GM’s 4l60e transmission seems to get a bad wrap most of the time from performance enthusiasts. These units are pretty solid for stock vehicles, as we have seen them go for 250,000-300,000 miles with no problems. However, when you start adding power, the 4L60’s days are numbered. And while some of us have lived our lives one 4L60e at a time, you will come to a crossroad at some point in your life: should you build another 4L60e from a top-notch builder or go a different route?

You might think that the 4L60e is a much larger transmission than the TH400 since it houses an extra gear, but that’s not the case.

A few months back, we had just completed a turbo installation on our 2000 Project Silverado and were getting ready to tune it. The transmission, a “built” 4l60e with a Circle D Specialties torque converter, had never given us any problems in the past. And while we never expected the modern-day four-speed to live forever, we did expect it to last longer than it did. After a handful of pulls on low boost (12-pounds), the transmission decided it had enough. Overdrive was acting a little weird, and as we headed to the house, things only got worse for the Silverado. By the time we made it home, we were down to three gears; first, second, and reverse. Now, I don’t know if you’ve blown up as many 4L60’s as we have, but eventually, you get to a point when this four-speed transmission is no longer an option.

The Dilemma

A four-speed transmission is excellent if you use them for daily commutes or long trips; the tall fourth gear and lockup converter will enhance fuel mileage while lowering the engine RPM. And while we knew we weren’t going to put a 4L60e back in the truck, we did consider a 4L80e. After looking at the prices for a built unit that will handle 1,000-plus horsepower, trans brake, and a manual valve body, we quickly reconsidered. We had quotes from $5,000 to $9,000 depending on the supplier and various options. So, this got us thinking about whether we need a fourth gear and lockup converter? Since our truck sees limited street duty and is hardly ever on the highway, a three-speed makes a lot more sense. It’s one-third of the cost of a 1,000 horsepower capable 4L80e and will be much cheaper to rebuild if we ever need to do so.

TCI’s TH400

We reached out to Jeff Reed, TCI production manager, to see what we’d need for our combination. Reed said, “The most significant advantage to a TH400 or a 4L80e over a 4L60E is that they are more robust units. The 4L80e has many of the same factory heavy-duty components as the TH400, but if there’s a weak link in the 80e, it’s fourth gear. Otherwise, it’s a solid piece — but the TH400 is stronger overall.” Since we’re looking for the most reliable transmission for the heavy Silverado, we were already sold at this point in our conversation. But we still had some questions about this transmission.

Upgrades

We know that the factory TH400 transmissions were stout straight from General Motors, but we wanted to know what TCI would change out for our combination.

