Almost by definition, intercooling is, well, cool. Before we can get to the cooling part, we need to first understand why things get hot. It matters little that the boost in question comes from a supercharger or turbocharger, as the effect is the same. The compression of the air we see as boost has a negative effect on the temperature of the air. One of the unfortunate laws of physics dictates that compression causes heat, and when we build boost in the intake manifold with any type of forced induction, we heat the air. The higher the boost pressure, the greater the increase in temperature. The heat causes both a reduction in power, from the diminished number of oxygen molecules per volume, while simultaneously increasing the chance of harmful detonation; the proverbial double whammy. Not surprisingly, cooling the charge air from the turbo or supercharger has become commonplace. Charge cooling or intercooling is simply running the elevated charge air through some type of heat exchanger. Cooling the air improves power while diminishing the likelihood of detonation.

Photos By: Richard Holdener

Charge cooling is nothing new to LS owners; in fact, it is usually an integral part of most turbo or blower build-ups. We purposely used the phrase charge cooling, as opposed to intercooling, since there are additional forms of cooling beside the usual heat exchanger. Things like fuel cooling from a blow-through, usually a carbureted application, water/meth injection and even alcohol-based fuel like E85, have all been used successfully to reduce the all-important inlet air temperatures. Of course, the two most common forms of charge cooling are the air-to-air (ATA) and air-to-water (ATW) intercoolers. Both systems work well, but do have specific design applications. For maximum cooling on high-boost, short-duration racing, we give the nod to running ice water in an ATW system. For extended durations under boost, with plenty of air flow, the ATA works well. For our test, we decided to further enhance a typical ATA system by using a secondary cooling agent, namely, nitrous oxide!

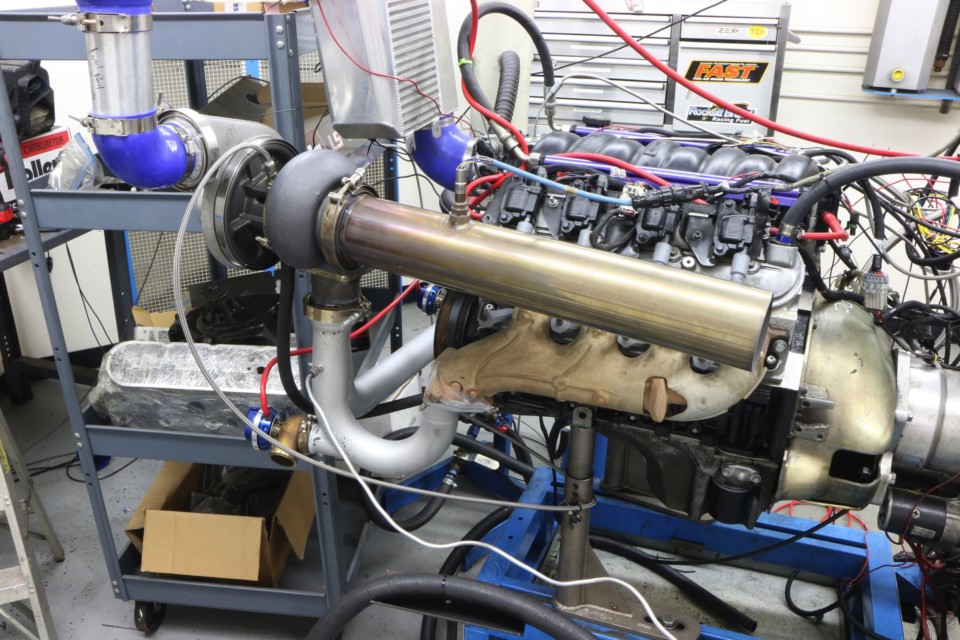

Nothing special about the bottom end of the test motor, just a high-mileage, LY6 with increased ring gap. The top end was another story and featured TFS 225 heads, a BTR Stage-3 turbo cam and Dorman LS6 intake. This 6.0L combo easily exceeded 500 horsepower in naturally-aspirated trim.

