Over the last decade and change, our sport has witnessed an incredible progression of technology in every facet of race car design that’s not only delivered previously unimaginable levels of performance, but innovative new measures to control and harness this newfound horsepower to get it down the race track. But producing and even managing power and torque are only half of the equation in drag racing, as one can only perform to the level that the racing surface will allow. Fortunately, just as the cars have evolved, so too have the processes for preparing and studying racing surfaces and their unique and ever-changing characteristics.

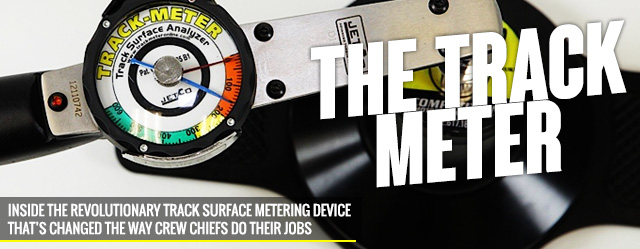

The Track Meter, as the name implies, is a device developed to provide exacting data to race teams on the tackiness (or lack thereof) of a given area on a racing surface, thus giving crew chiefs valuable information never before available to them.

For track operators, prep has become less of a basic necessity and more of an exacting science, and for race teams, understanding every inch of the surface better than the competition is perhaps the difference between winning and losing. Gone are the days where one can simply walk the track, rub their shoe in the groove and know which knobs and dials to turn. Like engines, boost controllers, traction control devices, and even tires, technology is front and center in the decision-making process of any good crew chief, and in addition to track specialists armed with all sorts of devices and a database of information in their pocket, one tool that you’ll find in the arsenal of the majority of the sport’s top teams today is a device known simply as the Track Meter.

The brainchild of longtime drag racer Larry Wolyniec, the Track Meter was devised as a means for accurately measuring the “bite” of a track surface, providing quantifiable data to race teams in a way that never existed prior to it’s creation. We recently got our hands on a Track Meter to utilize in the racing exploits of our Street Outlaw Camaro, Project BlownZ, to help us better understand the surfaces we’re trying to put the power down to. In this piece, we’ll gain some insight from Wolyniec about the invention of and purpose of the Track Meter, share with you some example track data, and even hear a few words from those that rely on this one-of-a kind device.

Larry Wolyniec developed what would become a vital tool in the arsenal of any serious racing team while working with the Bill Miller Engineering Top Fuel team as a means to gain more accurate track data while competing on a part-time schedule. After a long R&D phase, the device eventually went to market, and became known as the track Meter.

Development Of The Track Meter

Wolyniec, a respected veteran racer and crewman in the sport, developed the Track Meter a decade ago while working with friend Bill Miller on his Top Fuel Dragster that was driven at the time by Brady Kalivoda. Wolyniec recognized a need for a device that could deliver real, measurable data on the tackiness of a strip’s surface, in effect modernizing the age-old method of dragging or rubbing a shoe across the groove.

We worked on it for a number of years and tried to come up with some good ideas for how to do it, and ultimately, came up with what was a rather crude model that we started with. – Larry Wolyniec

“I was the Car Chief on Bill’s Top Fueler at the time, and we felt handicapped in the fact that we didn’t have a lot of data to understand or read the race tracks,” said Wolyniec. “We didn’t run all of the races then — only about ten a year — so we needed a better way to read the surfaces and acquire the data to help us tune the car. So I started developing what’s known today as the Track Meter.

“We worked on it for a number of years and tried to come up with some good ideas for how to do it, and ultimately, came up with what was a rather crude model that we started with. We began acquiring data and it seemed to be very beneficial to our program. Many of the teams saw what we were doing and told us they’d like to have one. Once we secured all of our patents, we brought the product to the market.”

How It Works

This is the very basis of the Track Meter — a pad located on the bottom device made of rubber very similar to that of a racing slick, thus delivering a relatively accurate reading in the rubber-to-surface relationship. The operator places their feet on the base of the Track Meter to press it down onto the racing surface, and the torque arm on the device rotates the rubber pad until it breaks free from the pavement.

Although there’s certainly a little more than what meets the eye in its assembly, the Track Meter is a relatively straightforward product that contains a rubber pad on the bottom with a surface designed to be very similar to a typical drag racing slick, that is pressed down onto the racing surface using the weight of the operator. A handle on the top of the device turns the pad and pulls it free from the track, with a inch/pound gauge on the handle returning the value of force required to pull the pad off the surface.

