We’ve shown you how much GM’s latest 6.6-liter L8T workhorse makes on the engine dyno in stock form, with a simple cam swap, and a max effort stock-short-block setup with a dyno-tested heads, cam, and intake manifold combo. But now it’s time to leave the naturally aspirated testing for another day and get down to business as we tear this engine apart to build a 2,000-plus-horsepower-capable L8T short block that’s as unstoppable as Arnold Schwarzenegger in “Terminator 2” with the help of Race Winning Brands.

Being the largest displacement Gen-V LT GM has ever offered from the factory, it’s no surprise the L8T crate engine made so much power with easy mods. But we know that this engine was originally created to handle the abuse of the work truck life. When in development, GM subjected the L8T engine to rigorous durability testing. One such test forced the engine to cycle between the peak torque and peak horsepower at 110 percent of its max-rated load for a continuous 600 hours without fail. This translates to a crankshaft that is stronger than other LT engines and a block that offers features that we can utilize to build a bottom-end that can handle all the abuse we can throw at it with the help of a lot of boost.

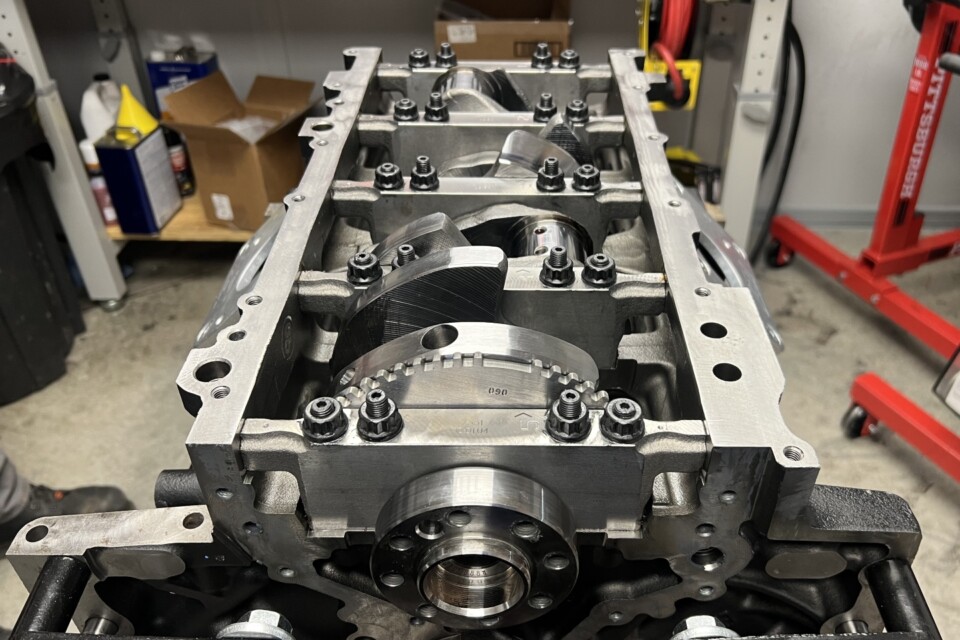

The factory L8T crankshaft is a stout piece. Made from forged steel, with center counterweights and a 3.858-inch stroke, we felt no need to exchange it for an aftermarket crank.

The crankshaft in the 6.6-liter L8T is a forged steel unit that offers a slightly longer stroke to get the extra displacement over its 6.2-liter little brother. The stroke measures 3.858 inches, which is 0.236 inches more than the 5.3-liter and 6.2-liter LTs. But this crank is more than a baby-stroker crank from the factory, it is designed to not break a sweat while towing heavy loads, so GM designed it with center counterweights to make it more stable at high-load. We decided to keep the stock L8T crank for our 6.6-liter short block build.

