LS swapping cars and trucks of all makes and models is widespread these days, and for a good reason. The Gen III and IV platforms offer massive improvements over the Gen I small-block Chevrolet architecture. And while it makes sense to swap a Gen I small-block with a Gen III, IV, or V LS engine, does it make sense to do the same with an iconic Gen I big-block?

Several months ago, we had the idea to do an LS swap. However, our vehicle of choice was not the standard car or truck like 99 percent of the swaps out there. So instead, we decided to yank a 489 cubic-inch big-block Chevy out of a boat and replace it with an all-aluminum Gen III LS. You can read more about the project here with the details and what’s involved.

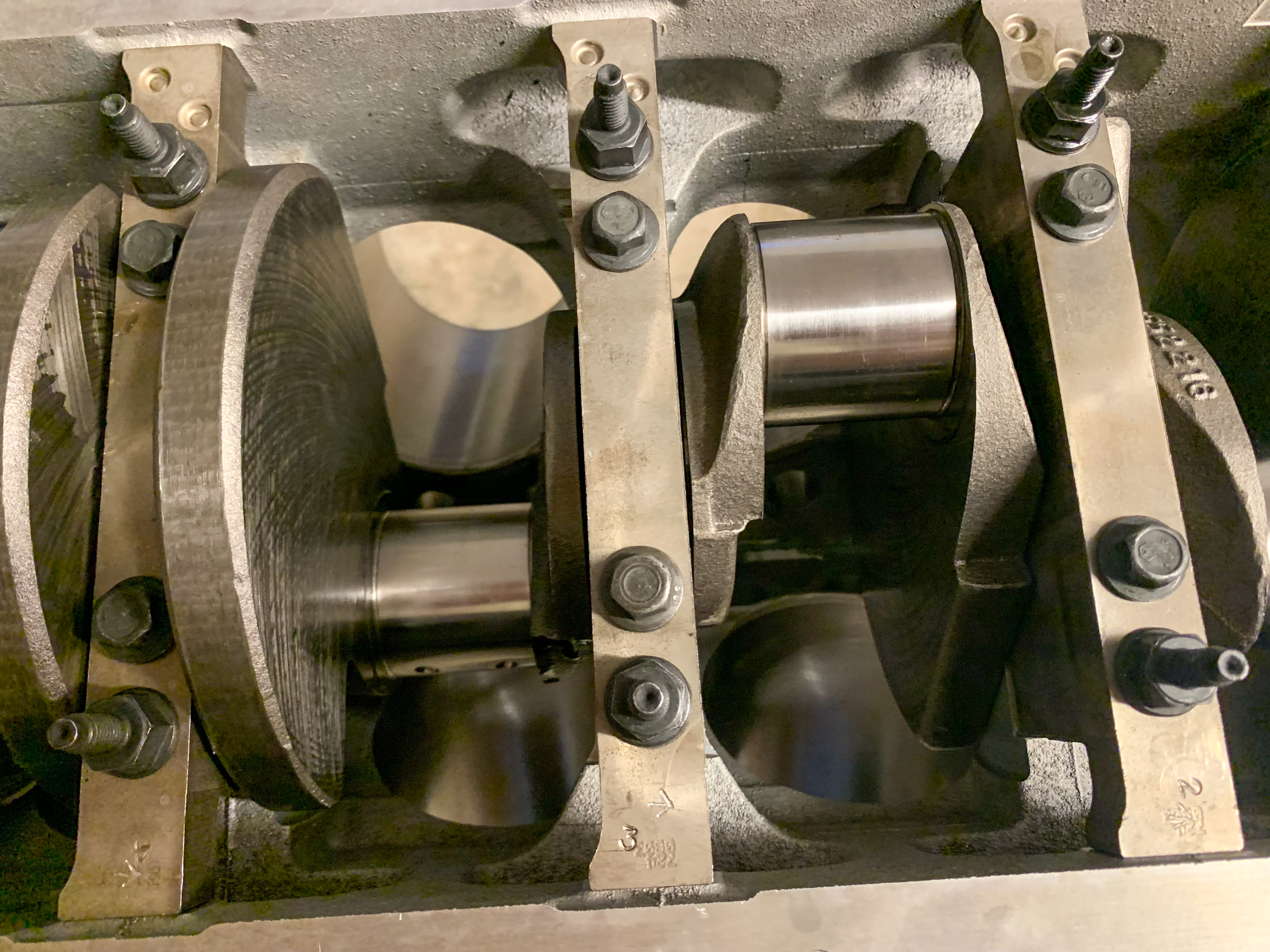

We decided to use a Chevrolet Gen III LS LM4 block to get even more weight out of the boat. The bottom end of our LS is stock other than the use of King main bearings.

In this article, we will cover the engine build before we install the unit for a final time and hit the lake, getting us one step closer to answering our question: is LS swapping a boat a good idea?

