When it comes to picking a camshaft, your author has zero problems stepping back and letting the pros handle it. However, when you have someone who not only understands all of the variables going into picking a cam profile but is also a great teacher, you don’t let that go to waste. Enter EFI University’s Ben Strader.

There’s no denying that he understands the dynamics of high-RPM engines better than most. So when it came time for us to order the camshaft for our LS5.0 project engine, we turned to Ben, but with a little twist. We thought it might be a good idea for your author to take a shot at picking the camshaft for the engine, and seeing what Strader thought of that selection.

Since COMP Cams has put a ton of time and effort into optimizing its line of Low-Shock Technology camshafts specifically for cathedral-port LS engines, we had a significant variety of off-the-shelf grinds to base our initial decision on. The cathedral-port LSR camshaft lineup offers an even dozen different grinds ranging from 215/223 duration at .050-inch, all the way up to monster 259/267 grinds.

Typically, to go upstairs in RPM, you’re going to need more duration. – Ben Strader, EFI University

COMP Cams has really done a lot of the hard work for LS enthusiasts, with a large number of hyper-specific camshaft grinds in the catalog. For example, there are 12 different LSR cathedral-port-specific grinds available for naturally-aspirated combinations. They even have complete kits that have matched and proven components.

“Something to keep in mind,” Strader starts out, “When you look at the lift of all the lobes within a particular family, they get designed to typically have either a constant velocity or a constant acceleration rate. To do that, as the duration grows, the lift has to grow with it, in order to keep the change in lift and the change in duration consistent. So that’s why when you look at the list, it starts out around .604-inch of lift and ends up about .624-inch, anywhere from like 215, all the way to 267 degrees.”

Before revealing our pick, Strader cautioned, “There are so many variables, and realize that no matter how well you do or how well I think I do, there’s going to be a million guys on the internet that have a different opinion. And that’s perfectly OK. but the reality is at the end of the day, the engine is going to tell you what it wants.”

Picking A Camshaft

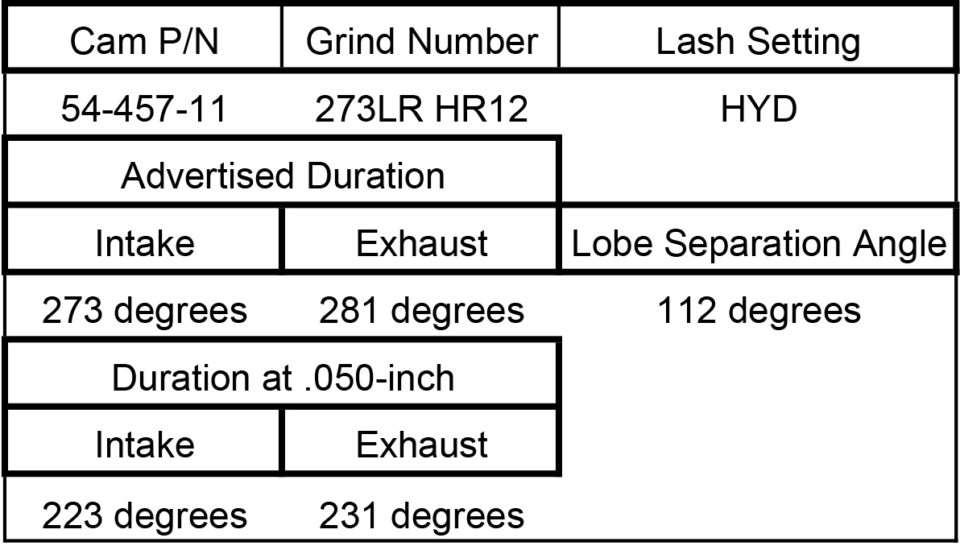

So your author took a stab at it, choosing the 54-436-11, trying to be conservative. The cam features .624-inch of lift at the valve with 247 degrees of duration on the intake and 251 degrees at .050 on the exhaust, with a 114-degree lobe-separation angle. However, that wasn’t the right call.

“I think you would absolutely be in the wheelhouse of what I would be looking for if I was looking at a normal LS engine displacement,” Strader explains. However, LS5.0 isn’t a typical LS displacement. It’s only 305 cubic inches instead of the more common 350-plus cubes.

Even though your author was trying to be conservative when choosing this cam, the math says this is too big for the LS5.0. Strader says this grind would probably be a more fitting choice for a high-RPM LS in the 350-cube range (or as COMP advertises, a more down-to-earth 400-inch combo).

