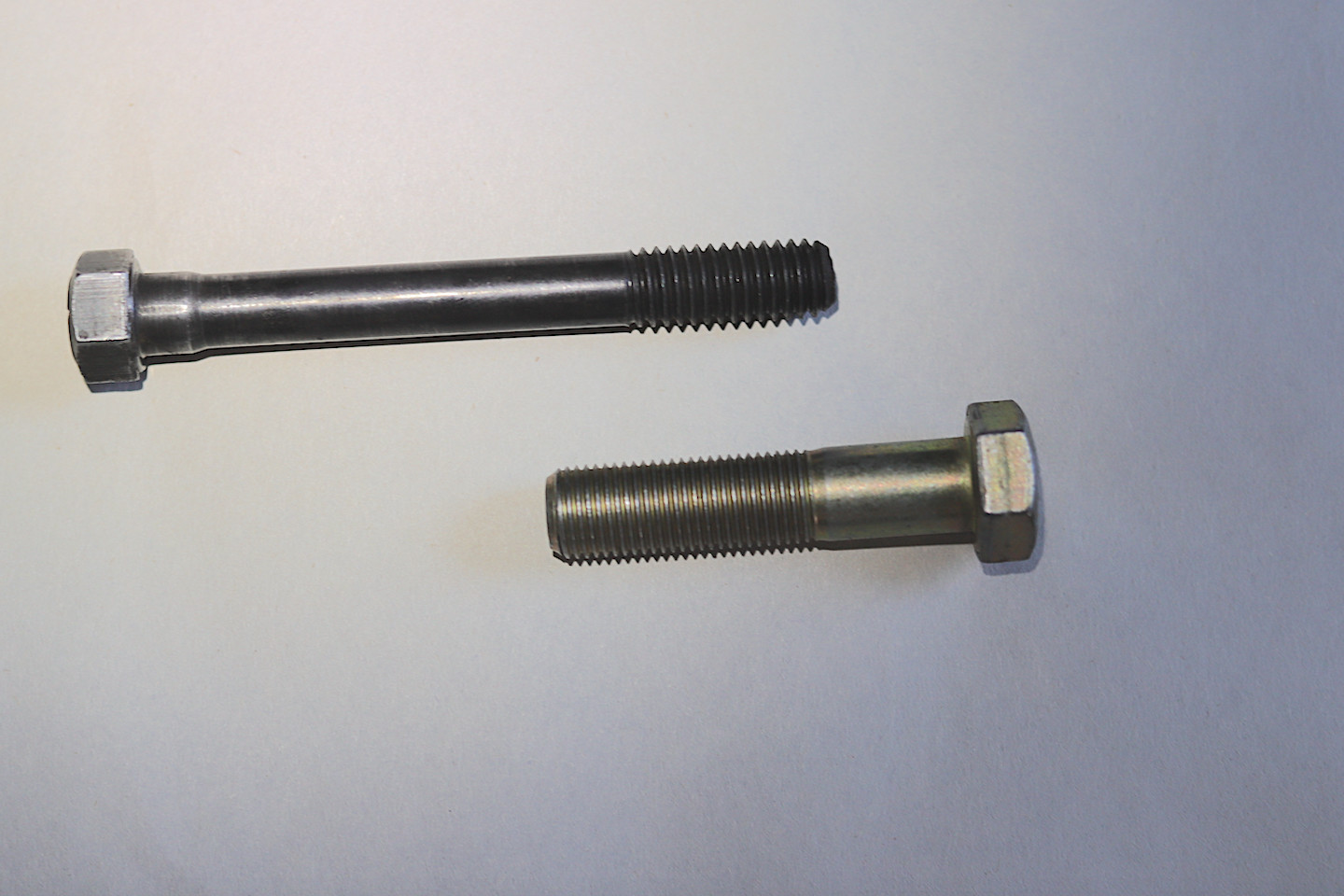

There’s a lot more to a common bolt than meets the eye. Sure, we can see the different thread sizes and some have wider threads where others have fine threads. But, some differences are not visible to the naked eye. Sometimes we can tell what material a bolt is just by looking at it, but it is much more difficult to tell how the bolt was made by sight.

