In the world of LS swaps, one of the main obstacles at-home wrenchers face when planning their swap is, “How am I going to control the engine?” EFI and engine control are a daunting task, especially if you have a classic vehicle and only have experience with a carburetor. Fuel injection offers a significant advantage in engine control, all-weather performance, and overall drivability; plus, the engine is designed for fuel injection, so why not use it? The next big question is usually: cable-driven throttle versus drive-by-wire throttle. Which is best for your project can be a daunting question. So, we enlisted the expert team at Performance Systems Integration (PSI for short) who possess extensive experience in wiring LS & LT swaps to help answer our questions.

This is the first in a short series of articles on comparing drive-by-cable and drive-by-wire throttle bodies to help map out which parts play nice with each other and some common confusion with these components and controlling them to dispel some online myths and inaccuracies. We will start with one of the most common and sometimes the most confusing – Early Gen-III LS and Vortec drive-by-wire throttle bodies.

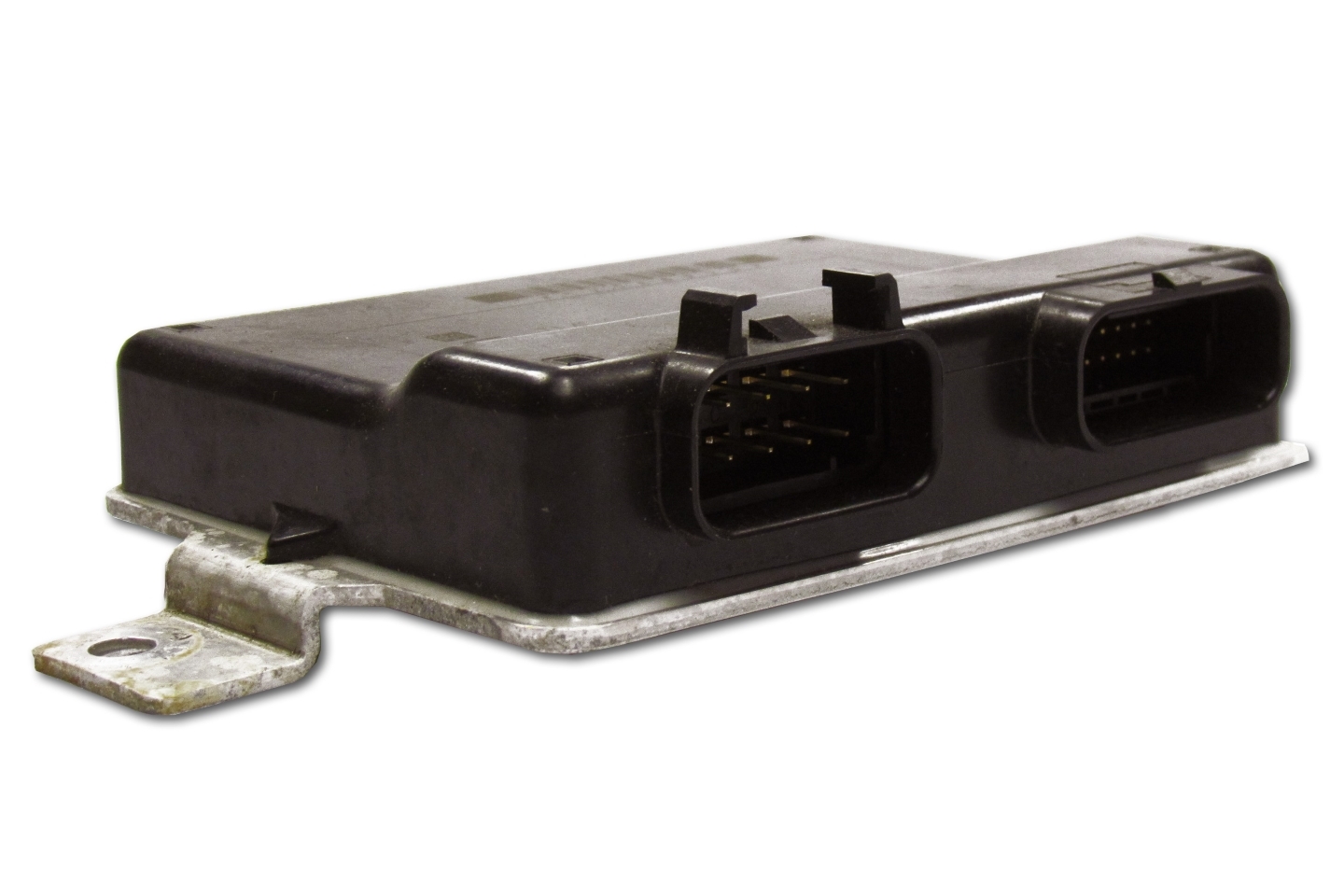

The 411 PCM (on the left) and the 242 PCM (on the right) look the same but are not interchangeable. You can identify them by the red and blue connections on the 411 PCM or green and blue on the 242 PCM.

Throttle Actuator Control Module

From the factory, all drive-by-wire controlled LS engines with a 24x reluctor wheel utilized a throttle actuator control module (TAC module for short) installed between the engine harness and the throttle pedal via a TAC module sub-harness. This module establishes communication between the throttle pedal, the engine computer, and the throttle body.