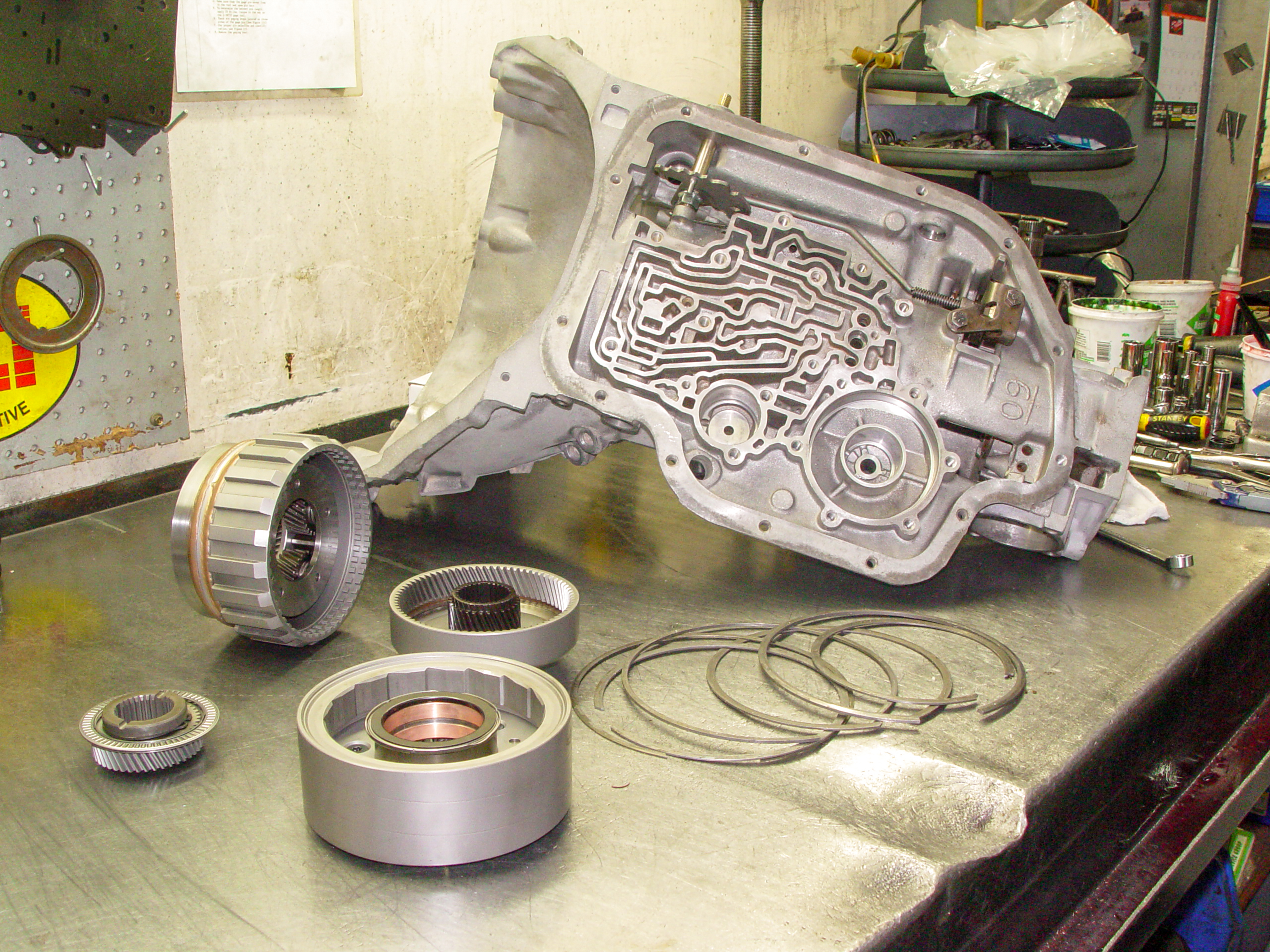

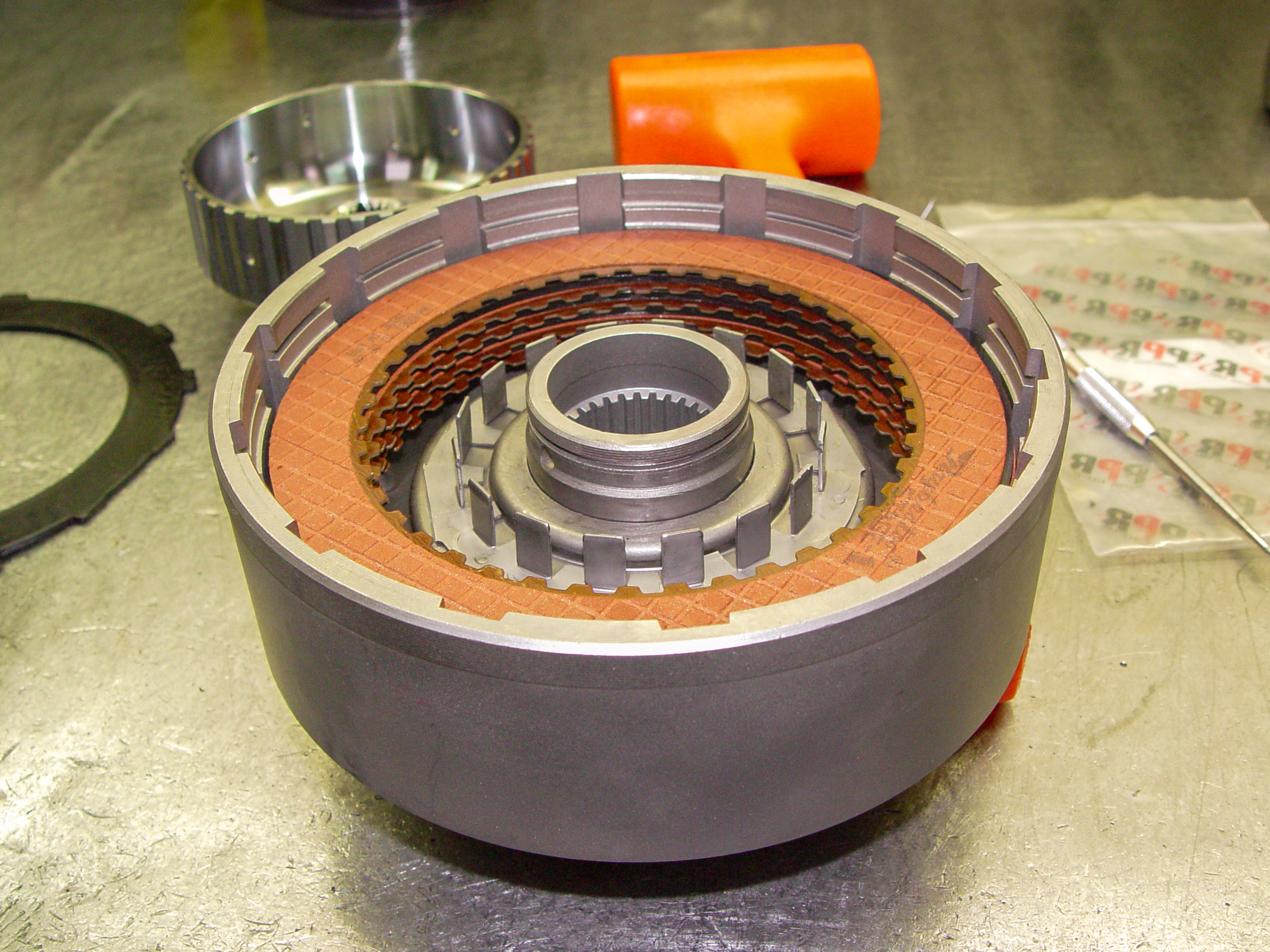

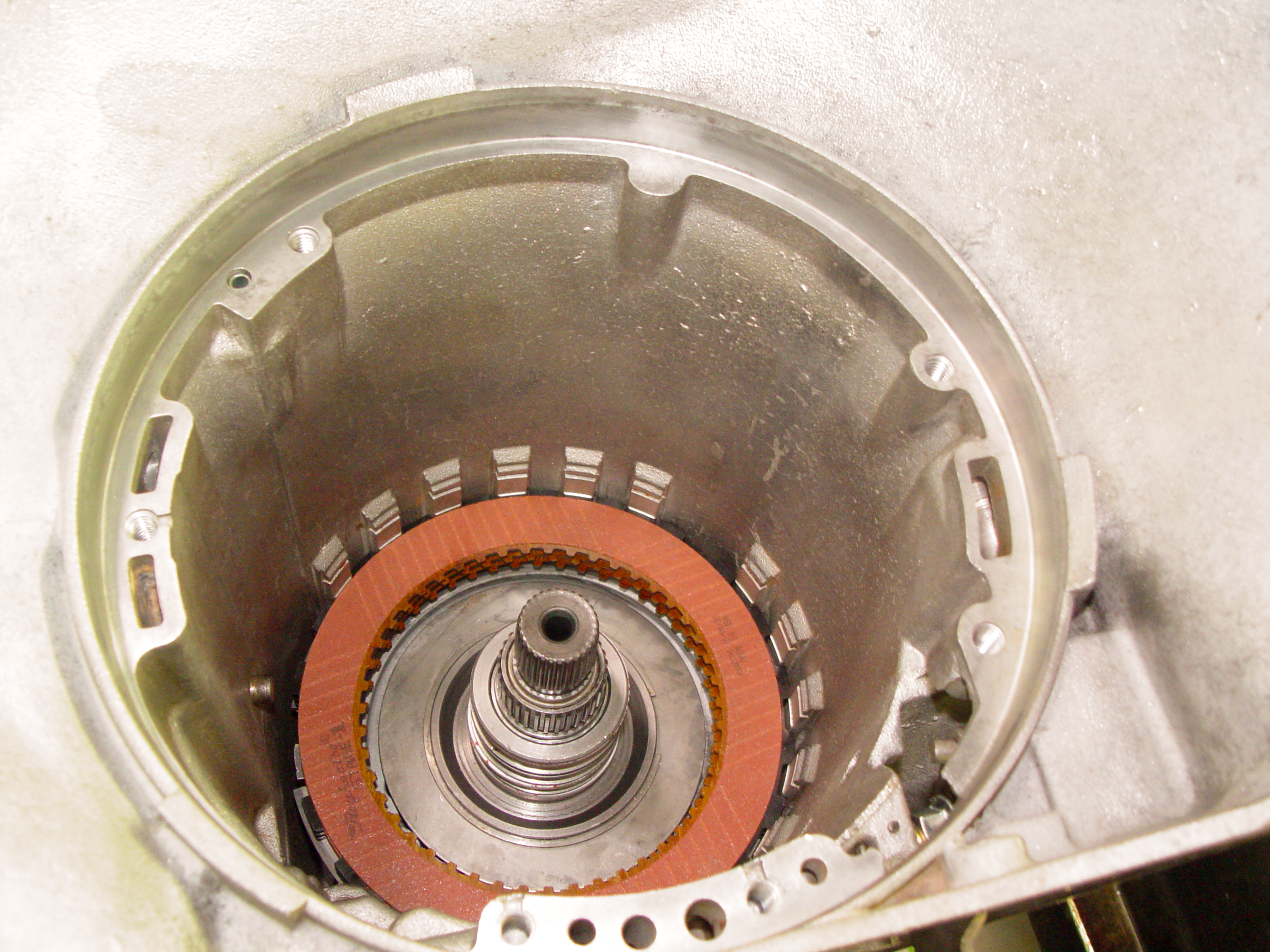

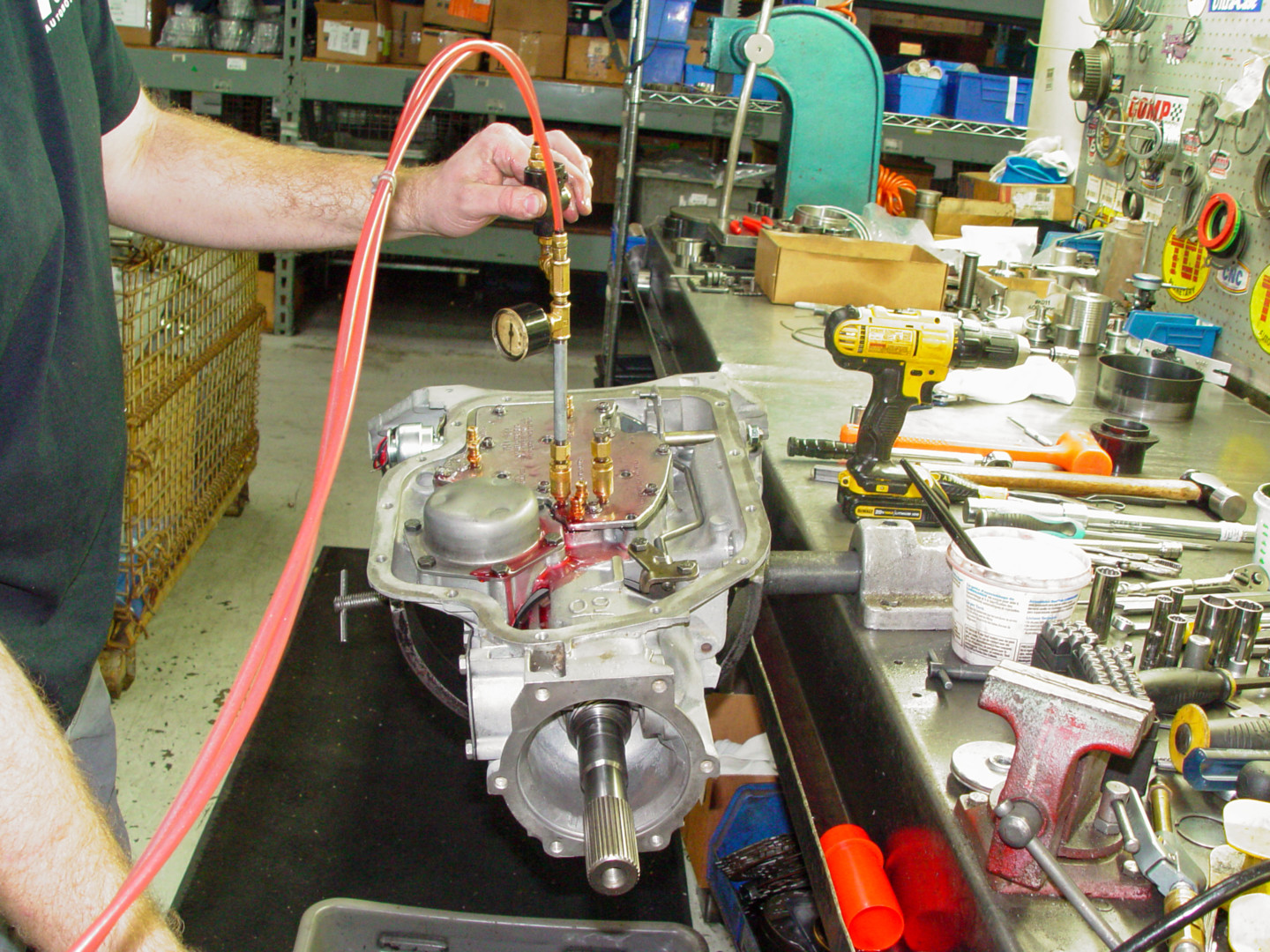

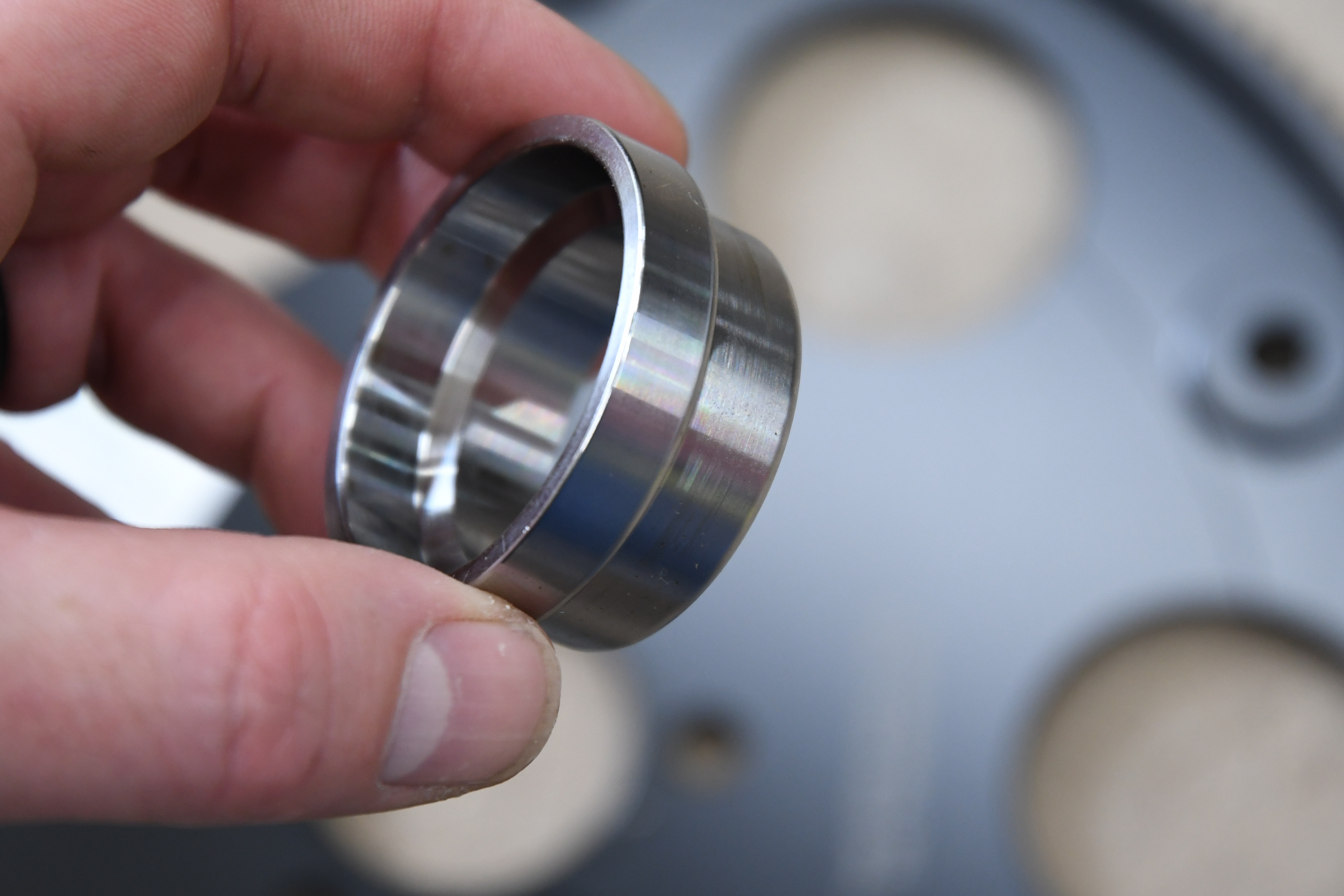

TCI updated many parts in our TH400 transmission, including the factory second gear sprag, input shaft, and the forward clutch hub. Red Eagle-style clutches were also used with Kolene steels and a Kevlar rear band.

“Many internal parts in the TH400 are very heavy-duty from the factory, and the ones that are not, are replaced by aftermarket parts. For this build, we replaced the factory second gear sprag with a 34-element cam-type sprag. The input shaft will also get an update with a Vasco 300 material shaft, and the forward clutch hub will be an aftermarket billet steel type. We will also use the Red Eagle style clutches, Kolene steels, and a Kevlar rear band.”

The Factory Case

There’s no doubt that an aftermarket case will hold more power than the OEM cases with better manufacturing processes. However, you might be surprised at how much the factory casting can take, because we certainly were.

“Even though the stock case isn’t as heavy-duty as an aftermarket case, we have built stock case units for applications with 2,500-plus horsepower and weighing 3,000-plus pounds,” explained Reed. Since we were gunning for 1,000 horsepower with our combination, the stock case is more than adequate for our needs.

Fluids, Cooling, and Breaking It In

Before we let Reed go, we had a couple more questions, like what’s the best type of fluid, and what does the break-in process look like? Reed said, “More and more people are going to synthetic type fluids, which is great because we sell that, too. But we sell more of our RTF for racing and street than anything else. It will not begin to break down until it’s between 230- and 250-degrees.”

Obviously, you want to keep the transmission temperatures as low as possible, so a big transmission cooler is an excellent idea, and Reed agrees. “When it comes to cooling the fluid, the bigger, the cooler, the better. If there is room to put something like our 10- x 15.5-inch cooler in front of the radiator, that’s what we would recommend for this application.” Since we’re working with a truck, room for a big trans cooler is not an issue, and we plan to install one before firing the Silverado back up.