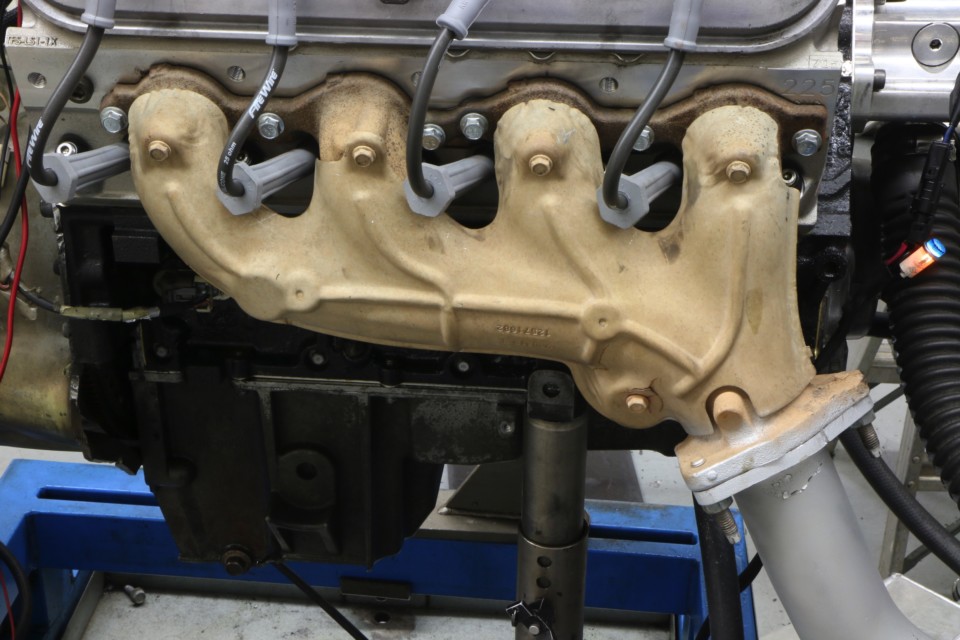

In preparation for the turbo testing, we installed a set of 6.0-liter truck manifolds. They were reversed to feed our custom Y-pipe. The use of the factory manifolds ensured plenty of plug and wire access.

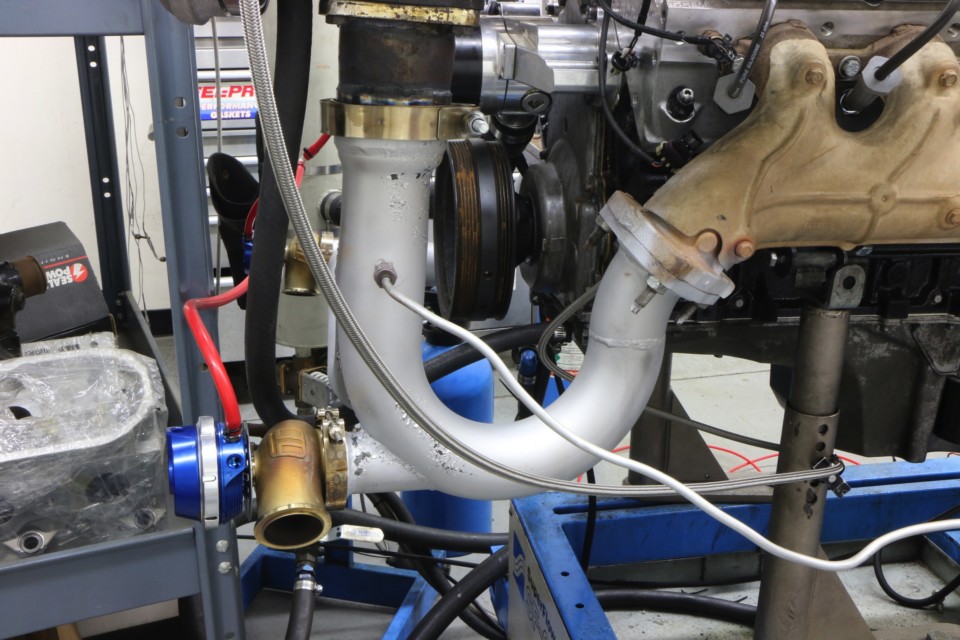

The reverse truck manifolds fed this custom 2.5-inch Y-pipe built by JFab. Note the dual wastegate provisions and pressure tap to monitor the back pressure before the turbo.