There were two different types of TAC modules used. An early style whose body and mounting tabs are made entirely out of plastic, and a later style that can be identified with a plastic body with metal mounting brackets built in. The all-plastic early style can be found on ‘97-’04 C5 Corvettes, ‘04-’05 CTS-V, and ‘01-’02 full-size SUVs. The later style can be found on the ‘03-’07 body-style trucks and SUVs.

On the left is the early style, all-plastic TAC module that can be found on C5 Corvettes, 04-05 CTS-Vs, and pre-2003 full-size SUVs. On the right is the late style TAC module with a metal mounting bracket found on 03-07 trucks. These two modules are not interchangeable.

While the LS platform has become famous for its simplicity and interchangeability, it is paramount to match these modules with their corresponding PCMs to avoid problems. The early style should only be used with the 411 PCM, which uses red and blue connectors, and the later style should only be used with the 242 PCM, which uses green and blue connectors.

GM didn’t have the computing power to put all of these functions into the engine control module in the early years, so they added this secondary module. It adds one more module to use, but makes for a capable and reliable system. – Jon Vezzosi, PSI Conversion

C5 Corvette Throttle Body

The Gen-III LS debuted for the 1997 model year exclusively in the then-all-new C5-generation Corvette with the LS1. This was also the first year to use a drive-by-wire throttle body (shortened to DBW) in a Corvette. These throttle bodies remained unchanged during the C5’s eight-year production run with a 78-millimeter throttle blade diameter and three-bolt mounting pattern.

The throttle body on all C5 Corvettes is unique to those cars and is not interchangeable with any other OEM throttle body.

They can be spotted easily in the wrecking yard with a throttle position sensor on the passenger side of the throttle body with a six-pin connector, and a barrel-shaped drive motor on the driver’s side with a two-pin connector. This throttle body can only be used with the 411 PCMs with the red and blue connectors and the early-style TAC module.