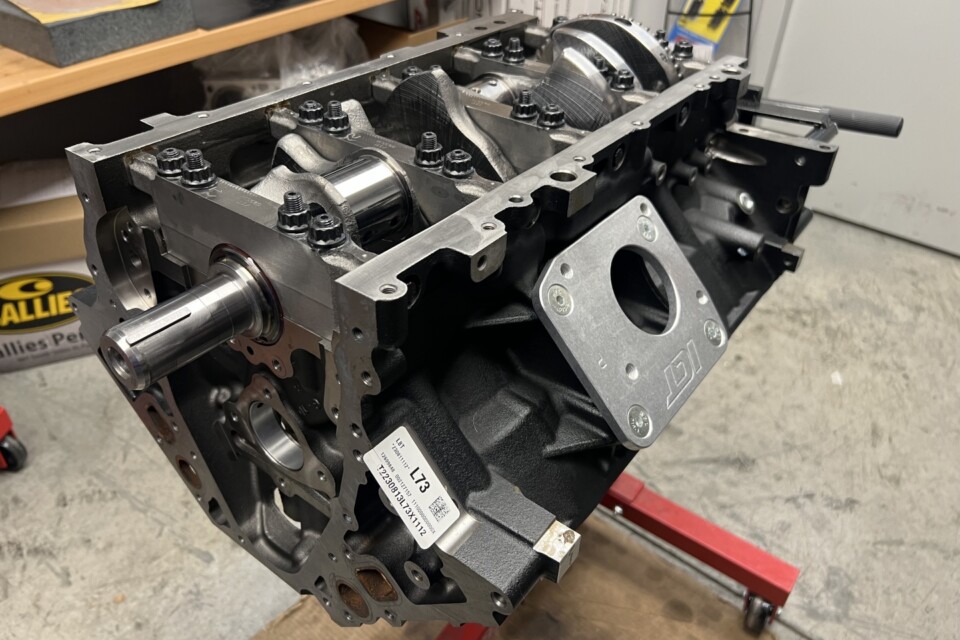

After stripping the engine down to the bare block, we honed the cylinders for our new pistons with extra piston-to-wall clearance for the new piston material and the extreme cylinder pressures and temperatures they will endure. The iron L8T block comes with very thick cylinder walls in stock form, so a slight 0.005-inch hone to bring the bore to 4.070 inches leaves as much material as possible. The L8T block offers a thicker deck to go with its thicker cylinders, which when combined with the 12mm head bolt holes (LS is only 11mm) that we are going to fill with ARP head studs, gives us a foundation for superior head gasket retention.

The OEM L8T block is the only Gen-V LT production block from iron instead of aluminum and features extra thick material in the cylinder walls and deck for extra strength. Our block received no special treatment for this build, just a quick bore and hone for the news pistons and rings before assembly.

Wiseco Professional Series Slugs

A 1000-plus-horsepower boosted street engine needs a forged 2618 piston that can take a beating and keep on ticking, but an engine looking to make double that needs something stronger. For this, we went to Race Winning Brands for a set of Wiseco Professional Series Pistons. While these may be an off-the-shelf piston, we knew that Wiseco’s legendary history of making tough race-ready pistons was going to give us what we need to hold over 250 horsepower per cylinder.

These Wiseco Professional Series slugs are precision CNC machined out of a unique forging with extra material and bracing to handle high cylinder pressures. The area under the crown has thicker material for the wrist pin and extra thick webbing for the wrist pin bore and behind the skirt. Combined with all the extra support and bracing for the wrist pin bores, these pistons also feature forced pin oiling that ensures the wrist pins stay lubricated under high-stress conditions.

Wiseco’s ArmorGlide skirt coating is a proprietary low-friction coating that resists scuffing and seizing under harsh conditions while reducing friction.

To improve durability and efficiency, every piston features Wiseco’s ArmorGlide skirt coating, a proprietary low-friction coating that resists scuffing and seizing under harsh conditions while reducing friction. The result is quieter operation, improved wear resistance, and better long-term performance under extreme loads. With the power we’re aiming to push, we need all the protection we can get in the cylinders.

Wiseco offers upgraded wrist pins as well to handle the extreme force transferred from the pistons to the connecting rods, an upgrade we decided to take them up on. These wrist pins are made from H-13 tool steel and utilize a 0.200-inch wall thickness. They weigh roughly 50 grams a piece more than the standard 0.927-inch wrist pins that come with the piston set, but the weight penalty is a necessity for the power we’re aiming to make.

A 0.927-inch pin made of H13 tool steel with a wall thickness of 0.200 inches makes for an unbendable wrist pin.

GFX Ringset Bears The Brunt

Our Professional Series pistons came with Wisecos’s GFX ringset for our L8T short block. When you take the leap from a high-horsepower street engine to a race-build that can withstand 2000-plus horsepower, your typical ringset can’t handle the heat (both figuratively and literally). The top ring in a ringset takes the most abuse, as it handles almost the entire job of sealing the cylinder under compression and heat transfer as well. When colossal cylinder pressures are introduced with exotic fuels, you need a top ring that can take the abuse while keeping the chaos under control.