The Chevrolet Gen III LS LM4 (LS) engine is popular among car enthusiasts and builders due to its lightweight and affordability. We worked with BoostLine Performance on this build, and Tommy Keeter, the owner of BoostLine Performance, helped us with all of the machining on this unit. The stock displacement of the LS engine is 324 cubic-inches, but Keeter increased it to 350 cubic-inches by using a bore and factory stroke of 3.898 x 3.622. The block used in this build is the elusive all-aluminum Gen III LS LM4. We also opted to keep the stock Gen III LS crankshaft as it is more than capable of handling the power level of this build.

King Bearings’ tri-metal coated products XPNC rod bearings not only look nice, but they also increase the engine’s efficiency.

Starting with the bottom end, we selected King Bearings’ tri-metal coated products XPNC (PN CR807XPNC) on the rods and XPC (PN MB5013XPC) on the mains to ensure the engine’s efficiency. We decided to go back with GM main bolts and the factory connection rods. While we contemplated aftermarket rods, it was really overkill for such a mild build.

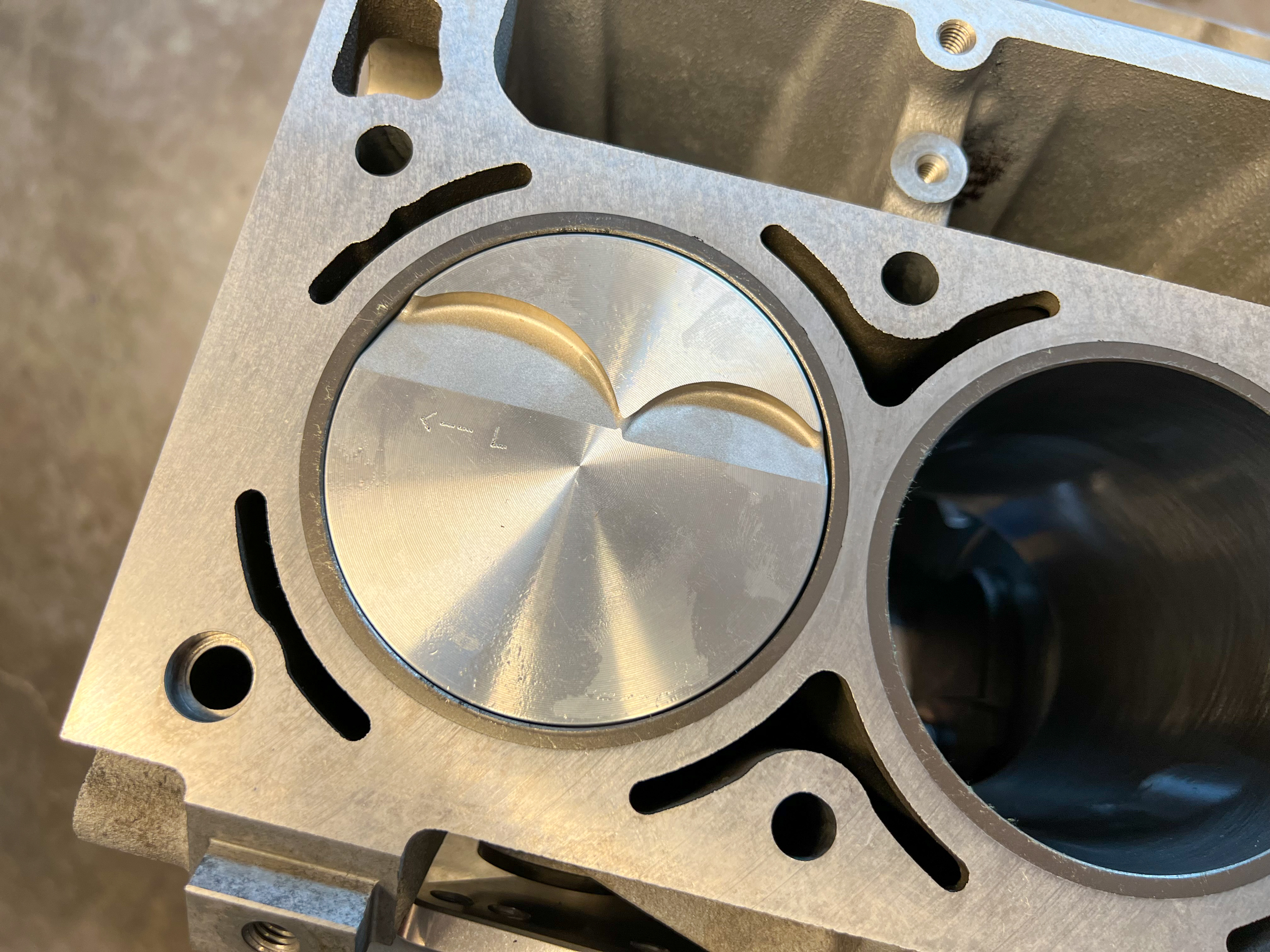

Despite our decision to use the factory rods, we did want a good piston for this build, and ICON’s forged FHR Series fits the bill. The ICON Forged FHR Series pistons are a great option for budget-minded engine builders who want a high-quality piston. These pistons are made from 11 percent silicon 4032 aluminum, which is a strong and durable material that can withstand the rigors of high-performance engine use, making them perfect for this build.

