Anytime you work on a car or project, you need the right set of tools. A hammer does you no good if you need a 10mm socket. The same rules apply when tuning an EFI system. Instead of having wrenches and sockets, you need software and hardware that allow you to monitor and log system data and to change the values stored in the powertrain control module (PCM). A number of manufacturers offer these tools, but the FlashScan from EFILive provides several advantages over competitive systems. One of these is a logical system that incorporates a dedicated identification number for each table within an LS-series PCM, ECM, or TCM.

EFILive FlashScan

If you don’t have FlashScan software, you can download it free of charge from EFILive’s website. Having access to the software will help develop an understanding of PCM operation and file structure. And although you can browse through and modify all but a handful of tables, you can’t apply any of those changes until the software is purchased and licensed.

As its name implies, FlashScan offers both flashing (the capability to “flash” a PCM with new programming) and scanning capabilities. It does so through two separate but interconnected programs. Data logs created by the scan program can be used by the flash program to locate data cells that relate to specific operating conditions.

The FlashScan system is supplied with a handheld device, cables, and software. The handheld device can monitor and data log ECM operations, read and flash tune files and read and reset trouble codes. It can be used in stand-alone mode or pass-through mode when connected to a laptop computer.

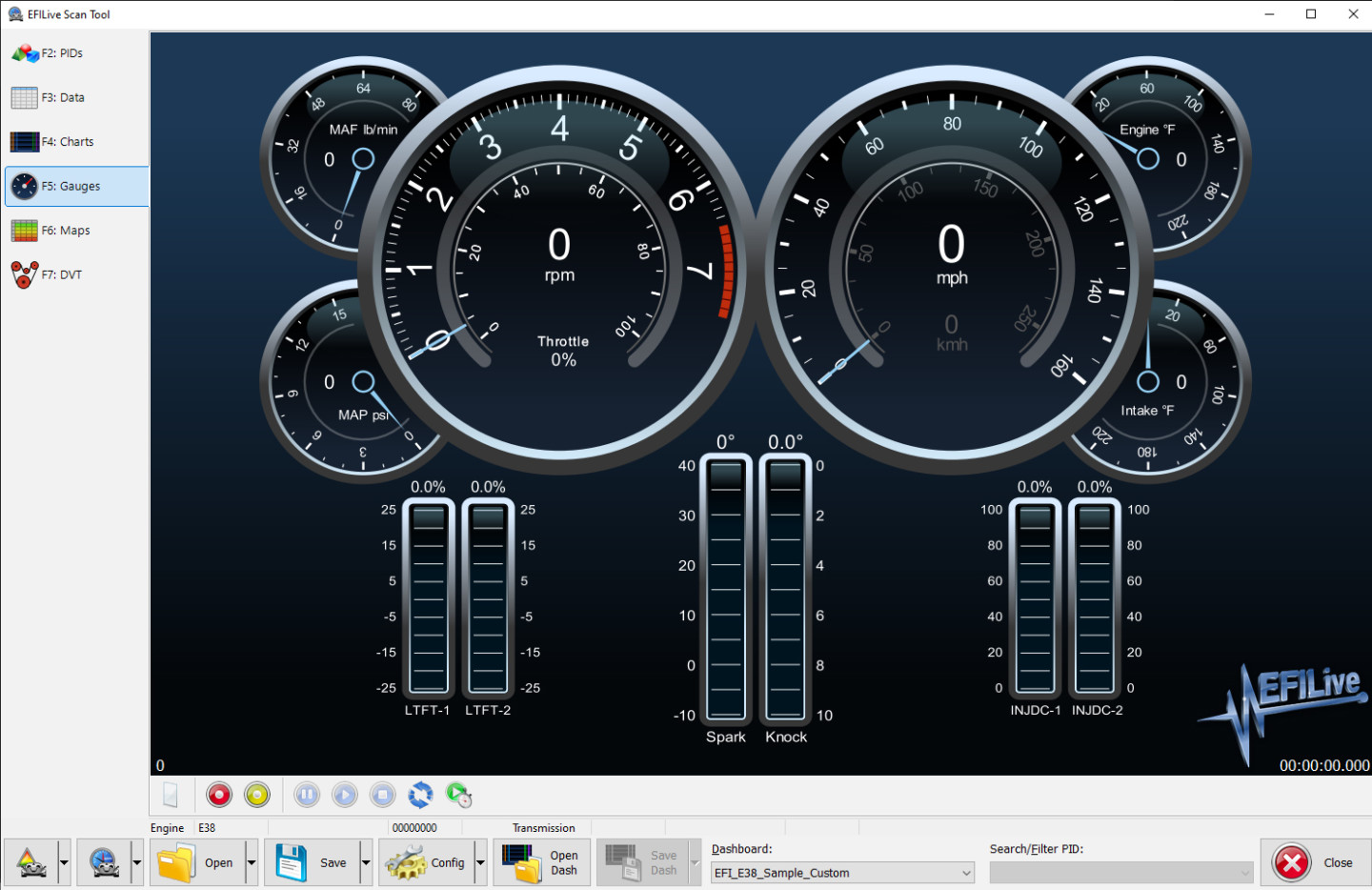

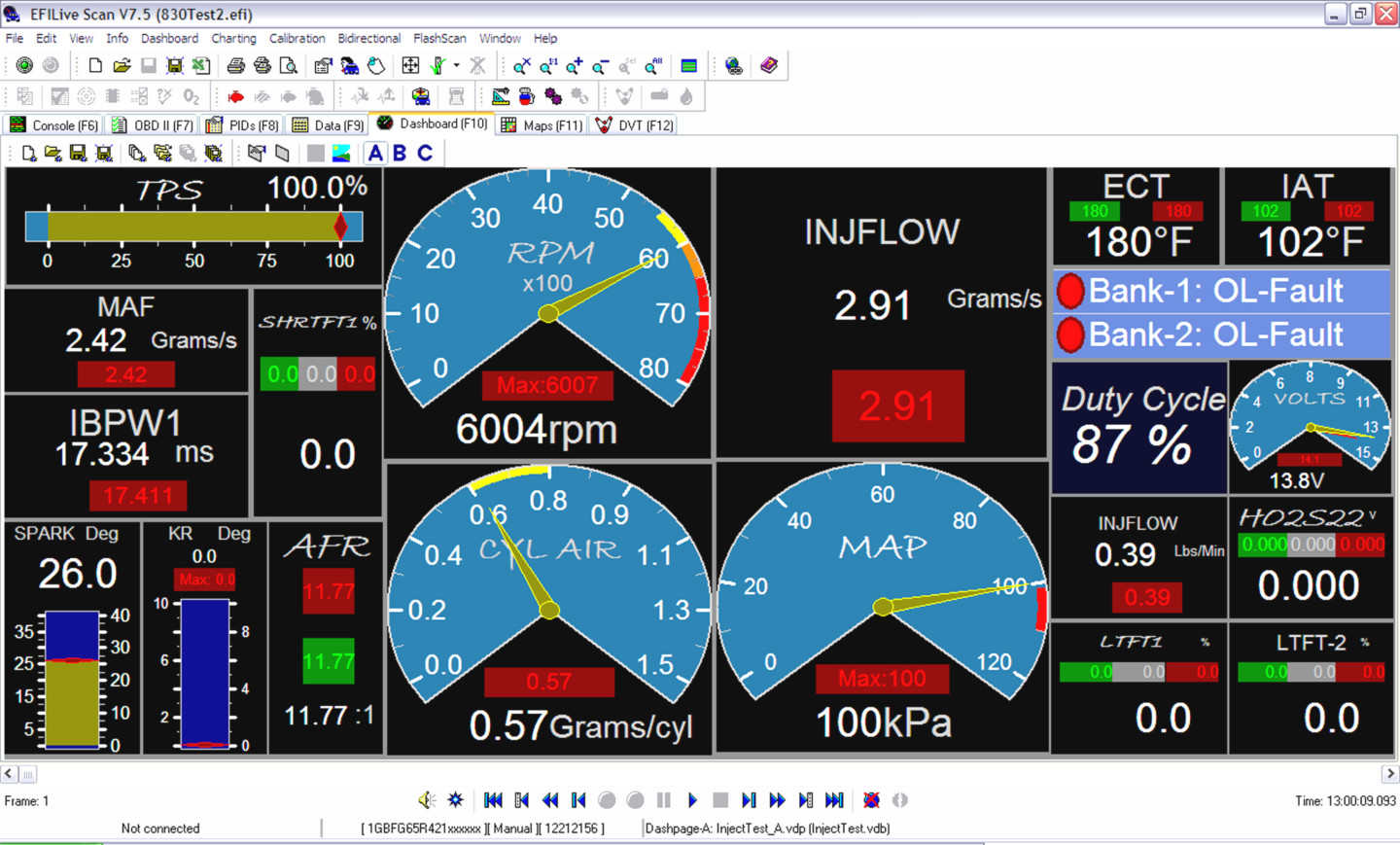

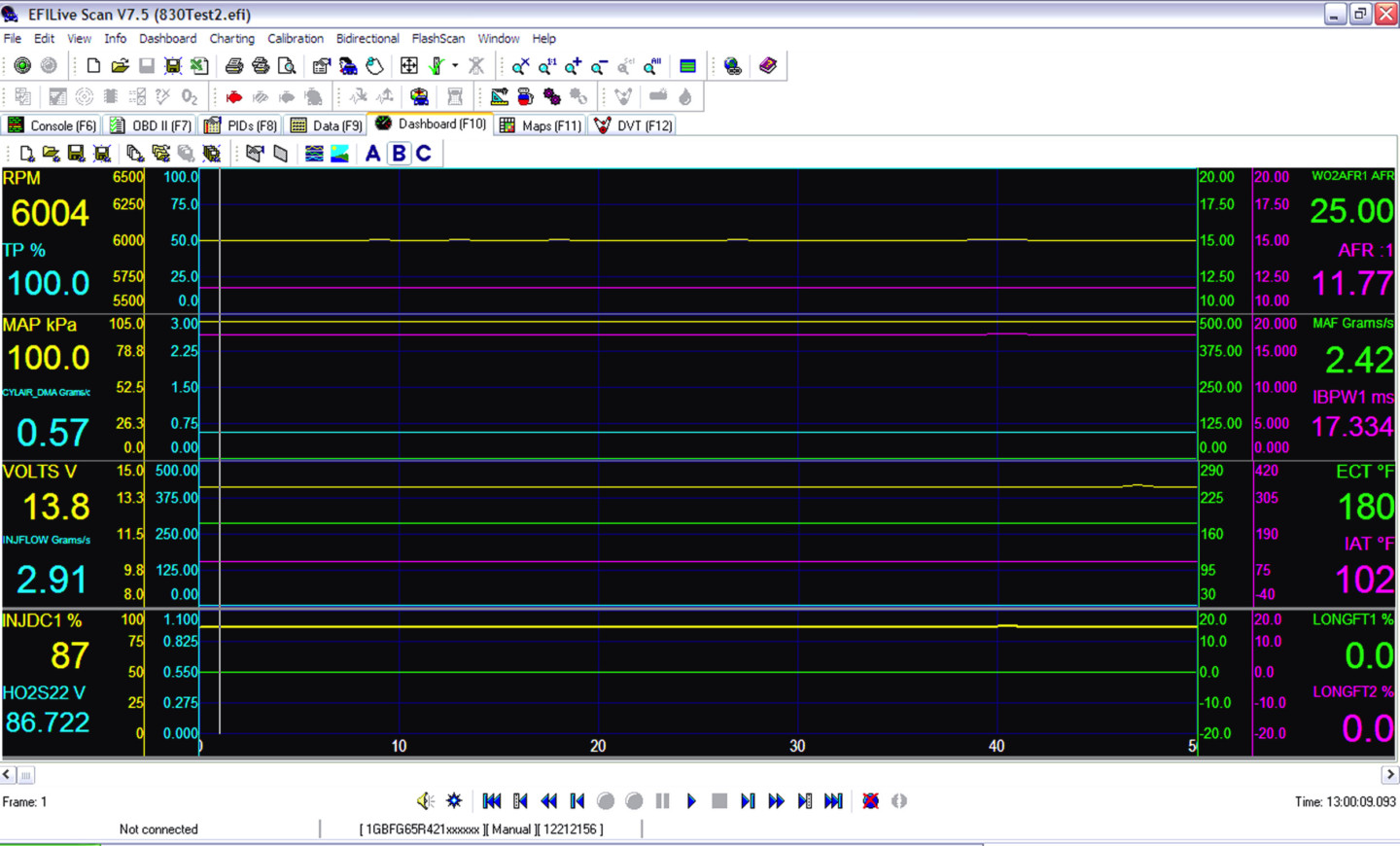

When used to monitor engine operation, FlashScan displays data on a virtual dashboard. If data is stored, it can be played back and viewed as a replay or a chart. The dashboard will also show real-time values any time the ignition is on, so sensor and controller operation can be checked with the engine not running. For example, when FlashScan’s dashboard is activated, the gauges will show actual values from inlet air temp, coolant temp, manifold pressure, and throttle position sensors. If a vehicle is equipped with an electronically-controlled throttle, the pedal movement will be indicated on the dash, which verifies that the throttle control circuit is operating properly. When an engine is running, FlashScan can work in monitor or record mode and is easily switched between the two. The difference between the two modes is that no data is stored when the system is monitoring.