There’s an old saying that goes: “You can’t tell which way the train runs by looking at the tracks.” When it comes to bolt threads, you can tell which way it turns to tighten or loosen by looking at the threads, but you have a harder time figuring out how it was made by looking at the threads. We contacted our friends at ARP for help in understanding some of the fundamentals of bolt threads.

“Making quality threaded fasteners is so important that we do everything in-house,” says ARP’s Director of Sales and Marketing, Chris Raschke. “From taking the wire off the spools to heat treatment and even repairing the thread dies, we do it all in our facility.”

The Basics

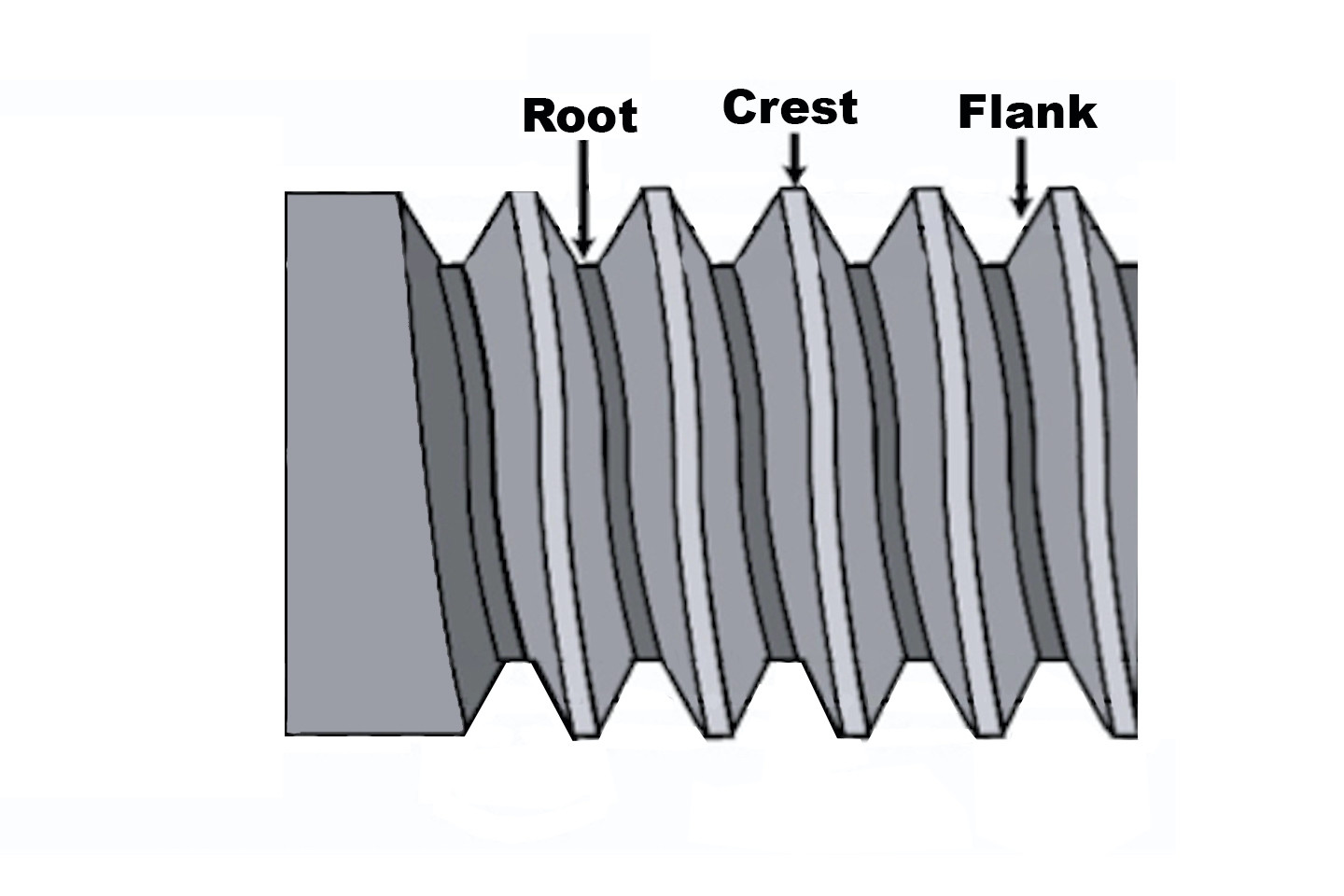

When you look at a bolt from the side, you get a profile view that shows several details of the bolt’s threads. At the top of each thread is a crest. From the crest, a flank runs down toward the center of the bolt on either side and these flanks meet at the root of the thread.

