With all the talk about the new mid-engine C8 Corvette, we thought we’d add to the cacophony with a little more information about the new, naturally aspirated LT2 engine. The LT2 is a great GM Regular Production Option (RPO), since it is more of a continuation of the LT1, but the C8’s mid-engine configuration has demanded enough changes to make the story interesting. Here’s what we know.

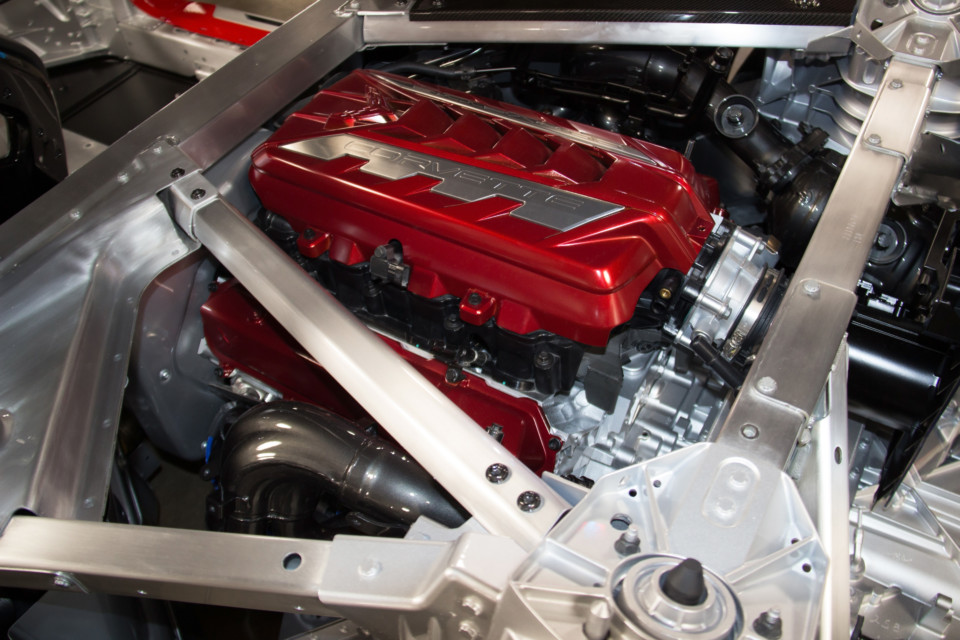

The headline is, there are actually two different LT2 engines available for the new C8. However, the only difference between the two configurations is whether you opt for the high-performance, tubular exhaust system. This package pushes the peak horsepower to 495 horsepower at 6,450 rpm with torque increasing to 470 lb-ft. The standard exhaust package only loses 5 horsepower and 5 lb-ft of torque. In reality, there’s little sacrifice other than the visual impact, since those equal-length headers are right there near the top of the engine where God and the world can see them.

Beneath the Glass

The LT2 retains the basic LT1 short-block configuration with its 11.5:1 compression ratio, forged crank, hypereutectic pistons, piston squirters, and gasoline direct injection. But there have been some changes along the way. The 25-horsepower improvement can be traced to several responsible areas. While we don’t have specific cam timing figures, it appears the intake is roughly the same as the LT1, but the exhaust gets a slight boost in valve lift, which helps support the additional peak horsepower.