TCI offers several different kinds of automatic transmission fluids (ATF) in both regular and synthetic formulas.

Our last question for Reed was regarding the break-in and maintenance of the TH400. We all know how often you should change the oil in an engine, but we feel like transmissions are typically neglected. And since we want our new transmission to live a long, happy life, we plan to do everything the correct way. We recommend doing a filter and fluid change after the first 500 miles. After that, it depends on how much use there is on the transmission and what it’s used for. Street applications, we recommend 12,000-mile fluid changes, but it would need to be sooner under racing conditions.

En Route

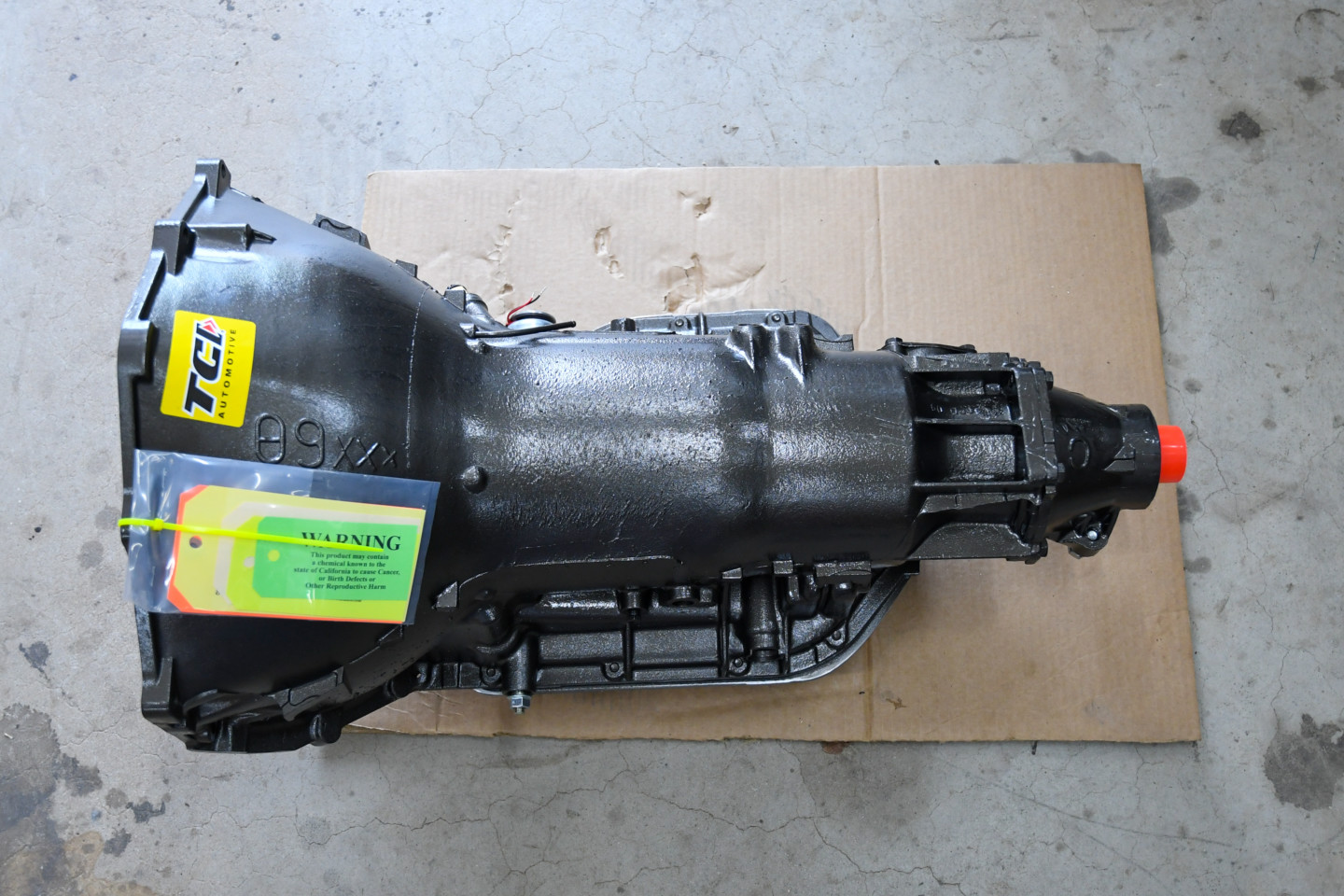

After we had asked all of the questions we could think of, we ordered a TCI TH400 with a transbrake, a TCI Outlaw X shifter, and a 4L80e SFI flexplate. Unfortunately, the torque converter would need to wait as we’re building a new engine for the truck and have yet to pick a camshaft for the new power plate.

