Here’s a scenario that I am sure has happened to many of us. The cruise night is over and it’s time to head home. Unfortunately, you’re stuck in the parking lot waiting for your buddy who owns a car trailer. Why? When you were ready to leave and twisted the key on your ride, you expected everyone in the parking lot to take notice of the exhaust “noise” of your ride. However, instead of cranking the engine, the starter motor has taken this opportunity to say, “neener, neener, neener,” and simply delivered a very audible “click.”

That remanufactured, parts-store starter you bought last year was surprisingly inexpensive, and now you know why.

The starter on a Chevy engine is in a (relatively speaking) easily accessible location. Add headers and an oil pan with kick-outs, and the installation and removal process gets much harder.

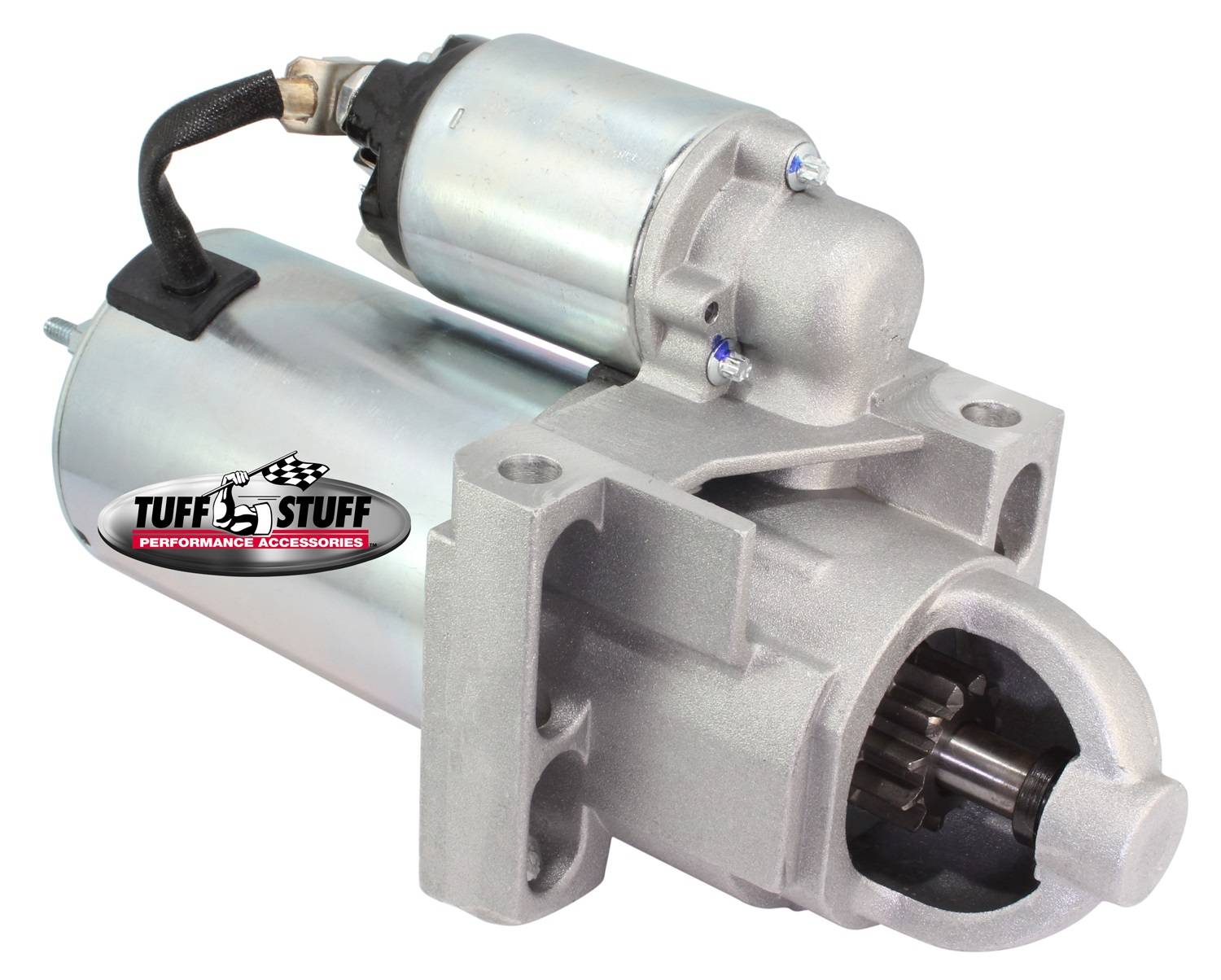

Hot rods have a unique way of rendering discounted, over-the-counter parts useless in a very short timeframe. Think about it, most classics are rebuilt with upgraded performance in mind. In the engine alone, you have probably bumped up the compression ratio and added some overlap to the camshaft. With the added compression alone, that remanufactured OE starter never stood a chance. But, there is a solution, and it comes from Tuff Stuff Performance.

The aforementioned no-start moment has made you realize that you need to do something different. You need to purchase a starter that is designed specifically for use in your hot rod. I’m not saying the parts-store starter you purchased wasn’t any good, but it probably wasn’t designed to live within a modified application. But, what are your options?

According to Matt Oliver of Tuff Stuff, you have a myriad of choices when it comes to buying a performance starter. We queried Matt to find out how you can make an informed choice, and he presented us with some interesting information we’ll share with you. When it comes to starters, the choices to make in order to get exactly the right unit can be accomplished by focusing on three aspects: fitment, horsepower, and kilowatt rating.

Filling A Tight Space

