One of the more popular questions we get asked here at LSX Magazine is “how much does an LS swap cost,” followed by “what’s involved?” Unfortunately, there’s not a good answer to either of these questions. And when asked, we will typically respond with “it depends,” due to all of the different options, engine combinations, available parts, or lack thereof. All of these factors play a major role in cost. And while we can’t give you an exact price, we will go down the line for everything needed for an LS swap and shed some light on what you can expect.

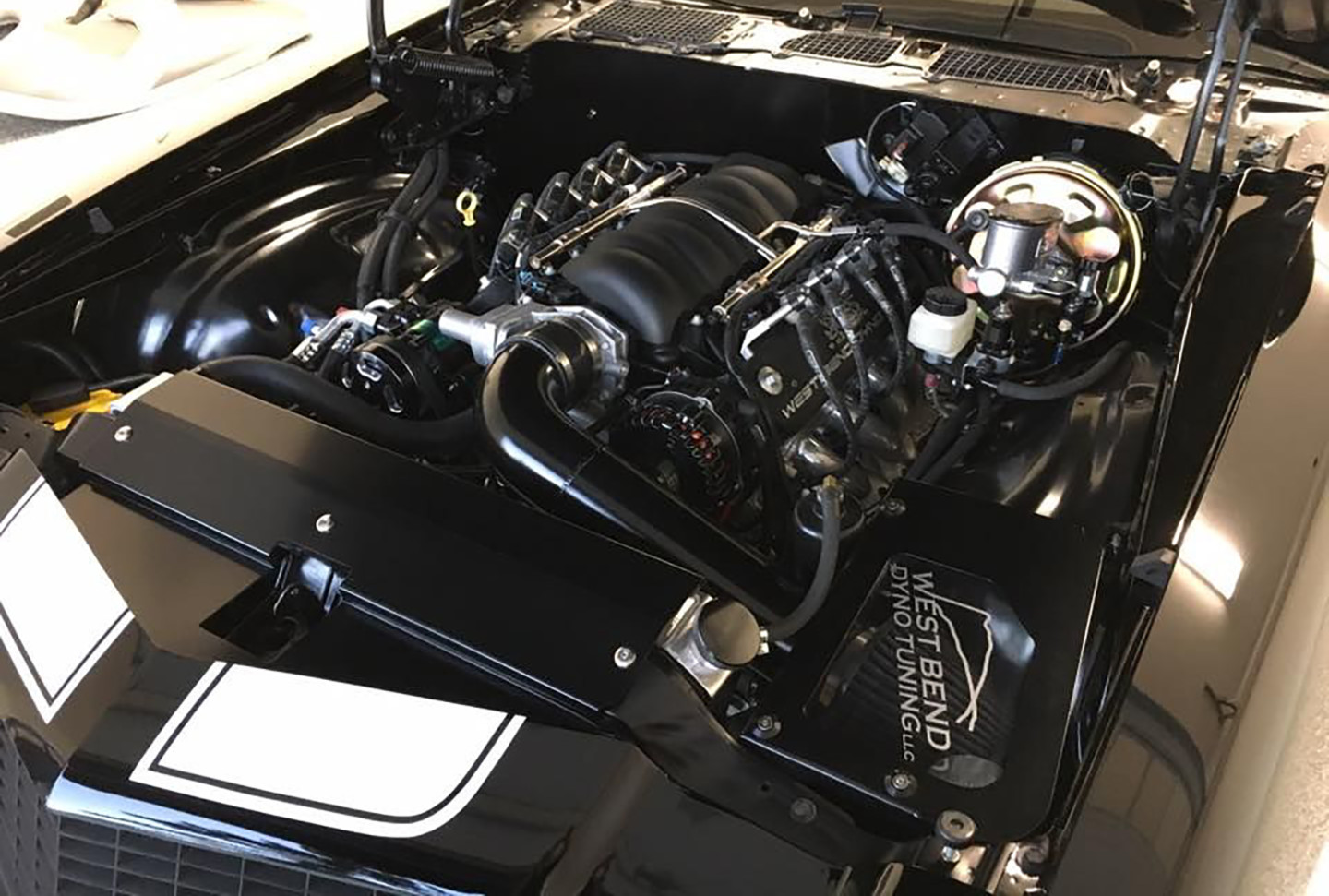

To help us navigate this piece, we reached out to West Bend Dyno and Tuning LLC. The company is well versed in converting classic cars and hot rods into modern times with LS-based engines and transmissions.

Choose Your Powerplant

When it comes to selecting an engine, there are a lot of choices to choose from. First, of course, everyone knows that the 4.8- and 5.3-liter LS engines are popular because they’re inexpensive. But if you are looking for more power, whether naturally aspirated or with a power adder, a larger engine will be your best bet as it usually costs the same to build any LS. The only difference will be the larger LS engines will cost a little more upfront.

