This modification marks the first for Project C700, a 2015 Corvette Stingray Z51 equipped with the eight-speed, paddle-shifted automatic transmission. The car currently only has a few thousand miles on it, and is truly in mint condition. To this point, we have been beyond pleased with the performance, drivability, sound, and handling of the Stingray. However, we can never seem to leave well enough alone, and as such we have officially kicked off the path which will hopefully allow us to fulfill the goal of this build, and thus proving it worthy of its name … producing 700 hp.

This modification marks the first for Project C700, a 2015 Corvette Stingray Z51 equipped with the eight-speed, paddle-shifted automatic transmission. The car currently only has a few thousand miles on it, and is truly in mint condition. To this point, we have been beyond pleased with the performance, drivability, sound, and handling of the Stingray. However, we can never seem to leave well enough alone, and as such we have officially kicked off the path which will hopefully allow us to fulfill the goal of this build, and thus proving it worthy of its name … producing 700 hp.

The intake system chosen for this installation is a K&N cold air intake part number 63-3081 which we chose for a number of reasons. While we ultimately will be running the full air intake system, we decided to go ahead and install the K&N drop-in air filter part number E-0665 first and run the car on our Dynojet to show the power gains from a simple K&N replacement. You may just be as pleasantly surprised as we were.

Cold Air Intakes

Installing an intake system into your vehicle can provide a number of benefits, including increased horsepower torque, quicker throttle response, and improved fuel economy. It can also save you money in the long run as it enables you to simply clean, oil, and reuse the same filter instead of constantly replacing the factory paper element. As our society continues to move towards being “green” in all aspects of life, reusable pieces like this will continue to grow in popularity.

Installing an intake system into your vehicle can provide a number of benefits, including increased horsepower torque, quicker throttle response, and improved fuel economy. It can also save you money in the long run as it enables you to simply clean, oil, and reuse the same filter instead of constantly replacing the factory paper element. As our society continues to move towards being “green” in all aspects of life, reusable pieces like this will continue to grow in popularity.

We had the opportunity to speak with Bert Heck, the K&N Intake Kit Manager who was happy to fill us in a bit further on his involvement with K&N and the C7 Stingray. Heck explained, “The 2014 Chevy Corvette was totally redesigned, making the need for an entirely new intake kit. During development many different size intake tubes were tested, but a four-inch tube delivered the best results. The new heat shield was designed to help prevent hot air from reaching the air filter, while still using factory mounting locations. Three vehicles were used and 126 dyno runs were made during the development stage, ultimately resulting in a consistent 12 horsepower gain.”

We publish estimated horsepower gains for most K&N air intake systems right on our website. Every K&N intake is guaranteed to increase horsepower. – Tapia

We also were able to chat with Lucio Tapia, the K&N Brand Manager who explained, “A custom made air filter with carbon fiber top and bottom is fitted to the inlet of the K&N Air Intake System to provide excellent airflow rates as well as outstanding filtration efficiency.

The Install

Again, we wanted to first test the drop-in filter element, and because this piece utilizes nearly all of the factory intake hardware, we did this portion first. To begin, we removed the center tube that runs between the throttle body and the airlifted housing. At this point it is very easy to pull the stock filter free and replace it with the K&N element.

After reinstalling the airbox cover and the intake tube, we were able to test the results on our in-house Dynojet, which you can read more about below in the improvements section below.

After our car cooled back down from the dyno passes, we moved through the installation as if nothing had been changed. To begin, we removed the radiator shroud and set it aside to make more room within the engine compartment.

After removing the intake tube and the entire air box assembly, we had a few lines that needed to be altered.

From here, we grabbed the filter housing and slid the supplied rubber gasket around all appropriate edges. We then set the housing and filter down into their appropriate locations. Note the routing of the new extended oil lines around the air box.

Next, we carefully removed the MAF (mass air flow) sensor from the factory intake tube and reinstalled it into the K&N tube, followed by installing the fitting for the factory vacuum line.

The intake tube was moved into place and clamped down at both ends, one with the air filter housing, and the other with the throttle body using the supplied silicone hose coupler and remaining hose clamps. Before moving on, you always want to take a moment to check fitment and clearances. As everything fit the way it was intended, we reinstalled our MAF plug, vacuum hose, and radiator shroud.

The next course of action was back onto the dyno to see how the full intake system would perform versus the drop in element, and ultimately compared to the factory intake system.