Many crew chiefs will often check varying points down the race track to collect their data, from behind the starting line clear to the 330-foot and even 660-foot clocks.

Crew chiefs and track specialists will typically utilize the Track Meter at multiple points down the track, often beginning right where the rear tires will be resting when the car launches, and working all the way down to the 330 or 660-foot markers. As data is gathered in varying conditions and even different race tracks, a better understanding of what those values mean and how they play into the final tune-up on the race car become more valuable.

“It’s about acquiring true variable data,” Wolyneic explains. “For example, as the track changes continuously, with the advent of this piece of equipment, you can really see where and how much it’s changing.” Wolyniec cites a race in Bristol several years ago, where the track was hot and slippery during eliminations, with Track Meter readings in the 200’s. When race day rolled around, overnight rain showers and a dramatic drop in ambient temperature improved the racing surface considerably, and as he shared with us, “Everybody was apprehensive about putting a lot of power to their cars, and many ended up shaking or smoking the tires. The issue was, only the teams that had the Track Meters and had and understood the data they were acquiring had enough confidence to put the power to it.”

Once the pad breaks free from the surface, the gauge on the device will register a variable measured in in./lbs. to illustrate how good or bad the track is at that specific point. Although these numbers may not mean much initially, once you have data to compare with at different spots, at different times, or on different tracks, it becomes incredibly valuable.

In the case of of the NHRA’s big show nitro teams, this track data can allow them to make changes in the primary clutch weights, timing curves, tire pressure, wings, and other variables. Of course the device isn’t just limited to the top-tier categories, as those in Pro Stock, Pro Modified, the Top Alcohol classes, small-tire racing, and even sportsman categories have them in their toolbox, with Wolyniec counting more than 400 Track Meters currently in use around the world.

The Track Meter In Use

Like any piece of equipment, the accuracy of the data returned by the Track Meter is largely dependent on the operator. As Wolyniec points out, the operator must be consistent in his process and truly understands how to use the equipment, which the company does walk through in the documentation supplied with the device.

“Certainly, when you’re working with a 1,000-foot or 1,320-foot track and you’re focused on a very small area, you can have some variations in the readings. What you’re looking at and where you’ll better understand the track is the wide spectrum.”

Wolyniec’s Competition Motorsports provides a software package with the Track Meter that’s similar to an Excel spreadsheet, and once you’ve walked the track and acquired your data points at the specific markers, allows you to input your readings. In measuring multiple points, you thereby spread out what would otherwise be a single data point into this wider spectrum, giving you a greater understanding of the track surface from the first measured point to the last. And the accompanying software make this process more visual by plotting out your data on a graph so you can see what’s happening on the track and have the ability to average it out or take specific approaches on the tune-up based on the track surface at specific points.

By metering the surface at several different points, you can plot the data on a graph using the accompanying software and actually gain a visual understanding of how the track surface is “working” as the car goes down the track. This is a huge boon for nitro teams that engage the clutch at different increments down the track based on their readings.

“Primarily, we’re looking at those critical points on the race track. The first is the launch point, or the point where the tire is sitting as the car leaves the starting line. From there, we’re looking at 30-feet, 60-feet, 330, and 660. We look at all of those positions on the race track and plot it all out on the graph,” says Wolyniec.

This, Wolyniec explains, gives you a much greater perspective than simply taking one reading, regardless of where it may be, and basing your understanding of the entire length of the track surface on that.

Shown here is track data gathered by the Bill Miller Engineering Top Fuel team at the spring Las Vegas event in 2012. The in./lb. measurements are entered into the appropriate cells in the Track Meter software, which is then plotted out on a graph (right). As you can see, the numbers remained relatively consistent from day to day in the same lane, with a particularly strong reading coming up in the right lane in the check prior to the first round of eliminations.

“Something that’s a bit of a misnomer is that many people think when you spray the track, that that first glue surface is everything,” says Wolyniec. “Well, just because it’s sticky doesn’t make it good. One of the other aspects of the Track Meter is that it’s actually looking at the coefficient of the surface, so it’s looking down beyond the glue and analyzing what the surface really looks like. From appearance and just walking on it, many think it’s a good track, but if the rubber below is too thick or greasy before they put the glue on it, the track won’t be any good.”

