If you’re an automotive enthusiast and your project takes advantage of electronic fuel injection (EFI), you’re more than likely familiar with the Florida-based fuel injector manufacturer Fuel Injector Clinic — you may even remember our high flow injector tuning article with the Fuel Injector Clinic team earlier this year. Well this time around we reached out to the company in an effort to take a closer look at their Data Match Technology sheet and ECU-specific scaling data provided on their website.

If you’re an automotive enthusiast and your project takes advantage of electronic fuel injection (EFI), you’re more than likely familiar with the Florida-based fuel injector manufacturer Fuel Injector Clinic — you may even remember our high flow injector tuning article with the Fuel Injector Clinic team earlier this year. Well this time around we reached out to the company in an effort to take a closer look at their Data Match Technology sheet and ECU-specific scaling data provided on their website.

We had the opportunity to sit down with Jens von Holten, owner of Fuel Injector Clinic, to get an in-depth lesson on what Data Match Technology is and how to interpret the scaling information means, and how you or your tuner would utilize this information in the real world. I’ll leave the technical details to von Holten, but simply put this data is essentially a cheat sheet for you or your tuner to get your vehicle off of the dyno and back on the street or racetrack much faster and with more confidence than ever before.

What Does It All Mean?

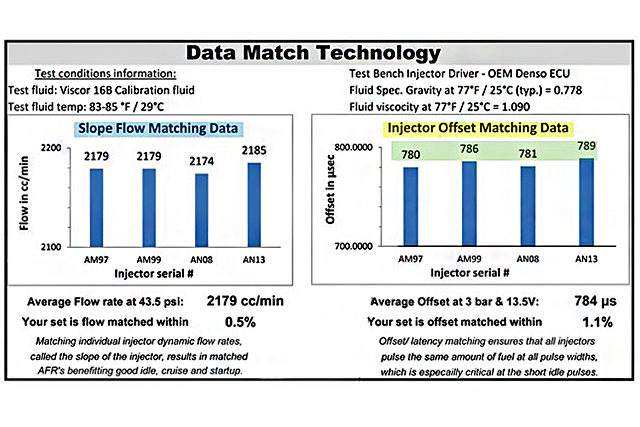

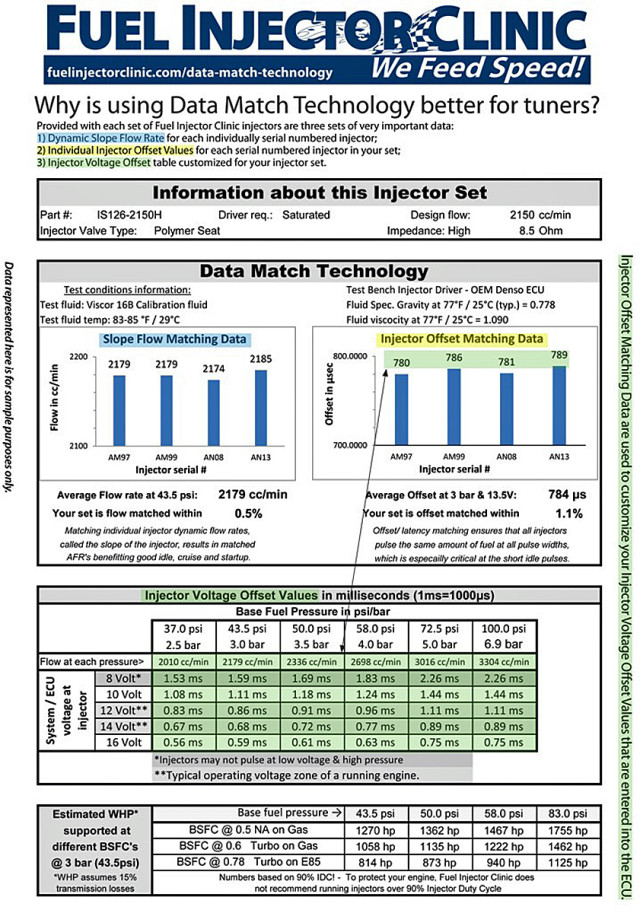

