Who would have thunk this 50 years ago? Most of you who have been around that long know what this writer is talking about. Back in the day – the best you could hope for was those hard to find factory castings – “fuelie” heads, PowerPaks, and a host of other high-performance Bow-Tie heads that were not only hard to come by, but pricy, made of iron and short on potential when you consider what we have now.

And, if you wanted fancy port and bowl work, you’d have to get out your checkbook and wait weeks for results. We’ve come a long way in the past 20 years with a treasure trove of great aftermarket cylinder heads for small- and big-block Chevys alike.

And, if you wanted fancy port and bowl work, you’d have to get out your checkbook and wait weeks for results. We’ve come a long way in the past 20 years with a treasure trove of great aftermarket cylinder heads for small- and big-block Chevys alike.

Few companies understand this better than Edelbrock. Edelbrock has been at the leading edge of cylinder head development, design, and manufacturing for the better part of the past two decades offering consumers great bang for the buck in an affordable cylinder head. Cylinder heads are a natural extension of what Edelbrock has been doing since World War II – high-performance induction systems.

E-Street From Edelbrock

Edelbrock’s Performer Series cylinder heads and induction systems have enjoyed great success making it possible for the masses to enjoy high-performance driving at affordable prices. Sounds like a sales pitch doesn’t it? It isn’t. Having been in this business for 30 years, I’ve witnessed the great evolution of aftermarket parts and services first hand.

Never has it been better when it comes to cylinder heads and induction systems. Edelbrock has led the charge for untold thousands of enthusiasts. Some say the pride is back, with jobs coming back to America.

However, at Edelbrock, they never left. Edelbrock’s new E-Street A356 aluminum cylinder heads for Chevrolet small- and big-blocks are developed, cast, and machined right here in the Los Angeles area and roll off delivery trucks worldwide with a message – affordable performance spoken here that’s also made in America. The all-new E-Street head is a completely new approach to Edelbrock deck topper castings because it offers entry level performance in the 300-400-horse arena. It is a great street head that’s good to go for your Bow-Tie project.

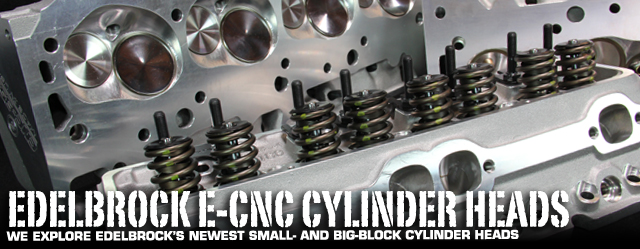

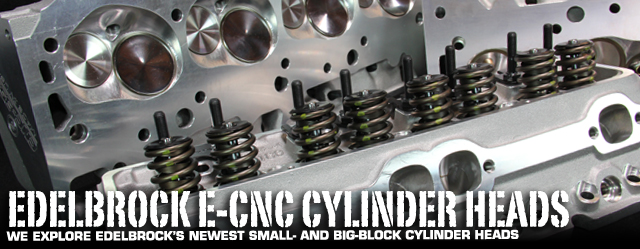

You've met E-Street from Edelbrock. E-Street meets Silicon Valley with cool CNC technology and a ported Chevy cylinder head you can afford.

Upnotch It…

First question we had for Edelbrock with E-Street is – how do you make a great street cylinder head even better? Edelbrock responded with E-CNC cylinder heads for small- and big-block Chevy. E-CNC is clean-shaven CNC-machined port and chamber work without the high cost of a custom port job. What this means for you is optimum airflow, horsepower, and torque. The E-CNC head stays with the stock 23-degree valve angle. It also engineered to accept pre-1986 intake manifolds.

Bare, the E-CNC 185 head retails for $738.99 at Summit Racing Equipment. At the other end of the scale at Summit is the complete E-CNC 355 big-block rectangular port head for $1629.95.