“You have a couple of things happening here. You’re right in that, typically, to go upstairs in RPM, you’re going to need more duration. But one thing I think a lot of people don’t always associate is the idea that the engine is really supply and demand, and you’re using a cylinder head that has been ported. 300 CFM is a ton of airflow from that cylinder head compared to what it flowed from the factory and you’ve made your engine displacement smaller.”

Strader continues the line of thinking, “Typically, as the engine gets bigger with the same cylinder head, I’m going to have to hold the valve open longer to be able to feed it,” explains Strader. “So I think you’re probably in the ballpark on that 247 duration — IF you had a 350- or 370 cubic-inch engine. But, the fact that you’re only building a 300-inch engine — if I’m picking the camshaft, I’m probably going to be considerably smaller than what you’re thinking there.”

That only makes sense, that since the engine is smaller, it demands less airflow from the camshaft than a larger engine to fill the cylinder. “I’m probably going to be in the 223-degree duration range on this camshaft,” says Strader. He also emphasizes that the math suggests this engine would be ok with an even smaller camshaft, but in the real world, there are variables the pure math doesn’t account for.

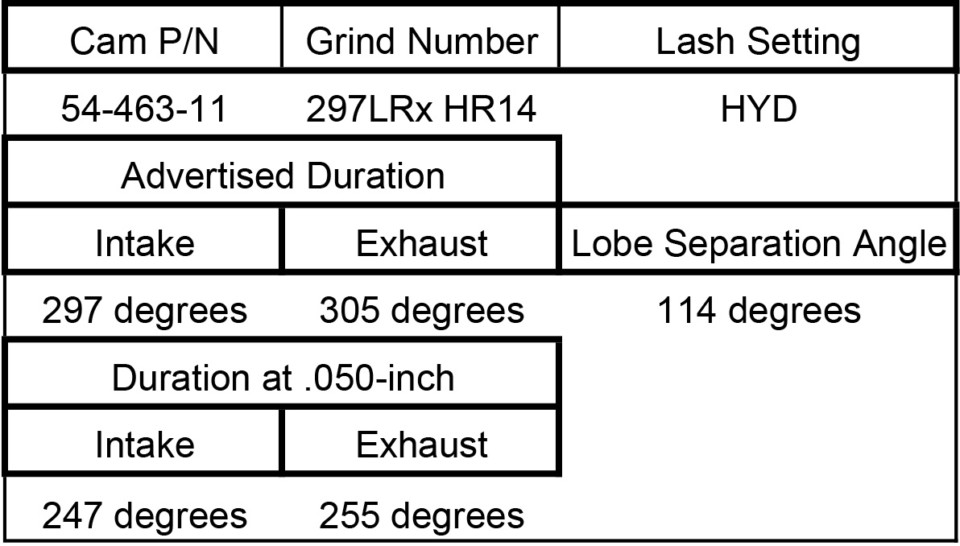

This is the cam that Strader picked and what we’ll be going with (initially, at least). The math actually says this might be a little bit much in a perfect world, but once deflection and real-world physics are accounted for, it’s going to be a solid starting point for the LS5.0.

“One thing I know about these engines from real-life experience is that the duration of the lobe that we put in there is never what the valve actually sees, especially with all the bending and deflection of the pushrod and the rocker arm. So I often tend to step up a number of sizes in the catalog than what my math really suggests,” Strader explains. “In severe applications, where we’re doing tons and tons of RPM, it’s not uncommon to see 10- or 12-degrees smaller duration at the valve than what the camshaft lobe is asking for.”