John Force Racing’s Larry Maglizzi

Good Track, Bad Track

Readings in the low 300 inch/pound range are generally considered characteristic of a “good” race track, whereas those averaging in the 250-270 range are “sketchy” by Wolyniec’s standards. “Anything below 250 and the track is generally requiring some pretty drastic adjustments to get from A to B for the kind of power that a nitro car is producing, but is still pretty good for lesser-powered cars,” he tells us. Tyler Crossnoe shared with us that the Track Meter registered as high as 510 in./lbs. at the radial tire event at Memphis back in March, marking the highest reading he’s ever seen on a race track. For a radial race, he typically shoots for 400 in/lbs. or higher, as the radial tires prefer a tacky “flypaper” type of surface.

“Early on we knew getting a reading from the Track Meter was going to be important and unlike anything we had previously used,” said Maglizzi. “With the Track Meter, we have a real number based on what the track is like. Before we had it, crew chiefs and track specialists would press their thumb or the ball of their foot into the track and have to guess on what the track was doing or what shape it was in due to the temperature at that time. It has become a very important tool in helping our teams make final tune-up decisions because we now have that solid number to go by instead of a guess.”

Maglizzi continued, “We’ve never before had a tool that we could use for checking the racing surface like this, so we definitely look at track readings in a different way now that we can utilize this piece of equipment. If we didn’t have this piece, we couldn’t be as accurate. Every decision we made about the race track would be a personal opinion, and not a solid number.”

Maglizzi checks the track surface with the Track Meter at least once per hour from early morning to late in the evening, if not more often, on qualifying and race day, to accurately gauge what the surface is doing through the day and to gather detailed data for different conditions and track temperatures. He typically checks behind the starting line where the tires begin the run, 10 feet in front of the starting line, and then at 100 and 300 feet. Prior to a session, he’ll radio the readings back to the crew chiefs, which they can then utilize to make adjustments to the clutch setup.

John Force Racing’s renowned Track Specialist Lanny Maglizzi was one of the earliest adopters of the Track Meter, which allowed him to relay invaluable data to the teams’ four nitro teams and their respective crew chiefs. (Photo courtesy John Force Racing)

“They have the opportunity to go back to their run journals and look at other recent runs they’ve made at that temperature and that same Track Meter reading, then they go from there on what they think the best call is, setup-wise. Usually, there are more peaks in the track, which means the further you go, the Track Meter reading increases along with the firmness of the track. Crew chiefs take this into consideration and will make clutch and power adjustments accordingly.”

With the Track Meter, we have a real number based on what the track is like. Before we had it, crew chiefs and track specialists would press their thumb or the ball of their foot into the track and have to guess. – Lanny Maglizzi

Tyler Crossnoe

Esteemed race promoter and track prep specialist Tyler Crossnoe, who has had a hand in the setting of a number of world records at tracks in the south, including the Memphis International Raceway, uses the Track Meter in his prep to gain a better understanding of the needs of the racing surface.

“I primarily use the Track Meter to see how the track starts out early in the day and then I’ll continue to check it throughout the day to see where it needs to be touched up. When I start prepping, I’ll check to see where the numbers are to determine where it needs to be for the type of event we’re doing. We can also use those numbers to see if we need to prep the track more in certain areas or calm it down some.”

Tyler Crossnoe, one of the up-and-coming young track prep specialists in the sport, makes regular use of the Track Meter in his prep processes, and monitors the racing surface throughout the event to ensure consistency from hour to hour.

At events with higher horsepower cars, Crossnoe will typically check from behind the starting line to clear out to the 330-foot mark to get an accurate feel for how the track is prepped and how it’s holding up to the conditions. “I really use the Track Meter a lot, because if the track is starting to go away, that little meter is going to alert me quicker then I can determine it by watching cars spin the tires.”

An Important Tuning Tool

For race teams and track specialists alike, the Track Meter has been a game-changing device — one that delivers data that racers and crew chiefs always wished they had, but simply had to rely on their shoe or their thumb to gather. Never before have teams been able to gauge a racing surface in the way that this revolutionary tool does, and it’s just another piece of technology, as simple as it may seem, that’s made today’s race cars quicker, faster, and more consistent than they’ve ever been.