The greatest starter in the world is useless if it doesn’t fit the application. Modified rides usually have headers and larger-than-stock oil pans that can cause interference. Another consideration is knowing what size ring gear (flywheel) your engine has. You can check out this article for more information on deciphering that quandary about matching a starter to a Chevrolet engine. When using a traditional GM starter, filling that tight space usually results in denting a header tube, and even hot-start issues. Many times, the mini starter can absolve your engine of those maladies.

Upper right: Starter 6550B is a gear-reduction starter with 1.6 horsepower and a mounting nose that rotates to facilitate clearance around headers and oil pans. Upper left: Starter 6510NB is a gear-reduction starter with a non-rotatable mounting location, Lower middle: An OE-style starter.

Torque Requirements

Actual fitment aside, a starter’s torque output is a very important consideration. Every component inside the engine that generates friction is working against the starter. The starter must possess the capability to spin the engine without overheating internally. We all know that it takes torque to spin the wheels and get a car down the track, but it also takes a certain amount of torque for a starter to crank an engine.

There is no such thing as having a starter with too much torque – even on a street vehicle. As a general rule-of-thumb, an engine with a 12:1 compression ratio or higher should use a starter with at least a 200 lb.-ft. Those engines having between a 10.5:1 and a 12:1 compression ratio should use a starter with at least 180 lb.-ft. Starters rated at 160 lb.-ft. are good for engines up to a 10.5:1 compression ratio.

Kilowatts, Not Gigawatts

A Kilowatt (kW) rating is how all electric motors are measured. According to Matt, 1kW is roughly the same as 1.34 horsepower. The higher the kW number, the more power output from the motor. While an engine’s compression ratio needs to be a huge consideration when choosing a starter kW rating, ignition timing also plays an integral role. An engine with a lot of initial ignition-advance, can make it hard for a starter to spin the engine. Even engines with an aggressive camshaft and valve springs with high spring-pressure can make it more difficult to start an engine.