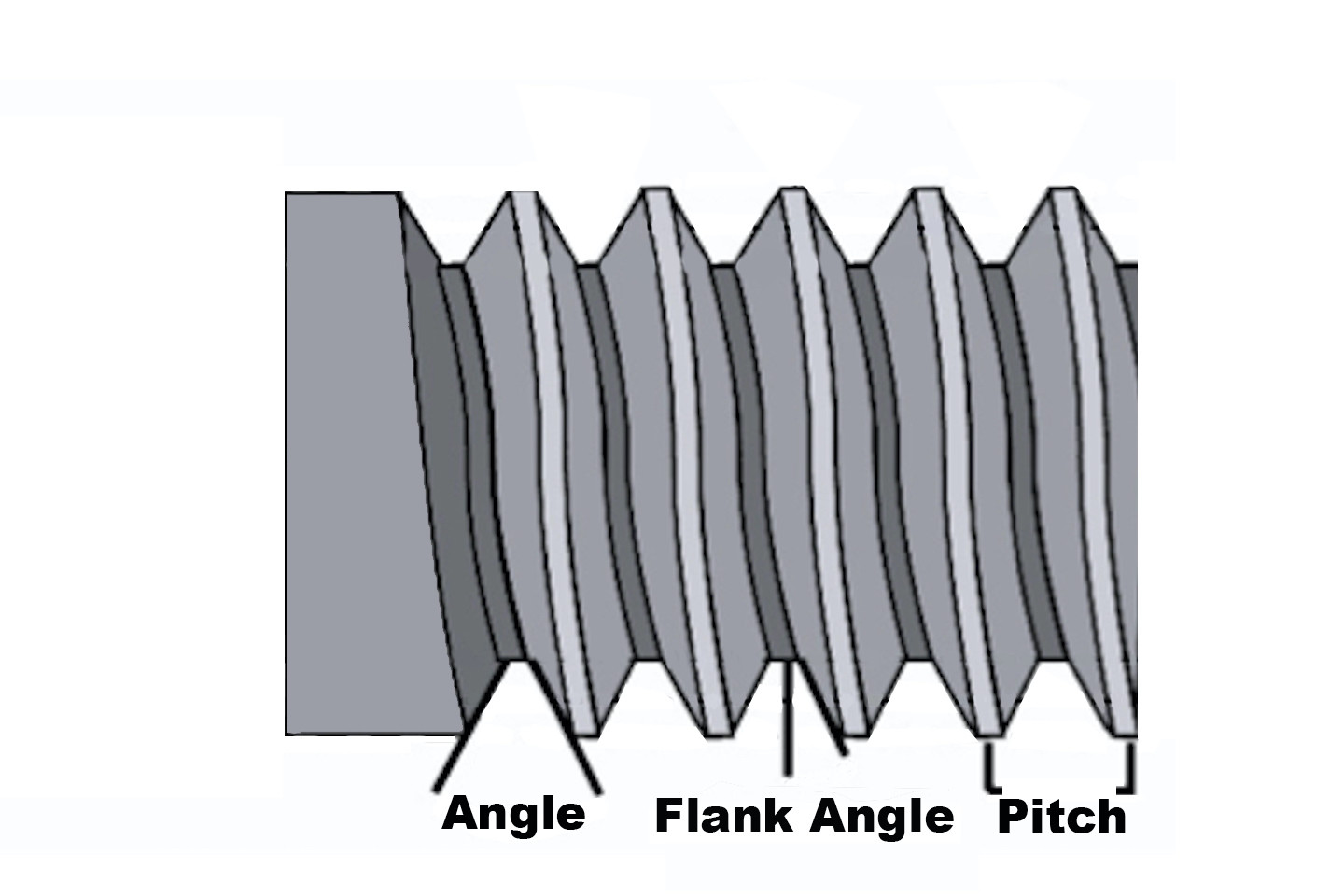

An angle is formed from the top of the crest measured down to the thread root and back up to the next crest. The flanks are also measured as an angle. The distance measured between the thread axis, from the center of one crest to the center of the next crest is the thread pitch. All unified threads are designated in threads per inch (TPI).

Unified threads are symmetrical which means the flank angles are identical from thread-to-thread on the bolt. Unified threads have a 30-degree flank and are commonly called 60-degree threads by professionals in the fastener community.

What It All Means

While all of this is interesting, you’re probably wondering what it means to you? In having unified measuring and angles within the bolt’s threads, there is an intentional clearance created between the bolt’s threads and the mating threads, whether that is in a threaded surface or a nut. This clearance is referred to as the “allowance.”

In most cases, the allowance is applied to the external thread during manufacturing. There are maximum and minimum tolerances permitted to bolt makers for manufacturing convenience. Generally speaking, the thread fit between the mating surfaces can be close or loose. The user needs to know what the thread fit is to choose the right fastener for the intended use.

Thread fit is the measure of tightness or looseness of the allowances between the mating threads. A clearance fit is one that allows a free turning assembly and interference fit requires tools for the initial run-down of the fastener. For the Unified threads, there are six classes of thread fit: 1B, 2B, and 3B (B is for internal threads) and 1A, 2A, and 3A (A stands for external threads). All six classes are considered clearance fit.

- Classes 1A and 1B are considered an extremely loose-tolerance thread fit. This class is suited for quick and easy assembly and disassembly.

- Classes 2A and 2B offer optimum thread fit that balances fastener performance, manufacturing, economy, and convenience. Nearly 90-percent of all commercial and industrial fasteners use this class of thread fit.