If you’re looking to have an engine built instead of using a junkyard engine, most shops can help. West Bend dyno told us that the starting price is around $4,500 for a complete long block. Typically, the price will go up from there based on your needs. While the LS engines are relatively affordable, you’re not going to be able to build a reliable 1,000 horsepower engine for a few thousand dollars.

And while there are guys out there going fast with junkyard engines, we’ve noticed that the ones who are doing it know how to tune to keep these engines alive. On the other hand, we know people on their seventh “junkyard LS” and have yet to go fast. In our opinion, you’re much better off spending the money needed upfront and building an engine that will last. As they say, “if it’s cheap and fast, it most likely won’t be reliable.”

LS Engine Accessories

Here’s another area where people try to save money on a swap: engine accessories. Some enthusiasts will try to use the factory oil pan, OEM accessory drive, wiring harness, and intake manifold for the transplant. The problem here is that most of these items will not work unless it’s going in an older vehicle with a ton of room, like a truck. The reason is they were specifically designed to fit a certain vehicle. That’s why engines out of cars have lower intake manifolds and tighter accessory drives than LS engines out of trucks or SUVs.

When it comes to accessories, we’re a fan of going ahead and purchasing new parts rather than trying to make the OEM parts fit. And believe us when we say we’ve done both, and buying new parts might cost you more, but it’s well worth it. For example, we’ve had to pull engines back out of vehicles because things didn’t fit, which cost us time and money. So we would rather spend a few extra dollars and do the job once, the right way.