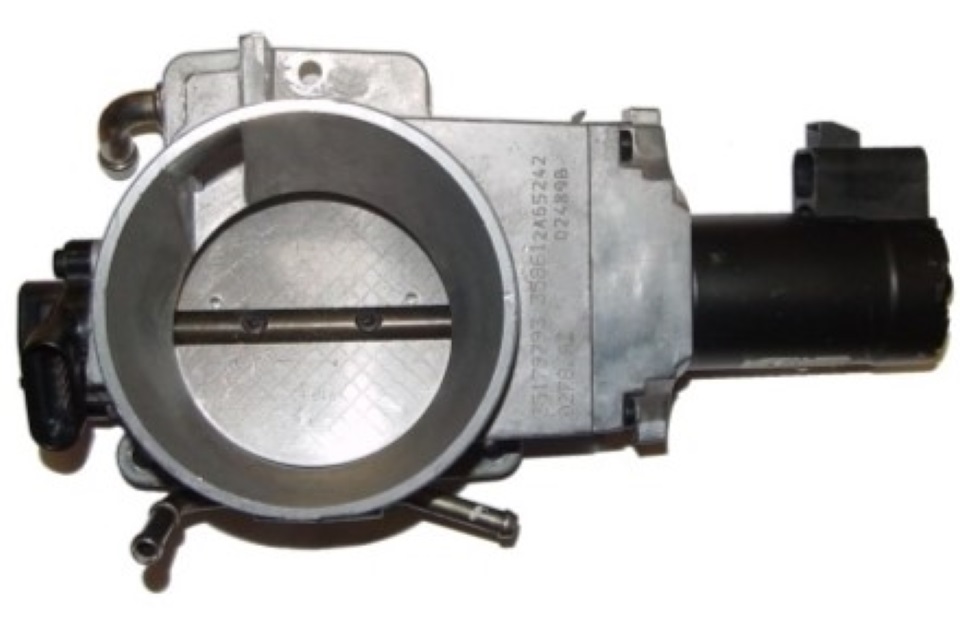

Pre-2003 Vortec Throttle Body

After the C5 Corvette and fourth-gen F-Body enjoyed the success of the new LS1, GM decided its truck line could take advantage of its latest small-block platform and made new 4.8-liter, 5.3-liter, and 6.0-liter truck versions of the LS for the 1999 model year using their “Vortec” moniker. Most of the half-ton pickups utilized a cable-driven throttle body much like the F-body, but the full-size SUVs and some pickups used a drive-by-wire setup similar to the Corvette.

The drive-by-wire throttle body used in the ‘01-’02 model year trucks and SUVs looks very similar to the Corvette style — but mirrored — with the throttle position sensor on the driver’s side of the throttle body and the drive motor on the passenger side, and still using the same two-pin and six-pin connectors. This change was made to clear the alternator mounting bracket that sits closer to the intake than the Corvette alternator bracket. It is important to note that the wiring is different between the C5 and early truck drive-by-wire throttle body and they are not interchangeable.

Drive-by-wire throttle bodies on the pre-2003 trucks and SUVs were not the most common and even though they look like a mirrored version of the C5 Corvette throttle body, they are not interchangeable.

Other than its drive motor and TPS being flipped when compared to the Corvette throttle body, it shares the same three-bolt mounting pattern and 78-millimeter throttle blade. Also like the C5 Corvette throttle body, this throttle body can only be used with the 411 PCMs with the red and blue connectors and the early-style all-plastic TAC module.