From 4L60e To TH400

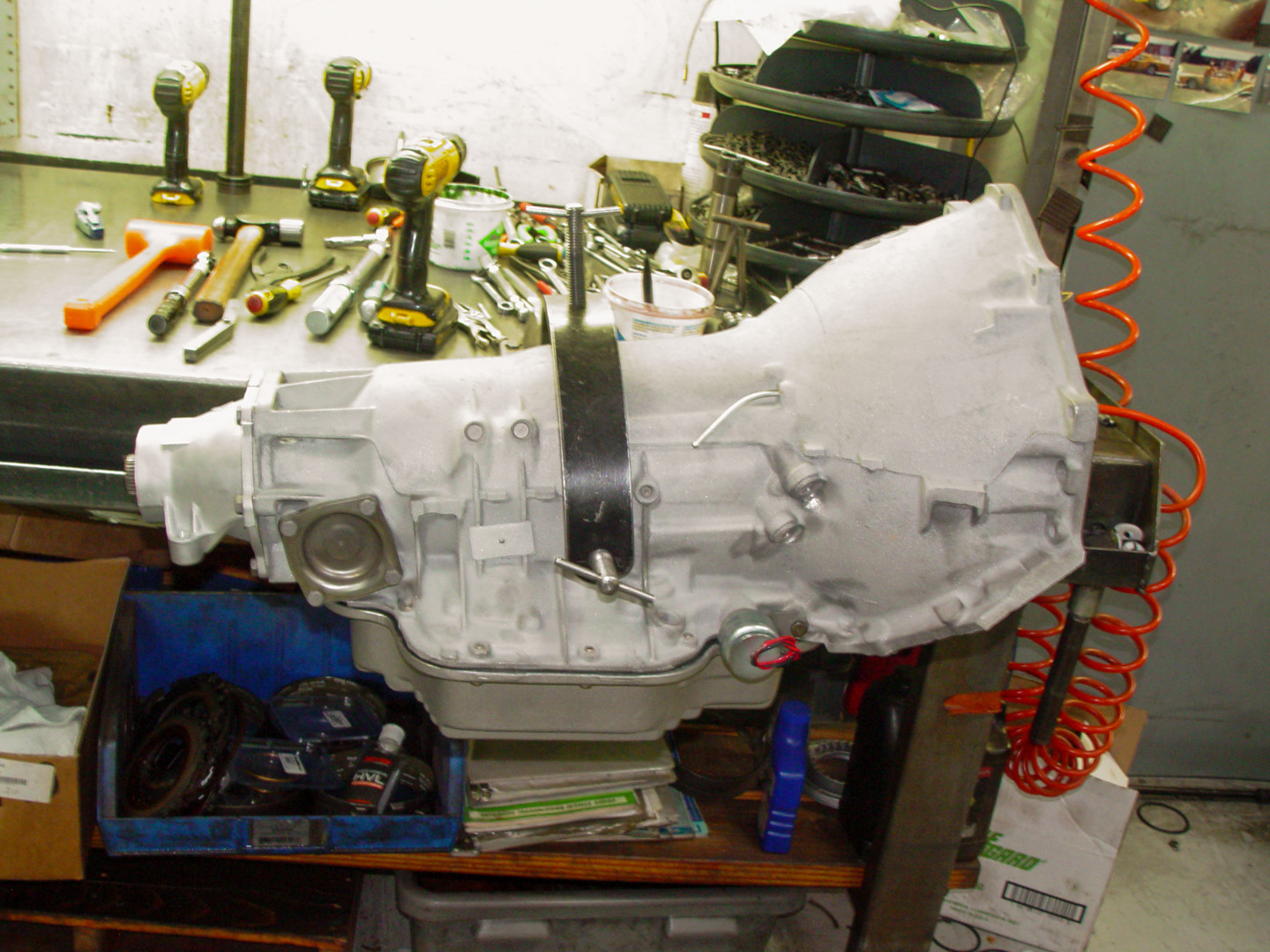

Our new TH400 arrived on a pallet within a couple of weeks with the parts strapped to it. It was time to mock up the transmission so we could measure for our new driveshaft. However, we were still missing one crucial piece of the puzzle: a transmission crossmember. Since the TH400 is shorter than the 4L60e, the cross-member would need to bridge the gap.