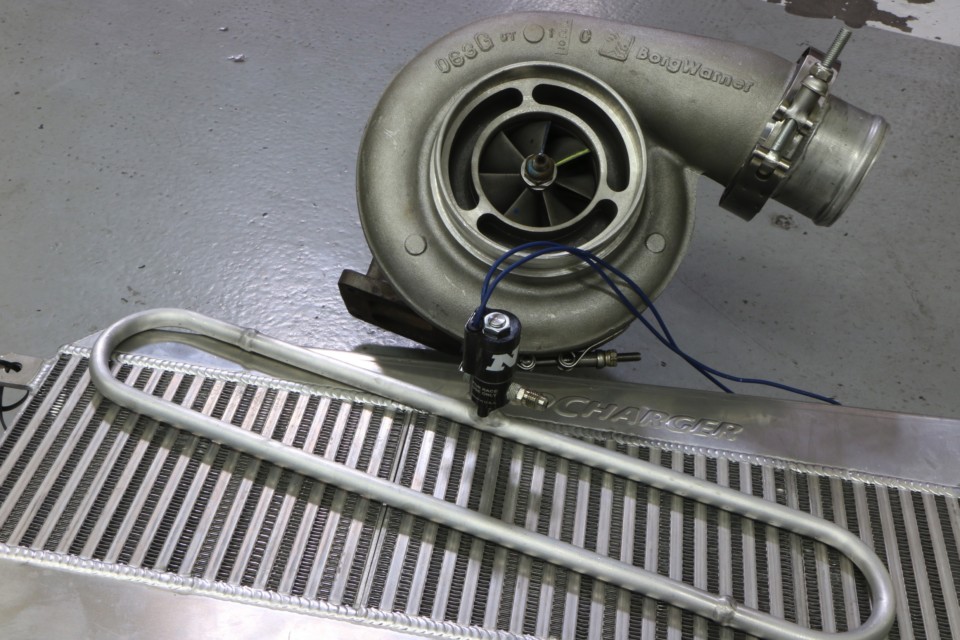

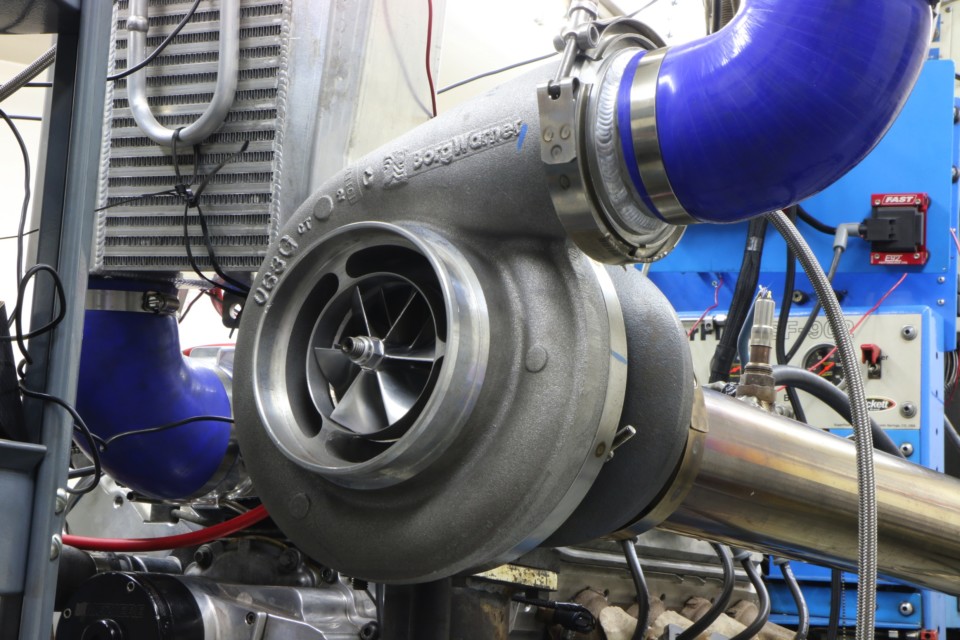

Feeding boost for our test was a billet-wheel, BorgWarner S480 turbo from Little Jon Motorsports (LJMS). The turbo featured an 80mm, billet compressor wheel, standard compressor housing, 92mm turbine wheel, and 1.25 AR T4 turbine housing.