- Classes 3A and 3B are suited for close tolerance fasteners. These fasteners are intended for service where safety is a critical design consideration. This class of fit has restrictive tolerances and no allowance.

Not all threads are the same. In the unified system, bolts are commonly classified as having fine threads or coarse threads.

Thread Series

To further classify threads, there are two main thread series in the unified thread system for fasteners: UNC (Coarse), and UNF (Fine).

Fine Thread

- Since they have larger stress areas the bolts are stronger in tension

- Their larger minor diameters develop higher torsional and transverse shear strengths

- They can tap better in thin-walled material

- With their smaller helix angle, they permit closer adjustment accuracy

Coarse Thread

- Stripping strengths are greater for the same length of engagement

- Improved fatigue resistance

- Less likely to cross-thread

- Quicker assembly and disassembly

- Tap better in brittle materials

- Larger thread allowances allow for thicker platings and coatings

Coarse threads have become popular in automotive use, mostly because of the strength and faster assembly. There are a couple of modified versions of the UN thread that mechanics should be aware of. The UNR thread has a mandatory rounded root radius. Most fasteners that are roll threaded use this type of thread because rolling dies with rounded crests have become the standard thread in fasteners.

This wire will eventually become a bolt or stud with external threads rolled into the material. This is how a bolt starts its life.

The UNR thread is a modified version of a standard UN thread. The single difference is a mandatory root radius with limits of 0.108 to 0.144 times the thread pitch. When first introduced, it was necessary to specify UNR (rounded root) threads. Today, all fasteners that are roll threaded (more on this below) should have a UNR thread because thread rolling dies with rounded crests are now the standard method for manufacturing most threads.