Back To The Basics

Understanding how to operate tuning and scanning software is one thing; knowing how to use the software to achieve desired results is quite another. That concept seems to elude a fair number of tuners, both new and experienced. You don’t just fall off a turnip truck and start tuning electronic fuel injection systems, even if an LS-type engine is beneath the hood of the said turnip truck. An understanding of basic fuel system operation is also necessary, and strange as it may seem, one of the best ways to learn the fundamentals of electronic fuel injection is to develop an understanding of carburetors.

As primitive as a carburetor may seem compared to an LS engine’s EFI system, it performs many of the same functions, (ignition control the obvious exception). A carburetor receives “input” and commands “output through direct mechanical means” (airflow and manifold vacuum) rather than relying on sensors and controllers, as does an EFI system. Those sensors and controllers and their electronic operation can muddy the waters when you’re trying to understand fuel and airflow fundamentals.

The capacity to connect external devices makes FlashScan especially useful for testing. As shown here, an Innovate wideband O2 sensor is feeding air/fuel data to a FlashScan system during dyno testing. This allows commanded and actual air/fuel ratios to be displayed on a single chart or digital dashboard.

You Can’t Control Everything

Another common point of confusion with respect to tuning an EFI system is that results can be somewhat inconsistent. That shouldn’t be confusing because…an engine is not a digital device.

The fact that its control system is digital does not alter the fact than an internal combustion engine operates as an analog mechanism; its input and output are continuously variable. That’s the primary reason that an engine may produce different horsepower readings in tests under identical conditions. These differences may be slight, but they are rarely, if ever, completely eliminated.

From a control standpoint, it’s virtually impossible to incorporate every possible data point within an engine’s operating range. Consequently, when an engine is spinning at an RPM that isn’t included in a particular table, the PCM computes a value based on those at the nearest data points. In the case of ignition timing, if an engine were spinning at 2,560 rpm, the PCM would use the values at 2,400 and 2,800 rpm (the entries closest to 2,560).