It all starts with Fuel Injector Clinic’s Data Match Technology. “There are three sections of data provided on the Data Match sheet – slope flow rate matching, to verify the individual flow rates of your serial numbered injectors for a consistent air/fuel ratio across each cylinder; injector offset [delay] matching, to make sure that the opening and closing rate is similar for each injector to keep fuel delivery consistent; and voltage offset matching, which is used by your tuner to set the starting point for battery/ignition latency compensation at various system voltages and fuel pressure settings.”

“The matching that our team performs is measured using the individual flow rate and offset of each injector. And while flow rate is fairly self explanatory, offset can be most easily explained as the delay in the opening and closing time of the injector; and is a very important aspect in being able to verify that you have equivalent fueling in each cylinder,” says von Holten. “I believe we are the only company in the United States that gives you all of that data on a single sheet provided with every new set of fuel injectors. In most cases you can’t really put this data directly into your ECU, but it’s still used to show that your injectors match really well.”

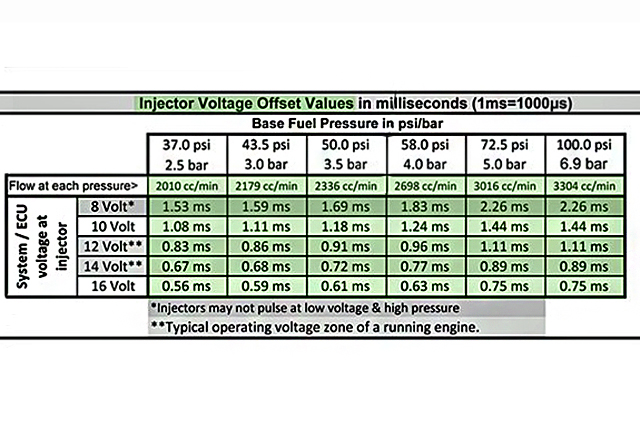

“Then a little further down on the sheet we also provide accurate injector voltage offset information that can be entered directly into the ECU to help verify that it sends the right commands to the injectors feeding your engine,” continues von Holten. “There are fuel injector companies out there that will literally just pick random injectors of the same size out of a bin, and might send them to you with just an average flow rating or even no data at all, instead of individual characteristics.”

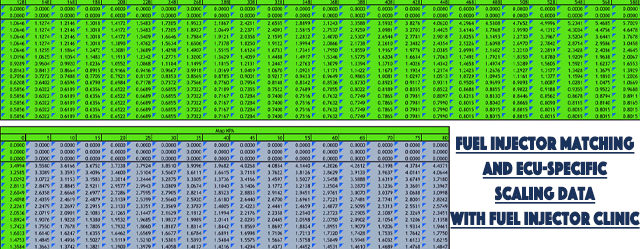

The injector specific flow and latency (delay) information to verify equivalent fueling (left), and the injector voltage offset values that can be used as a starting point when dialing in these injectors during tuning (right).