No ordinary piston ring set will handle the heat and abuse we plan to throw at our L8T, Wiseco Professional Series pistons comes with their GFX ringsets to take the heat.

The top ring supplied is made from steel with a nitride PVD coating. PVD (physical vapor deposition) is a thin coating that is chemically bonded on the surface of the ring using chemicals evaporated by heat with a reactive gas in a vacuum chamber. The result is a hardened compound bonded onto the ring that gives the surface increased hardness for wear-resistance, a smoother finish for friction reduction, and an increased resistance to high temperatures.

The second ring’s main job in the ringset is oil control. With higher cylinder pressures, different blends of race gas or alcohol, and looser piston-to-wall tolerances, oil control becomes a difficult task compared to a street engine. With that in mind, Wiseco’s GFX ringset comes with a reverse back twist (RBT) second ring with a tapered face. An RBT ring has a bevel cut into the lower edge of the ring on the inside. This bevel causes the ring to twist slightly, downward towards the skirt on the up stroke and upwards on the down stroke. When combined with the taper face, this action prevents oil buildup behind the ring while the taper face scrapes the bore to wipe away oil more efficiently.

MGP Making The Connection

Our combination of using the factory L8T 3.858-inch stroke crankshaft with an off-the-shelf-compression-height piston makes the required rod length unique. Combine the specialty length with our lofty power goals and we knew we needed something more than your typical forged-steel aftermarket connecting rod. We went back to Race Winning Brands to see what we could get to pair with the Wiseco pistons they supplied for our L8T short block build. We quickly landed on a set of MGP’s Pro 2500 series aluminum rods for LS and LT applications.

The MGP Pro 2500 series aluminum rods feature full radial serrations at the cap mating surfaces and custom-made ARP 7/16-inch rod bolts to keep the big end secure. The bronze dowels you see are to keep the bearings from rotating.

Instead of the typical forged steel, these are machined out of billet aluminum with a robust solid design resembling a support girder for a high-rise bridge. Measuring 6.185 inches in length, we needed the strength and weight savings an aluminum rod has to offer. On the big end, the MGP Pro 2500 series aluminum rods feature full radial serrations where the cap meets the body of the rod and custom-made ARP 7/16-inch rod bolts to ensure zero cap movement. The small end does not have a typical bronze bushing for the wrist pin, but a proprietary MGP “Hard Bore” process that provides a hardened surface of the aluminum in the bore for reduced wear and bore deformation.

It All Comes Together

After months of carefully choosing these components for our L8T short block build, it was time for assembly. With fresh bearings nestled in the mains, our factory L8T crankshaft was laid into place and torqued down under the stock main caps with ARP main studs. Once the MGP Pro 2500 series aluminum rods were fitted to each Wiseco piston with those super-thick tool steel wrist pins, they were carefully inserted into each cylinder and the rod caps were torqued down with the ARP L19 rod bolts.

This may sound like it was thrown together carelessly, but a build like our L8T short block can’t afford anything but precise tolerances to live under the cylinder pressures we’re about to serve it. The higher the load the rotating assembly sees under maximum horsepower and torque, the looser the tolerances have to be when it comes to those rotating parts like the rod bearings, main bearings, and even the wrist pins. The extra clearance will be filled with higher-pressure oil that will act like a cushion under heavy load when we mash the throttle down on the engine dyno.

The stock main caps were retained and cinched down with ARP main studs. Note the eight-bolt flywheel pattern on the L8T crankshaft.

The extra clearance for the pistons and rings helps with the ever-increasing cylinder temperatures the cylinders will ensure on the engine dyno and at the drag strip. The wiseco pistons are tough, but 2618 aluminum expands more than the stock hypereutectic pistons, so that extra piston-to-wall tolerance will give it more room to grow as the aluminum expands under the extreme heat. The piston rings will expand as they transfer that unfathomable amount of heat to the iron cylinder walls, so a large ring gap will keep them from butting against each other and failing.

With Race Winning Brands supplying us with the parts we needed for our 2,000-plus-horsepower-capable L8T short block build, the anxiety of trying to make an ultra-high horsepower Gen-V LT live under boost is significantly lessened. Stay tuned for our final article on our L8T To The Party project to see how much horsepower and torque it will crank out on Brian Tooley Racing‘s engine dyno and how much boost our 6.6-liter modern small-block can (or maybe can’t) handle.