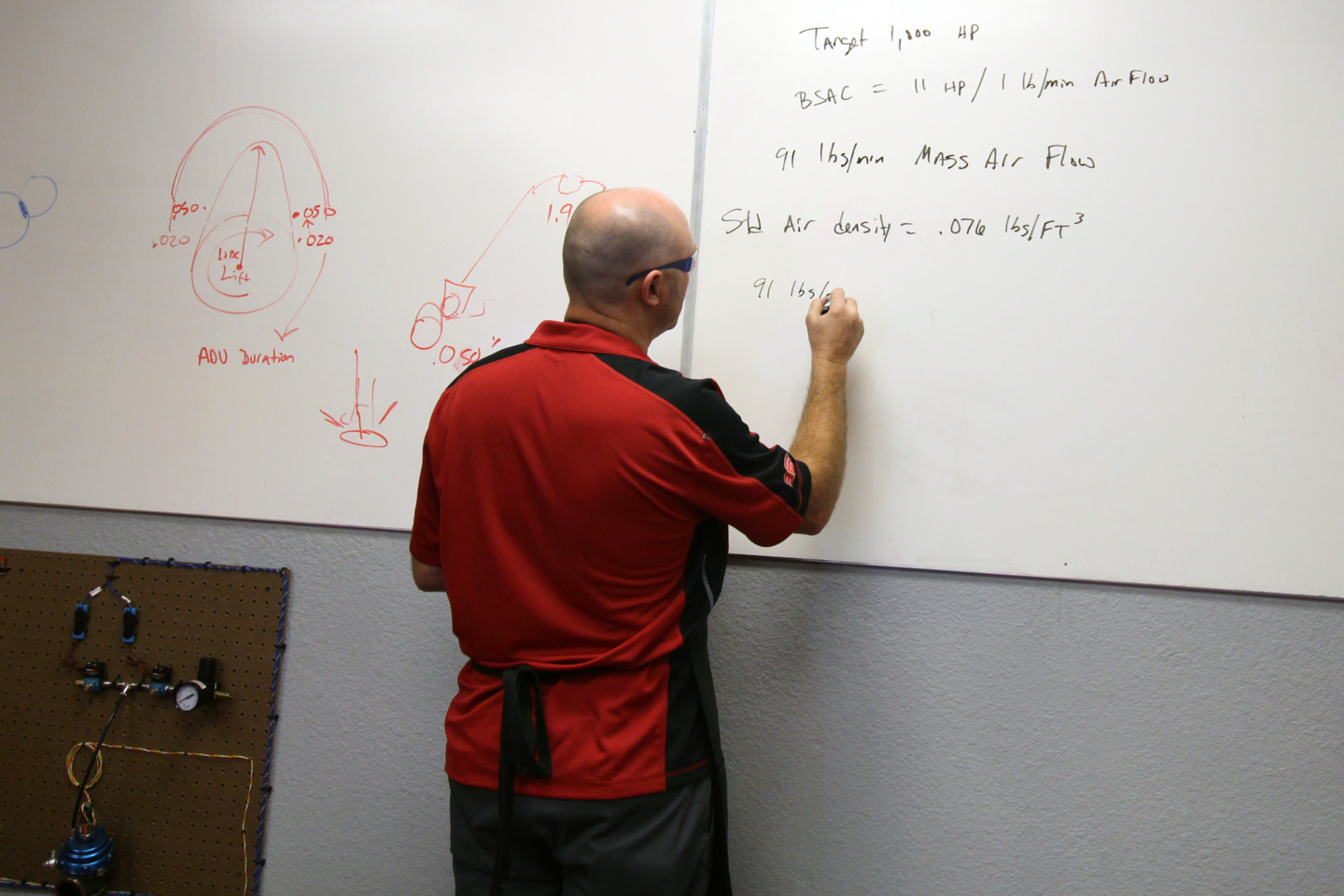

Looking At The Math

Remember, at the end of the day, the engine is a known set of variables governed by the laws of physics. For the most part, we can use math to calculate those physics. “Your engine is 305 cubes and you want a 7,500-rpm power peak, right?” asks Strader as he gets ready to work his magical calculator. “Well, 305 times 7,500, divided by 3456 tells us that the engine needs — I’m going to round here to 662 cfm. Your cylinder heads flow 302 cfm at .600-inch lift. BUT, that’s each port that flows 302 cfm, and you’ve got eight of those. If you take 8 x 302, that means you have a total of 2,416 cfm available.”

With those numbers in mind, we now need to figure out how long the valves need to be open, in order to supply that 662 cfm we need at 7,500 rpm. “The camshaft is the door to the cylinder, allowing airflow in, and it only does that when it’s open. To find out how much air a given duration will allow, we take the duration at .050 and divide it by 720. For the 247-degree cam you chose, that comes to 34.3-percent of the entire engine cycle. So, if you take the 662 cfm required, and divide it by .343, you get a demand of 1,930 cfm.” That’s well under the available 2416 cfm available, meaning 247 degrees is significantly more duration than is needed.

When it comes to engine math, Strader is a wealth of knowledge. It’s almost like he’s a teacher or something…

Strader then runs the numbers for his smaller 223-degree selection. “223 degrees out of 720 is only 30.9-percent of the cycle. I divide that 662 cfm by .309 and then it says that I need 2,100 cfm of total flow. So, even 223 degrees show up as bigger than you actually need. But, keep in mind that what you end up calculating here will be smaller than what the engine really needs.”

Obviously, all of this math assumes a perfect system, and figuring out the system’s imperfections is where experience really comes in handy. “We’re assuming 100-percent volumetric efficiency here, and you’re going to have to account for that bending and deflection of pushrods and valvetrain. Theoretically, you could go all the way down to that 215-degree camshaft, but I think you’re going to find a point where it gets to be too small because we don’t account for the bending and deflection.”

