The late-model American high-performance, four-passenger car can trace its roots to the late-80’s Ford Taurus SHO, which boasted a sweet 3.0-liter, dual overhead cam Yamaha-built V6 engine and a chassis to match. Thankfully for us, Ford jump-started a market segment that’s on fire today, with the Cadillac CTS-V playing a starring role thanks to its outstanding supercharged 6.2L LSA engine that’s based on the Corvette ZR1’s powerplant. With heritage like that, and Cadillac’s recent focus on performance and handling, the CTS-V is a monster masquerading as a luxury car.

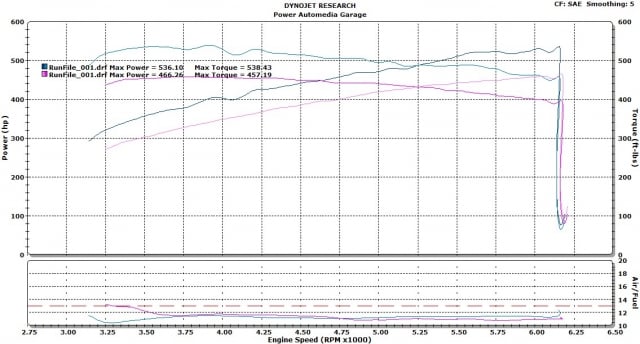

Our ‘before’ Dynojet runs showed 466.2 horsepower and 457.1 pound-feet of torque at the wheels – adequate motivation for our 3,850 pound car, but here at Power Automedia, ‘stock’ is never enough.

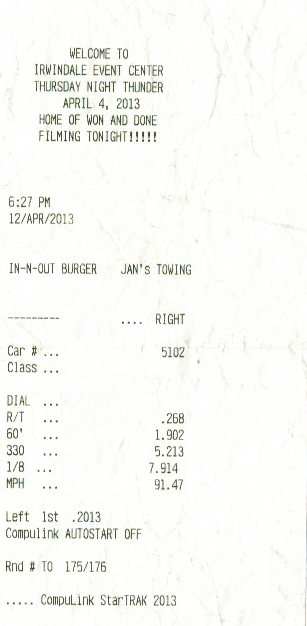

As powerful as it is, the second-gen CTS-V practically begs to be upgraded, and a lot of well-known tuners and manufacturers catalog a wide variety of go-fast parts for it. But before we ever lifted a wrench, we thought it would be a good idea to get some baseline numbers on our CTS-V at the track to see exactly what the mack-daddy Caddy could accomplish with the stock setup.

The closest dragstrip to our SoCal home base is Irwindale Speedway, which is an eighth-mile track carved out of an oval track parking lot. Our results after a night of flogging the machine? How about a 1.90 short time and 7.91 ET at 91.47 MPH? That equates to a 12.40 or so at about 113 MPH in the full quarter-mile – a stout number for a stock car.

Time For More

Enter the performance experts at Lingenfelter Performance Engineering in Decatur, Indiana. Company founder John Lingenfelter was legendary within the racing community with a racing career that spanned four decades and included 13 NHRA national event titles and numerous other achievements that catapulted his company to the forefront of the performance aftermarket. Though John’s no longer with us, his legacy lives on in the form of an incredibly experienced team of engineers and craftsmen headed today by Ken Lingenfelter.

Now that we’ve got the “who” out of the way, let’s talk about the “what.” It’s simple; we’ve got a project CTS-V in our stable, and we wanted to improve its performance.

That’s where LPE comes in – they’ve got a number of packages for the CTS-V to improve performance, and our gaze set upon the 650-horsepower supercharger upgrade kit [PN L250300709, MSRP $1,948.95] that can be purchased and installed by you right at home. In conjunction with the supercharger upgrade kit, you’ll also need to hook up with their tuning kit [PN CTSVETAC650, MSRP $650] so that the ECU knows what to do with the hardware improvements.