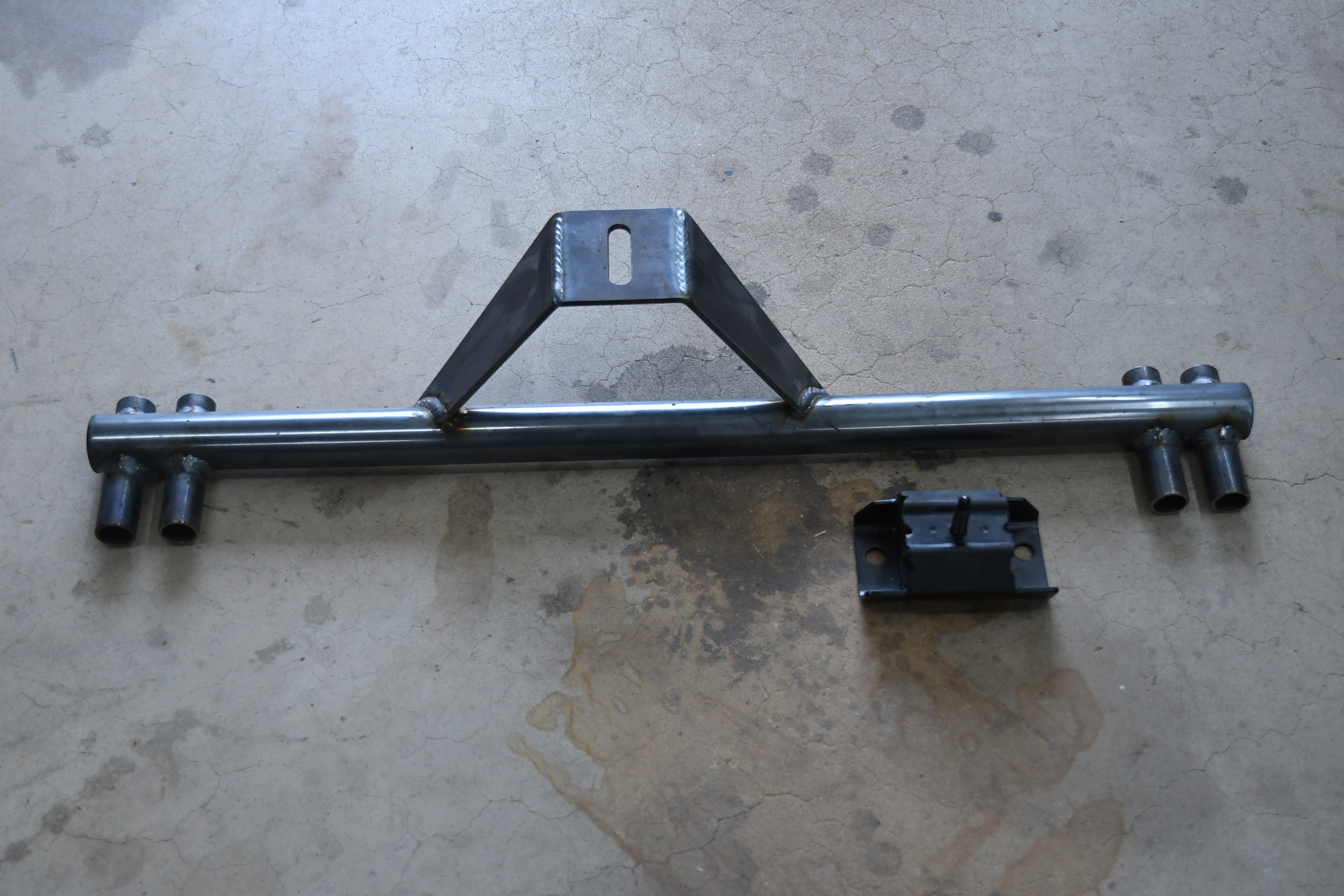

A quick search on Facebook led us to Tyler Scruggs, owner of DTR Fab LLC, who builds precisely what we needed: a TH400 crossmember for our 2000 Silverado. Before you order one, you will need to know which factory-style cross-member you have, since GM produced two different types. The cost of the new crossmember was $165 shipped for the 2wd transmission. We also ordered a tubular crossmember that bolts in under the oil pan. It has nothing to do with the transmission install, but we thought it was cool and adds some clearance under the oil pan.

Instead of fabricating a new TH400 crossmember for our Silverado, we contacted DTR Fab. The company manufactures a high-quality bolt-in unit designed for our specific application. They also offer a cross brace that replaced the stock unit under the engine. We will talk more about this piece in a future article.

The Differences

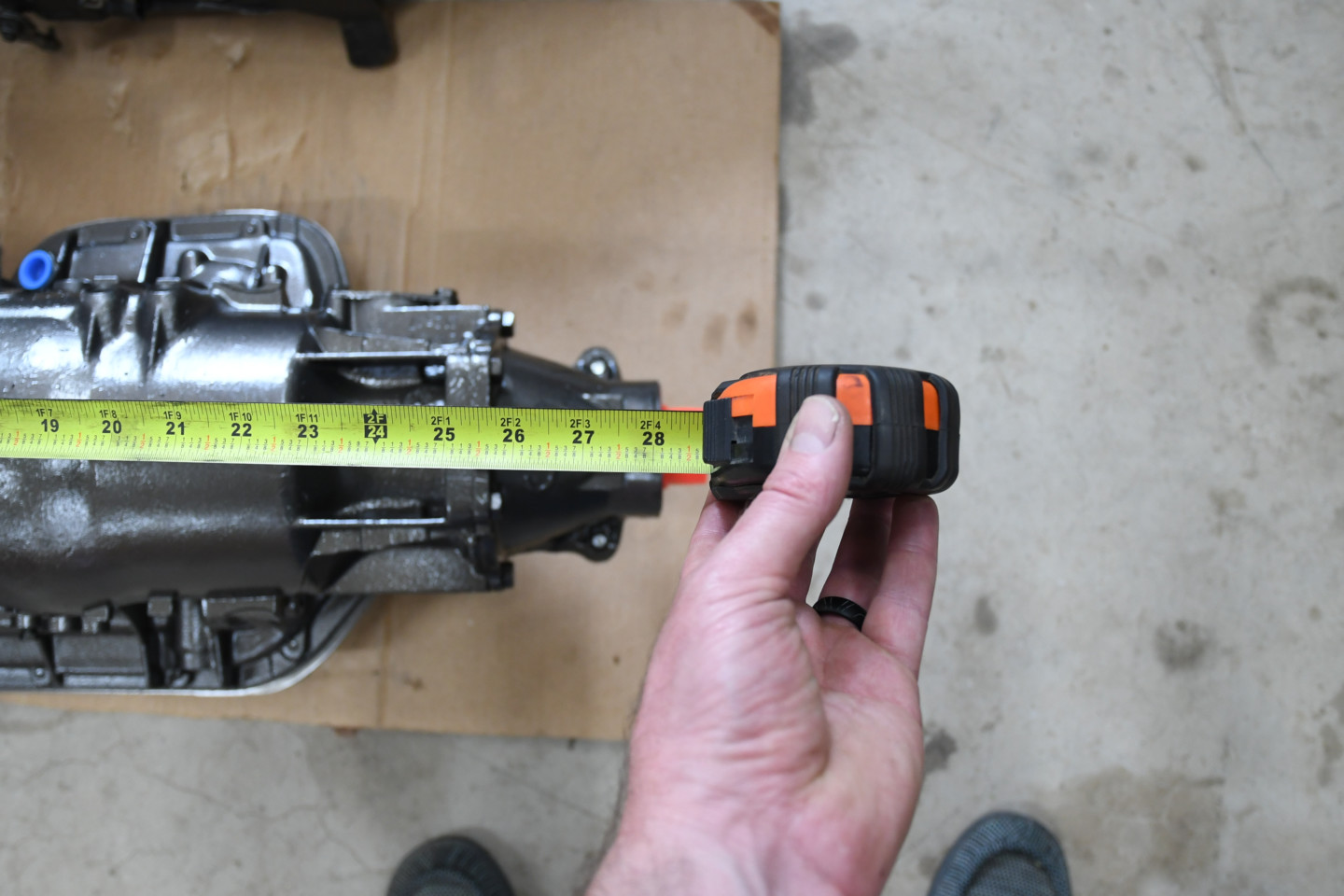

The 4L60e and the TH400 have their differences, as you can imagine. You would expect the modern four-speed to be larger and heavier than the TH400, however, we were surprised at how similar these two units are. The 4L60e weighs 133 pounds without transmission fluid, and the TH400 tips the scales at 134 pounds. A 4L80e weighs in at a hefty 178 pounds. The 4l60e, which measures 30.75-inches, is a little longer than the short tail TH400 at 28.25-inches. As you might expect, the 4L80e is the longer of the three transmissions, with a length of 32.187-inches.

Much to our surprise, the 4L60e transmission is only 2.5-inches longer than the TH400 and only weighs a pound less than the three-speed transmission.