Spotlight On Greatness – Rick Roberts

“My design philosophy for heads starts with selection of the intake valve size. I first find the peak air flow at 100% volumetric efficiency (air consumption at peak power rpm). Using this volume flow rate, I calculate the cross-sectional area that will produce an average air velocity of 300 ft/sec during the 180 degrees from TDC to BDC during the intake stroke,” Dr. Rick Roberts, Director of Engineering at Edelbrock briefed us, “From the cross-sectional area I calculate the diameter of a circle that has that area and that’s my intake valve diameter. I will design the port with a throat of about 88% to 90% of the valve diameter and if possible try to keep a constant cross-section area throughout the port. All of that will pretty much dictate the volume of the port for a given engine platform.”

Rick and the engineering staff at Edelbrock has the latest technology available, which allows them to conceive the most effective port design possible. Roberts has his roots in Northeastern Ohio. From there, he attended the Illinois Institute of Technology where he received his degree in Mechanical Engineering.

E-CNC Big-Block Chevy Oval Port

- RH Intake Flow at .600-inch Lift: 332cfm

- LH Intake Flow at .600-inch Lift: 335cfm

- Exhaust Flow at .600-inch Lift: 232cfm

- Chamber Size: 112cc

- RH Intake Runner Volume: 325cc

- LH Intake Runner Volume: 308cc

- Exhaust Runner Volume: 133cc

- Intake Valve Diameter: 2.25-inch

- Exhaust Valve Diameter: 1.88-inch

- Deck Thickness: 9/16-inch

- Valve Spring Diameter: 1.55-inch

- Maximum Valve Spring Lift: 0.700-inch

- Rocker Stud Diameter: 7/16-inch

- Push Rod Diameter: 3/8-inch

- Spark Plug: 14mm with 3/4-inch reach (Champion RC12YC)

He moved on to the California Institute of Technology (Caltech) to receive his PhD. Roberts cut his teeth at Air Flow Research where he came to know the late Ken Sperling and his wife, Phyllis. Sperling was a mentor and friend to Roberts, allowing him to practice and learn his craft. In 1991, Roberts joined Edelbrock where he has been ever since.

We asked Roberts about how the E-CNC cylinder head came to pass. “Like many projects this one was an evolution. We experimented 12 years ago with what I refer to as a factory angle milled head. During my days in a porting shop we routinely performed an angle mill operation to reduce the chamber size after extensive port and chamber grinding. It was a whole lot of work to correct the head bolt holes and intake face so everything would go together,” Roberts reflected.

“I got the idea to just ‘roll’ the deck of the head from the very start of machining rather than do it after the fact like we had to in the porting shop. Our first version was a big block Chevy and we rolled it 1 degree. The only problem with the head was the rolling operation dropped the height of the exhaust ports around 1/8-inch and caused some problems with the outboard short head bolts.”

Development of the E-CNC head began with the big-block Chevy according to Rick Roberts, Director of Engineering at Edelbrock. The result has been a spectacular and affordable street head. Edelbrock's own 555ci crate made 676 horsepower and a whopping 646 ft/lbs of torque with 10.0:1 compression.

We asked Roberts to expand on development of these heads, “Pat Musi came along with his 555 crate engine idea which was first built using our big bad race 24-degree head. The problem with that was that the exhaust ports were raised 0.531-inch over stock which made header fitment in the chassis of a door car a real pain. There were a lot of complaints. We then took our old rolled over head design and dusted it off. Since we were going full CNC it meant the exhaust height issue in the original head could be addressed. I decided to change the roll angle from 1 to 1.5 degrees and not only restored the original stock exhaust bolt height but raised over stock an additional 3/16-inch. I figured that would help exhaust flow performance without requiring custom headers in a door car.”

Roberts’ review of the overall E-CNC program is exceptional, “In the end we were delighted with the results. Here you have a good flowing fully CNC ported cylinder head compatible with off the shelf pistons, intake manifolds, rocker arm systems, and headers for a very reasonable price. The intake port ended up a little smaller than that on the race heads but gave up nothing in the final product and now does not require any kind of special exhaust system.” We learn from Rick Roberts development of these heads didn’t require much computer aid time because they’re an adaptation of castings that already existed.

Although the E-CNC cylinder head is machined via CNC technology, very little computer time was employed in its development, proof of the kind of seasoned know how you have at Edelbrock. Check out this extraordinary machine work performed without aid of human hands.