Deciphering ECU Specific Data

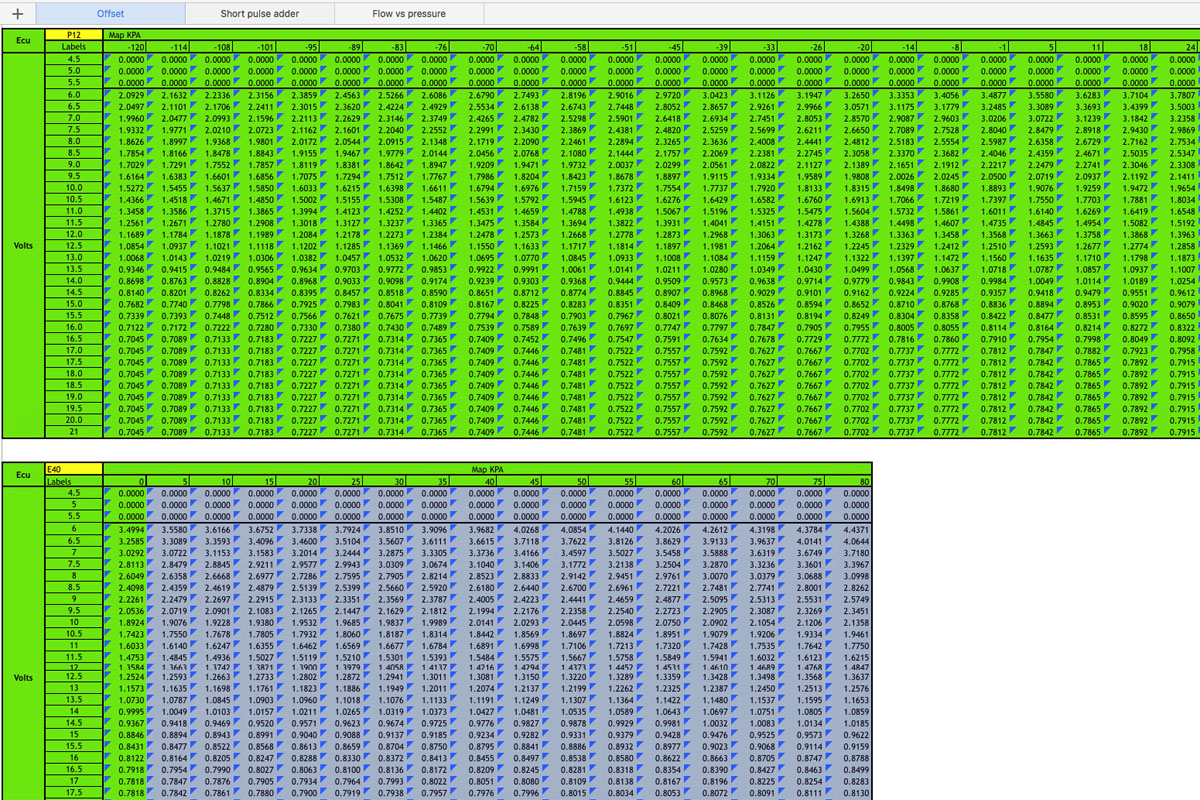

Not all ECUs are created equal, and when it comes to dialing in fuel injectors — especially with the factory ECU — the formatting of the software and the units used will vary depending on what the engineer who wrote the factory code was most comfortable with or was required to use. This means that the way that the data will need to be formatted and converted will vary from vehicle to vehicle, and sometimes even within the same manufacturer and vehicle generation.