The UNJ thread is the standard for aerospace and many industrial fastener applications. Thread class 3A/3B thread tolerances are the standard for UNJ threads. UNJ bolts are similar to the UNR, but the curve of the thread root is more gradual which requires that it be shallower. The UNJ thread root is so shallow that the bolt thread cannot mate with a UN nut. Therefore, there is a UNJ nut specification to match the external threads on the UNJ bolts.

Cut Threads And Rolled Threads

Do you really need to know how the threads on a bolt are formed? Well… the short answer is yes! Any time metal is cut, ground, heated, or otherwise worked, it changes the physical property of the material by strengthening, hardening, or making the material more or less brittle than before. It pays to know if threads are cut or rolled in manufacturing.

ARP is very adamant the bolts and studs go through every process, including heat treatment, before threads are rolled into the blank. According to Raschke, this method creates the strongest threads.

Threads can be produced by either cutting or by a rolling operation. In the thread cutting method, bolt blanks will have material cut from the shank of the bolt blank by one or more cutting edges to create the threads. This method cuts across the grain flow of the material. Thread cutting is a common practice that many home garage mechanics have attempted with locally purchased tap and die sets. A cylindrical wire or rod is inserted into the opening on the die, and the die is rotated around the part to create external threads on it.

Thread cutting involves using one or more cutting points to remove material from a rod or wife to create threads. Most home mechanics either own or have used a simple tap and die set with cutting dies like these. This is a low-cost method of putting threads a bolt.

