modular design allows for easy disassembly and porting. This new design gives you the ability to remove individual runners from the manifold for modification. The best part, this intake manifold is 50-state legal and C.A.R.B. approved (E.O.D.-279-8). We’re anxious to see what kind of power this manifold will produce.

FAST shared with us, “When used with a Big Mouth 102mm Throttle Body, the LSXR Intake Manifold produced gains of 16+ horsepower on a near stock LS7 engine and 26+ rear wheel horsepower on a 500ci RHS LS Aluminum Block based engine.”

The combination of a large FAST intake and throttle body should give us plenty of breathing room.

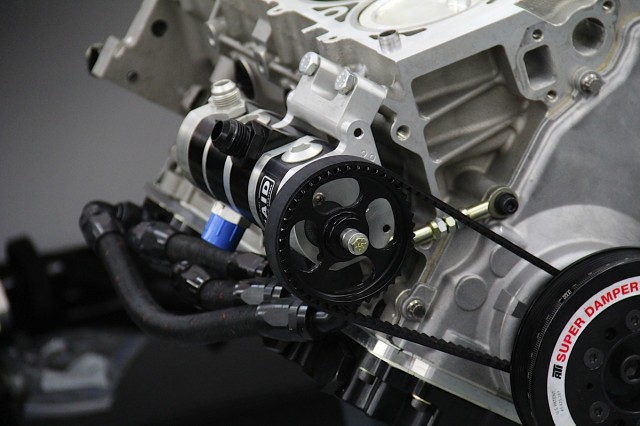

Aviaid Oiling Systems

Buttoning up the remainder of the build included sealing up the bottom-end with a high-quality and purpose-built oil pan. We were well aware of this particular engine’s extra swing from the stroker crank and rpm potential and weren’t going to cut any corners when it came to controlling oil flow and efficient dispersement.

In our case, we contacted John Schwarz, owner of Aviaid, for the full treatment. With oil control of great importance, John recommended their one-piece, Billet Aviaid dry sump oil pan. It’s good to note, since we’re running a 4.600-inch stroker crank, it was also necessary to run a 3/8-inch spacer between the block and oil pan to give us the clearance needed. While the spacer is necessary for our particular stroker application, this may not be the case for your RHS block.

In our case, we contacted John Schwarz, owner of Aviaid, for the full treatment. With oil control of great importance, John recommended their one-piece, Billet Aviaid dry sump oil pan. It’s good to note, since we’re running a 4.600-inch stroker crank, it was also necessary to run a 3/8-inch spacer between the block and oil pan to give us the clearance needed. While the spacer is necessary for our particular stroker application, this may not be the case for your RHS block.

To continue the Aviaid theme, we outfitted the rest of the build’s oiling system with a four stage externally mounted dry sump, which featured a 1.25-inch pressure side and larger, 1.50-inch scavenge. Additional parts included a remote oil filter and Aviaid dry sump oil tank. Of course, we made sure to install the remainder of the miscellaneous oiling system with Aviaid components.

ATI Super Damper

With build progress coming close to an end and closer to our big-inch LS hitting the dyno cell, we still had a couple more things to take care of. Case in point, controlling engine harmonics. As the engine is running, the crankshaft causes vibrations through torsional flex. It’s these vibrations which can shake an engine apart, literally.

Engine dampers also create additional benefits by increasing engine response. As the vibrations of the engine are absorbed, engine response becomes smoother and vital engine components like main and rod bearings endure less punishment; essentially creating a longer life. Controlling these vibrations, especially on a build of this magnitude was of great importance. However, with limited room to run the four-stage Aviaid dry sump system, LME was left with devising a plan to include a method for driving the pump (6-rib belt) while also controlling engine harmonics. ATI and LME created a solution, which included a combination of an ATI steel hub and an ATI aluminum balancer; making our 7.53-inch diameter damper the perfect addition to this build.

- The patented ATI Super Damper is the only crankshaft damper designed exclusively for high performance Chevy engines

- Eliminates torsional crankshaft vibrations

- Exceeds SFI 18.1 specs

- Black zinc chromate finished

- OEM equipment on ZZ572 GM Crate Engines

- Tunable, rebuildable, and extremely efficient at all rpm

- Laser engraved 360-degreee timing marks

We’ve made mentions of the ATI Super Damper before on this particular LS build. As LSXMag Associate Editor Rick Seitz stated in a prior news piece, “Our LS mill is assembled with the best of everything and since it’s running a dry sump oiling system, we relied upon an ATI Performance Products Super Damper.” To finalize the damper’s place on the LS engine, we fastened it down with a an ARP LS balancer bolt.