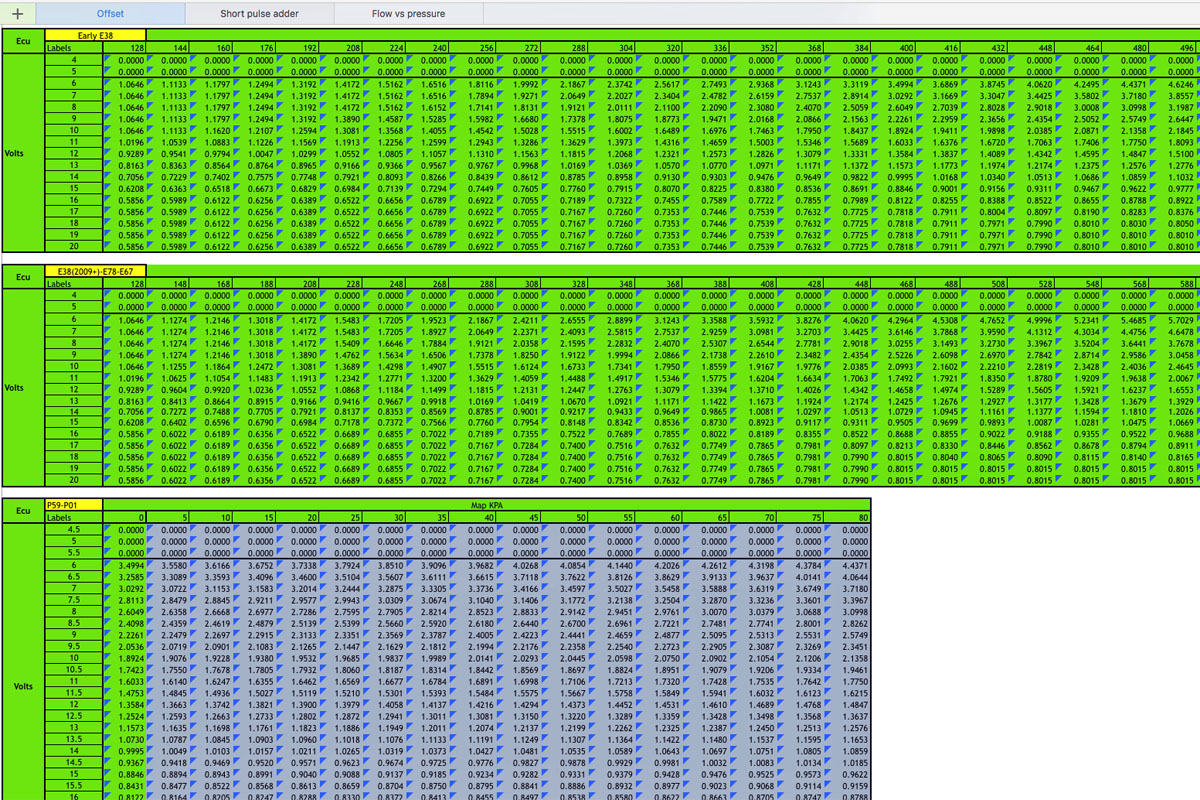

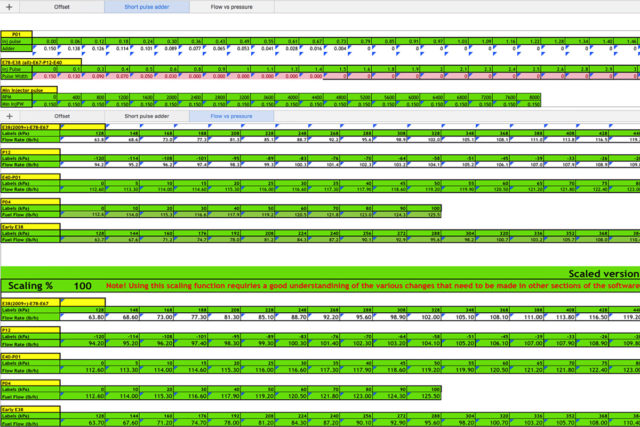

“When it comes to factory ECU tuning there are many different types of ECU reflash software out there, like HP Tuners, EFILive, MegaSquirt, Cobb, ECUFlash, and so on. And each of these reflash programs have to present their data in the same formatting as the engineer who programmed the factory ECU [with very minor variances in some cases],” explains von Holten. “So when we provide this data to the end-user, we have to use each ECU’s original formatting, which has become an increasingly daunting task. Just take a look at the calibration data for the 1,000 cc/min GM injectors off of our website as an example, you can see how complex the data is that we have to provide — such as short pulse width corrections, voltage offset data, and flow versus pressure values.”

The 1,000 cc/min scaling data provided by Fuel Injector Clinic for several of the most popular GM ECUs (above and below).