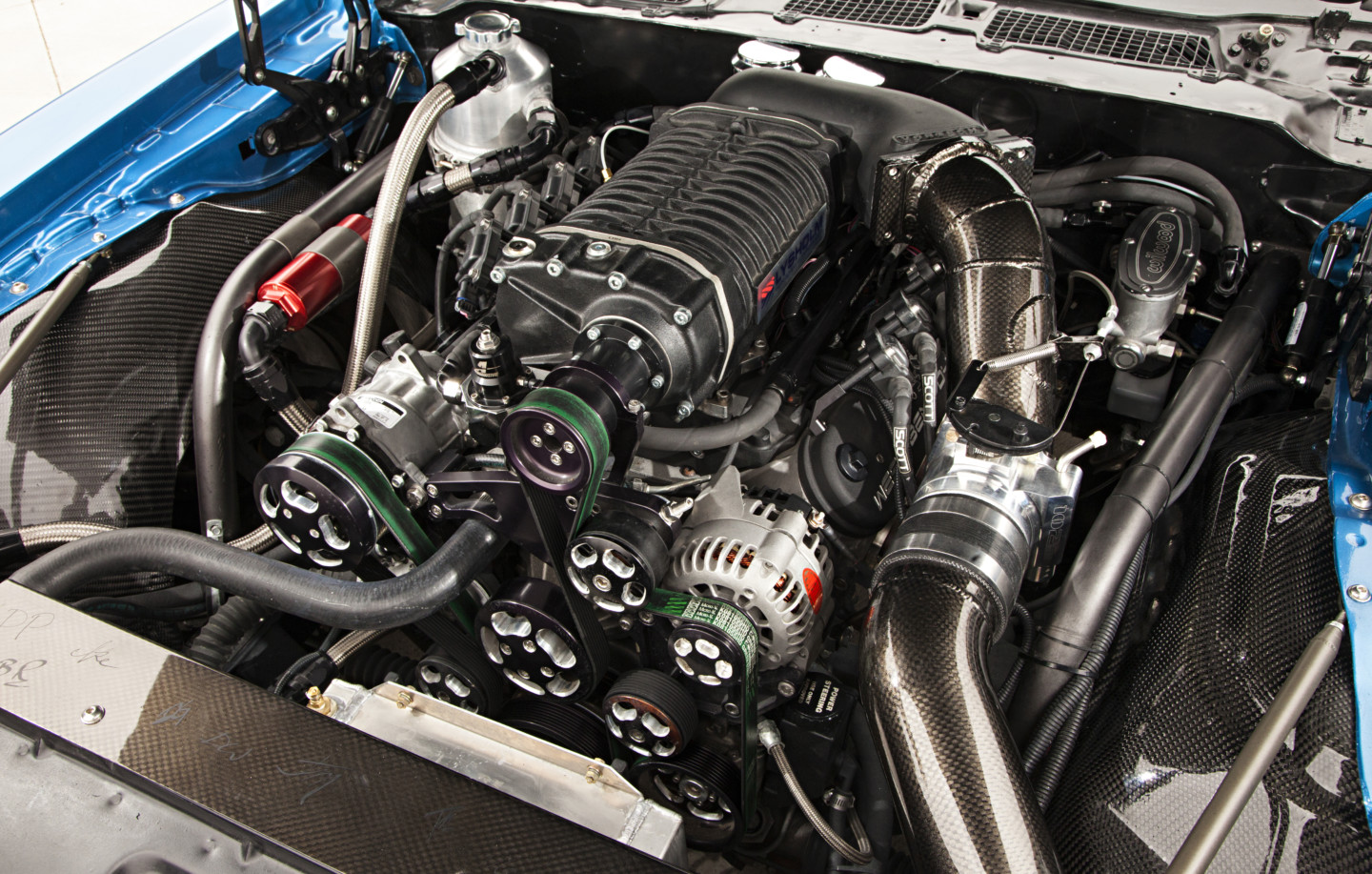

Companies like Holley offer just about everything you need, from accessory drives, swap oil pans, intake manifolds, exhaust manifolds, motor mounts, and more. If you visit the website, it even offers conversion kits based on the more popular vehicles for LS swaps. And while oil pans and other knick-knacks are relatively affordable, you will need to spend some money if you plan on using an aftermarket intake. West Bend Dyno said A complete top-end kit ranges from $850 to $3,000, depending on your needs. Also, while most intake manifolds are pretty affordable, things start to add up rather quickly if you need a new throttle body, fuel rails, injectors, and even a carburetor.

Accessory drives can also be pretty pricey. A custom accessory drive costs around $1,150 without A/C, up to $4,000 with all the bells and whistles, including custom finishes, billet material, aftermarket damper, power steering, A/C compressor, from West Bend Dyno. Supercharger drives are also costly, as well, so keep that in mind if you’re looking to add boost to your hot rod.

Standalone Harness

Many enthusiasts have more time than money and will use the factory ECU and modify the factory harness for their project. However, there are several problems here that we have figured out over the years. One, it’s a very tedious process and can take several hours to complete. Two, taking a high-mileage harness with brittle wires is asking for trouble down the road. Finally, you don’t have options for adding longer wires to mount the ECU and will be at the mercy of the factory lengths.

While building a custom harness might be OK for a DIY guy – and we would argue that point – this is a terrible idea to have a shop perform these services. Since they have to charge for their time, you are much better off purchasing a new standalone harness. This will not only save you money, but you will also have a new customized harness explicitly built for your needs that will be trouble-free. These harnesses start in the $750 range without an ECU.

OEM ECU vs. Aftermarket

The OEM vs. aftermarket ECU is a hot topic and one that is still debated. Each has its pros and cons, and West Bend Dyno says that selecting one is determined by intended vehicle usage and anticipated horsepower output. For example, some people prefer the factory ECU and standalone harness for a mild build. However, if you plan to make significant power or add nitrous or boost, the tunability in an aftermarket ECU can’t be beat.

West Bend Dyno pricing for an OEM computer and standalone harness starts at $1,500. The pricing for an aftermarket unit, like Holley’s Terminator X MAX harness and computer, starts at $1,400. And while you would think that choosing the aftermarket ECU is the better route, again, it depends on the application and what you intend to do with the vehicle.

Transmission Upgrades

The odds of hooking up an LS engine to an older vehicle’s drivetrain are pretty standard these days, especially if it’s a GM vehicle. Companies offer parts to bolt the modern engine up to a Powerglide, TH350, TH400, 200R4, 700R4, and most manual transmissions.

There is a problem though: some of these transmissions were not designed to hold the power that the LS can generate, specifically when the engine is modified with high-performance parts. Plus, when combined with high mileage, they don’t last long. So whether you’re planning on rebuilding a factory transmission or replacing it with a new one, be prepared to spend some money. Depending on choices and configuration, prices can range from $2,200 to $9,000 and up.

Axle Options

Like the transmission issue, the rear axle is another concern that will need to be evaluated.

West Bend Dyno said that on some applications, the existing rearend can handle your new engine output. Like the transmission, they recommend a rebuild/refresh of the rearend to support the increase in power. However, a new rearend may be the best option.

If your rear axle needs some work, parts can range from a simple set of seals to replacing the entire differential and axles. West Bend Dyno pricing starts at $1,200 for a typical teardown and rebuild. If a new rearend is the best option, pricing starts at $2,200. And if your horsepower goals are high, a customized rearend can easily range from $3,000 to $4,000 and up.

Driveshafts

The driveshaft is another area of consideration when it comes to an LS swap. Most of the time, enthusiasts will choose to run a more modern four-speed automatic transmission. These units are longer than the two- and three-speeds, requiring a shorter driveshaft. A new driveshaft can be purchased for $350, including a new slip joint and u-joint. But, if you’re planning on making a ton of horsepower, get ready to spend some cash.