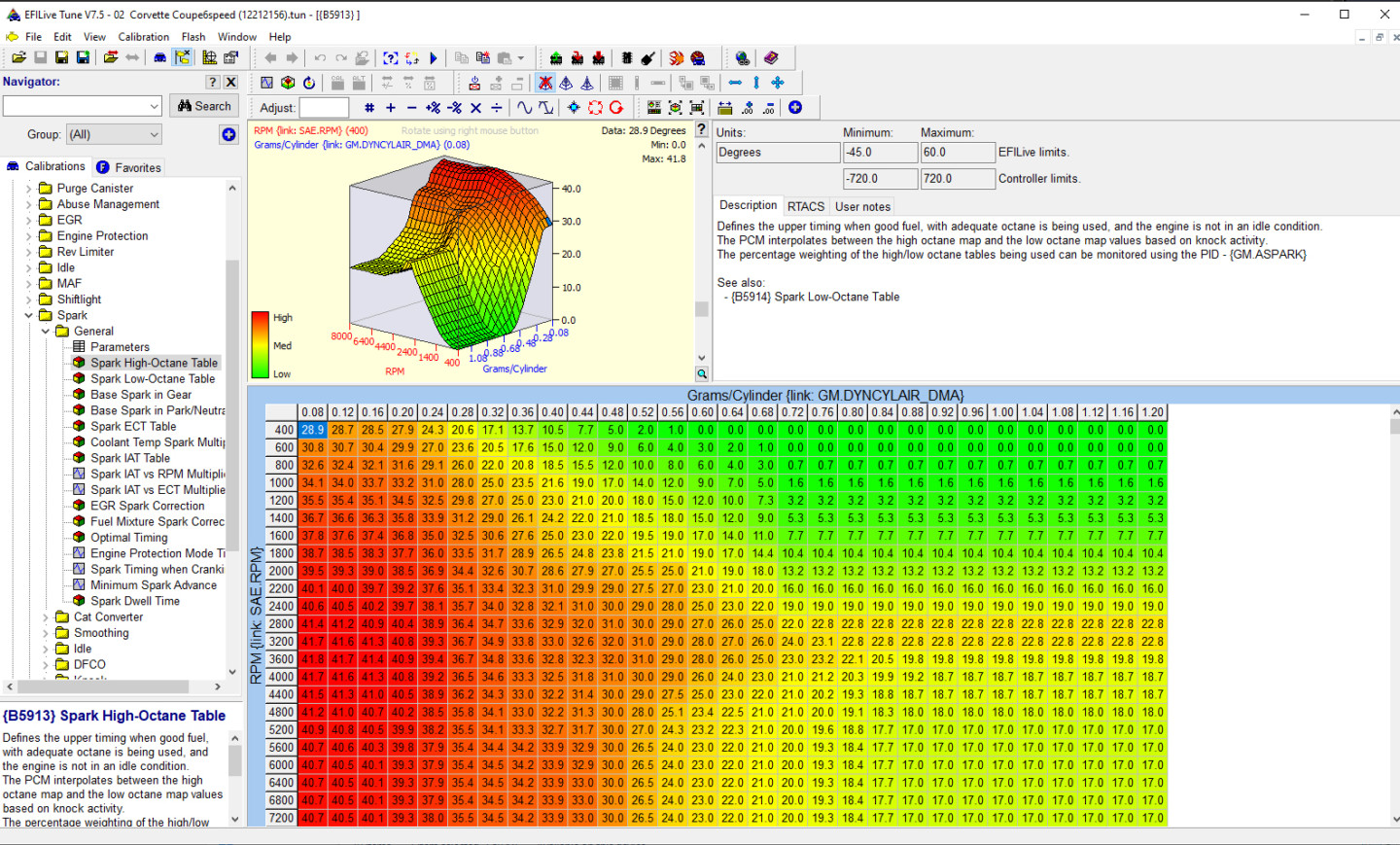

When creating a custom tune file, FlashScan simplifies the process by displaying data in various formats. Here, a high octane spark table is displayed as a 3D graph above a spreadsheet-type chart. The display can be easily changed to show only a map or only a chart.

Commanded ignition timing is also a function of engine load, so the PCM also calculates values when conditions fall between those at predefined data points. Consequently, it has to make interpretive calculations based on values along two axes of a table. In this case, engine load lies along the X-axis and engine speed along the Y-axis.

The same types of interpretive calculations are made for fuel flow, and the accuracy of these calculations play off one another. Even so, under worst-case conditions, the results are rarely very far off the mark and are only apparent during monitoring and testing. Often, tuning “errors” are actually the consequence of interpretive calculations compounded by a tune that isn’t highly refined. That doesn’t necessarily mean that the tuner did a poor job; he or she may have, in fact, done the best job possible within the constraints of a customer’s budget. If the only “problems” that surface are those found while logging data, the tune isn’t very far off.

On the other hand, many “professional” tunes appear to have been done by little Johnny during his first day of tuning school. If you’re working with one of these, it’s often easier to go back to square one and start with a stock file. For example, I once had a racecar owner who wasn’t happy with the results of the “professional dyno tune” in his vehicle’s PCM. He asked me to download and evaluate the file. After going through a few of the tables, it occurred to me that you can fall off a turnip truck and tune an EFI system. You just can’t do a very good job. The values in a number of tables were so far off that the tuner had specified a commanded air/fuel ratio of 16:1 under wide-open throttle.

