With the advancement and growing adoption of electronic fuel injection and other technologies, tuning a race car with a computer or even a smartphone has become not the exception, but the norm. With the introduction of mass-air sensing and more advanced ECU’s, electronic engine control has become more versatile, but demands a strong level of expertise in order to know how to tune it. Today, the aftermarket industry has gotten on board with electronic engine control in a big way, providing racers with more user-friendly tools to tune their machines than ever before.

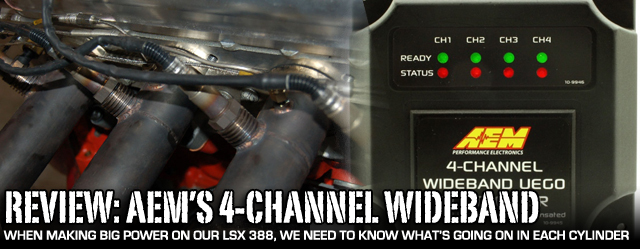

AEM Electronics, one of the industry’s leading manufacturers of high performance products, has launched their new 4-Channel Wideband UEGO controller, allowing the racer or hardcore street enthusiast to monitor all eight cylinders (with two units) with accurate air/fuel ratios. Also it, brings to the table a number of new tuning advancements with the racer and the hardcore street/strip enthusiast in mind. Today, we’re going to take a look at the new unit from AEM and give it a run on our LSX 388 powerplant.

AEM’s 4-Channel Wideband UEGO Controller

AEM Performance Electronics’ new 4-Channel Wideband UEGO controller allows you to monitor the air/fuel ratio in four cylinders at a time (or eight cylinders using two controllers). Most standalones rely on one to two wide band sensors (one in each header) to determine the air/fuel ratio from a blend of cylinders. By having the ability to input eight sensors via 0-5 volt inputs, racers and tuners alike have the ability to fine tune each cylinder to harness the maximum horsepower potential of an engine…and increasing reliability by eliminating lean cylinders…all in a compact package with a minimum of wires.

AEM 4-Channel Wideband UEGO employs four O2 sensors and custon AEM-spec bungs located in each exhaust header primary tube. Each sensor reads oxygen content to turn this information into air/fuel ratio indication for that cylinder.

Stainless steel sensor bungs are welded to each primary tube without causing significant exhaust restriction. Four sensors detect oxygen content one cylinder at a time, which is directly proportional to air/fuel mixture. Virgina Speed used two of AEM's 4-channel wideband controllers to tune our LSX 388 motor that is destined for our 275 Drag Radial fourth-gen Camaro.

What Makes 4-Channel Better?

Ultimately air/fuel varies from cylinder to cylinder even when safely tuned with a wideband controller, and power (and reliability) is left on the table.

“Achieving consistent air/fuel ratios on a cylinder-to-cylinder basis in an engine is critical to efficiency, reliability and power production,” Lawson Mollica of AEM tells us. “Common aftermarket wideband air/fuel systems typically include one wideband sensor for each bank of cylinders and achieve an average air/fuel reading across the bank at a central collection point like the collector of an exhaust manifold prior to the exhaust system.”

Mollica continued, “While this is a great tool for engine tuning, it also stands to reason that you are tuning for an average air/fuel reading from each bank or all cylinders, meaning that ultimately air/fuel varies from cylinder to cylinder even when safely tuned with a wideband controller, and power (and reliability) is left on the table.”

Lawson claims the 4-Channel UEGO is more advanced than a single channel unit and also faster responding since it is able to see gas sooner in each individual runner, which enables your engine to perform more efficiently. What’s more, if you want to make more power, knowing air/fuel ratio one cylinder at a time becomes even more important.

The AEM 4-Channel Wideband UEGO controller looks at air/fuel mixture one cylinder at a time, enabling you to tune each bore as if it was a standalone engine. This advanced system is ideal for datalogging, engine management, and racing applications where individual cylinder tuning is a must.

No longer are you looking at broad based engine tuning from all bores, but instead treating each cylinder as a single engine contributing to collective power. Imagine being able to tune your engine for an optimum air/fuel mixture one cylinder at a time and with optimum results. This is done with 0.5-volt analog outputs to each air/fuel ratio (AFR) channel (sensor) as well as a CAN data stream output, which helps you track and chart air/fuel ratio.

Why One Cylinder At A Time?

Although we have four, six, eight, ten, or twelve cylinders on a common crankshaft, each bore is as unique as a fingerprint. Port and combustion chamber shape and size, quench, compression height, swept volume, dish or dome, and ring sealing all vary. This is why we have to look at a V8 as eight individual cylinders attempting to dance in perfect unison.

If you can fine tune injector pulse width to where you have uniform air/fuel ratio, you have achieved a near perfect state of tune across the board. To tune injector pulse width one cylinder at a time, you have to be able to read air/fuel mixture one cylinder at a time.

Here are two AEM 4-Channel Wideband UEGO controllers in a dyno room. For four-cylinder engines, you need one controller. For sixes and V-8s, you will need two. Because this is a four-channel controller, it reads no more than four cylinders per unit. That means three controllers for 10 and 12-cylinder.

What makes AEM’s 4-Channel Wideband controller more advanced is how it reads air/fuel mixture, which is known as UEGO or Universal Exhaust Gas Oxygen analyzer.