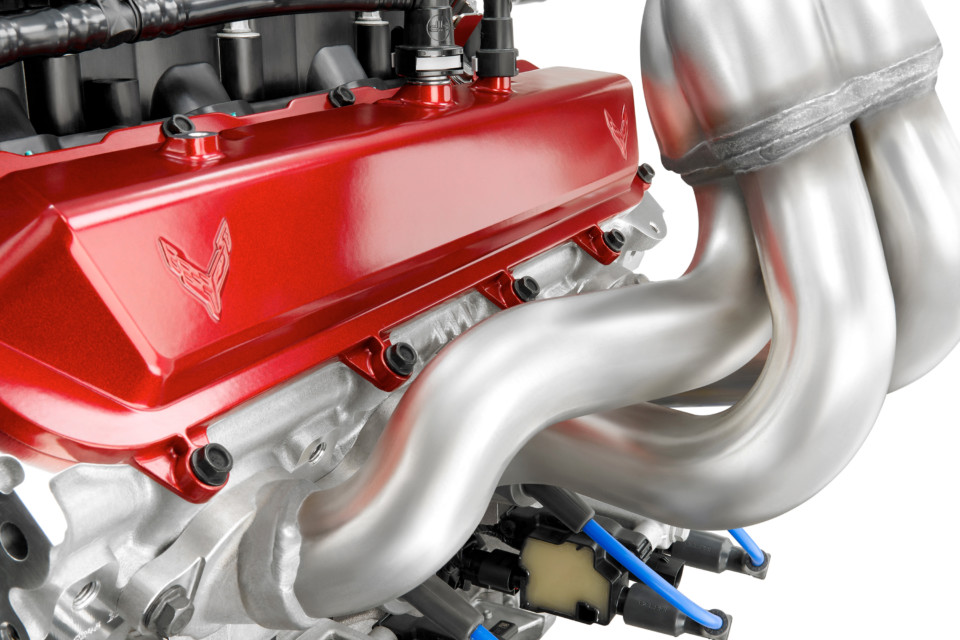

With its mid-engine configuration, the symmetrical intake port design — which goes all the way back to the first LS1 — makes it easy to merely spin the intake manifold around 180-degrees to point it toward the rear of the engine. The LT2 intake is also taller and sports equal-length intake runners. Combined with the equal-length tubular exhaust, these factors could be the primary contributor to the added 25 horsepower.

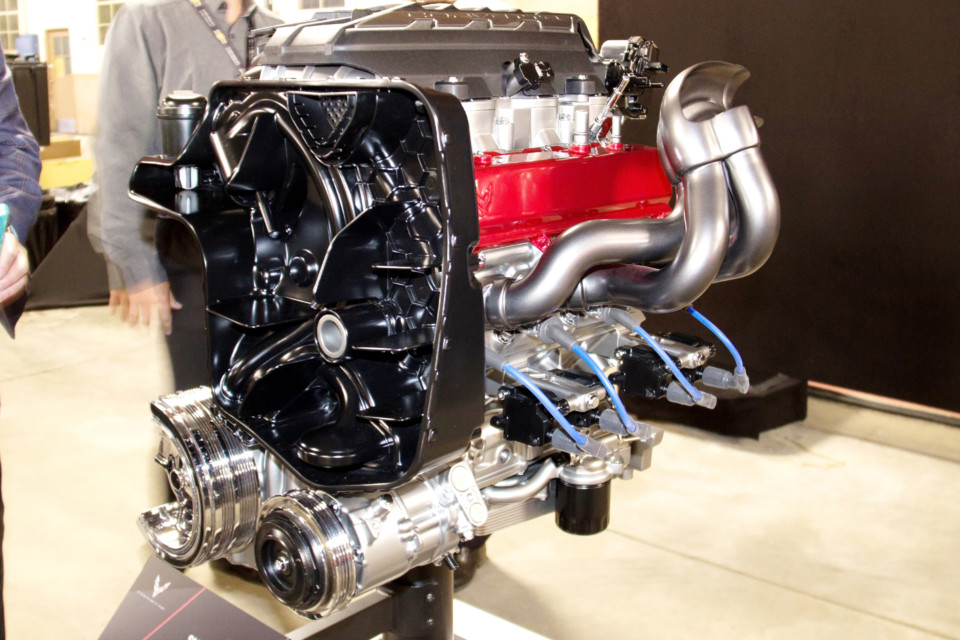

With the LT2 sitting behind the driver, the intake is rearward facing. That red cover hides the intake but we know it is taller than its predecessor, with the addition of equal-length runners to complement the power curve.

