If you needed more proof that we’re living in the real golden age of performance, look no further than the current battle for pony car supremacy. Hot on the heels of Ford’s all-new Mustang for 2015 is Chevrolet’s counter-punch, the all-new sixth generation Camaro. Both V8 offerings pack an admirable amount of firepower right from the factory, but of course there’s always room for improvement.

Along with the new LT1 power, the 2016 Camaro SS is several hundred pounds lighter than the outgoing car, giving the new model a 15 percent better power-to-weight ratio than the fifth generation SS right out of the box. That makes for one hell of a template to start with. With 455 horsepower as the baseline output, getting into the 600-plus horsepower club is just a matter of dialing up Lingenfelter Performance Engineering to add some boost to the mix.

At first glance the new Camaro might not look like a dramatic departure from the fifth-generation model it replaces, but the new car is a very different vehicle underneath the skin. Seventy percent of the parts used in its construction are all new to the model, and much of this sweeping change can be attributed to the fact that the Camaro has moved from the Holden-based Zeta platform that underpinned the fifth generation car, and onto the Alpha platform that it now shares with the Cadillac ATS.

For the SS model, performance is up substantially, not only because of this new lightweight set of bones it’s sporting, but because 2016 marks the year that the Camaro gets the C7 Corvette’s direct-injected, 455 horsepower LT1 V8.

As both the Camaro and Mustang move away from their sedan-based muscle car origins and toward a more traditional sports car design, the Camaro gets a substantially smaller footprint. It may look a lot like the fifth generation car, but side by side the difference is immediately noticeable. That size reduction helps the Camaro in just about every performance metric you can test, but if you were planning on putting a walrus in the trunk you might be in for some disappointment.

Simply put, the Camaro SS has set a new standard for performance in the segment, able to dispatch zero to 60 mph in four seconds flat on its way to a low 12 second quarter-mile time right off the showroom floor.

2300 vs 1740

While this supercharger system is similar in design to GM’s LT4 V8, which also uses an Eaton TVS supercharger, the Lingenfelter kit uses a larger 2300 rotor pack. Compared to the 1740 rotor pack that GM uses, the supercharger in Lingenfelter’s system doesn’t need to spin as quickly to create the same boost, which in turn helps it manage heat more effectively. Less heat means more horsepower for longer amounts of time, something that’s really worth taking into consideration if you plan do you any road course work with your supercharged Camaro.

A New Heartbeat

The new supercharger kit promises some big gains: 630 horsepower and 600 lb-ft of torque at the crank on 91 octane gas while boasting 50-U.S. state CARB emissions certification and excellent drivability. And, through the wizardry of modern engineering, highway mileage is not adversely affected despite the heap of additional power on tap.

But offering a supercharger kit for a modern vehicle isn’t just a matter of slapping a blower on top of the engine – there’s a number of considerations beyond simply ratcheting up the performance.

Magnuson and Lingenfelter started discussing the project long before the sixth generation car ever hit the street. -Mike Copeland, Lingenfelter Performance Engineering

When it came time to collaborate on the new Camaro, engineers had some of the heavy lifting already taken care of, since the LT1 debuted a few years prior on the 2014 Corvette and made its way into GM’s full-sized truck and SUV line before landing in the Camaro SS. But even still, the Camaro required some special attention and engineering prowess to make the system work the way they wanted it to.

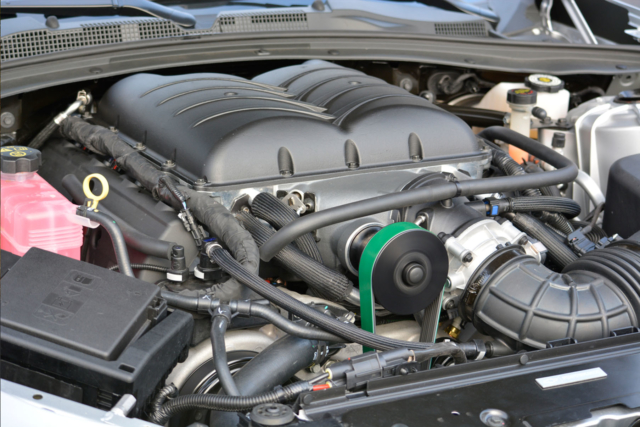

Despite having additional capacity versus the LT4 setup, the Lingenfelter kit manages to squeeze into the stock location without any need to swap out the stock hood or modify anything else in order to make room. The kit looks so at home in the Camaro’s engine bay that you’d be forgiven for not immediately realizing that this isn’t stock.

“The first car to arrive was an automatic. Those are the hardest to tune, so that was helpful during the development process,” says Copeland. “With both an electronically-controlled throttle and transmission, it’s a bit more challenging – you run into issues where there can be flat spots in the power delivery and the transmission’s shifting calibration needs to be tuned for drivability. The vacuum-operated wastegates on superchargers can’t really be calibrated in the same way the other systems it interacts with can, so we calibrate those systems around that.”

Lingenfelter tells us that designing a system like this is something of a balancing act: If you don’t specify enough capacity you run the risk of heat management issues, but if you overdo it you run the risk of adding too much weight to the nose of the car, which can negatively impact performance.

When GM develops a new model, it provides an electronic blueprint of the vehicle to aftermarket companies so they can develop around those constraints. Magnuson took the template for the sixth generation Camaro SS and designed its supercharger system around that, determining the packaging strategy for the lines, brackets, intercooler, and the supercharger itself electronically before moving on to real-world testing.