First, you need the AEM 4-Channel UEGO controller. And if you’re reading more than four exhaust ports, you’re going to need two controllers. Each exhaust port gets a Bosch 4.2LSU oxygen sensor, which allows the controller its speed and accuracy. These guys are factory calibrated and never need free air calibration. They’re good to go right out of the box. If you’re running a turbocharger, there’s an exhaust back pressure calibration feature, which means you never have to sweat out measuring average air/fuel mixture across multiple cylinders.

Each sensor tip must be located in the exhaust path right off the flange and cylinder head for best results. “The sensor must be mounted at an angle of at least 10 degrees from horizontal in order to prevent liquids from collecting in the sensor housing,” Lawson suggests, “For boosted applications, you will need to install our Exhaust Back pressure Compensation kit.” AEM’s unique bung with an integrated heat-sink allows the sensor to be within two to three inches of the exhaust port without damaging the sensor.

Compatible With Other Electronic Control Systems?

We asked Lawson about compatibility with other engine electronic control systems, “Absolutely, AEM 4-Channel UEGO Wideband will work with most aftermarket programmable engine management systems that offer O2 feedback control and it is AEMnet enabled (AEM’s CANbus network), so it will communicate directly with AEM’s programmable engine management systems and AQ-1 data logger via a one-plug connection, as well as some competitive aftermarket engine management systems/loggers that can read the AEMnet CANbus protocol.” Lawson cautions, “AEM publishes this data, but we recommend users with non-AEM systems contact that manufacturer to confirm.” We used it with our FAST XFI system and inputed the eight wideband O2 sensors into the XFI using the ECU’s standalone’s analog inputs.

What’s In It For You?

- AEM 4-Channel UEGO Controller #30-2340 $572.85

- Stainless Steel Bung Install Kit #30-2063 $95.48

- Exhaust Back pressure Install Kit #30-2064 $242.47

- Replacement Bosch 4.2LSU Sensor #30-2001 $84.44

- Tall Stainless Steel Bung #30-2003 $10.80

- Tall Stainless Steel Bung Kit (4) #30-2003-4PK $46.65

AEM's Wideband controller can be used in conjunction with AEM's datalogging software or they can be wired as a 0-5 volt sensor to virtually any popular engine management system or datalogger.

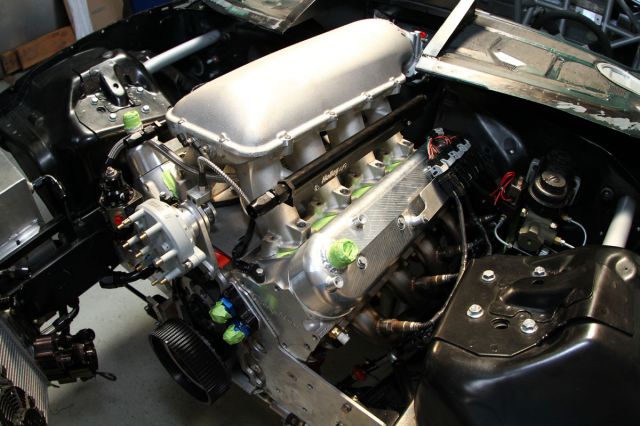

Virginia Speed Shakes Down AEM’s 4-Channel Wideband On Our LSX 388

Our very own LSX 388ci stroker is based on the GM Performance LSX block stuffed full of Lunati 3.622-inch stroker kit flanking eight bores with 4.125-inch JE forged pistons. Ported Trick Flow LS1 aluminum cylinder heads top the block sporting Ferrea titanium intake and Pro Alloy exhaust valves. Comp Cams has worked with us on the cam and valvetrain package. Holley has provided the induction. The result is a tremendous amount of power thanks to generous bore and stroke coupled with just the right combination of parts. It isn’t just about parts, but technique. Virginia Speed brought our LSX 388 project to life.

When Virginia Speed built and tested our LSX 388ci stroker on its dyno, we asked Shawn Miller, builder and tuner, what his observations were about the new AEM 4-Channel Wideband system, “When we need to ring every last horsepower out of an engine, being able to monitor air/fuel ratio on a cylinder-by-cylinder basis is absolutely crucial.” He added there are two many variables from one cylinder to the next, which makes it important to be able to tune and observe air/fuel ratio one bore at a time.

Shawn gave us something to think about. It’s isn’t just cylinder dynamics that determines performance, but also the induction system, “Not all intake manifolds are created equal, and front to rear cylinder air/fuels can differ up to 10%.”

Virginia Speed tuned our LSX 388ci stroker using AEM's 4-Channel Wideband UEGO system with impressive results. Shawn Miller of Virginia Speed stressed no two cylinders are of the same dimensions nor is the induction system the same from runner to runner.

Virginia Speed put our LSX 388 to work yielding some interesting results, “When we first started tuning the 388 on some light runs, we saw there was a 4-5 tenths difference in the air/fuel ratio between the front and rear cylinders. This allowed us to fine tune those air/fuel ratios by adding fuel to those injectors through the FAST’s individual cylinder fuel trim adjustments.”

Engineered By Racers For Racers

Serious race engines need serious tuning devices, and any well-known tuner will tell you that proper air/fuel ratios are the key to running fast. When spending a big chunk of money to build an engine that is competitive in a given racing class, it is imperative that you get the most out of it in terms of horsepower and reliability. In the case of our LSX 388, we learned that while our Holley intake manifold worked great and distributing air properly, we still needed to richen our rear cylinders ever-so-slightly to even out our air/fuel ratios. Now when we hit the track with our BlownZ Camaro, we can do it with the peace of mind knowing that our AEM dual 4-channel wide bands are going to let us know exactly what is going on in every cylinder.