Once we had some solid dyno and dragstrip numbers as a baseline, it was time to open up that big box from LPE. So what’s in it? Lingenfelter Engineer Jason Haines spells out the details. “ATI Performance Products makes the harmonic balancer for Lingenfelter to our specifications. The CTS-V has a three-belt system; you’ve got a four-rib drive for the air conditioning system, all of the other accessories run on a 6-rib package, and then the supercharger runs on a standalone 8-rib drive system. We’ve also got it set up so that the 11-percent overdrive, 8.66-inch supercharger drive pulley bolts to the damper, so it’s fairly easy to change drive ratios by just swapping that front pulley. The damper has the primary drive for the A/C and accessories built into the shell,” he explained.

In order to begin the modifications, we needed to remove a number of the stock components to access the supercharger snout. The battery is disconnected and the strut tower bar is removed to begin the process. The airbox, throttle body, and a number of other components come off before you can remove the supercharger cover. Lingenfelter provides incredibly-detailed instructions with the kit, making it very straightforward.

We’ve written about ATI’s extensive line of harmonic damper products and their technology in the past on our sister site, Dragzine.com, but a quick rundown of the technology inside is in order. A damper, contrary to what you might believe, doesn’t make power on its own, but the vibration reduction it offers does indeed help an engine to build more power, safely. ATI’s elastomer design consists of a center hub, an inertia weight, and tuned elastomer rings that fit between the damper’s hub and shell.

Our Lingenfelter-specific ATI Performance Products-built harmonic damper installs from underneath the car and uses a separate supercharger drive pulley, available for varying levels of boost depending upon your level of modifications.

The damper absorbs the harmonics of the crankshaft, which is always trying to twist in one direction or the other, as it undergoes the forces of combustion – it’s basically a shock absorber for the engine. It is tuned to work at the specific frequency of the particular engine platform to absorb the unwanted vibrations.

According to ATI’s JC Beattie Jr., tuning the “third order” harmonics out of an engine provides the largest gain in both engine longevity and horsepower improvement. Decades of research and development have found that the third order of harmonics is most damaging to an engine, and it’s within this spectrum that ATI focuses most of its efforts.

The Lingenfelter/ATI damper meets SFI’s 18.1 specification for dragstrip compliance – and to make sure that it won’t fail when subjected to those increased forces of spinning the supercharger and engine harder.

Basically, it’s insurance against engine failure, and well worth the expense. As an added benefit, the Lingenfelter/ATI damper weighs 13.0 pounds with the supercharger drive pulley attached, while the stock damper weighs 16.45 pounds. That’s a rotating mass savings of 3.45 pounds – a big deal at 7,000 RPM.

Once you have the supercharger snout off, the stock pulley gets pulled off, the new one gets pressed on, and then you need to drill the snout of the pulley to pin it in place to prevent it from spinning on the shaft. This step is not a requirement, but is a strong suggestion from Lingenfelter to prevent issues. Take it apart one time!

The Lingenfelter supercharger pulley and air intake kit includes a 2.55-inch steel supercharger pulley in the factory 8-rib design and a new supercharger drive belt to go along with a solid supercharger coupling. The company also includes a sweet Lingenfelter-branded air intake tube, silicone couplers, and new hose clamps.

The airbox gets modified to make use of the new low-restriction reusable K&N panel air filter. Lingenfelter also provides an aluminum intake tube, which prevents the intake tract from getting sucked shut under our increased boost levels.

Solid Coupling

The solid isolator coupling for the supercharger shaft has a distinct purpose. “The production supercharger has a spring-loaded coupling (shown above on the right) that’s designed to reduce wind-up noise and oscillation especially at idle and light load transitions,” says Haines. “But as you speed up the supercharger, you tend to run ‘to the stops’ of the spring-loaded coupling design, which will tend to make noise and cause abnormal wear due to the supercharger spinning more quickly.”

Also in the box is a set of 63 lb/hr fuel injectors; necessary due to the hopped up blower ratio requiring more fuel as well. According to Haines, “At these power levels, you don’t have the fuel flow necessary from the stock injectors once you change the upper and lower pulleys. The engine in stock form produces 556 horsepower, and you’ll be making more airflow and horsepower than the stock injectors can handle. The rest of the fuel system consists of a dual-pump module and can handle the extra power without any upgrades save for the injectors.”