Adding to the engine's efficiency, we used Total Seal's gapless gas-ported ring set.

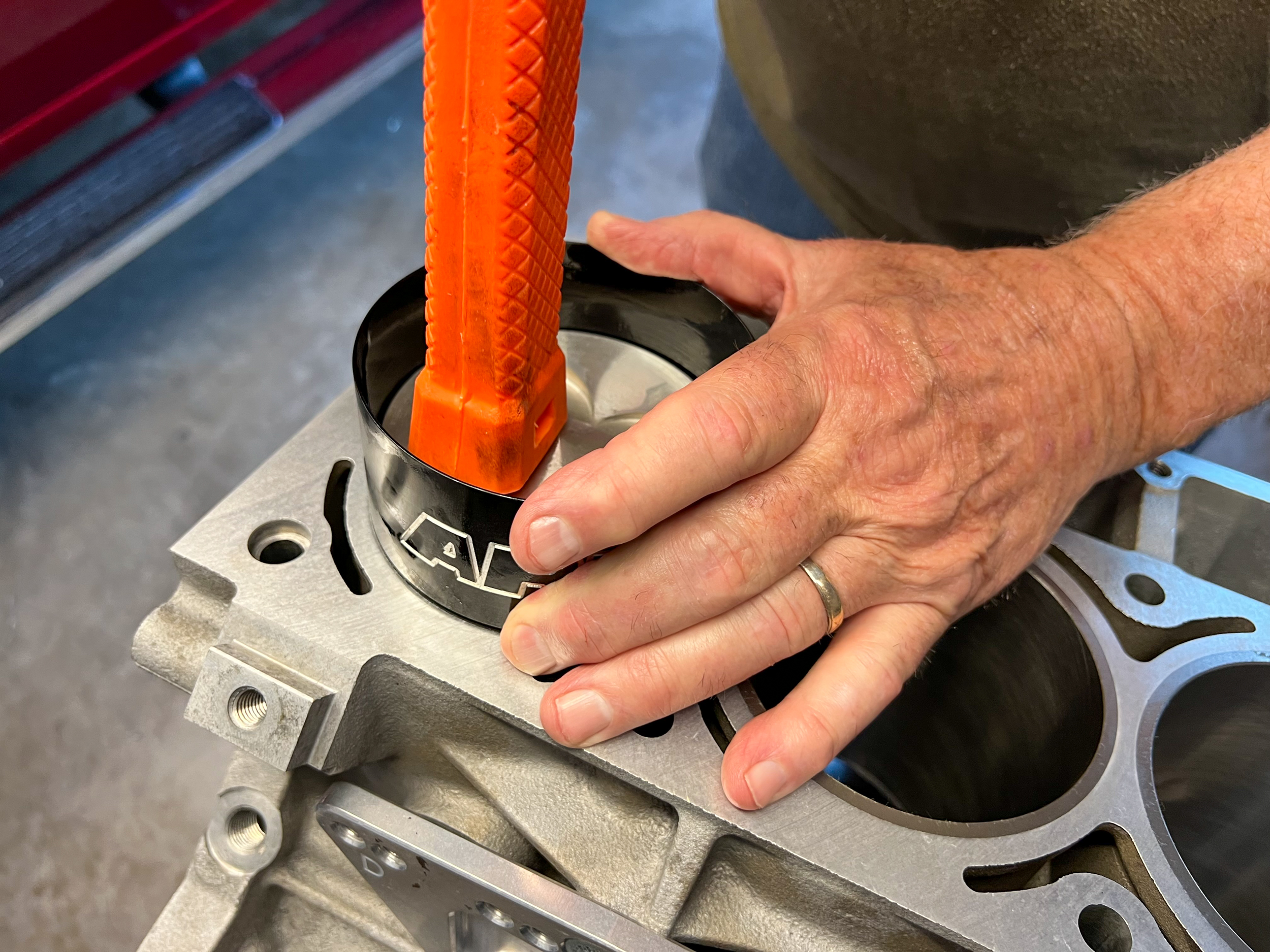

The ICON forged pistons offer .945-inch wrist pins and a +3.2cc dome. These pistons combined with 799 heads result in a compression ratio of 10.67:1. To seal the combustion chamber and reduce friction, Total Seal gas-ported and gapless rings were used in sizes 1.5mm, 1.5mm, and 3.0mm. You can read more about the ring technology here. We then opted for an ARP tapered ring compressor to coax the pistons within the cylinder walls of the freshly bored block.

ARP's tapered ring compressor makes installing pistons a snap.

The camshaft used in this build is from Brian Tooley Racing (BTR) with the PN BTR-LS3STAGE1. It has an intake valve lift of .612 inches and an exhaust valve lift of .604 inches, with a lobe separation of 114.1 degrees. The lifters used are BTR OEM replacements in conjunction with the company’s pushrods.