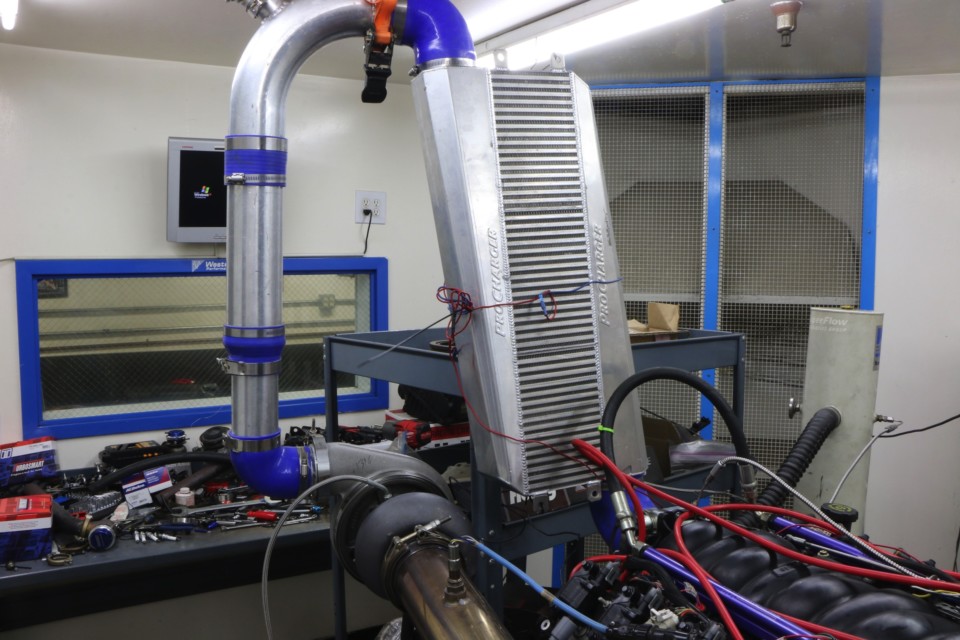

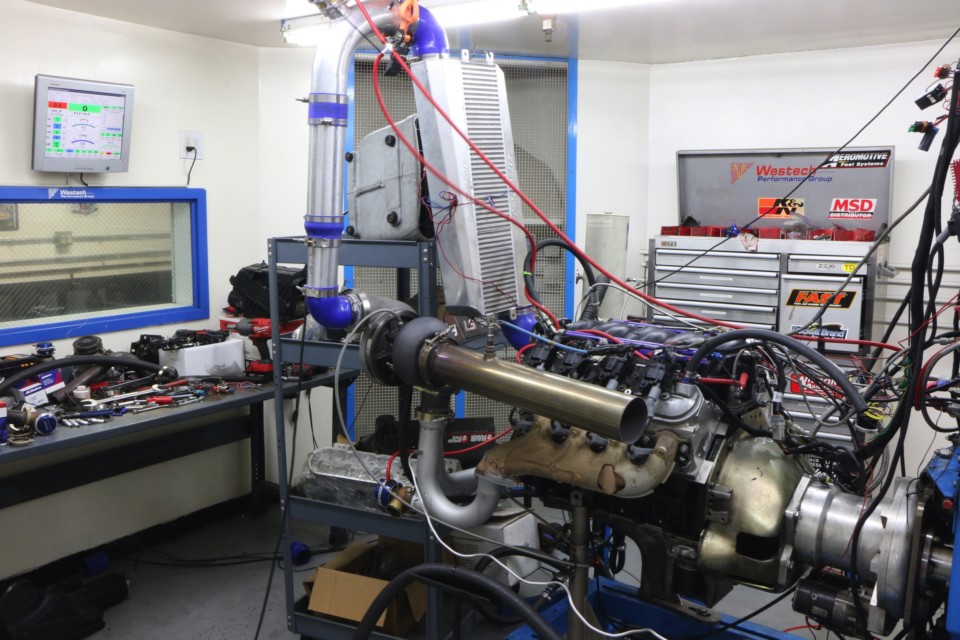

Lest we confuse you, it should be stated that we were not running nitrous oxide through the motor, though that works very well on turbo applications. Instead, we employed nitrous oxide through a cooling ring supplied by Nitrous Express (NX). The ring was positioned in front of the air-to-air intercooler in such a way that the super-cool (-129-degree Fahrenheit) nitrous oxide was injected across and through the core. The idea was to allow the heated charge air from the turbo to come in contact with the super-cooled intercooler core. The result should be a further drop in temperature and, we hoped, an increase in power. Before we could run the test, we needed a suitable test motor, so we dusted off an old turbo 6.0L. The 2008 high-mileage, LY6 short block featured only one change, extra ring gap using the original rings. This 6.0-liter engine had previously been subjected to 29.2-pounds of boost at 1,543 horsepower and lived to tell the tale, so this turbo testing was no problem. The stock bottom end was augmented with a Stage-3, twin-turbo cam from Brian Tooley Racing, a set of Trick Flow TFS Gen X 225 heads and Dorman LS6 intake manifold (complete with inlet air temp sensor). Additional goodies included a set of 120-pound injectors, a Holley HP engine management system, and Accufab throttle body.

Since boost control was critical, we relied on a pair of Gen-V, Hyper-Gate45 wastegates from Turbosmart. The new design even featured provisions for water cooling.

