There’s no doubt that the 2013 Camaro 1LE is built for the race track. With a name resurrected from the Chevy performance machine of 1989, the new 1LE package brings the best of both street and race worlds to the already popular fifth-generation Camaro. With that being said, however, there’s always room for improvement on a factory-built car and we were lucky enough to be able to catch a Fluidampr install on a very special 1LE by Cunningham Motorsports recently to prove it.

What You Should Know About Fluidampr Technology

What You Should Know About Fluidampr Technology

Now, there are a lot of choices out there when it comes to harmonic balancers or crankshaft dampers for any given car. You’ve got stock, OEM replacement and the more substantial performance derivatives. What Fluidampr offers with their products are performance components that increase the protection of vital engine components tenfold by protecting across a broad frequency range. This protection is thanks to Fluidampr’s exclusive design and technology.

The point of a crankshaft damper is to reduce destructive crankshaft torsional vibration naturally generated while your engine is running. Stock dampers on cars these days are limited to around just a 50hz peak variance. If your car’s peak variance goes above that, you could be looking at unprotected engine components and damage to vital parts.

“The harmonic balancer directly relates to an engine’s durability and performance,” Fluidampr Sales and Product Development specialist Ivan Snyder told us. “The factory harmonic balancer is a tuned elastomer type. While adequate for mass produced daily drivers (like our car’s LS3 powerplant), tuned elastomer harmonic balancers only reduce the single worst destructive crankshaft torsional vibration peak within a narrow RPM range determined by the factory.”

By adding performance upgrades to your car, such as a camshaft swap, or even something as simple as an engine tune to allow higher revs, the chances of increasing your engine’s peak variance is high. That’s why on modified performance cars, it is recommended that you exchange the stock harmonic balancer for a more performance-capable unit.

By adding performance upgrades to your car, such as a camshaft swap, or even something as simple as an engine tune to allow higher revs, the chances of increasing your engine’s peak variance is high. That’s why on modified performance cars, it is recommended that you exchange the stock harmonic balancer for a more performance-capable unit.

“Fluidampr is a viscous type harmonic balancer,” Snyder explained. “Viscous damper technology can be found as original equipment on premium super cars from Audi, Lamborghini, McLaren and even Ford. Rather than just focusing on a single narrow peak, Fluidampr protects against a broad range and multiple orders of destructive torsional vibration across the entire RPM range for improved durability and performance. It also provides peace of mind that you’ll retain engine protection when making performance modifications.”

Goodbye Bad Vibes

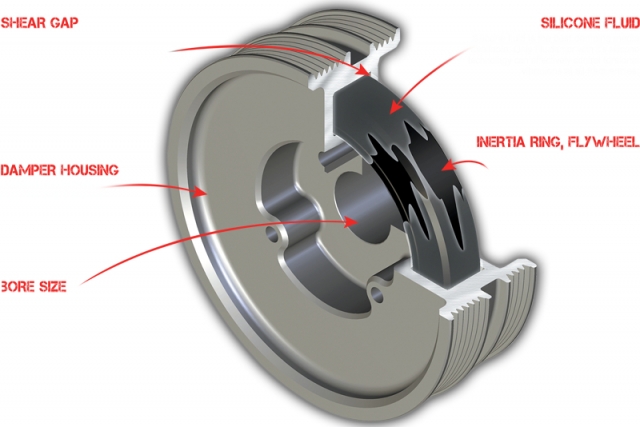

Unlike stock crankshaft dampers, Fluidampr performance dampers protect your engine across a broad frequency range. This ability comes from the unique damper design, featuring a laser sealed outer housing, free rotating inertia ring or flywheel, and a shear gap pressure injected with viscous silicone.

When your engine is running, the Fluidampr housing rotates with the engine’s RPM while the self-centering inner ring is free to move with every jolt of torsional vibration.

As the inner ring moves, it sends the torsional vibration through the special silicone layer, which transforms the vibration into heat. This heat then dissipates through the damper housing.

“Consider a Fluidampr performance damper a basic building block that is going to contribute to durability over the life of the engine, plus unleash lost torque and horsepower,” Snyder told us.

Safety First

Another important feature of the Fluidampr balancer is the fact that it meets SFI 18.1 specifications. Initially created for drag racing sanctions (if you run quicker than 11-flat in the quarter mile, it’s a requirement), but now used across a range of different motorsports, the 18.1 spec calls out some details on how dampers should be constructed and tested for safety.