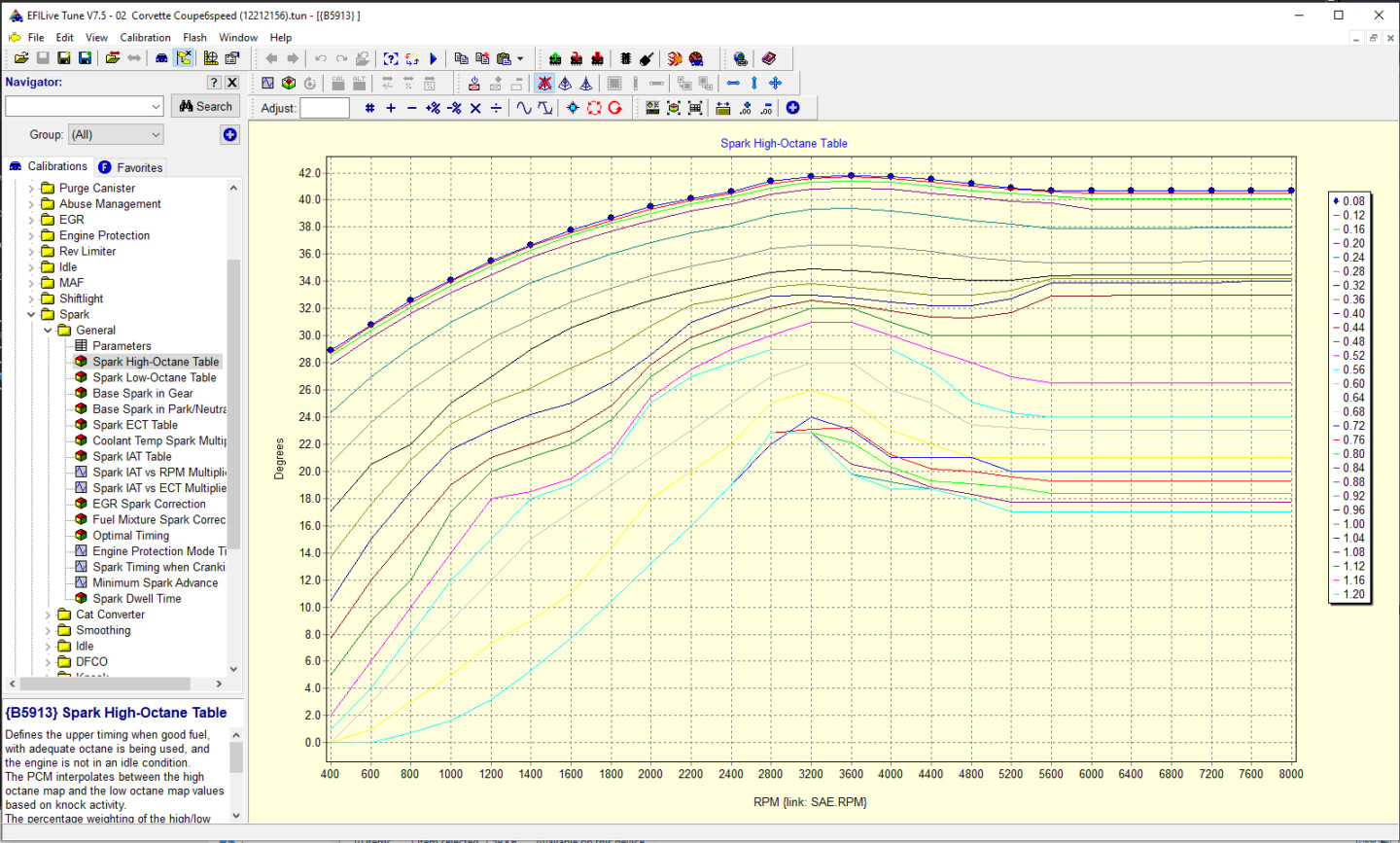

Sometimes, it’s easier to see hills and valleys in the data using a 2D display. Values can be changed by selecting a particular line of data, clicking on one of the dots, and dragging it to the desired position.

Obviously, the engine wasn’t operating at that air/fuel ratio, but if a 16:1 commanded value was required to achieve actual ratios of 12.5:1- 13.0:1, the data in a number of other tables were about as accurate as a cost estimate for a government project. In this case, it would have taken more time to ferret out all the bad data than it would to modify a file that was known to be good. But irrespective of the starting point, you should always keep a practical endpoint in mind. Some tuners waste a lot of time trying to achieve a precision level that is unrealistic because digital precision is tough to achieve from an analog mechanism.

Finding a Starting Point

As soon as Little Johnny graduated from EFI Tuning School, the first thing he wanted to do was take a car to the dyno, whip out his laptop, and start tuning. Unfortunately, there are far too many real-world equivalents of Little Johnny who want to do the same thing. If your only concern is a dyno sheet with a number of sufficient magnitude to impress your friends, there’s no question that the dyno should be your first stop. If, on the other hand, you want a vehicle that delivers optimum performance and efficiency at all throttle settings, the dyno should be your last stop.