The ATI damper allows this 502 to not only minimize harmonics buts also drives the Aviaid dry sump pump.

FAST Fuel Injection Control Systems/Components

For our tuning needs, it was necessary to point out LME’s use of the FAST XFI 2.0 engine control system. For this build, it was an easy choice. There really is no other ignition control system that allows its users to process, analyze and adjust parameters more quickly.

The C-Com XFI Windows-based software is easy to navigate and features field-flashable capabilities. This allows users to download the latest software updates through email or directly from FAST. These XFI control units also feature Qwik Tune for programming without a laptop. You can pre-program up to four different EFI maps allowing the ability to optimize a setting for daily driving, one for racing conditions, and still another for fuel economy. With on-board diagnostics, EZ test indicator lights, 5-bar MAP sensing and controls, plus enhanced data-logging capabilities and memory helped influence our choice to run this unit for this high-end build.

FAST XFI 2.0 At A Glance

Built-in wideband O2

Built-in wideband O2- Fully sequential and/or bank-to-bank capability

- Individual cylinder correction

- Fan and fuel pump control

- Dynamic scaling of vectors in 2D and 3D tables

- Torque converter lockup control

- Air conditioning wide-open throttle cutout

- Boost control

- Fuel and oil pressure logging

- Adjustable injector timing

- Multiple ignition strategies

We continued the FAST theme throughout the remainder of our ignition control systems. Maximizing processing capabilities and ease of wiring, LME went with the FAST EFI harness. With clearly labeled connections, it made wiring up our monster LS build quick and easy.

We also included a bevy of additional FAST components including, the FAST MAP sensor, IAC, ACT, Coolant Temp sensor, TPS Switch, Fuel injector harness, FAST 65-lb Fuel Injectors, Oil Pressure Sensor, AIR Temp Sensor and FAST Billet Fuel Rails for LS7 LSXR intake Injectors. Finally, we were ready for the FAST EFI 102mm throttle body. The FAST 102mm throttle body are machined from durable 6061-T6 billet aluminum in precision CNC machining centers. This throttle body will maximize air flow while also creating a well-mannered, street-driven engine.

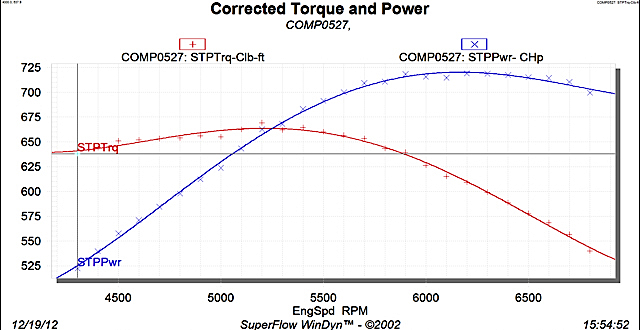

LME Dyno Results

With the RHS 502 finally buttoned up, primed with oil and strapped down to the LME dyno, we could begin our break-in dyno process. The break-in process will allow the rings to properly seat, keep an eye on oil pressure and provide a chance to make sure there are no leaks. LME also took time during the break-in period to check the condition of the oil. If there was any metallic material in the oil, now would be the time to shut it down. However, our oil was clean.

We began our dyno pulls at 4,000 rpm. This RHS 502 stroker makes so much torque down low, pulling the engine down any lower than 4,000 rpm would not be necessary. From there, we kept our pulls short and gradually increased its maximum rpm. All the while, LME was constantly checking air/fuel ratios as well as tuning the FAST EFI software for optimum power.

We began our dyno pulls at 4,000 rpm. This RHS 502 stroker makes so much torque down low, pulling the engine down any lower than 4,000 rpm would not be necessary. From there, we kept our pulls short and gradually increased its maximum rpm. All the while, LME was constantly checking air/fuel ratios as well as tuning the FAST EFI software for optimum power.

All said and done, LME made a mind-blowing 27 dyno pulls with the RHS 502. Sometimes the dyno process can be an all day affair and our experience was no different to dial in our beast. LME took their time to perfect the EFI software making absolutely sure the engine was top-notch.

