When it comes to making as much power from an engine as possible, it can become somewhat of a guessing game as to what’s the best recipe. There are literally millions of combinations to choose from, which can become pretty overwhelming. Of all the choices of pistons, crankshafts, cylinder heads, valvetrain and modes of induction, perhaps nothing is more important than the camshaft. While the camshaft can’t be wholly regarded as the brain of the engine, it definitely can be considered the frontal lobe as it determines much of your engine’s personality, behavior and attitude, dictating much of your engine’s ability to make power.

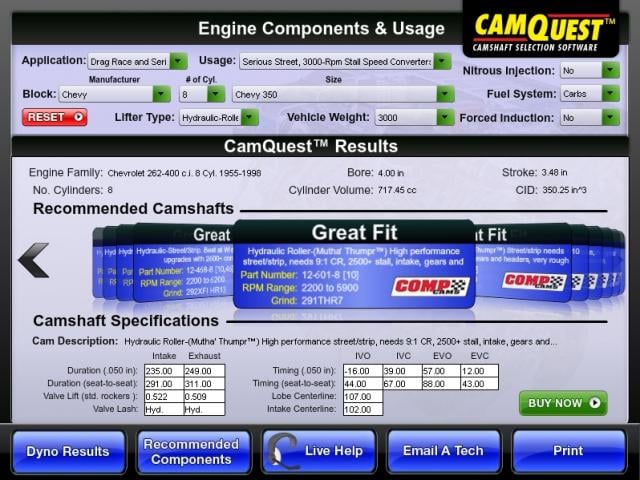

When an off-the-shelf camshaft won’t work, COMP Cams’ CamQuest digital software and helpful technicians will help take the mystery out of ordering a custom-grind cam.

To help take the guesswork out of building the perfect engine for your needs, COMP Cams – known worldwide for offering nearly every off-the-shelf grind available, as they’ve been at it for over 30 years – has the experience and know-how to help guide you in your way towards street and/or strip supremacy.

It all starts in engineering, were COMP designers use CAD programming to design a new or custom grind. They have programs in place that can estimate how the slightest changes in lobe and duration will effect valvetrain at varying RPMs.

That being said, sometimes one of COMP’s existing off-the-shelf grinds doesn’t fit the bill for maximum engine efficiency – particularly in the case of unique or unusual applications. Rather than just sending you on your way, COMP is still by your side to help you along.

COMP Cams handles custom-grind cams on a daily basis and can tell you everything that you need to know to do it! Just like painting a car, the real benefit of a custom grind camshaft is in the prep work. Specifically, having as much information as possible on the engine that you’ll be building will be the key to success versus an experience that leads to head-banging frustration.

What Are You Building?

First and foremost, before giving COMP a call to order your custom grind you’ll need to have some basic information on the engine you have. Is it a small block Chevrolet? If so, what size? It may sound like a basic question to ask, but COMP assures us that sometimes people call without having this basic question figured out.

Also, they stress that you give them the information based on the engine that you’d LIKE to build, so if you’re planning to punch it out to a larger displacement or make it a stroker motor, this is the time to say so. According to COMP’s Director of Special Projects/Operations, Derrick Hubbard, “This is an area that people really need to consider upfront. It may sound basic, but start with the end game in mind for your motor. It’s not a good idea to start your build with a custom grind before thinking about the rest of the motor because you may bore it out, change the stroke, or do other things before your build is done.”

With a new profile programmed into the COMP machines, a piece of stock is ran through a series of programs to create a new unique bumpstick.

Also, knowing the usage of the engine is key to getting the desired outcome, and of all of the information that COMP needs from you this may be the most important. Will this be a daily driver setup, needing a smooth power band? Will this spend most of it’s life on the dragstrip and need it’s power to come on after a specific RPM? You’ll need to get these areas addressed upfront in order to enjoy the cam that you order to the fullest.

What Are You Using?

Next, having as much information as possible on your cylinder heads is incredibly beneficial. Ideally COMP would like to know the flow numbers on the heads that you’ll be running, and if you’re using after market heads they can get the flow numbers based on the manufacturer and model that you’ll be using.

If you’re using factory heads, try to give as many details as possible here as well. Is it a double-hump head? Have you had it ported? Did you put bigger valves in it? These are all areas that you’ll need to be well versed in. COMP also tells us that if you have a cylinder head that’s mandated for a specific class of racing to mention that upfront as well as sometimes there can be some confusion. Again, it all comes down to the specific usage of the engine.