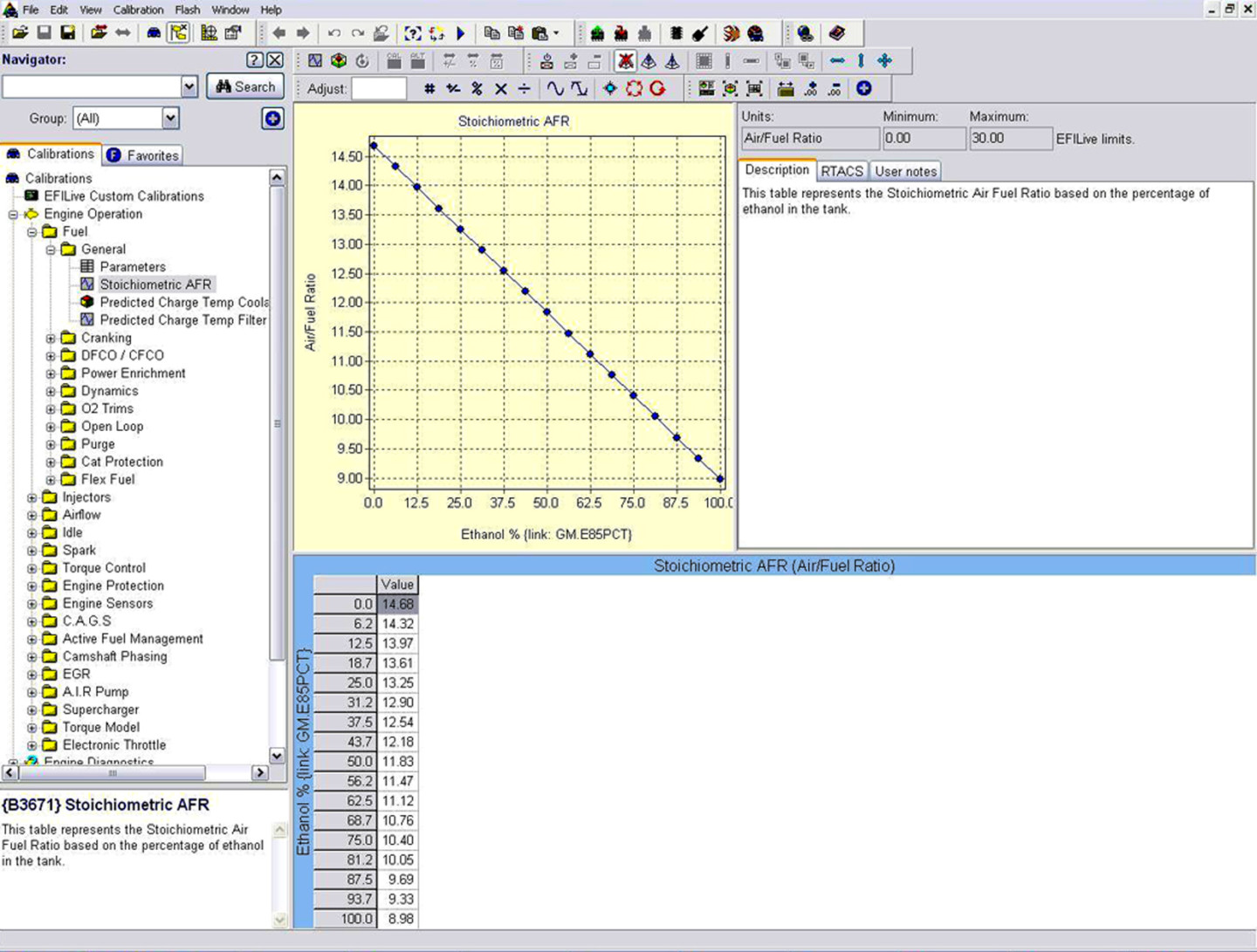

Now that most gasoline contains at least 10-percent ethanol, stoichiometry is rarely 14.7:1. Many ECM operating systems include a table that allows a specific stoichiometric air/fuel ratio to be established for various ethanol percentages.

Wide-open throttle tuning is the easy part. A naturally-aspirated engine safely produces maximum power when the air/fuel ratio is approximately 12.9:1; depending on boost levels, turbocharged and supercharged engines respond best to air/fuel ratios between 11.5:1 and 12:1. Ignition timing that is a few degrees less than the point at which it causes detonation, is typically the second part of a maximum power equation.

Experienced tuners develop preferential settings based on experience, but as settings approach their optimum values, they reach a point of diminishing returns. Within a specific range, “optimum settings” are simply subjective trade-offs between power and safety. Maximum power comes at the expense of safety, and the highest safety comes at the cost of power. It’s always better to give away a few horsepower with a conservative tune than to carry an engine home in a basket because it was too aggressive.

In most cases, changes made when tuning for maximum power do not affect part-throttle operation. However, many settings used to improve idle quality, low-speed drivability, and throttle response will affect wide-open throttle operation. For example, if the injector flow rate has to be changed to bring long term fuel trims into line, the entire fuel delivery rate will be affected. If wide-open throttle tuning has already been completed, it will have to be redone.

EFILive’s V8 software provides new dashboard graphics. Like the older style dashboard, each gauge can be customized.