Keep in mind these power and torque numbers are rated based on the SAE J1349 correction factor. This horsepower and torque rating system has been in place for roughly 30 years. It uses a much higher air temperature and lower atmospheric pressure factor than the much older standard correction factor that the aftermarket uses.

| LT1 (A) | LT1 (B) | LT2 (Standard) | LT2 (Z51) | |

| HORSEPOWER | 460 | 465 | 490 | 495 |

| TORQUE (LB-FT) | 455 | 460 | 465 | 470 |

This is an important point because if all we did was apply the older standard — or “hot-rod” — correction factor to the LT2, the power would immediately increase by roughly four-percent. This pushes the J1349 rating of 495 hp up to nearly 515 hp and the torque from 470 to almost 489 lb-ft.

We have some experience with the earlier LT1 engine on the dyno. With just headers and an electric water pump instead of the full accessory drive, this engine immediately made over 505 horsepower and almost 510 lb-ft of torque on Westech Performance Group’s SuperFlow dyno. The OEM J1349 rating was 460 hp.

The new power numbers used the standard correction factor, yet still indicated over 40-plus more horsepower than the factory rating system. Part of that is the contribution of the headers and the removed accessory drive. All of this is just to give you a better idea of how much power this new engine can create.

The optional Z51 performance package delivers (among other desirable items) the four-into-one stainless steel equal length headers that no C8 should be ordered without. The standard iron manifolds will be of the 4-2-1 arrangement.

It’s Now A Dry County

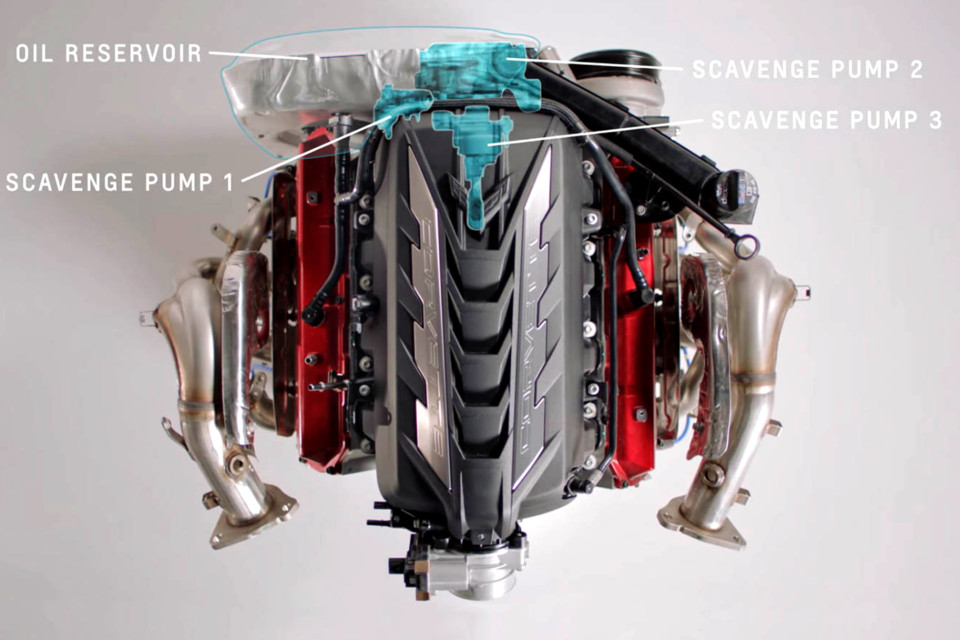

The new LT2 is also equipped with a dry sump as were earlier-version Corvette engines, but with several interesting twists. Most importantly, the dry sump system allows the engine to sit a full inch lower in the car. That inch has a dramatic effect on the car’s center of gravity. The older dry sumps used only the existing oil pump to pull oil out of the engine, while the LT2 adds two additional scavenge pumps in the crankcase and in the lifter valley.

This essentially becomes race-engine-like and contributes to a measurable reduction in windage inside the engine. Just like an aftermarket multi-stage dry-sump pump system, the factory LT2 system results in power gains. First, by reducing the amount of oil hitting the crankshaft. Second, the two added scavenge stages contribute to reducing internal crankcase pressure and increasing vacuum.

This illustration from a GM video shows the location of all three of the LT2 scavenge pumps. Scavenge Pump 2 is the main oil pump, with Pump 1 positioned in the crankcase. Pump 3 is found in the lifter valley area and prevents oil from draining onto the crankshaft. This reduces windage and lowers oil temperature.