As you can imagine, a damper that breaks at high RPM would not only tear the crankshaft apart – it would also buzz-saw its way through the engine compartment and anything else unfortunate enough to be in its path. To meet the 18.1 spec, a damper has to endure spinning at between 12,500 and 13,500 RPM for an hour, among other things – far higher than our LS will ever rev.

Prepping The 1LE

Being a performance-built factory car, the Camaro 1LE’s harmonic balancer is already pretty good. But with any good performance upgrade comes the probability of increased torsional vibrations in different frequencies, ones above the peak variance rating of the stock unit.

For the install on the 1LE at Cunningham Motorsports, the Fluidampr upgrade went hand-in-hand with a proposed camshaft install. And with the balancer having to be removed for the cam install anyway, it was a perfect time to kill two birds with one stone.

Upgrading the LS3 with a Fluidamper Performance Damper

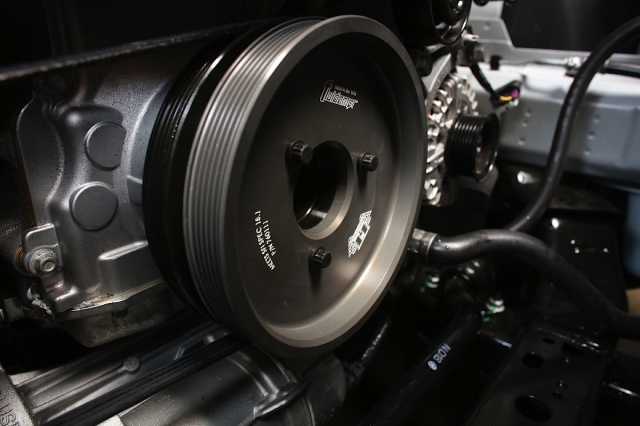

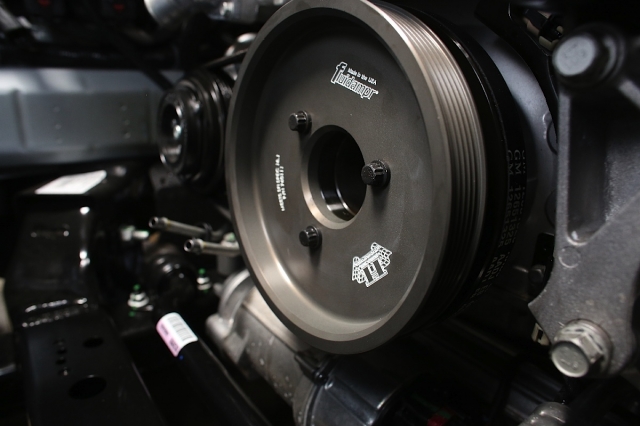

The difference between the stock elastomer damper on the left and the new Fluidampr unit is apparent at a glance. The Fluidampr will be a vast improvement to the Cunningham Motorsports-modified Camaro 1LE.

Diameter Decisions

One choice 5th Gen Camaro owners will face when selecting a Fluidampr balancer is which pulley diameter to choose. While we went with the model that keeps the stock 7 3/4-inch diameter for both belts, they also offer part number 760121 which underdrives the front belt by 25% while keeping the A/C at the stock ratio. Why do it that way? Well, your A/C will automatically cut out at WOT anyway, so there is no benefit to underdriving it…

Following Fluidampr’s recommendations, the 1LE Camaro was set up with a damper specifically for Chevy LS3/ L99 V8 engines with stock pulleys (Part # 760111). With the promise of reduced wear to the main bearings, reduced wear to the timing gear, more accurate valvetrain operation and a lower risk of crankshaft failure, this non-underdrive component seemed to be the best option for the already performance-geared fifth-gen.

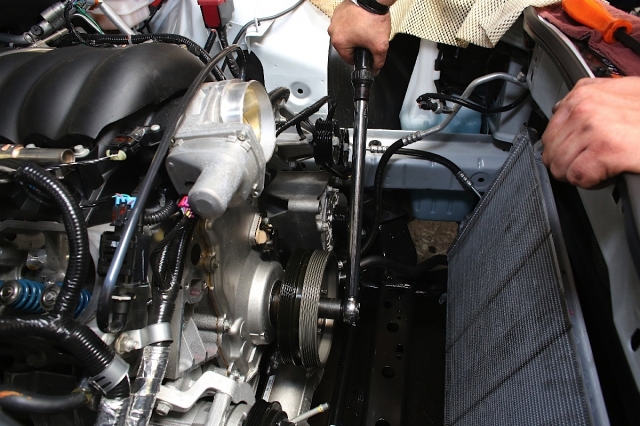

Before Cunningham Motorsports could really get at the Camaro’s stock harmonic balancer, they first had to remove all the components in the way, like the radiator and fan setup.