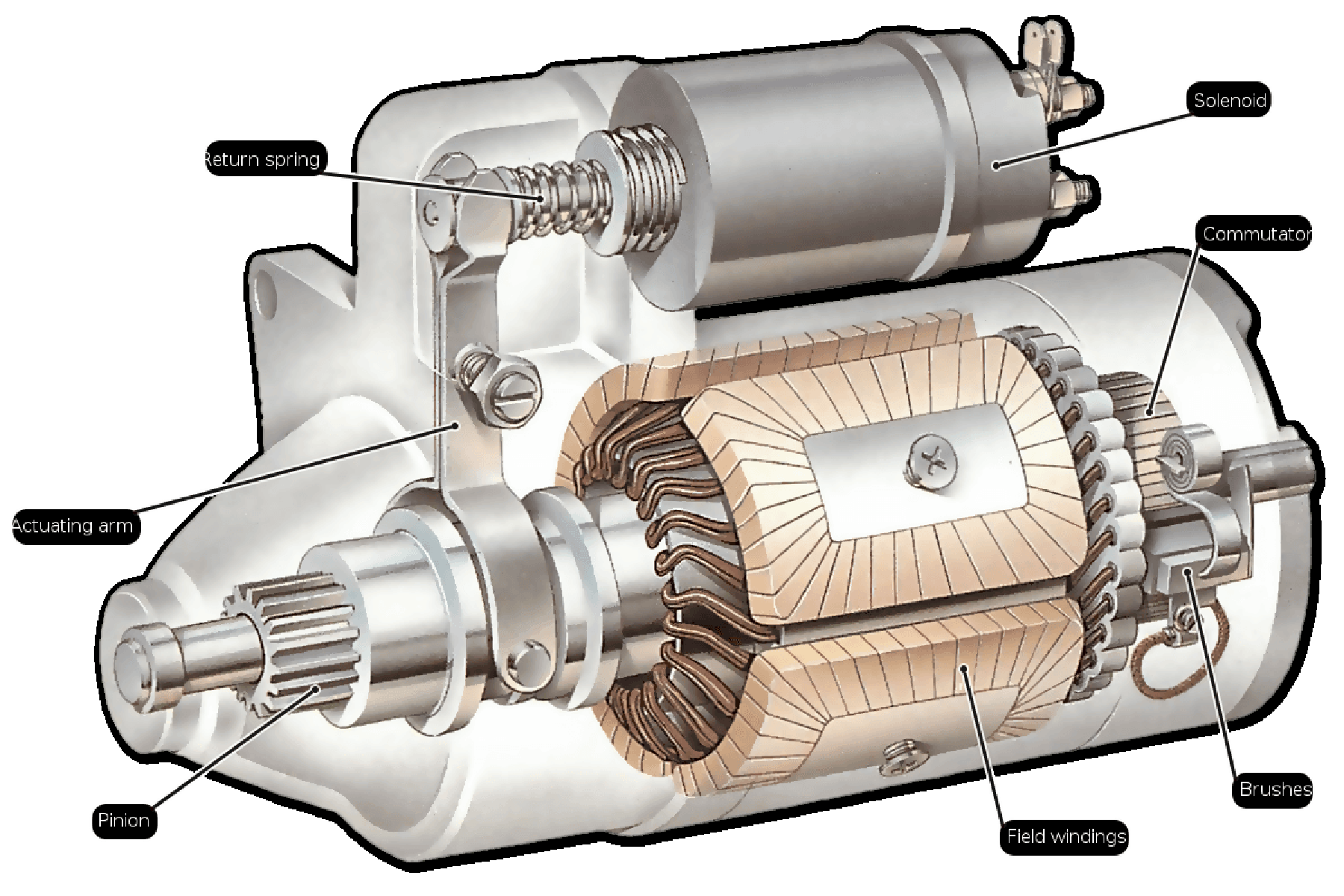

From the factory, your classic Chevy utilized a direct-drive starter to get the engine fired. Direct-drive starter motors have a straightforward design. The armature and the Bendix drive – which engages the flywheel’s ring gear – are directly connected and positioned in-line with one another. There may be differences in construction, like the use of field coils or permanent magnets within the motor, but the working principle is the same. That all changed in the ‘60s, when Chrysler introduced the gear-reduction starter.