Earlier dry-sump engines, like the supercharged LT4, employed a separate oil tank located adjacent to the engine. The LT2 now employs an integrated plastic oil reservoir located adjacent to the accessory drive on the front of the engine. By improving the scavenging system in the engine, Chevrolet engineers were also able to reduce the overall oil volume of the system. The older LT dry-sump engines required 9.7 quarts of oil while the LT2 demands only 7.5 quarts of 0W-40 GM Dexos synthetic oil.

While dry-sump systems typically reduce oil temperature slightly because of superior oil management, the Chevrolet engineers assume this new mid-engine Corvette will be driven much harder than previous versions. The engine design team added 25-percent to the oil-cooler capacity to compensate for what they expect will be a more challenging application of all that power.

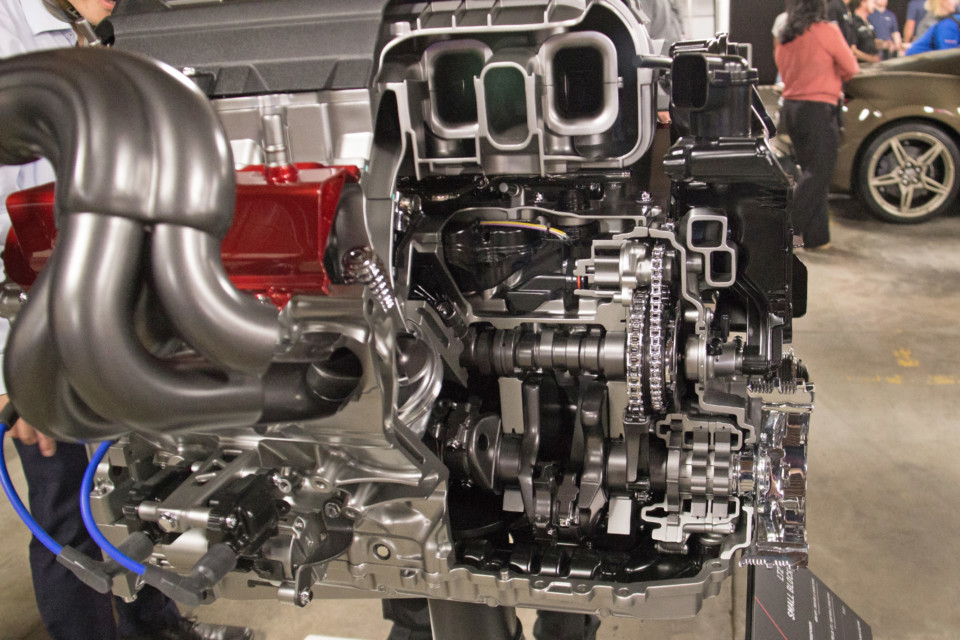

This cutaway photo reveals a second chain driven off the camshaft that operates the lifter valley oil scavenge pump. Also, note the radiused runner inlets in the intake manifold.

Variable Valve Timing and Active Fuel Management

Other continuation features include variable valve timing (VVT) as well as Active Fuel Management (AFM), which were both found on the LT1. The ECU is also a relatively new upgrade using the E99 processor first seen in the C7 ZR1 Corvettes. This more-robust ECU also incorporates what is called over-the-air (OTA) automatic electronic updates.

GM first introduced OTA in May 2019 for the upcoming 2020-model CT5 Cadillac. The robust system can transfer as much as 4.5 terabytes of data per hour. This allows GM to update the software on compatible vehicles automatically. Early indications are, the Corvette’s new E99 ECU will also make aftermarket tuning changes a bit more challenging. It appears some tuning companies have already fought their way into the system, but changes may require swapping the ECU for a modified unit.