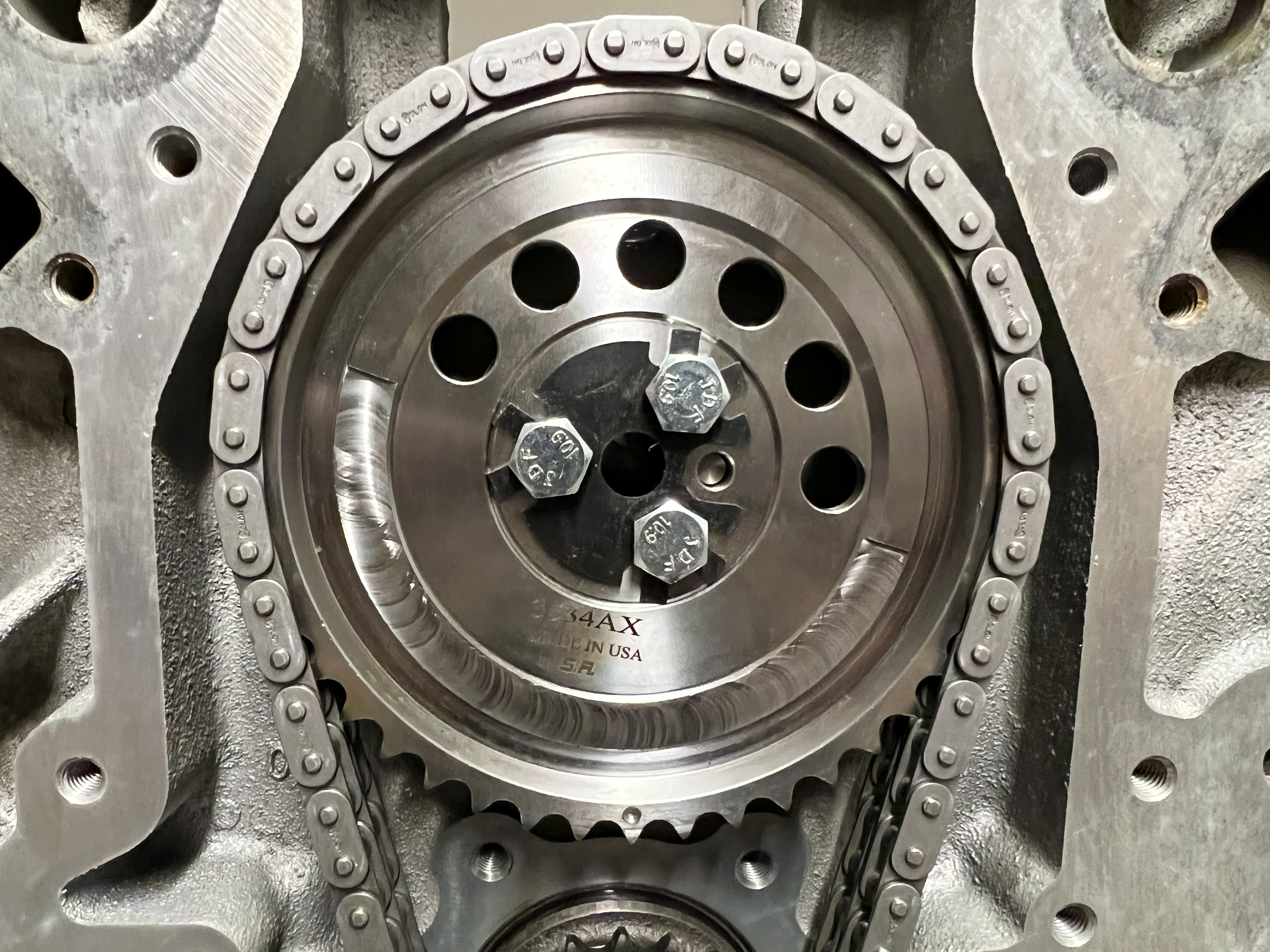

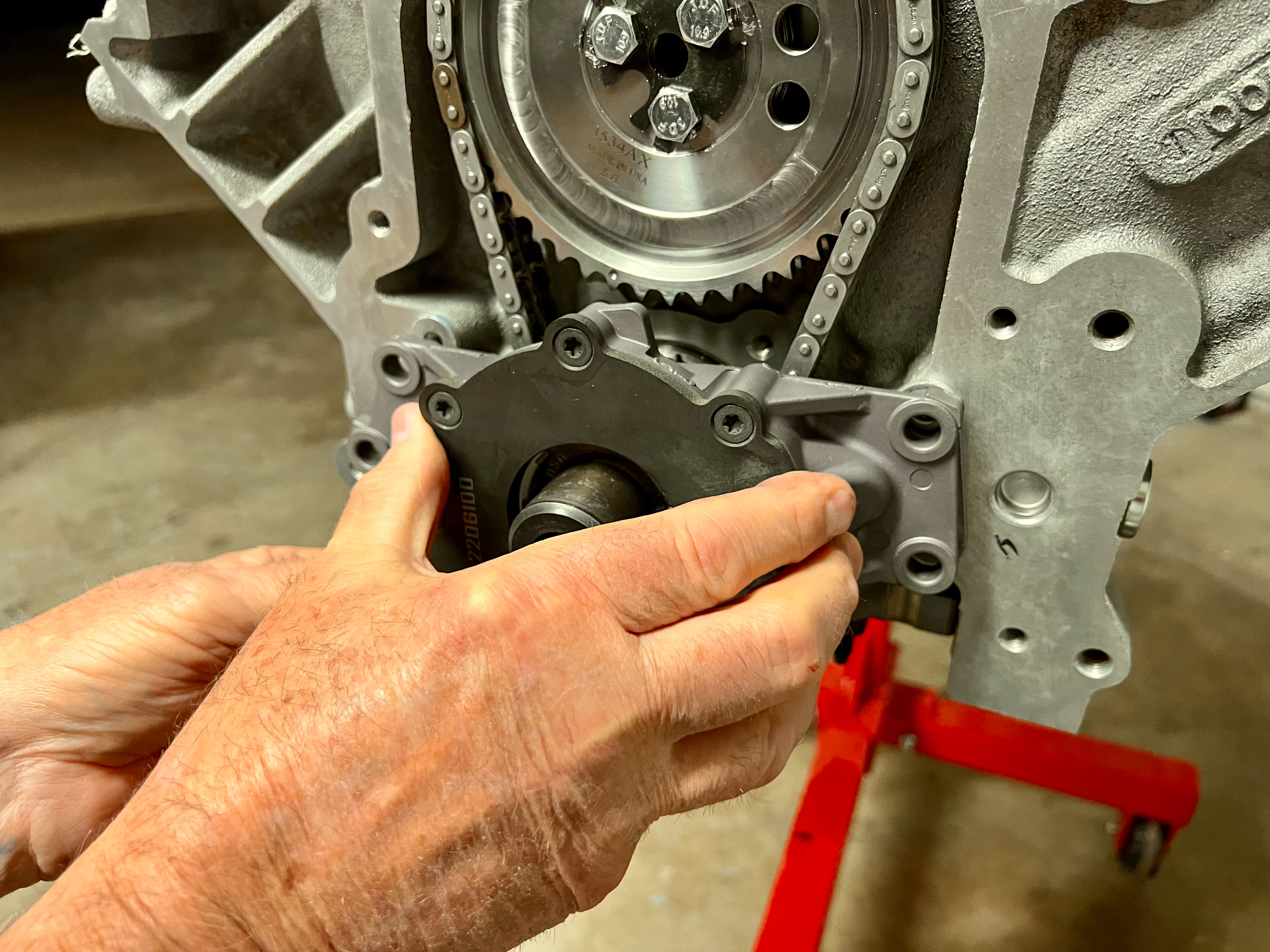

The timing set used in this build is the Melling Timing set (PN 48561T-9) and camshaft lock plate (PN 5461-LPK). Reliable oiling is essential on any engine. So, we chose a Melling oil pump (PN 10295) to ensure the engine has a steady supply of black gold as we rip across the lake. In addition, a Holley GM LS swap oil pan in Carbon Black Ceramic with a pickup tube (PN 302-1BK) will keep the oil at bay in case we hit rough water.

We used a Melling timing set, oil pump, and Holley oil pan to finish up the bottom end of our LS.