“This all began when ECUs started relying more on correction tables and other more advanced features like VE modeling in the last decade or so. These OE engineers put a lot of additional tables in their ECUs which often never get reverse engineered by the aftermarket, and this is where we run into speed bumps in the factory ECU tuning world,” said von Holten. “Yeah, we might have discovered six out of a total of ten fueling tables and the vehicle ran fine at that time. The problem is that we don’t even know that tables seven, eight, nine and ten exist, when they’re triggered, or how they influence other areas of the calibration.”

“In reality, these tables might be referenced at a specific intake air temperature, barometric pressure reading, or something else weird that they decided to create a patch for to overcome a problem that we aren’t even aware of,” states von Holten. “We even work directly with some of these third party companies that are reverse engineering these ECUs when we can’t crack it on our own. This partnership has provided us with complete data sets for the injector tables in almost every major vehicle format, with more still to come — including GM, Ford, Dodge, Subaru, and Mitsubishi right now.”

“Because so few people truly understand what all of these tables actually do, drivability tends to get messed up pretty quickly. In the HP Tuners reflash software, for example, there are fuel injector tables that act as a global scaling multiplier, which allows for a single table to make large adjustments in fueling across the board,” von Holten explains. “When people first started to tune at this level they just left the stock values in those individual injector tables [either because they were not defined in the software or their function was not understood], and instead simply messed with that global scaling value in an attempt to reach their fuel target at peak power; which would then throw off fueling at idle and while cruising.”