The easiest way to check for proper starter engagement is with a small wire or even a paper clip. With the starter’s pinion gear pulled out, measure the backlash between it and the ring gear. Ideal clearance is roughly 0.020-inch — the width of a paper clip.

Unlike direct-drive units, gear-reduction starters use smaller, faster-spinning motors to rotate the pinion gear at roughly a 4:1 ratio. This results in lower power consumption and higher torque output. When comparing direct-drive and gear-reduction starters, direct-drive units are typically less expensive, and gear-reduction units tend to be smaller, lighter, and more efficient. “When a customer calls and asks for a starter recommendation for their high-compression big-block, I typically go straight to the gear-reduction units,” said Matt.

Also, a gear-reduction starter delivers two huge benefits over direct-drive. One, is that it provides more torque, which is a necessity when an engine utilizes a higher-than-stock compression ratio or significant initial timing. The second benefit involves physical size. A gear-reduction starter is much smaller. Tight header clearance, wide-sump oil pans, and engine swaps where space is limited, can benefit from the smaller-size of the gear-reduction starter.

Suggested pinion clearance is roughly 1/16-inch. If the clearance is too tight, the ring gear might scrape on the pinion gear and cause damage.

Tips For Choosing A Tuff Stuff Starter

Choosing a starter can be confusing, but before you can even begin, first, you need to determine the starter type your engine requires. Tuff Stuff has two starter styles, the full-size, OE-type direct-drive starters that features copper coils, and the smaller, lighter, gear-reduction starters.

If you have an engine with a stock compression ratio, or simply want the look of a stock engine turner, the OE-style starter is a good choice. If you have a high-compression engine, a gear-reduction starter would be the better choice. Besides providing considerably more torque, most Tuff Stuff gear-reduction starters can be rotated in relation to the engine-mounting block to provide additional clearance for headers and deep-sump oil pans.