According to Hubbard, once you’ve got the displacement and heads figured out well, if you have any other areas of the valve-train picked out, let them know. Hubbard stated, “at times we’ve had to give people the bad news that the stamped-steel rocker arms they’ve purchased already can’t be used with the cam that they’d like to order.”

In fact, Hubbard mentioned that COMP is happy to help people address each and every area of the valve-train while deciding on the custom grind of the cam as each and every component is a part of the equation.

Other areas that need to be determined upfront are determining whether the cam might require a small base circle. In our conversation with Hubbard, he explained, “Confusion over this area is the number one reason that custom grind camshafts are returned. As a rule of thumb, a smaller base circle cam could come into play with stroker engines as it’s actually possible for certain connecting rods to hit lobes on the cam if the cam lobes are too large. The actual profile of the cam lobes can be matched with a smaller base circle, so getting the same lift is easily achieved either way.”

What Will It Be Working With?

Again, this is another area of information to give COMP up front when placing your order as they’ll be able to help you determine as to whether a small base circle cam is needed for your setup. Continuing on, COMP will need to know the compression ratio you’ll want, the kind of transmission you have, and if it’s an automatic transmission the type of stall-speed converter that you’ll be running. In addition, the cam journal size (standard or over-sized) is another important and often overlooked factor, so have information on this as well.

Finally, the last area of importance is to determine the firing order that you’ll plan to be using. For many people the standard SBC firing order will be the choice, but Hubbard explained that as of late the popular route to go is either a 4/7 swap or in using the firing order from the LS1.

The 4/7 swap literally changes the small block firing order from 1-8-4-3-6-5-7-2 to 1-8-7-3-6-5-4-2. Some have claimed that the 4/7 swap can add up to 15 horsepower to an engine in the upper RPM range, and this is a trick that has been used by circle track racers since the 1960’s. The LS1 firing order is different yet and sets it to 1-8-7-2-6-5-4-3. According to COMP, the LS1 firing truly smooths out engine harmonics and makes life for the valve-train much better!

Things The Customer Should Know:

- What kind of engine is it?

- What will the engine’s purpose be?

- What size engine is going to be AFTER the build?

- Does it need to be a small base circle cam?

- What compression ratio will it be running?

- What kind of transmission is it running?

- What stall converter will it be running?

- What size journals will he be using? Standard or oversized?

- What firing order?

- What cam rotation? Is it reverse?

Tools At Your Disposal

If the process of obtaining all of this information seems overwhelming, simply head to COMP Cams website and do a little reading. We have found that they’ve got one of the best websites in the industry when it comes to needing information and specifics. If you find yourself struggling to understand all of the areas of the engine specifics be sure to check out their online tech forums and tech articles.

You can e-mail COMP questions directly from their website as well. In fact, we spoke to Aaron Mick at COMP about this and he stated, “You can pretty much determine almost all of the information you’ll need to prepare for a custom grind order by simply using the online Cam Help Tool. That’s where I’d recommend people start.”

Before the cam is boxed and readied for shipment, the final touch on the cam is a polish done by hand.

The Quick List

Once you are armed with more engine information than you ever thought was possible, the ordering process itself is really fairly simple:

- Call a COMP Cams sales/tech rep. They can be reached at (800) 999-0853. Please take the tech’s name for future reference regarding this cam.

- Listen to what your tech has to say. It’s their job to help you get the best setup possible. Use them as a resource!

- After walking through all of the information requirements on the engine you have they will choose a cam profile for you and make a cam confirmation sheet.

- The confirmation sheet will then be e-mailed to you for approval.

- Once you have approved the order it will be placed immediately.

- It will take roughly 3-5 days to get your cam grind completed. Once it’s done it will be sent to you and will be fully ready to run!

Believe it or not, ordering a custom grind camshaft may not be more expensive than purchasing an off-the-shelf one. COMP tells us that most custom grind camshafts use a standard style core, and if that’s the case the cost of the custom grind is identical to the off-the-shelf choice!

Long story short, it’s best to have a battle plan in place before ordering a custom grind cam. Mick joked, that as good as COMP is in the performance world, they simply do not have the power of being “mind reader.” Giving them as much information as you possible can upfront is the key to getting the engine performance that you’re looking for.

That being said, COMP tech experts would love nothing more than to walk customers through the process to help them achieve their desired results, so don’t be afraid to call even if you don’t feel you’re completely prepared to answer every question to the nth degree. They have years of experience in putting together the ideal valve train based on the purpose you have in mind for the engine and will likely have some recommendations that you may not have thought to ask.