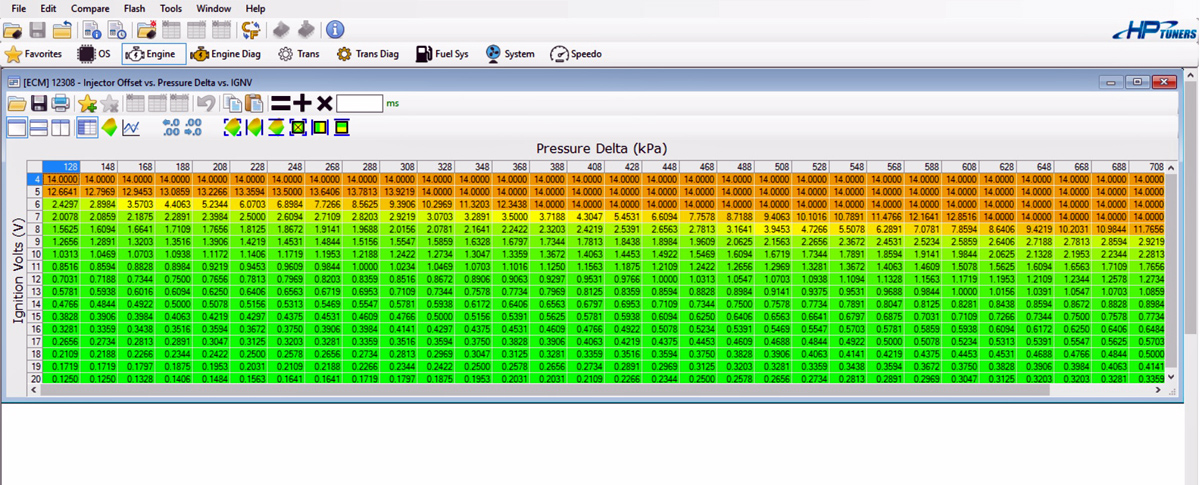

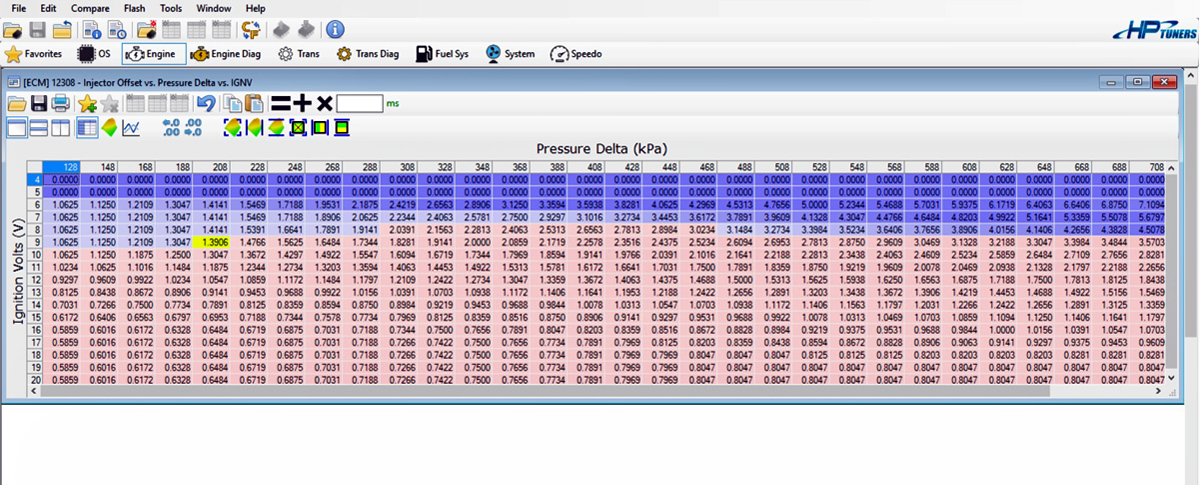

The factory Camaro ZL1 fuel injector offset data (top left), versus the updated offset data provided by Fuel Injector Clinic for their 1,000 cc/min injectors (top right); and the factory fuel injector short pulse width adder (bottom left), versus the updated pulse width adder (bottom right). As shown in HP Tuners.

“The industry as a whole has really struggled to keep up, especially in the early years, when people generally referred to as ‘top tuners’ were not looking good,” states von Holten. “Many lost a lot of business because of how long it took to reverse engineer the raw code to find these random tables that would improve drivability. And although our methods have improved greatly in recent years, this can still be an issue even today.”

“One of our team’s current projects is for the R35 Nissan GT-R. The OE programmers decided to use some sort of proprietary scaling for their injector latency table that makes absolutely no sense to us,” says von Holten. “So we’re having to reach out to the best people we can find, like the engineers at EcuTek and some of the top independent tuners in the world and simply ask them, ‘Are you guys making any more sense out of this than we are?!’ — and we still haven’t come up with a great solution at this point, but we’re working on it!”

“Just over four or five years ago, none of this data even existed. They’re finding addresses for more and more of these tables that have really been there for the past decade, we either just never found them or we didn’t know that it would be beneficial to define the tables at that time,” explains von Holten. “At the end of the day, I feel like these OE programmers are just trying to give themselves some kind of future job security. Because there is really no logical reason for the software code to be as complex as it is, but that’s what the data looks like in these modern ECUs for whatever reason, so we have to work with it.”

Reviewing What We’ve Learned

In this article, von Holten introduced us to the three levels of data that Fuel Injector Clinic provides to the end-user or tuner in an effort to cut down on dyno time, and get your vehicle back on the street or at the track much sooner and running much smoother than ever before.

Those three levels provided on the Data Match Technology sheet are:

- Injector Flow Rate Matching – Which is simply used to provide a clear visual representation of how closely matched each set of fuel injectors are in flow, providing the customer and tuner with the peace of mind in knowing that whatever command the ECU sends will affect each of the injectors equally.

- Injector Offset Matching – Used to display how closely matched each injector is in latency (delay), guaranteeing that each set of injectors takes a similar amount of time to fully actuate.

- Injector Voltage Latency – Supplies the tuner with accurate fuel injector voltage offset (delay) data for various system voltages (8 volts, 10 volts, 12 volts, 14 volts, 16 volts, etc) and base fuel pressure settings to enter directly into the ECU as a starting point.

Then of course there is the ECU specific scaling data, which essentially takes what we have above and converts it into a higher resolution version of whatever the specific OE format is for the ECU being tuned. And this is where most of Fuel Injector Clinic‘s R&D time is spent these days.