Much to our surprise, the most significant difference between the TH400 and the 4l60E transmission is the first gear ratio — the 4L60E has a 3.06 first gear, 1.62 second, 1.00 third, and a .70 overdrive. The TH400 and 4L80E both come with a 2.48 first gear, 1.48 second, and 1.00 third gear. Of course, the 4L80E has overdrive which can be a huge advantage over a three-speed transmission if it’s needed.

4L60e Removal

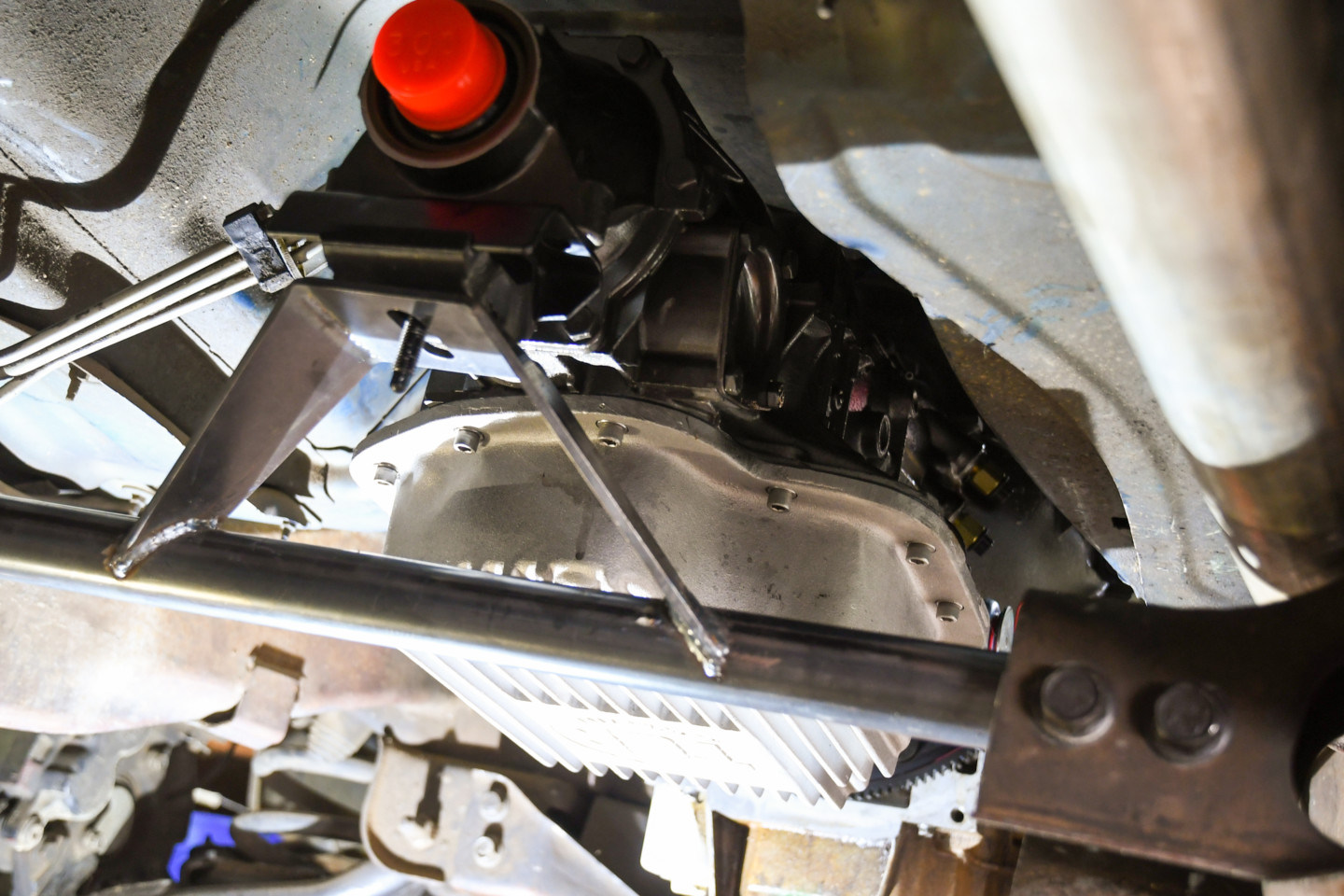

The next step was to remove the damaged 4L60e and replace it with our TCI three-speed unit. It’s wise to drain all of the transmission fluid at this time before removing the driveshaft. Next, you will need to remove the transmission dipstick, trans cooler lines, and starter before unbolting the torque converter. We then used a transmission jack and lowered the tail of the trans to allow easy access to the bell housing bolts. With all of the bolts removed, we carefully slid the 4L60e back and dropped the jack.

Turbo 400 Time

You would think that bolting in a transmission introduced in the 1960s in a 2000 model truck would be complicated, but it’s not…as long as you have the correct flexplate and adapters. The TH400 and other non-electronic GM transmission bolt right in. The only difference is one bell housing bolt hole is not utilized because the hole is missing in the back of the LS engine. And since we didn’t have to fumble around with the torque convertor, the TH400 went right into place effortlessly.

TCI's SFI approved flexplate kit (PN 399754) came with everything we needed for our TH400 swap including, the flexplate, bolts, and an adapter for the torque converter.

With the bell housing bolts in place, we then jacked the transmission into place before installing our new DTR Fab TH400 crossmember. We can now measure for a driveshaft to connect to our Moser Fab-9 rear axle.

We were able to make quick work installing the TH400 with the DTR Fab crossmember which bolted right into place with no issues.

More To Come

While the new TCI transmission is in place, we still have some work to do. We need to order a new dipstick, transmission cooler, torque convertor, wire in the transbrake, and mount the Outlaw X shifter. We will document our progress as the Silverado continues to move forward so be sure and check back next month for more updates on this build.

TCI's Outlaw X shifter is next on our list, but we need to fabricate a pedestal for the shifter before finishing up this installation.