Great quantum leaps in power today come from cam and head development mostly.Behold the E-Street small-block head with the benefit of CNC port, bowl, and chamber work. CNC machines do in minutes what normally takes human hands days.

E-CNC – Bang For The Buck

If you’re on a tight budget – and even if you are not, the E-CNC head is great bang for the buck for even the most modest of street engine projects because when you consider what it costs to take factory iron heads and massage them to spec, putting them on the shelf and opting for E-CNC is a no brainer.

Expect to spend on the order of $500 for a valve job with hardened seats, fresh guides, and new valves for those rusty old iron heads not including port, bowl, and chamber work. Bare, the E-CNC 185 head retails for $738.99 at Summit Racing Equipment. At the other end of the scale at Summit is the complete E-CNC 355 big-block rectangular port head for $1629.95.

Of course many elements go into how much power an engine will produce including technique. However, E-CNC coupled with proper cam selection and compression ratio could net you 450 horsepower and 428 ft/lbs of torque.

The E-CNC cylinder head is assembled using manganese bronze valve guides, powdered metal interlocking valve seats, one-piece stainless steel valves with hardened tips, duty-designed valve springs, hardened spring cups, and 3/8-inch rocker arm studs for durability.

What you have on your side with the E-CNC is technology mostly with advanced combustion chambers and port design – air/fuel management that will net you more power than those stock iron heads ever could. And because they are A356 aluminum, they remove excess heat like an iron head never could.

E-CNC 185 Small-Block Chevy

- Intake Flow at .600-inch Lift: 254cfm

- Exhaust Flow at .600-inch Lift: 203cfm

- Chamber Size: 64cc

- Intake Runner Volume: 185cc

- Exhaust Runner Volume: 75cc

- Intake Valve Diameter: 2.02-inch

- Exhaust Valve Diameter: 1.60-inch

- Deck Thickness: 9/16-inch

- Valve Spring Diameter: 1.46-inch

- Maximum Valve Spring Lift: 0.575-inch

- Rocker Stud Diameter: 3/8-inch

- Push Rod Diameter: 5/16-inch

- Spark Plug: 14mm with 3/4-inch reach (Champion RC12YC)

Spring Pressure – You Need To Know

Two E-CNC heads are available for the small-block Chevy – one with springs for flat-tappet hydraulic cam and the other for roller hydraulics, which boils down to spring pressure. Otherwise – same castings. If you’re seeking a complete head, consider spring pressure in the process.

Though Edelbrock offers you one E-CNC small-block head with two different spring pressures, keep in mind valve springs must be cam profile, valvetrain weight, and rpm compatible.

Another factor is valvetrain weight. The lighter the valve, the less spring pressure needed. By the same token – the heavier the valve, the greater spring pressure should be. Roller tappets require greater spring pressure because roller lifters are heavier. The more valve train weight you have meaning valve, retainer, keepers, rocker arm, push rod, and lifter – greater spring pressure required.

Too much spring pressure will cause excessive wear. Not enough spring pressure will cause valve float at high rpm. Follow your cam manufacturer’s directions to the letter. When you order a camshaft, opt for a complete kit including valve springs.

The E-CNC head is the result of collective experience - know how - from people who have been designing cylinder heads and induction systems for most of their careers.

What Does It All Mean?

Edelbrock continues to demonstrate to us it still has kept its corporate foot in street and strip performance and hasn’t let up on the throttle even in the toughest of economic times. Instead, it has kept its imagination at work developing exciting products enthusiasts want – and at a price enthusiasts can afford. That said, we will cop a pair of E-CNCs, please.

And, if you wanted fancy port and bowl work, you’d have to get out your checkbook and wait weeks for results. We’ve come a long way in the past 20 years with a treasure trove of great aftermarket cylinder heads for small- and big-block Chevys alike.

And, if you wanted fancy port and bowl work, you’d have to get out your checkbook and wait weeks for results. We’ve come a long way in the past 20 years with a treasure trove of great aftermarket cylinder heads for small- and big-block Chevys alike.