The exit out of the turbo consisted of a free-flowing, 4-inch open exhaust. Note the oxygen sensor used to dial in the A/F curve of each combination.

Of course, a turbo LS motor is no good without a turbo, so we set up the 6.0-liter with a system capable of making plenty of power. Starting with a pair of stock truck manifolds, we reversed them, then joined the exhaust using a custom 2.5-inch Y-pipe from JFAB. The Y-pipe was built to accept any turbo flange using a 3-inch v-band adapter. We installed a T4 flange for this testing. The Y-pipe also featured provisions for a pair of TurboSmart, Gen-V wastegates and a single pressure sensor to monitor back-pressure before the turbo. The boost was supplied by a single BorgWarner S480 turbo that featured a billet 80mm wheel. Capable of supporting over 1,200 horsepower, the S480 also featured a standard compressor housing, a 92mm turbine wheel, and 1.25 AR exhaust housing. The boost was fed through a high-flow, Procharger air-to-air intercooler with 3.5-inch inlet and outlets. The discharge tubing also featured a single Race Port blow-off valve from TurboSmart. The Nitrous Express N-Tercooler, was installed onto the front side of the intercooler core to allow the dedicated fan to help blow the nitrous through the core.

All that wonderful boost was fed through a Dorman LS6 intake manifold from Summit Racing. Note also the Wilson fuel rails and Holley 120-pound injectors.

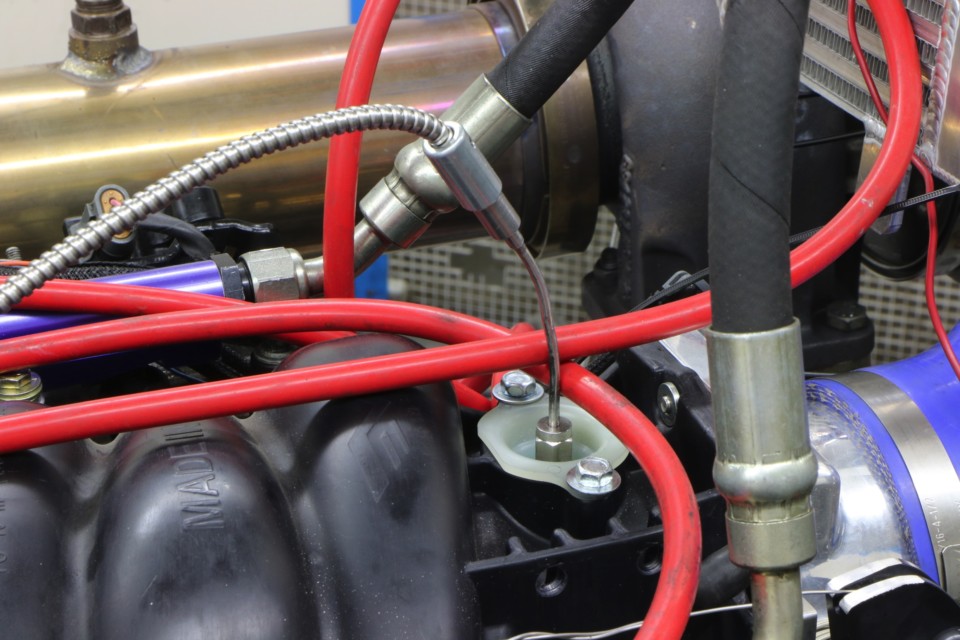

We drilled and tapped the plastic plug in the Dorman intake to allow the installation of an air temperature sensor. This allowed us to monitor the change in inlet air temps before and after the use of the NX N-Tercooler.