Left - while the supercharger is out of the way, it's also time to install the new 63 pound-per-hour fuel injectors. Right - Lingenfelter also supplies a new 160-degree thermostat, which will help to keep engine temperatures consistent at the dragstrip.

In addition, a 160-degree thermostat is present in the kit. Per Haines, “When you reduce the engine coolant temperature, you reduce the spark knock sensitivity, so you’re able to make more power for the same amount of timing and fuel octane. Its primary advantage is at the dragstrip where you can keep it cool; as you drive under sustained high loads like road racing or on the street, the thermostat is less in control of the temperature and the rest of the cooling system is more in control. But at the dragstrip you can let it cool down in between each run and that’s where it works best.”

We have a handheld flash tuner that will be sent with the calibration; the customer can then just plug it into the vehicle and load the new calibration.” – Jason Haines, Lingenfelter Performance Engineering

More Power in, More Exhaust Out

In conjunction with our newfound horsepower, we also decided it was time to upgrade the car’s bark, achieved by installing an axle-back exhaust system from Corsa Performance [PN CP14942-E, $1,219], ordered directly from Lingenfelter. This straight-through, 2.5-inch system maximizes the airflow in addition to providing improved performance and fuel economy. It features mandrel-bent stainless tubing to minimize any chance of restriction and deliver increased airflow over the stock exhaust system, necessary in our application as the increased boost levels need a way to exit the engine in orderly fashion.

In order to install the new Corsa Performance exhaust, we raised up our CTS-V on the Power Automedia shop’s lift. This can be done in the driveway but the extra room is helpful.

The system uses Corsa’s patented Reflective Sound Cancellation technology to give an aggressive sound under acceleration but a drone-free experience during cruising. It has a straight-through design and uses acoustic tuning to cancel out unwanted frequencies; after all, this is a Cadillac, not a Mustang, and you likely expect it to sound nice and smooth when you’re on the highway. Nobody wants to have to shout over a poorly-designed set of aftermarket mufflers that fill the passenger cabin with unwanted noise.

More on Corsa’s RSC Technology –

The entire exhaust system is crafted from fully-polished stainless steel – everything from the piping to the clamps and hangers, ensuring that if you live in a rust-loving area of the country your exhaust system will last the life of your vehicle. It’s 50-state legal, carries a limited lifetime warranty, and is made right here in the US of A – what more could you want? Dual rear exits with 304 stainless-steel 4.5-inch tips give a refined, sleek appearance to the back of our CTS-V, and the sound; oh, the sound. Needless to say, we love it!

In order to install the axleback, the factory pipes are cut off just after the crossover point. New stainless-steel pipes and mufflers are installed easily - the Corsa Performance exhaust is all stainless and features a sweet set of 4.5-inch stainless tips.

Our before-and-after Dynojet tests show a substantial gain of 69.8 horsepower and 81.2 foot-pounds of torque, and as you can see from the dyno sheet the gains were basically straight across the board, improving the seat-of-the-pants meter by leaps and bounds over the stock setup.

We’ve installed this extensive list of goodies, made a ton of power, and now it’s time to go back to the track for our “after” test, right? Well, we tried that… and didn’t get even one iota of traction. The power gains put us in the unenviable position of annihilating the stock tires to the point where we were unable to get even one good, clean pass to show off the performance of the new parts.

Sticking It To The Ground

Once we realized we needed to get a set of sticky tires under the car, the decision was made to outfit the CTS-V (for track-only use) with a sweet set of Weld Racing‘s finest S71 forged aluminum wheels. The rear wheels are 17 by 10-inches wide with a 7.20-inch backspace [PN 71HP7100N72A, MSRP $471.54 each], using the factory 5x120mm bolt circle. In the front, we opted for an 18 x 5-inch wheel using a 2.1-inch backspace [PN 71HP8050N21A, MSRP $556.80 each] to lessen the rotating weight while still providing good braking and directional control at the strip.

Weld's S71 wheels need no introduction - they are some of the sexiest pieces of aluminum you can bolt onto your car. A set of sticky Mickeys completes the package.

Weld Racing’s Chris Bovis explains, “Forging wheels allows us to produce a much higher quality product, because the strength of the forged aluminum is so much higher – that allows us to meet a high performance and durability standard. The resulting wheel design is lighter, it will accelerate faster and brake quicker, and takes less energy to get it started and stopped. The forging process makes for a better-performing product.”

