It isn’t easy to know where some of the automotive aftermarket performance products are manufactured in this day and age. And unfortunately, we live in a world where the dollar is mighty, and some companies will cut costs wherever they see it possible to save a buck or two. Not long ago, we ordered an off-brand LS swap harness, and it was pretty obvious it was produced overseas. The wires were not automotive grade, the spices were wrapped in electrical tape, and the connectors for the ECU had pins open to the environment. And while all of these points indicated overseas manufacturing, the fact was undeniable after seeing the instructions for the first time.

Fortunately, companies like BP Automotive take pride in their products and still build them in the USA. And while this is a tremendous advantage over some of the foreign-made products on Amazon, BP takes it one step further with product testing before its harnesses even arrive at your door.

No Room For Error

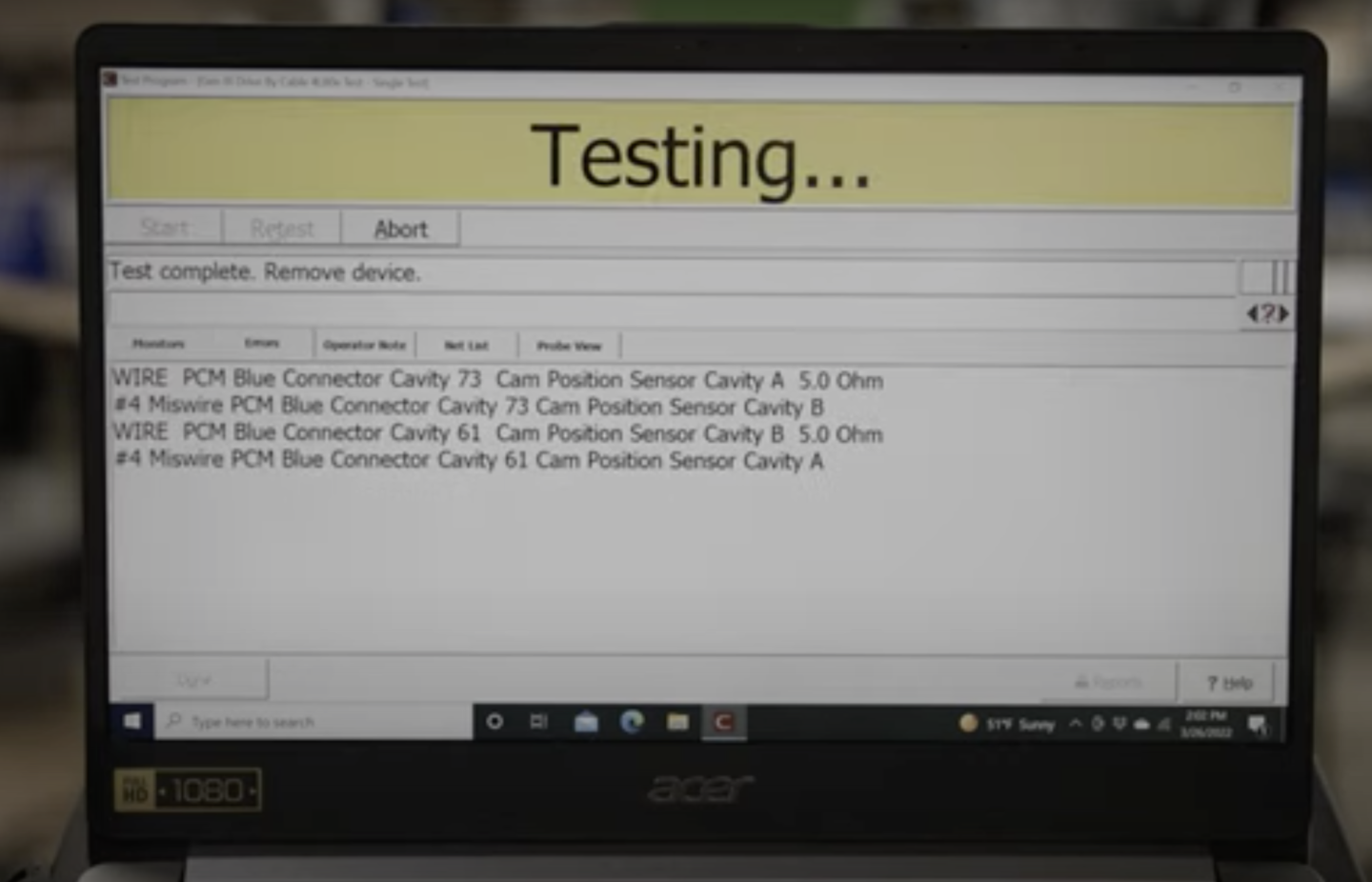

If you’ve ever had a job, you know that sometimes life events happen that can distract you from work. Now, imagine building an EFI swap harness with hundreds of wires, terminals, and connectors. Imagine if an employee has a bad day and pins a connector incorrectly. You can imagine the ensuing problems. First, it would likely take several hours to troubleshoot the assembly to see what went wrong. Then, after diagnosing the issue, the harness would need to be fixed or replaced. BP Automotive implemented a safeguard to check its work because humans are prone to error once in a while.

The BP Automotive computer harness tester guarantees that each harness that goes out the door is perfect. If a problem arises, the company knows that it’s from the installation and not because of oversight during the harness assembly process. And this device is so accurate that it will pinpoint the problem in some cases. And the best part is that the customer will never have to worry if the harness is faulty.