In preparation for the test, we installed the solenoid into the threaded fitting on the aluminum ring.

Though it is possible to run CO2 through the ring, we chose what we had on hand, namely -129-degree nitrous oxide.

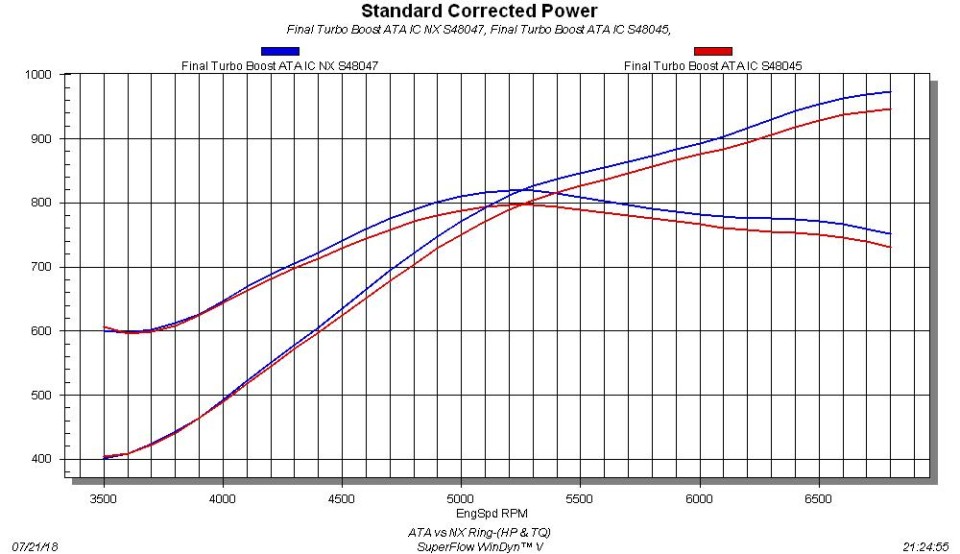

With everything set up, it was time to test. The first order of business was to run the turbo motor in anger with just the air-to-air intercooler, then repeat the process after activating the N-Tercooler. Naturally, the air/fuel ratio and timing remained constant during the testing, while the boost was controlled by a manual wastegate controller from Turbosmart. Run with just the air-to-air cooler, the turbo 6.0 produced 947 horsepower at 6,800 RPM and 797 lb-ft of torque at 5,200 RPM. The peak boost registered was just under 13-pounds, while the peak air temperature in the manifold was 137-degrees. After activating the N-Tercooler, the air temperature dropped to 118-degrees and the power output jumped to 974 horsepower and 820 lb-ft of torque. The N-Tercooler improved the power output through the majority of the curve (see graph), while simultaneously increasing the boost pressure ever so slightly (see boost and back-pressure graph). While we used nitrous oxide in the NX ring of power, it is also possible to run less expensive CO2 with similar cooling properties. Remember, lowering the charge temperatures not only improves power but also reduces the chance of detonation. Cooler is better!

Graph 1: Turbo 6.0L-ATA Intercooled vs NX Cooling Ring (Horsepower and Torque)

As is evident by the change in power, turbo motors like to chill out. Run with the air-to-air intercooler alone, the turbo 6.0-liter produced 947 horsepower and 797 lb-ft of torque. The combination was perfectly repeatable at this power level. After activation of the NX N-Tercooler, the power output jumped to 974 horsepower and 820 lb-ft of torque. Both combinations produced peak power and peak torque at the same engine speeds. The cooler air charge charge improved the power output through most of the curve.