Higher horsepower applications will need more exotic materials and larger diameters and can easily exceed $1,000. Material choices include carbon fiber, chromoly, and aluminum. You might also need to beef up the u-joints and add a driveshaft loop for extra protection.

Exhaust

With a new LS powerplant, you will need at least a new set of headers or exhaust manifold. Cast exhaust manifolds and shorty headers are the least expensive option, starting at $150, while long-tube headers begin at $750 and go up from there. But, In some cases, the entire exhaust system will need to be replaced and that’s where exhaust systems tend to get expensive.

According to West Bend Dyno, your existing collector back exhaust may not be sufficient for the horsepower output of an LS engine. The condition and materials of the existing exhaust may also be poor and need improvement.

If this is the case, then a new system is a must. A stainless steel collector-back exhaust system starts at $1,100 but could be much more, depending on your choice. An H-pipe, X-pipe, grade of stainless steel, and the mufflers of choice will all play a part in the final cost.

Fuel System

Since most LS swaps occur in older cars without fuel injection, the fuel system will need to be upgraded. While some shops will utilize the factory tank and modify it to work with EFI, West Bend Dyno advises against it because most LS swaps require a completely new fuel system. Therefore, primary or secondary in-line fuel pumps and retaining existing questionable fuel tanks and lines are not recommended or advised. Instead, West Bend Dyno recommends a new fuel system, which would consist of an EFI-ready fuel tank, fuel pump(s), feed, return, vent, filter, fuel pressure regulator, and new lines and fittings. A package like this would start at $2,400.

Cooling System

It’s no surprise that some existing OEM radiators can be modified to work with an LS swap, but most are not up to today’s standards with efficiency. Plus, older vehicles use manual fans that are less than ideal on a hot rod and lack efficiency. Fortunately, the performance aftermarket has just about any combination you can think of with electric fans, as well.

Pricing for a new cooling system will start at $800. After that, things like fan choice, size of radiator, single or dual fans, fan shroud, and finishes will undoubtedly drive up the price rather quickly.

But the radiator is not the only thing that needs to be addressed. A secondary transmission cooler is a good idea if you’re using an automatic transmission. If you’re running an automatic, chances are you have a mild to wild torque converter specced to match your camshaft profile and horsepower goals. The transmission cooler in the radiator is most likely not sufficient for your needs. The addition of a secondary trans cooler is usually required.

Pricing for a basic secondary trans cooler, including lines and fittings to install, from West Bend Dyno, starts at $450.00. This package will include plate style cooler, -AN lines, and fittings. You can also choose to run an electric fan and finishing options for an additional cost.

Miscellaneous Parts

While we covered most parts needed for an LS swap, we’re not out of the woods yet. As with any project, you always have those small required items from the parts store or aftermarket that will, as they say, “nickel and dime you to death,” which is why it’s no surprise that shops have to keep track of this.

There are several items often overlooked with an LS swap. All the miscellaneous items needed to complete the swap can add up quickly and must be accounted for. Some of these items include transmission mount, gaskets, belts, hoses, lines, clamps, clips, heat sleeve, exhaust wrap, fluids, filters, flexplate or flywheel, and a starter, to name a few. You might also need an A/C recharge, suspension alignment, or a catch can.

For all of the above parts and services, West Bend Dyno starts at $1,400. And like everything else, this is a starting point because more items might be needed depending on the project.

Labor

If you decided to do an LS swap yourself, you could omit this section. In that case, it will be considerably cheaper than taking it to a shop because, as car guys, most never consider our time. However, if you plan to take your project to a shop like West Bend Dyno, be ready to pay for its time and expertise with engine swaps, as the company charges a $15,000 minimum when performing an engine swap. And while that may sound expensive, they are doing much more than just installing a new engine. They also address the transmission, driveline, exhaust, cooling, and fuel systems, which can take several days and sometimes weeks to complete. A job this big is not something you can do over the weekend’s time, regardless of what the internet might say.

In The End

If you’re planning on dropping off your project with a shop, here are a few ways to save yourself some of that hard-earned cash. First, start with a car that can be easily swapped. LS conversion kits are available for just about every popular GM car or truck. There are also a few Fords and imports that have the full support of the performance aftermarket when it comes to LS swaps.

Second, if you’re having a shop swap the engine for you, consult with them first. West Bend Dyno said that if someone starts a project before consulting them, it almost always ends up costing more, as some parts will not work or are incompatible or installed incorrectly.

Finally, be realistic with your expectations. An LS swap is not a small task and takes time. Even professionals will encounter problems that need to be managed during an engine swap. And as with any project, you will likely spend more money than you predicted, whether you let a shop handle the installation or if you decide to tackle it yourself. If you’re dropping your car off with a shop, call them first and discuss your needs and price. Doing so will give you a solid baseline of what’s involved and a ballpark price.