The S71 wheels are three-piece modular wheels that use a forged center section and cold-forged rim shells. Weld uses a proprietary welding process to graft the three pieces together.

The RT-S wheels are unique in that they offer three different pad heights (low, medium, and high) to clear different types of OE and aftermarket braking systems.

Here’s a quick graphic explaining the differences between pad height – you can see how the high pad option offers much more room for large brake caliper fitment.

Our wheels are of Weld’s “high pad” design, which offers the most brake caliper clearance of the three styles and is designed to fit right over our monster Brembo stoppers.

“We’ve worked very hard with Ben at Weapon X Motorsports on the wheel fitment for these cars,” says Bovis. “Ben put a lot of time and effort into making sure this fitment was correct and produces the results that CTS-V owners are looking for. Using the different pad designs allows us to have more flexibility to curve the spokes of the wheel to get the wheel/tire/fender clearance that people are looking for. We actually have three separate forgings for the S71 design.”

The S71 is available with your choice of polished or black anodized centers, and both center treatments feature a polished rim shell.

Part of Weld Racing’s claim to fame is that they are made right here in America – in good ol’ Kansas City. The other part of their claim to fame is the fact that they’ve been a part of countless championship-winning machines throughout all forms of motorsports.

You didn’t think we were going to pick up these badass wheels and not outfit them with a set of sticky Mickeys, didja? Of course not! A pair of Mickey Thompson Tires’ ET Street Radial II tires in a 295/45/17 size [PN 3745R, $260.99 each] was ordered up for the rear of our machine, and on the front we installed a set of 26x6x18 radial Sportsman SR radial tires [PN 6682, $206.00 each]. The ET Street Radial II has a soft compound that will offer us the greatest amount of traction on the strip without running a full slick; the radial construction of the Sportsman SR on the front means we won’t have to worry about getting out of shape at speed. And the car still handles pretty well on the street, although we won’t be carving any corners with these wheels and tires installed.

At The Track, Again

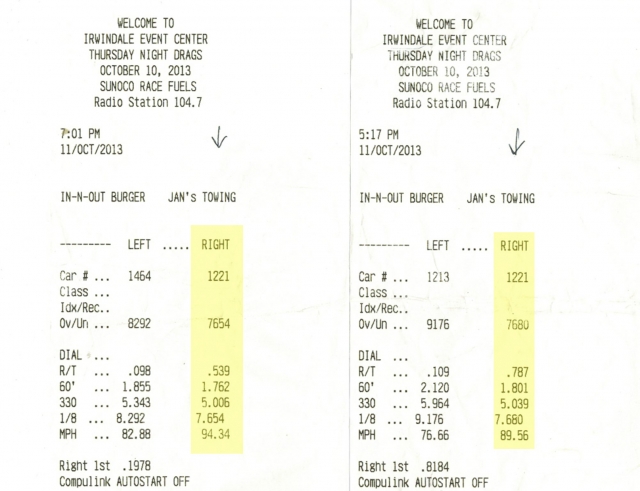

As you can see from the timeslips to the right, when we made it back to the track with our new wheel and tire combination we found an immense improvement in traction, allowing us to put this newfound horsepower to the ground without fear of turning the tire over.

As you can see from the timeslips to the right, when we made it back to the track with our new wheel and tire combination we found an immense improvement in traction, allowing us to put this newfound horsepower to the ground without fear of turning the tire over.

The short times came down considerably with a best of 1.76 – an improvement of nearly a tenth and a half. That improvement carried all the all the way down the track, allowing us to put a best eighth-mile time of 7.65 at 94.3 MPH up on the board.

Those numbers translate to somewhere around an 11.93 on the big end of a quarter-mile track. That’s stout performance from a car that rides and drives like stock, but screams like the unleashed animal it really is, and the temperature at the track was brutally hot, meaning there is even more in store with better air.

A full half-second improvement on a quarter-mile track from a cold-air kit, new pulleys, a new exhaust system, and sticky tires? We’ll take it, any day of the week.