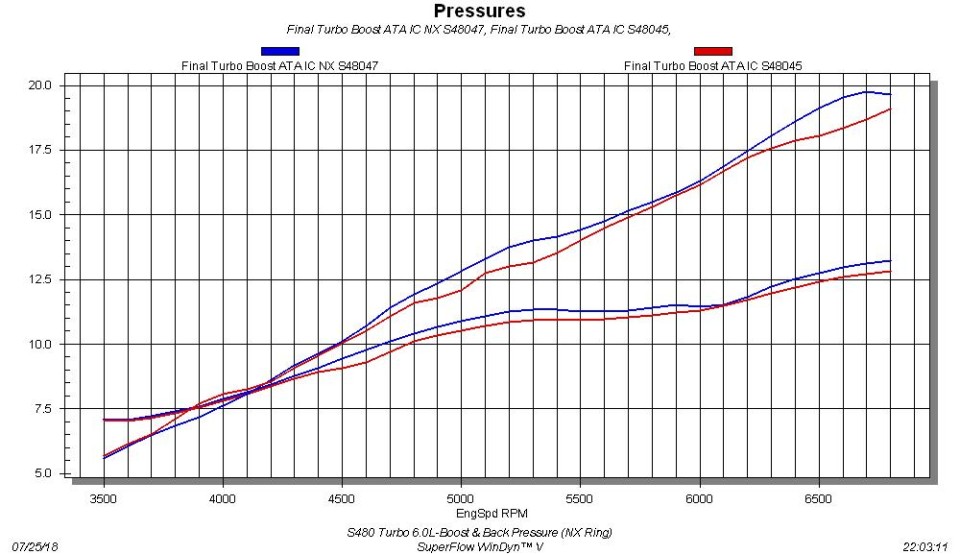

Graph 2: Turbo 6.0L-ATA Intercooled vs NX Cooling Ring (Boost & Back Pressure)

When running this turbo motor on the dyno, we relied on a simple manual wastegate controller from Turbosmart. This graph shows both the boost pressure and back-pressure curves generated by both the standard intercooled turbo motor, and then after the introduction of the NX unit. Both the boost and back-pressure increased ever so slightly, and only in some areas. Measured at 6,000 RPM, there was almost no difference in boost, but a significant difference in power.

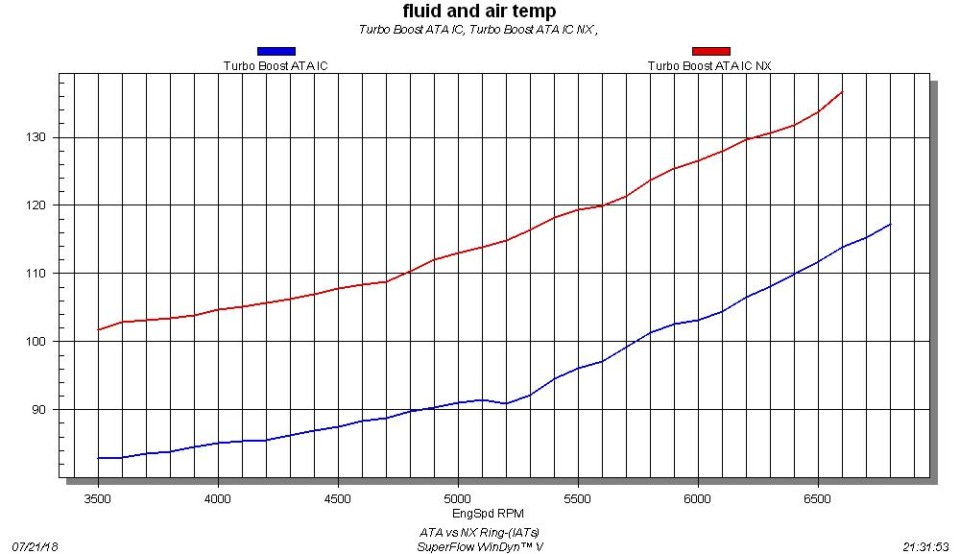

Graph 3: Turbo 6.0L-ATA Intercooled vs NX Cooling Ring (IATs)

This graph shows the change in inlet air temperature between the two runs. Activation of the NX ring showed a drop in air temperature of over 20-degrees, on an already efficient ATA intercooler. A little more efficient positioning of the ring might result in even greater power gains in the real world.

The turbo LS was run with and without activation of the N-Tercooler ring. The change in charge temperature improved the power output over 25 horsepower and nearly as much torque. Cooler really is better.