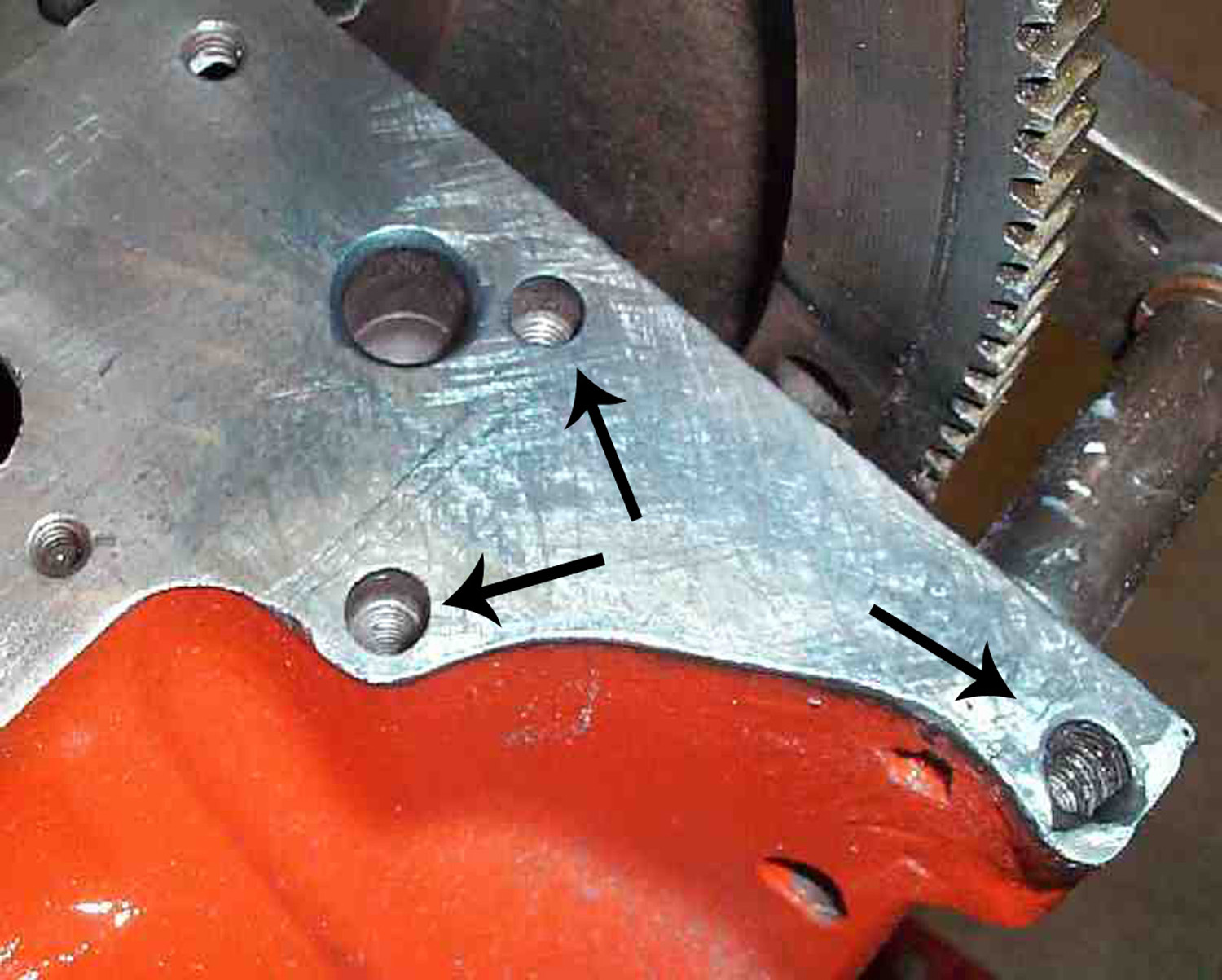

Chevy engine blocks have provisions for two mounting-style starters. If the bolt holes in the starter nose are parallel to the crankshaft, your car uses a 153-tooth flywheel/flexplate. If the bolt holes are offset/staggered, the starter is for use with a 168-tooth flywheel/flexplate.

Installation Obstacles

When installing any starter, it is important to measure the pinion clearance and engagement depth. A standard rule of thumb is to have 0.060 to 0.140-inch clearance from the face of ring gear to the front face of the starter pinion. This should be checked in at least three locations on the ring gear. If not within spec, verify that the ring gear is properly mounted and does not have excessive run-out.

To check pinion engagement with the flywheel, pull the pinion out of the starter to engage the ring gear. This can be done by using a small pick-tool to pry the pinion out of the starter, or by connecting a 12-volt source to the S (switch) terminal only. Do not connect the battery cable to the BAT terminal on the starter solenoid. A word of caution, do not engage the solenoid like this for more than 30 seconds at a time while checking clearance, as the solenoid will overheat.

Another aspect that needs to be verified, is proper backlash between the ring gear and starter pinion. There should be 0.020 to 0.025-inch clearance measured from the flank of the starter pinion to the flank of the ring-gear tooth. A paper clip works well. Again, check clearance in at least three places on the ring gear. If the clearance is too small, add shims. Tuff Stuff has both instruction sheets and videos to show you how to properly set the clearances.

Final Thought

Many times, a hard-start condition is blamed on the starter, when in fact, the wiring is the culprit. If there are any wiring issues – like damaged or undersized cables, or missing ground straps – the starter will crank slowly or not at all. The starter needs a good ground. The starter mounting surface needs to be clean, free of any dirt, paint chips, or grease.

Hopefully, this outline for selecting a starter can help you, and for easy product selection, visit the Tuff Stuff website and use the Year/Make/Model lookup. There, you can also find installation instructions, product dimensions, a dealer locator, and a whole lot more. You can even give them a call at (800) 331-6562.