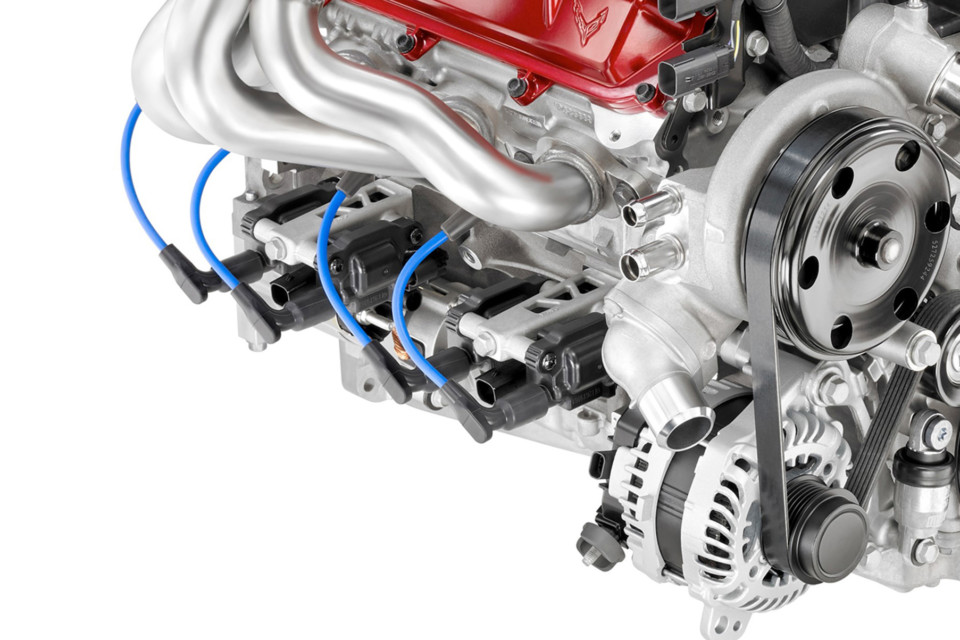

Engineers moved the coils underneath the exhaust and off of the valve covers to minimize heat damage, and also so the plug wires avoid the exhaust headers. This also sanitizes the valve covers for a cleaner appearance.

While some may be disappointed because the click-bait rumors of a DOHC small-block V8 were not substantiated, the reality is probably far better — really. Even with significant vehicle dynamic controls regulating the handling, driving a real-world 500-horsepower, eight-speed supercar promises to be a superlative experience.

The envelope-pushers will immediately begin the process of building a 600- or 650-horsepower naturally aspirated version, and Chevrolet probably already has a supercharged version of the LT2 ready to go once the initial buying frenzy tapers off. A DOHC V8 Corvette engine down the road seems unlikely, but our crystal ball is currently in the shop for software updates.

The performance claims are impressive: 0-to-60 mph times in the sub-three-second range, from a naturally aspirated, pushrod V8 — in a vehicle that likely weighs nearly 3,800 pounds with a driver. Count in all the linear-power finesse of a 500-horsepower engine, able to produce 25 mpg highway numbers and we’re indeed living in the internal combustion golden age.

That large black area on the engine is the dry sump tank that is now much closer to the front of the engine. The A/C compressor is relocated to the driver-side of the engine, below the oil reservoir.

LT2 Spec Sheet

| Displacement: | 6.2 liters (375.4 cubic inches) |

| Horsepower: | 490 at 6,450 rpm (with iron manifolds), 495 at 6,450 rpm (with tubular manifolds) |

| Torque: | 465 at 5,150 rpm (with iron manifolds), 470 at 5,150 rpm (with tubular manifolds) |

| Block: | Cast A319-T7 aluminum, iron cylinder liners, steel main caps |

| Compression Ratio: | 11.5:1 |

| Bore and Stroke: | 4.062-inches x 3.622-inches |

| Cylinder Head: | Cast-aluminum A319- T7 |

| Valve Sizes: | Intake: 2.126-inch, hollow-stem; Exhaust: 1.590-inch sodium-filled |

| Combustion Chamber: | 59cc |

| Throttle Body: | 87mm, electronic |

| ECU: | E99 32-bit processor, 58x reluctor |

| Fuel System: | Gasoline direct-injection, Active Fuel Management, 2,175 psi fuel pressure |

| Redline: | 6,600 rpm |

| Lubrication System: | Dry sump w/ 3-stage scavenge |

| Oil: | Dexos 0W-40 synthetic |