When you tune an engine for the first time, even if it has already been tuned by someone else, the most logical approach is, to begin with known information and work through the relevant tables in the following sequence. The numbers in parentheses identify the tables in FlashScan that relate to the individual functions for LS1 controllers. If you’re trying to improve the performance of an engine that hasn’t been modified, changes may not be necessary. Use this sequence as a checklist to verify that the values in the respective tables properly match known information. All of the following values can be established before a newly-installed or modified engine is started for the first time. (The following EFILive table numbers are for an LS1 PCM. Other model PCMs, such as E38, E67, E92, may have a different number for the described table.)

- Injector flow rate (B4001): this should be a known value based on flow test data or advertised flow rates. Note that actual injector flow rates are dependent on system fuel pressure. Values entered in table B4001 must be matched to the flow rate of the injectors at the operating pressure of the system in which they are installed.

- Idle speed (B4603): Desired idle speed should be based on cam specifications. Most performance-oriented street cams are “happy” with an idle speed of 800-850 RPM.

- Idle Desired Air Flow (B4307): this value will vary depending on cam profile, engine displacement, and torque converter stall speed. If you’re starting with a stock calibration and trying to establish initial values for an engine with a newly-installed performance cam, increase the values by one gram per second. Keep in mind that this is only a starting point, and additional refinement will be required.

- ETC Throttle Area Conversion (B4349): Electronically-controlled throttle bodies do not contain Idle Air Controllers. Idle air flow is controlled by throttle position. If the original throttle body has been modified or replaced with one having a larger diameter opening, this value may need to be changed. It’s also possible to compensate for different airflow capacities by altering the desired settings to a degree. If an engine has a mechanically-controlled throttle body, it may be necessary to adjust the throttle stop screw to bring IAC counts back into range.

- High Octane and Low Octane Spark Tables (B5913 and B5914): Most performance cams “like” aggressive idle spark settings. Typically 20-degrees is a good starting number for the 600, 800, and 1,000 rpm rows from the .08 and .24 grams per cylinder columns.

- Base Spark in Gear & Base Spark in Park/Neutral (B5923 & B5933): The values in the high and low octane spark table for the corresponding RPM rows should be duplicated here to smooth the transitions between tables.

- Cylinder Volume (B0104): The value in this one-cell table requires modification only if engine displacement differs from that of the tune file’s original installation. The value in B0104 “tells” the PCM the displacement of a single cylinder (expressed in cubic centimeters). Typical values are:

Engine Displacement Volume of single Cylinder

- 4.8 liters 600

- 5.3 liters 666

- 5.7 liters 708

- 6.0 liters 705

- 6.2 liters 775

- 7.0 liters 875

For other displacements, divide engine size in cubic centimeters (liters times 1000) by the number of cylinders.

EFILive dashboards operate in real-time and can display data in digital or analog form or both. Some displays, such as the ones for fuel system status, use a color indicator. In this case, the indicators are red, which indicates the system is in an open loop. When it switches to a closed-loop, the indicators turn green.

After establishing the appropriate values in the tables noted above, open the Engine DTC Processing Enabler Table (C6001) and set the codes for unused sensors to “Not Reported.” As an example, if you’re installing an LS engine in an off-road vehicle that will not be equipped with catalytic converters, set P0420, P0430 (Converter efficiency) to “Not Reported.” If catalytic converters aren’t installed, there’s no need for post catalytic O2 sensors, so the appropriate codes (P137, P138, P140, P141, P157, P158, P160, and P161) should also be set to “Not Reported.”

You may also need to modify two other diagnostic tables before starting an engine for the first time after installation, or after certain modifications. If an engine is equipped with a ported or aftermarket electronically-controlled throttle body, there’s a good chance that actual airflow will exceed the maximum values in table C6101. If that happens, DTC 1514 will be set, and the system will enter “Reduced Power” mode, in which case the gas pedal will appear to be disconnected from the throttle body. Normal operation will be restored after DTC 1514 is cleared.

After data is logged and saved, it can be displayed in graph format. If a particular area of the graph is selected, the cells in the active tune file are highlighted. That dramatically simplifies tuning because you don’t have to guess which sections to change to correct or optimize engine operation.

Some tuners, with unrealistic opinions of their driving prowess, eliminate the potential for setting DTC 1514 by setting all cells in C6101 to the maximum value which is not a wise move. This table exists to prevent the throttle from remaining open in the event of a throttle controller or sensor failure. Although such failures are extremely rare, they can occur, so it’s best to use values that eliminate the possibility of engine, vehicle, or personal damage caused by a throttle that doesn’t close when it should.

While tuning is not impossible, having the right tools, and knowing how to use them is a necessity for success. With EFILive and these tuning tips, you will be headed in the right direction. Be sure and download the latest version of FlashScan software here and check out EFlLive’s website for other products.