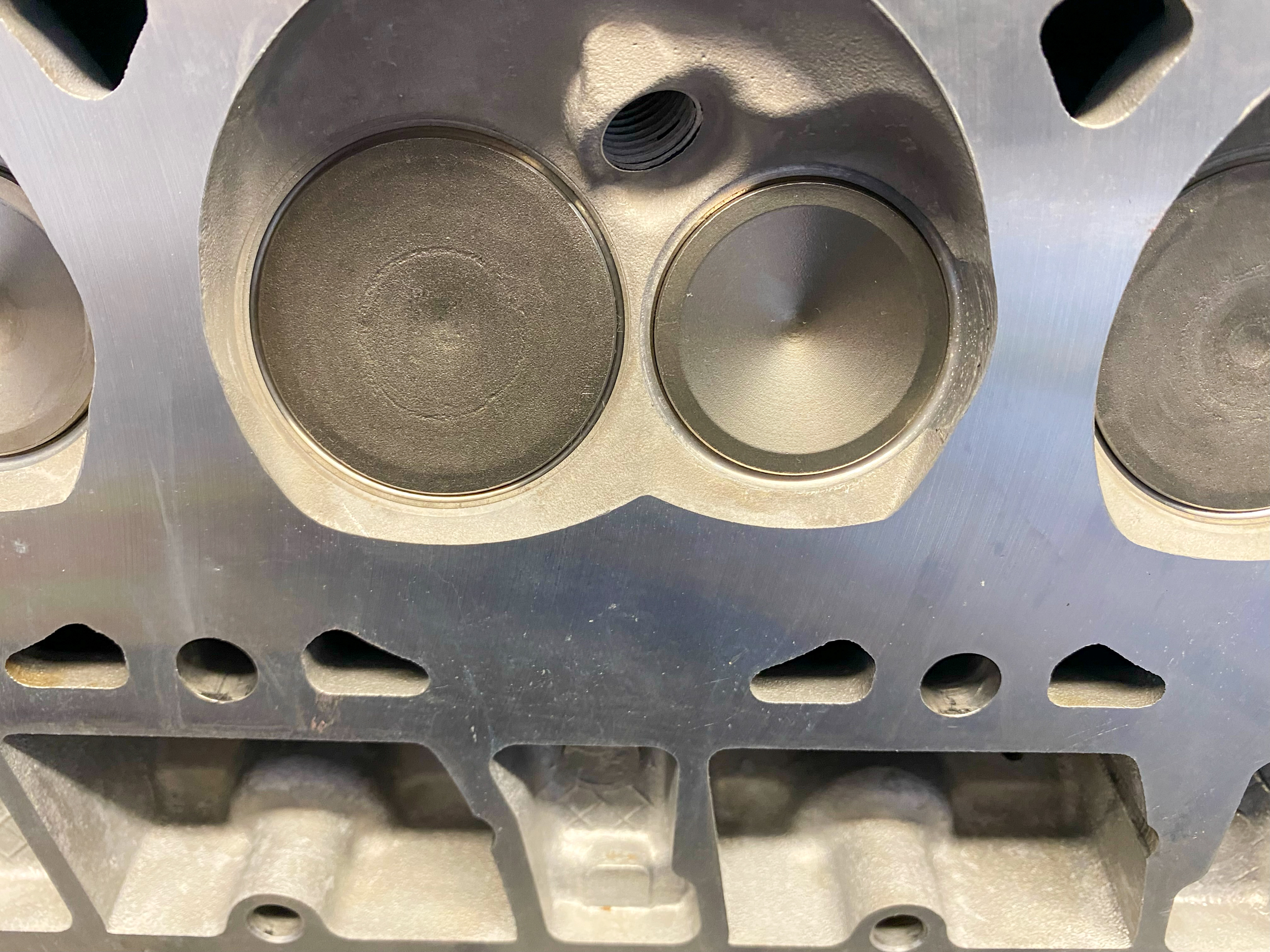

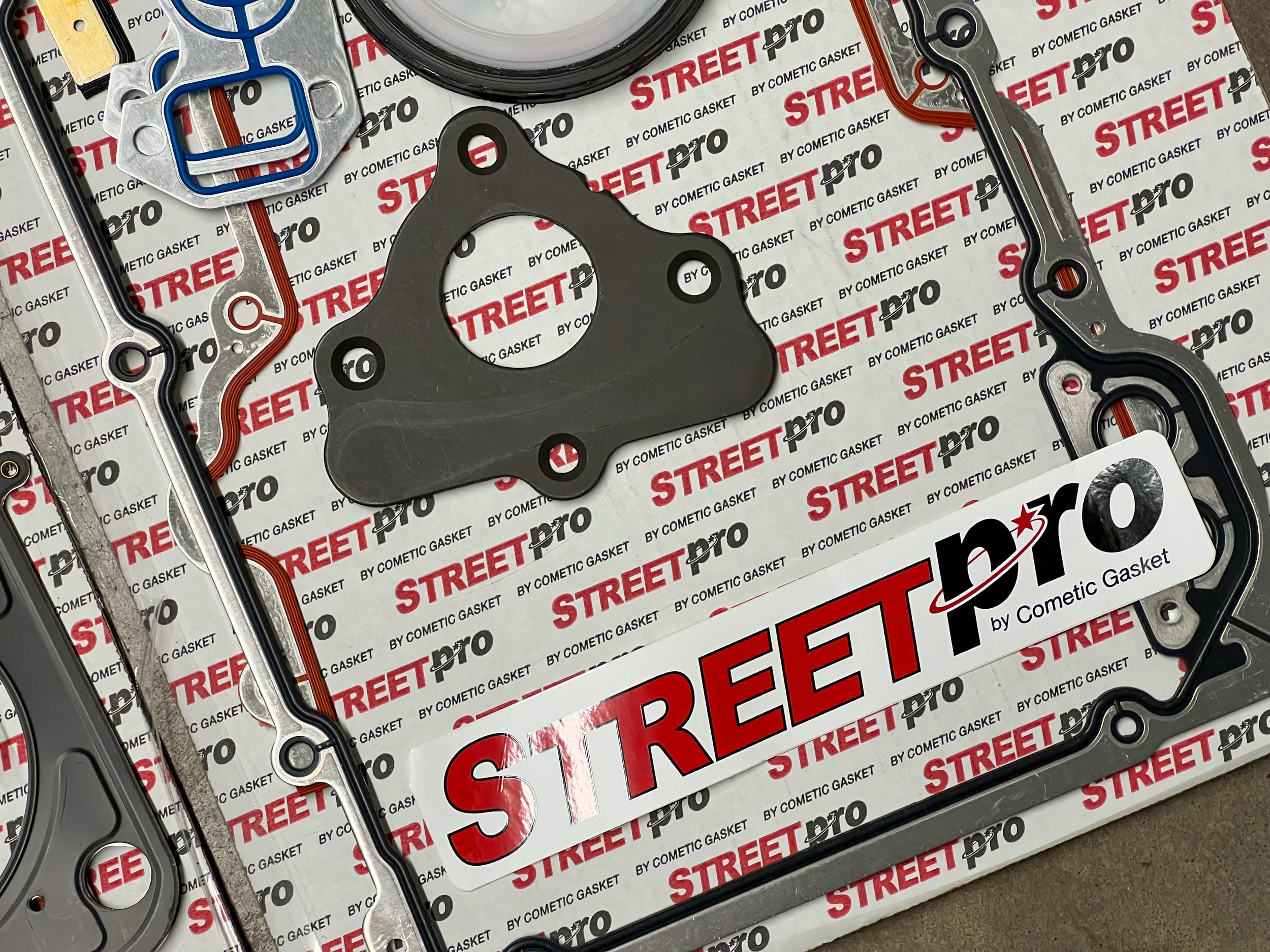

The cylinder heads used in this build are 799 LS heads, which are known for their high flow rate and good performance. The exhaust valves used are Melling intake valves (PN V1935) with a diameter of 1.55 inches, stem size of .313 inches, and length of 4.920 inches. The intake valves are also Melling, with a diameter of 1.890 inches, stem size of .313 inches, and length of 4.880 inches. We had BoostLine Performance resurface the heads and complete a valve job upon reassembly. To ensure that the valves open and close smoothly, Brian Tooley Racing (BTR) Beehive valve springs were installed. The heads were then installed with Cometic MLS head gaskets using ARP head studs. In fact, all of our gaskets on this build were from Cometic. Their Street Pro gasket sets (PN PRO1007T-3910-040) and (PN PRO1036B) include every gasket needed for a bottom- and top-end LS rebuild.

Melling lifters were installed before we outfitted our engine with ARP head studs and Cometic gaskets.

Melling factory replacement rocker arms (PN MR1341) are more than adequate for this build and won’t break the bank. With the cam and valvetrain in place, we used ARP’s LS 12-point stainless steel fasteners set (PN 534-9505) to attach the front and rear covers, oil pan, valve covers, and coil brackets. ICT Billet‘s Gen III LS valley cover (PN 551629G) was installed as well to button up the long block.

Melling replacement rockers were used to keep tension on the BTR Beehive springs. We then used ARP's LS fastener set to clamp down the LS parts.

To ensure that the engine has a steady supply of fuel and air, we used a Holley 750 CFM marine carburetor (PN 0-80537), which will bolt to Holley’s Dual Plane Intake (PN 300-130BK) in black, of course. One of the key considerations for marine carburetors is their ability to withstand the unique challenges of the marine environment, such as moisture, vibration, and exposure to saltwater. The marine carburetor is built to handle these conditions, incorporating corrosion-resistant materials and special coatings to protect against rust and deterioration. This ensures the longevity and reliability of the carburetor in marine applications.