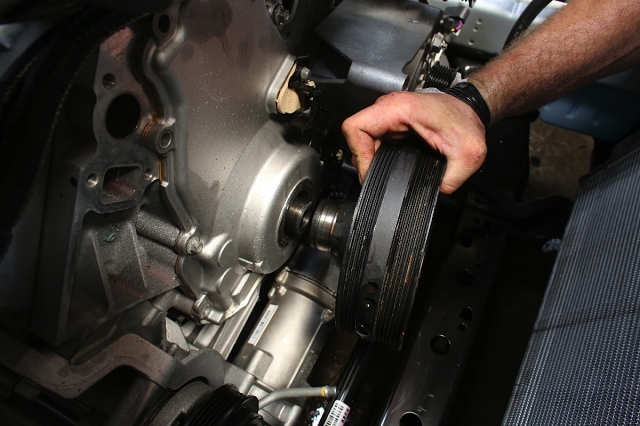

Once all the components obstructing access to the balancer were removed, it was on to removing the accessory belt drive and the A/C compressor drive belt, which Cunningham Motorsports walked off the pulley.

Using a puller, Cunningham then removed the stock damper, making sure to save the stock damper bolt for use in the installation of the Fluidampr unit – more on that in a moment.

Once the old damper was off, the thin metal washer on the back of the stock unit was readily accessible and able to be pulled off for use with the new unit.

Saving the metal washer from the back of the stock harmonic balancer is a vital step in installing your new Fluidampr unit.

After inspecting the crankshaft snout for any imperfections, the guys at Cunningham coated the crankshaft snout and damper inside diameter with an anti-seize compound to prevent any galling during the installation of the new damper.

The thin metal washer, taken off of the old damper, was then put on the back of the Fluidampr hub, where it was checked for being centered and fully seated to the back of the new component.

With the Fluidampr placed on the end of the crankshaft snout, the crankshaft damper installation tool was inserted into the end of the crankshaft. Once the nut on the end of the crankshaft installation tool was tightened down, seating the Fluidampr properly, the installation tool was removed and replaced by the factory bolt taken out of the stock balancer. Torqued to 240 foot-pounds, the bolt is then discarded after the damper is fully seated.

Using a torque wrench, the crew at Cunningham Motorsports then installed a new GM torque-to-yield bolt, torquing it to 37 foot-pounds before using a torque angle meter to tighten the bolt an additional 140 degrees.

Using a torque wrench, the crew at Cunningham Motorsports then installed a new GM torque-to-yield bolt, torquing it to 37 foot-pounds before using a torque angle meter to tighten the bolt an additional 140 degrees.

Once the new Fluidampr unit was fully installed, the A/C drive belt was walked back on to the rear damper and A/C compressor pulleys. The accessory drive belt was then reinstalled, followed by the equipment that was removed initially to access the damper.

What More Could You Ask For?

Completely made here in the USA, Fluidampr products have been race-proven for over 25 years now.

“Fluidampr originated from engine builders requesting to bring the premium, highly durable viscous damper technology, then found in heavy duty industrial and commercial applications, to the motorsports industry,” Snyder explained.

“Fluidampr originated from engine builders requesting to bring the premium, highly durable viscous damper technology, then found in heavy duty industrial and commercial applications, to the motorsports industry,” Snyder explained.

That means a huge advantage for foreign, domestic and diesel truck performance applications, as well as your grass roots all the way up to professional racing teams.

Per Snyder, “Fluidampr performance dampers are maintenance free, never need to be re-tuned with future engine upgrades and are designed to exceed the life of the engine.”

With the Fluidampr crankshaft damper fully seated in the Cunningham Motorsports-modified Camaro 1LE, we can’t wait to see how our upgrades transfer to the track, performance street driving and the overall life of the potent Chevy’s engine. While it’s not a part that has the kind of sex appeal under the hood that you’ll get from a supercharger or set of polished headers, it’s a crucial key to keeping your high-performance LS happy, no matter what you throw at it. Consider it cheap insurance against bottom-end woes in the future…