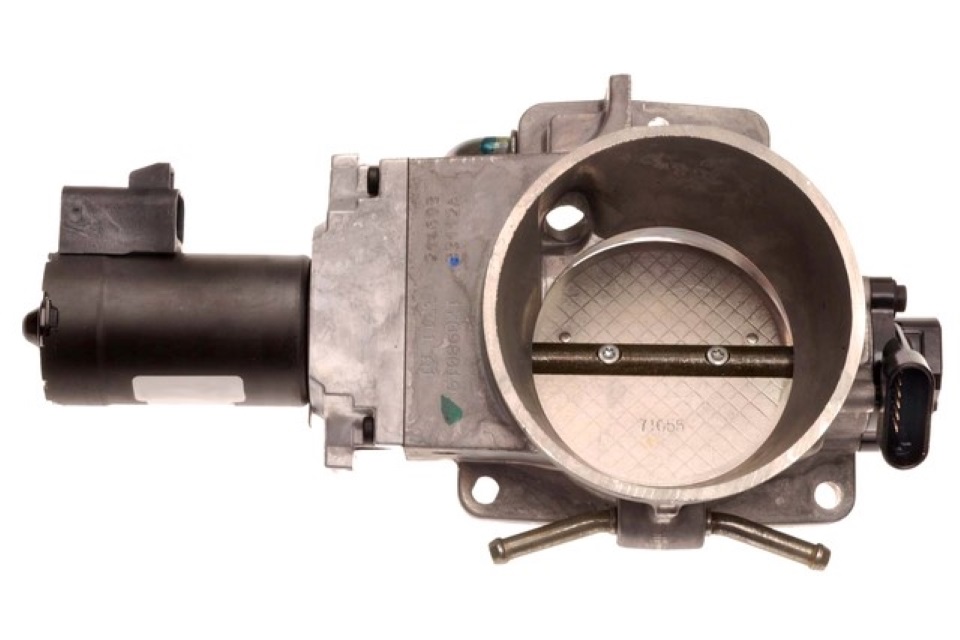

2003-2007 Vortec Throttle Body

For the 2003 model year for the full-size trucks and SUVs, GM redesigned its drive-by-wire throttle body. A completely reengineered aluminum housing still housed a 78 millimeter throttle blade and the three-bolt mount pattern, but the guts were overhauled and installed behind a large black plastic cover on the passenger side of the body.

The throttle body found on the 03-07 full-size model trucks and SUVs received a makeover, in looks and function. They’re still 78mm bore like the previous versions.

No longer were there two different connectors; now there was only one connector built into the black plastic side cover with eight pins. Behind that cover was a throttle position sensor and the drive motor, now driving the throttle shaft via a gear drive. These throttle bodies can only be used with the 242 PCMs with the green and blue connectors and the later style plastic and metal TAC module.

Throttle Pedals and TAC Harnesses

Just like the throttle bodies requiring the proper pairing with PCMs and TAC modules, you have to make sure the throttle pedal and the TAC module sub-harness that connects the pedal to the TAC module are compatible. Otherwise, you will have no control over your LS.

The throttle pedal used in all ‘97-’04 C5 Corvettes utilizes a nine-pin rectangular connector. It can only be used with an early-style all-plastic TAC module and 411 PCM with the matching TAC module sub-harness. Be careful, as the connector on the C5 pedal looks almost identical to the truck-style throttle pedal, but the wiring is different. Mixing up this simple mistake can leave you with hard-to-diagnose throttle issues.

On the left is the throttle pedal from 01-05 full-size truck and SUVs, and on the right is the pedal from 97-04 C5 Corvettes. Even though the connector looks the same between the two, they are different and require a specific TAC module sub-harness for each.

The throttle pedal from the 2001-2005 full-size truck and SUVs with a steel arm is also popular for swaps due to its slightly more compact pedal size and is very common in the local wrecking yards. This pedal requires its own TAC module sub-harness that looks very similar to the C5 Corvette TAC module sub-harness, so don’t get them mixed up. This pedal and its TAC harness can be used with either the early style TAC module and 411 PCM, or the 242 PCM and later style TAC module. This versatility also adds to its popularity for swaps.

The throttle pedal on the 2006 and newer full-size trucks and SUVs was redesigned and features a plastic arm and a large mounting footprint.

Starting in 2006, GM began using a plastic throttle pedal in its trucks and SUVs. Outside of the obvious plastic construction compared to the steel-armed truck pedal, these can also be identified by the six-pin electrical connector. These pedals can only be used with the later style TAC module and 242 PCMs, so don’t think you can wire up your own TAC harness to make it work with other TAC modules and PCMs. Due to its bulky construction and larger footprint needed for mounting, this is a less-popular choice for most swaps.

For those of you with a 1973-1998 GM full-size truck or SUV, PSI also offers a direct-fit solution. A drive-by-wire pedal that was not offered from the factory, but bolts directly in place of the mechanical-linkage OEM throttle pedal, making your Gen-III drive-by-wire LS swap a breeze. Due to its compact and all-metal construction, it can also be easily modified to fit other platforms and applications as well.

For those looking for a direct-fit pedal for your 1973-1998 GM truck, PSI offers a solution. This pedal requires it’s own TAC module sub-harness, which is also available through PSI.

The early years of the LS engine platform showed that GM had a little bit of a learning curve when it came to controlling their new hero-V8. The use of different throttle bodies, PCMs, throttle pedals, TAC modules, and TAC module sub-harnesses during the first decade of production is evidence of GM doing its best to learn on the fly. Thankfully, the team at PSI has this properly mapped out due to their years of experience with wiring and controlling LS swaps with every possible combination of parts under the sun. If you’re in the market for any LS-related parts or just need some information on how to use what you already have, check out their website or give them a call!