This LME-built powerhouse proved with our initial pulls that this monster could handle whatever we threw at it. After some post examination of the fuel tables and previous dyno pulls, LME decided to continue safely with more pulls. So, what was the RHS 502 producing? After a final pull for all the glory, we were blown-away.

Once dialed in, our RHS 502ci LSX made an impressive 720.3 horsepower at 6,400 rpm and 669.6 foot-pounds of torque at 5,300 rpm.

The RHS 502 made a very impressive 720.3 horsepower at 6,400 rpm and 669.6 foot-pounds of torque at 5,300 rpm. While this isn’t your typical, backyard build, LME proved that with the right combination of parts anything is possible; even building an LS-backed 502 stroker for the street. Stay tuned, we’ll have this powerplant going into a ’69 Camaro project soon. Be sure to check out our Blank Slate Camaro’s ongoing progress right HERE!

Parts List // LME 502 Part 2 Build Sheet

| MFG | DESCRIPTION | PN | COST (Approx.) |

| ARP | 2000 Pro Series for LSX 6 Bolt Block | 234-4319 | N/A |

| LS Balancer Bolt | ARP2342503 | N/A | |

| ATI | 6 3/4-inch O.D. 6-rib serpentine shell, 25 tooth HTD drive on hub | 917239A | 376 |

| Aviaid | Aviad 4-stage externally mounted dry sump oil pump | 14120 |

N/A |

| Remote Oil Filter | 50040 | N/A | |

| Dry Sump Oil Tank | 50030 | N/A | |

| Billet Oil Pan | N/A | N/A | |

| Chevrolet Performance Parts | GM LS7 Intake, 1.8:1 | 12579615 | 23/each |

| GM LS7 Exhaust, 1.8:1 | 12579617 | 23/each | |

|

Crank Trigger |

12585546 | 53 | |

| Cam Sensor | 12591720 | 46 | |

|

LS2 Front Cover |

12633906 | 90 | |

| LS2 Valley Cover | 12570471 | 134 | |

| COMP Cams |

COMP Dual Springs |

26926-16 | 270 |

| COMP Titanium Retainers | 779-16 | 258 | |

| COMP Machined steel locks | 623-16 | 32 | |

| COMP Viton w/steel jacket seals | 511-16 | 27 | |

| COMP Machined steel spring cups | 4709-16 | 23 | |

| Comp Short travel Hyd. Lifter # Ti-bar lifter | 15956-16 | 535 | |

| Pushrods Will coTrant when lenght is measured Comp 3/8 x .135 wall | N/A | N/A | |

| Trunion Kit for Rockers | 13702KIT | 140 | |

| FAST |

Intake have FAST 102MM LSXR Intake for LS7 Heads |

146202 | 1,002 |

|

Intake Spacers have RHS LS7 Intake Spacers for Tall Deck Block |

549109 | 253 | |

|

ECU/Tuning here FAST XFI |

301000 | 1,666 | |

|

EFI Harness |

301108 | 356 | |

|

MAP Sensor |

307029 | 50 | |

|

IAC |

307059 | 80 | |

|

Coolant Temp |

307003 | 10 | |

| Fuel Injector Harness | 301209 | 122 | |

| FAST 65-lb. fuel injectors | 30657-8 | 403 | |

|

FAST Billet Fuel Rails for LS7 LSXR Intake |

146027-kit | 191 | |

|

FAST Throttle Body 102mm |

54103 | 569 | |

|

AIR Temp Sensor |

307004 | 10 | |

|

Ignition Box |

301312 | 590 | |

|

Coils Comp/FAST |

30256-8 | 306 | |

| FEL-PRO |

RHS/Fel Pro MLS 6-bolt Head Gaskets .040-inch |

549402-set | 229 |

| Ferrea |

Ferrea Custom Titanium 2.200″ dia. x .313″ stem x 5.565″ oal. x .290″ tip |

Custom | N/A |

| Ferrea Custom Stainless Steel 1.615″ dia. x .313″ stem x 5.595″ oal. x .290″ tip | Custom | N/A | |

| NGK | NGK Spark Plugs TR6 | 4177 | 2.40/each |

| MSD | Plug Wires | 32819 | 75 |

| RHS | Pro-Elite RHS LS7 6-bolt heads, CNC-Machined | 54501 | 2,236 |