Strader sums it all up for us by saying, “the better the cylinder head is, the less cam you actually need. Or, if you have the same head on a smaller engine, you find out it just doesn’t need to be open as long. We give away so much of the bottom end and we give away so much torque that we could have had for free without sacrificing the top end [by over-camming the engine]. Now, maybe I’m wrong, and maybe this thing wants 275 degrees, but I kind of doubt it. We’ll get this thing on the dyno and you’ll find out exactly what it wants.”

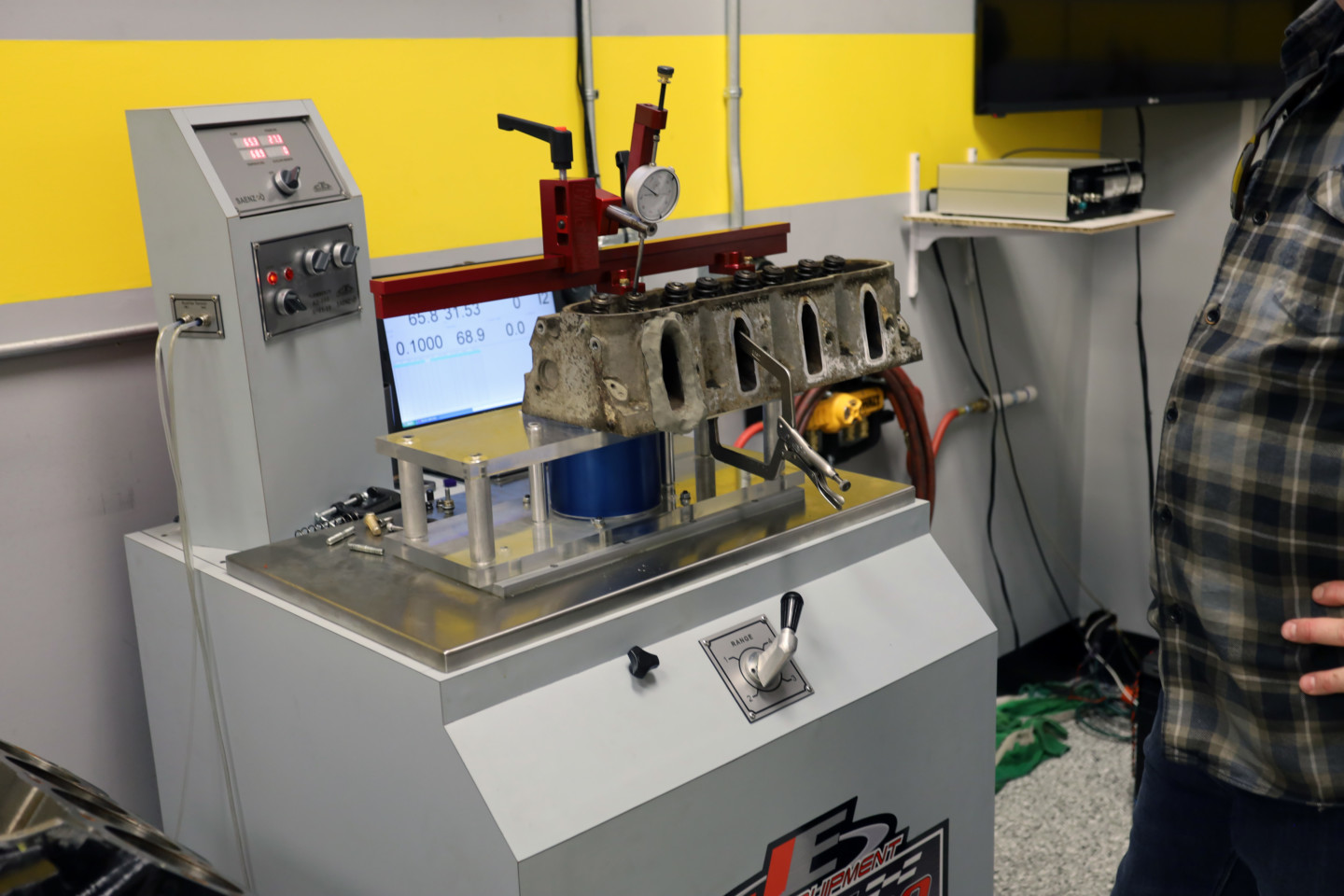

Most of the cam math is ultimately based on the flow capabilities of the cylinder heads. We flowed the stock 799 heads from the core engine and even though they flowed a respectable-for-stock 243 cfm, we opted to send them out to Lingenfelter to get the full CNC treatment. They now flow over 300 cfm at .600-inch of lift.