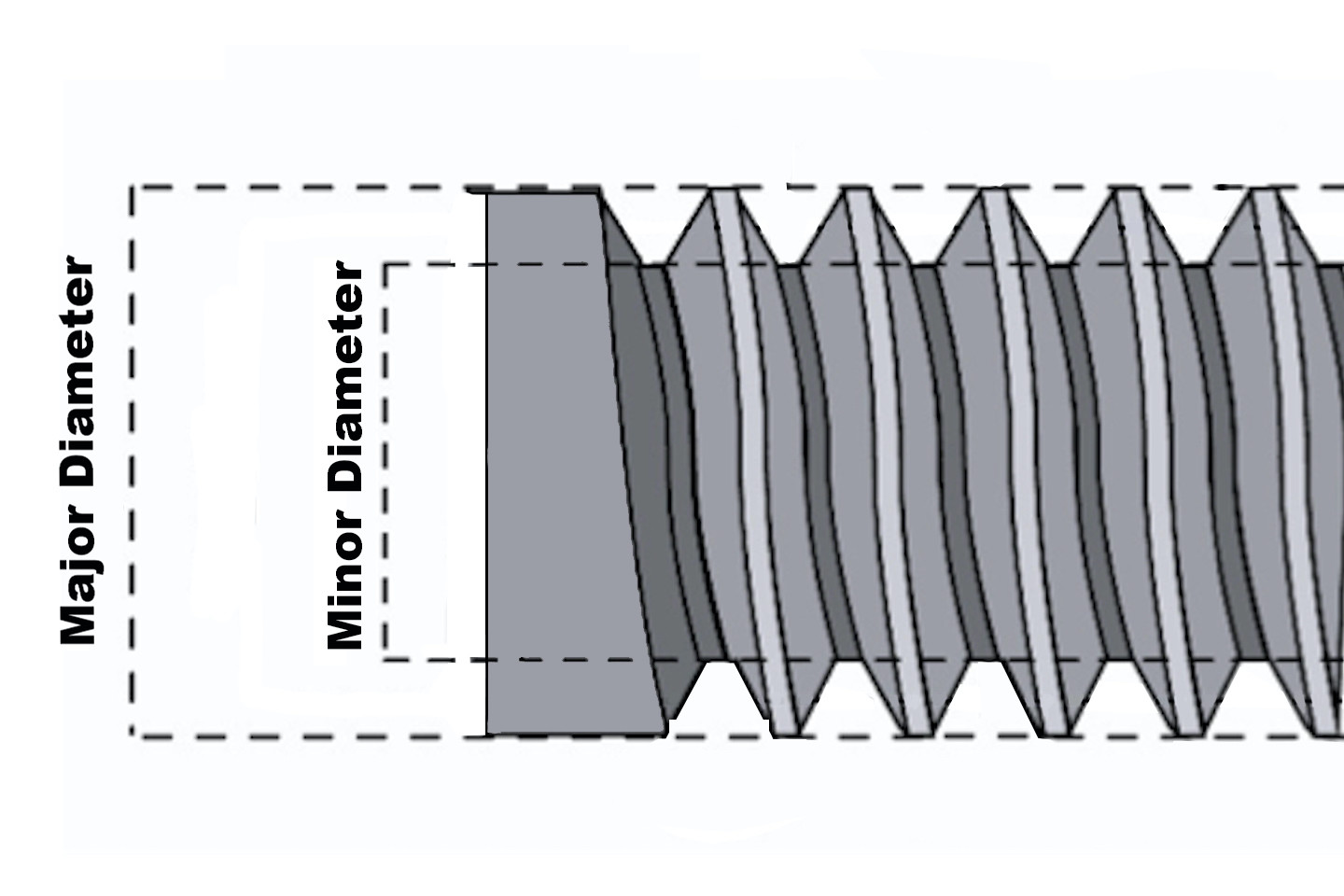

Using a lathe to cut threads is similar but there is only a single cutting point and many of the variables (the pitch, lead, major diameter, minor diameter, depth, and machine speed) have to be calculated and set up on the machine. Because of the complexity of single-point thread cutting, a die is almost always used for an efficient blend of speed and accuracy.

We consistently go beyond standard aerospace specs. – Gary Holzapfel, CEO of ARP

Thread Rolling

Rolled threads are formed by rolling the bolt blank with a reduced diameter shank between two reciprocating serrated dies. The dies compress the bolt blank and force that material up to form the thread crests. Rolled threads have multiple advantages such as accurate and uniform thread dimension, smoother thread surface, and greater thread strength.

Thread cutting requires the least amount of tooling costs and thereby is still the most commonly used method for internal threads. Some fasteners are made by rolling threads prior to heat-treat —when the material is softer and easier to form. Raschke says that by thread rolling after heat-treat, the fatigue life is improved ten-fold. This, of course, is harder on the tooling and increases manufacturing costs, but makes for a vastly superior product.

ARP founder Gary Holzapfel is clear about the company’s thread rolling process and the motive behind it. “Thread rolling is the last mechanical operation in our manufacturing process,” he has said. “For each production run, the thread rolling machine is shut down after a few parts. These parts are inspected for dimensional accuracy and thread quality and are physically tested for both strength and fatigue before the run is continued. Random samples are inspected and tested throughout the run. Extremely critical components are individually inspected for dimensional integrity.”

Here an ARP employee is feeding a blank stud into a thread rolling machine. A set of flat dies moves horizontally under pressure to roll the threads into the material. This process takes more time and is harder on equipment, but ARP assures us this procedure produces a stronger fastener.

ARP’s patented process begins with a softer wire that can be cold forged. “The process work hardens the head and the under head area to the desired hardness. We then power extrude the front end to achieve the reduction and hardness in the shank resulting in a bolt with even strength and hardness from end to end,” said Holzapfel.

“The same is true of thread rolling. Temperature and die speed must be controlled and changed for different alloys. Many bolt manufacturers who meet the Aerospace Specifications don’t come close to meeting our standards. We consistently go beyond standard aerospace specs.”

Here a worker is repairing or maintaining one of the dies used in the thread rolling procedure. Everything is taken care of under the ARP roof.

More Than Meets The Eye

As we said in the opening, there’s much more to bolt threads than you might think. The engineering behind those grooves in fasteners is far greater than almost anyone thinks when they look at a handful of these clamping marvels. If you’ve read this article, we promise you’ll never look at fastener threads the same way again.

For more information on ARP’s line of fasteners, visit them online at www.arp-bolts.com. One last thing: ARP bolts are not “just for engines” either. If there is an application where you need reliability and strength, that’s where you need an ARP bolt.