With this kit we wanted to make sure we retained the reliability and street manners of the OEM benchmarks while offering a lot more power. -Andrew Mernone, Magnuson

Dialing In Usability

Of course this isn’t the first time that GM’s direct-injected V8 has seen some boost – the LT1’s big brother, the supercharged LT4, comes installed in the engine bay of every new Corvette Z06, Cadillac CTS-V, and the upcoming Camaro ZL1. But this is one situation where the OEM solution might not be the best course of action, as the Z06 in particular has been plagued by heat management issues ever since the engine debuted, with reports of the car dialing back power after just a handful of road course laps and hitting critical engine temps shortly thereafter.

Lingenfelter's kit keeps the Camaro looking pretty stealthy, though would-be combatants will likely be able to hear that something's going on, if not from the blower whine then from the Corsa exhaust system.

Some of the trouble can be attributed to the design of the supercharger GM went with, a decision that was made in order to comply with Federal pedestrian safety regulations.

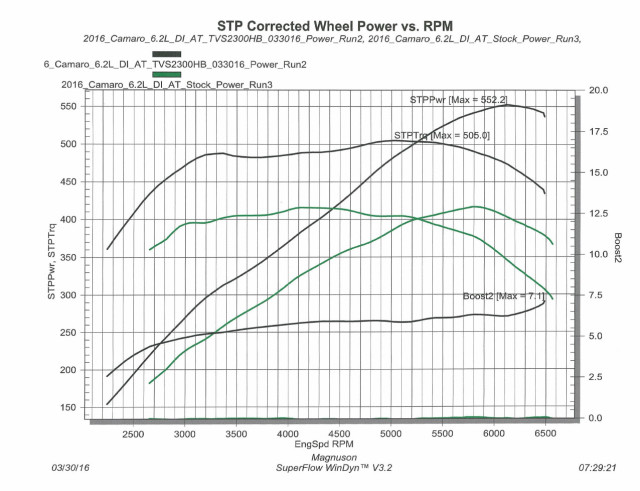

Here’s Magnuson’s dyno test results with the stock baseline overlayed in green. With the kit installed, the LT1 is making 552.2 horsepower to the rear wheels at 6,100 rpm and 505 lb-ft of torque at 5,000 rpm, a difference of about 90 pound-feet of torque and more than 130 horsepower versus stock. The power also comes in much earlier with the Lingenfelter kit installed and drops off more gradually on the top end.

Those regulations specify how much the hood must bend in in the event of a pedestrian collision, and because of it, GM chose the 1740 rotor set for its Eaton TVS supercharger to meet that target. Compared to the 2300 rotor set used in the Lingenfelter kit (which is also an Eaton TVS design), the OEM system must spin significantly faster to create similar boost, and with those higher RPM, more heat is generated.

“We’ve seen 20-plus horsepower disparities from one dyno pull to the next [with the GM system],” Copeland says. “This packaging constraint also reduces the cooling capacity and the size of the intercooler, which in turn leads to power reductions because the ECU has to take timing out to protect the engine.”

Lingenfelter reports that when running dyno pulls on LT4-equipped cars it has seen as much as a 20 horsepower drop from one pull to the next. GM’s software is keenly aware of heat at all times, and will dial back power in anticipation of fluid temps getting too high. Keeping the engine within safe operating temperatures is in Lingenfelter’s playbook as well, but with the added capacity of its kit, the engine is less likely to trigger the ECU’s fail-safe measures.

Fortunately for aftermarket companies like Lingenfelter and Magnuson, those specific federal regulations do not apply, so they have more freedom to design their system to run for longer amounts of time with less heat. “GM’s calibration changes dramatically depending on internal fluid temps,” adds Mernone. “With larger charge coolers and a larger plenum, our system can manage heat effectively, which helps avoid the ECU having to dial back the power.”

Upgrade Path

But for some more is never enough, and these guys understand that. While the Lingenfelter supercharger kit just hit the streets a few weeks ago, plans are already in development to offer even more LT1-based power beyond this standard supercharger kit through the use of an upcoming pulley swap, as well as some top secret stuff that should be announced in the coming months. Rest assured though, there’s room to grow with the LT1.

Both Lingenfelter and Magnuson report that there’s plenty of room to bump the power up even further on the LT1, and a pulley swap offering should be available for this kit soon. At about 650 horsepower the LT1’s fuel pump becomes a bottleneck in the equation, though simply switching over to an LT4 pump will provide enough fueling to get into the 750 to 800 horsepower range.

So what’s the real limit with this engine? Both Copeland and Mernone say there are a few constraints worth considering.

“The LT1 fuel pump is good for approximately 650 horsepower,” says Copeland. “Beyond that, enthusiasts will need to either switch over to an LT4 fuel pump, or swap the camshaft for one with more lift for the direct injection pump.” While there aren’t any aftermarket pumps available for these engines as of yet, the LT4 pump is good for about 750 to 800 horsepower. Anything beyond that and you’re likely to start to discover other elements of the car which aren’t ready for the power.

As of the time of this writing, CARB certification for the Lingenfelter/Magnuson supercharger kit is pending, but expected shortly. With it, the kit will be 50-state emissions legal.

The 91 octane pump gas in California also remains a limiting factor, but one that’s necessary to consider in order to make their systems truly plug and play. Copeland points out that Lingenfelter’s primary focus is to create reliable performance that can be used every day without the need for constant maintenance.

“We’ve designed this system so that enthusiasts can jump in the car and drive across the country without giving it a second thought.”