Testing

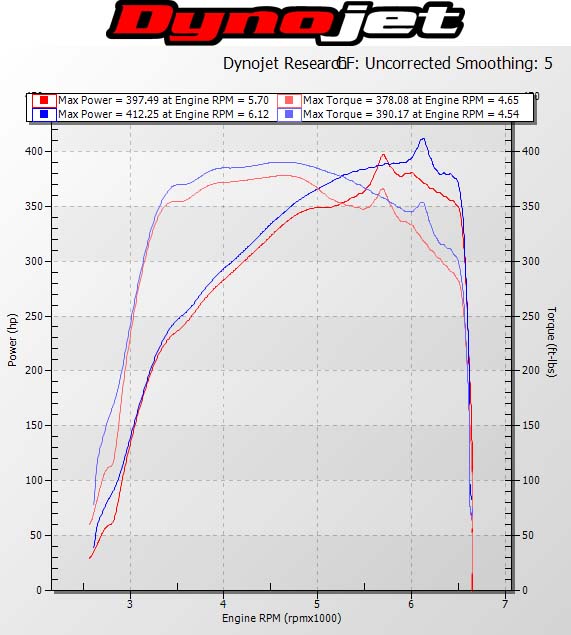

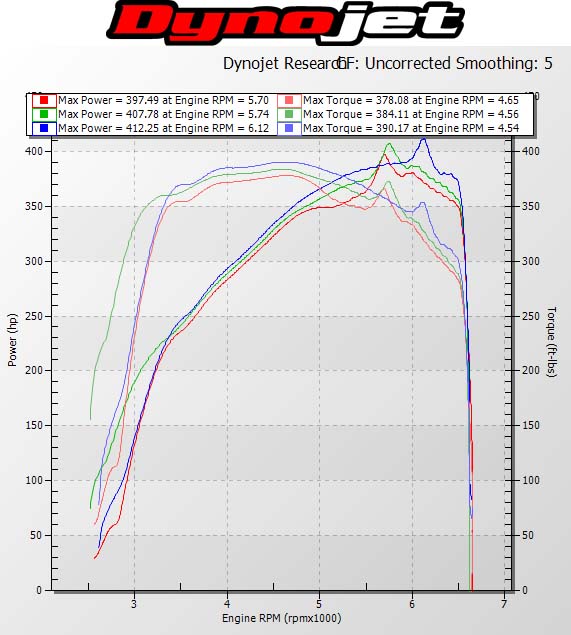

As we mentioned, this is a Z51 car, with only a few thousand miles on it, and is sporting GM’s latest eight-speed automatic transmission. When we strapped Project C700 to our Dynojet dynamometer for the first time, it produced a clean 397.4 hp and 378.0 lb-ft of torque.

When we mentioned that we were pleasantly surprised earlier, it was in part due to the gain from the simple drop-in filter. With that simple and very inexpensive change, our Stingray produced 407.7 hp and 384.1 lb-ft of torque. This is an increase over stock of 10.3 horsepower and 6.1 lb-ft of torque to the rear wheels, which really is quite impressive.

When we mentioned that we were pleasantly surprised earlier, it was in part due to the gain from the simple drop-in filter. With that simple and very inexpensive change, our Stingray produced 407.7 hp and 384.1 lb-ft of torque. This is an increase over stock of 10.3 horsepower and 6.1 lb-ft of torque to the rear wheels, which really is quite impressive.

Moreover though, we were looking forward to our second part of the testing, which was to test the full intake system. These results showed that with the full K&N system in place, our LT1 pushed out 412.2 hp and 390.1 lb-ft of torque. Overall, this modification gave us an increase of 14.8 hp and 12.1 lb-ft of torque compared to our stock base run.

The dynograph shown here also depicts an important aspect we like to look at, which is known as the power under the curve. Simply put, this means that while peak numbers are great, there is more to it than that. We like to look at the shape of the curve which shows us at what RPM the power comes on, goes steady, and eventually falls off.

You can see with this example that the drop-in filter raised the performance slightly, though it nearly follows the stock contour. The intake system however, reshaped our curve a bit. The torque curve flattens out at a lower more usable RPM and stays there longer, while the horsepower curve moved up in the RPM range, yet produces in excess of 375 hp for a much longer period.

We are happy that we outperformed the results claimed by K&N, as they said you can expect a gain of 12.51 horsepower. When comparing two different test cars, on two different dynos, there are several factors that can produce some differences in results to include: one car being a manual versus an automatic, various levels of use or break-in, what atmospheric conditions were present, and even differences due to the dynos themselves.

Driving Impressions

As we have mentioned previously, we think our Stingray is an amazing vehicle, even if we never modified it. When you are starting out with such a large amount of horsepower, it takes more substantial gains to really notice a difference from the driver’s seat. While the car may not “feel” a whole lot faster, we definitely felt a difference pulling through some of the taller gears. The LT1 no longer sounds starved for air and its throttle response is noticeably improved.

We couldn’t be happier with our results and to report positive power numbers with either choice. Moreover, we know that this modification will really be beneficial with our next installation of long tube headers and a complete exhaust system. For more builds and testing data with Project C700, keep it locked on Corvette Online.