Holley's black ceramic dual-plan intake manifold will work great in conjunction with the Quick Fuel marine carburetor. You can also see ICT Billet's valley cover peaking out from under the intake manifold which is quite an improvement over the factory GM unit.

The ignition system used is the Holley Red MSD LS Ignition Control (PN 6014) with Performance Distributor SOS coils bolted to ICT’s coil brackets and Livewire spark plug wires connected to NGK TR55 sparkplugs. The fuel pump used is a Holley 110 gallons per hour (GPH) Blue electric fuel pump (PN 712-802-1) with a regulator designed for carbureted marine applications compatible with gasoline. We plan on using good ole 93 pump gas as fuel on this combination, which should be plenty of octane for our build.

You can never have too much spark, so we opted for Performance Distributors Sultan Of Spark LS coils and the company's LiveWire spark plug wires as well.

There’s nothing worse than an engine that won’t start, especially at the boat ramp. So, we turned to Powermaster Motorsports, who recommended its XS Torque starter for the LS. XS Torque starters are known for their efficiency and robust motors capable of generating 200 lb-ft of torque. Paired with a 4.4:1 gear-reduction ratio, these starters provide consistent and reliable cranking power, even for engines with up to 18.0:1 compression ratio. To ensure durability, these starters come equipped with a billet adapter/mounting block, and they’re designed to clear the LS oil pan, just like the original starter.

Powermaster’s XS Torque is rated up to 18:1 compression so we will never have an issue getting our moderate LS to turn over.

With the engine buttoned up, we turned our attention to the exhaust. Unfortunately, as you may or may not know, there are no economical solutions for LS-swap boat headers on the market. However, we did manage to score a set on Facebook Marketplace. The units we found are water-jacketed marine headers and, much to our surprise, equipped with catalytic converters and O2 bungs, which will play a part when we get to the second part of our plan in the future, fuel injection and forced induction.

We thought we had the exhaust pointed in the right direction. However, we would find out later that is not the case.

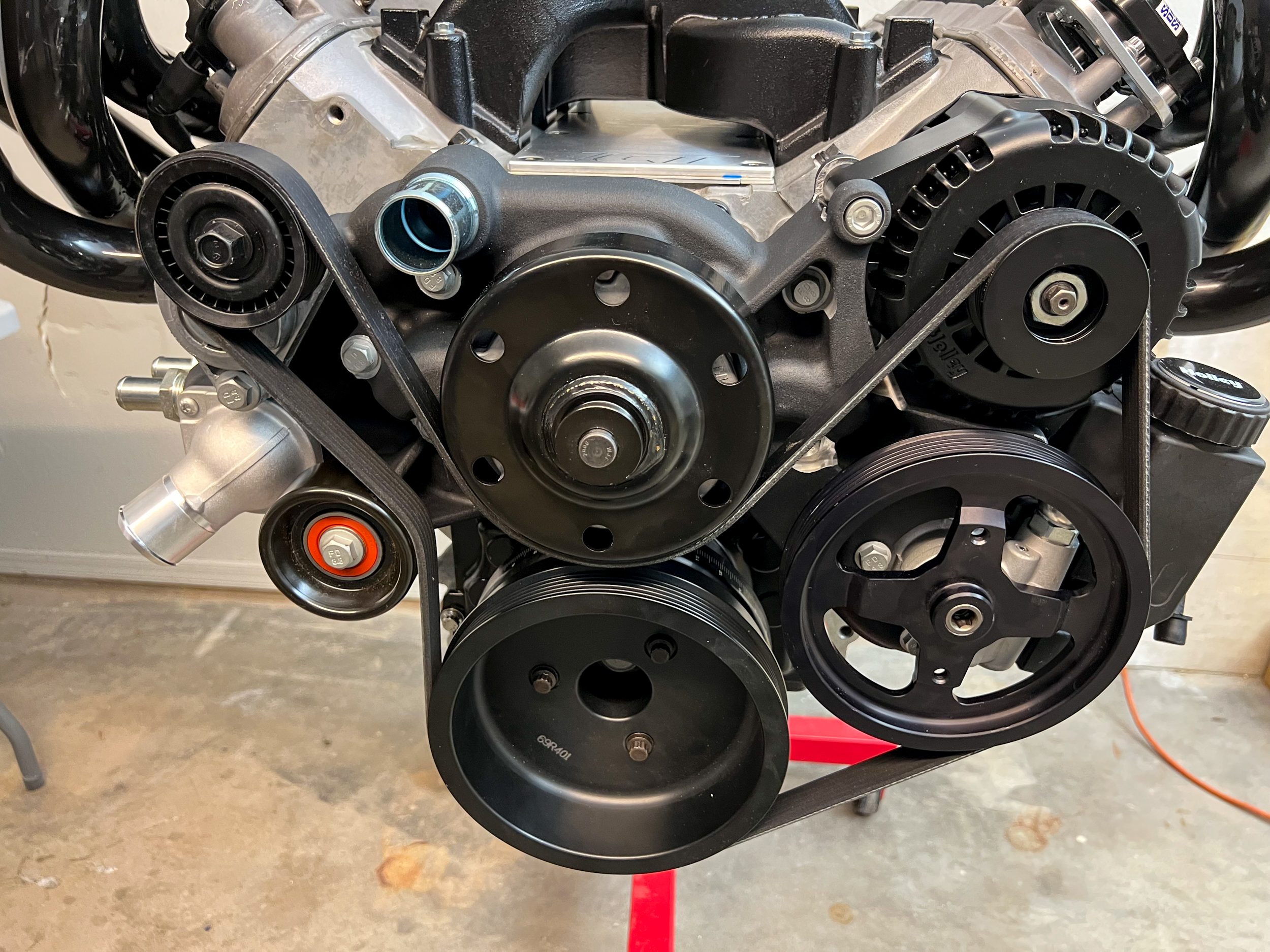

With 95 percent of this project done, we still needed an accessory drive for the boat. For that, we turned to Holley for its Mid-Mount race accessory drive system for the LS engine. This product offers bracketless accessory mounting, easy assembly, and looks killer. It includes options for bottom outlet heater hoses, a premium 150 amp alternator, a water pump with a cartridge design, a power steering pump with a baffled reservoir, and a steam tube input port. We opted for the SFI-approved ATI harmonic damper as well for added protection for our engine. This system is easy to install and looks great on any engine.

Holley's Mid-Mount race accessory drive was a perfect fit for this project. This unit offers bracketless accessory mounting and easy assembly. Not to mention it's super sexy by design and includes an ATI damper too!

With our engine complete, it was time to drop it in the boat. The LS fit without issue, and we are currently finishing up some odds and ends before we hit the lake and see how the new powerplant performs. The only question we have is will all of this work be better than a big-block? We will soon find out.

With the engine in the boat, it's almost time to fire it up. Will it perform as well as the big-block? We sure hope so.