One of the great things about aftermarket centrifugal superchargers is that they can last a long time in street applications. Many easily run over 100,000 miles, keeping up with today’s modern engines that easily hit that mark and oftentimes double that. Just like your engine, though, the supercharger does require routine maintenance to keep it performing at its best and ensure it will produce the desired horsepower bump with every hit of the throttle. We talked to the folks at ProCharger and Vortech about what enthusiasts should be checking, how often they should make these inspections, and what happens when you don’t keep up on the maintenance on your high-performance street blower.

Get Onboard With The Clean Air Act

Just as with any engine, keeping a clean air filter ensures proper performance of the supercharger, as a dirty one can reduce airflow, which isn’t good when you’re trying to compress it.

“A dirty air filter means higher restriction, lower power, and lower boost,” explains ProCharger’s Walt Sipp. “These circumstances are not good for the engine or the supercharger.” Both ProCharger and Vortech equip their supercharger systems with serviceable air filters so the end user can keep the filter clean and not have to replace it along with the vehicle’s other service items.

“You need to check supercharger air filter,” says Vortech’s Jimmy Martz. “You can have a dirty one and it causes a restriction, which brings boost down. We use a K&N-type of cotton filter that is serviceable. Some systems are draw-through, so you want to be extra careful how much oil is applied, “Martz says of the maintenance process.

ProCharger’s Sipp notes that some enthusiasts swap out the included filter for a variety of reasons, and that it is not usually beneficial.

A clean air filter is essential to proper supercharger as well as engine operation. It’s also important to note that the air inlet tubing should be engineered so as not to pose a restriction.

“Some guys will make their own if it’s an older swap or transplant,” Sipp adds. “Guys will say ‘I’m using this air filter’ and it’s a tiny little one that nothing will flow through. A lot of people don’t understand how much restriction is on the inlet with an incorrect filter. Cleaner, more straight-through air is going to pick up efficiency and boost. Some use fancy tubes and a small air filter, and boost will drop because it’s a restriction. Some of the cold air kits add a straw to the front of the blower, which doesn’t like it. Some will do this trying to keep the heat away from the intake charge, but you will get better performance from clean air with the least amount of restrictions than you will from a restrictive air flow and a couple degrees cooler inlet temp.

Take a 2016 Camaro. Everything is masked so tightly under the hood and the Chevy engineers have done such a good job of cleaning the air out from the engine bay when you’re at speed, there’s a lot of air moving. A little bit of under-hood heat isn’t going to be noticeable.”

Sipp offers one simple concept to those considering changing the included air filter out for something else.

“Start with the air filter that we provide and go bigger, not smaller. When we choose the air filter, we are selecting the largest we can fit in a given area.”

Self-contained superchargers like those from ProCharger and Vortech generally never lose oil, but checking the level whenever you’re under the hood is a good idea.

Oil Changes and Leaks

The next item on the very short supercharger maintenance list is changing the oil regularly.

Vortech’s oil change interval is 7,500 miles, and Martz expressed that along with performing the recommended oil change with the recommended oil at the service interval, that it was also good practice to inspect the supercharger for any leaks.

“With self-lubricated superchargers, you shouldn’t have to check the oil unless you see oil coming out of the vent or any leaks anywhere,” Martz says, noting that it’s good to perform a visual inspection during one’s normal engine oil change.

“If oil-fed, check the oil nozzle filter for debris and inspect the unit for oil leaks.” Martz says that around 99 percent of Vortech kits sold today feature self-contained blowers, but customers can still choose to use an oil-fed unit.

“We recommend these for road race, drag race, or high spirited driving. It allows the oil to dissipate the heat easier through the engine oil and allows them to spin the unit a little higher, as these units typically utilize heavy-duty bearings.

When it comes to aftermarket superchargers, it’s important to utilize the manufacturer’s recommended oil, as it is specifically engineered for a specific product.

“Clean oil is the lifeblood for the mechanical systems that depends upon it for lubrication,” Sipp says.

Sipp points out that ProCharger only recommends using its own oil in its superchargers for long-term reliability and warranty purposes. “Ninety-nine percent of our customers run our oil. however, we’ve seen blowers come in with all different types of oil in them, and we have to explain to the customer that what they ran was not good for the blower’s internal mechanical parts.” Additionally, Sipp says that the oil change interval for all ProCharger products is between 5,000-6,000 miles, whether you have a P-1SC or an F-1X.

“Quantity is a little bit different and depends on the blower. Like the engine, superchargers do best with fresh, clean oil.”

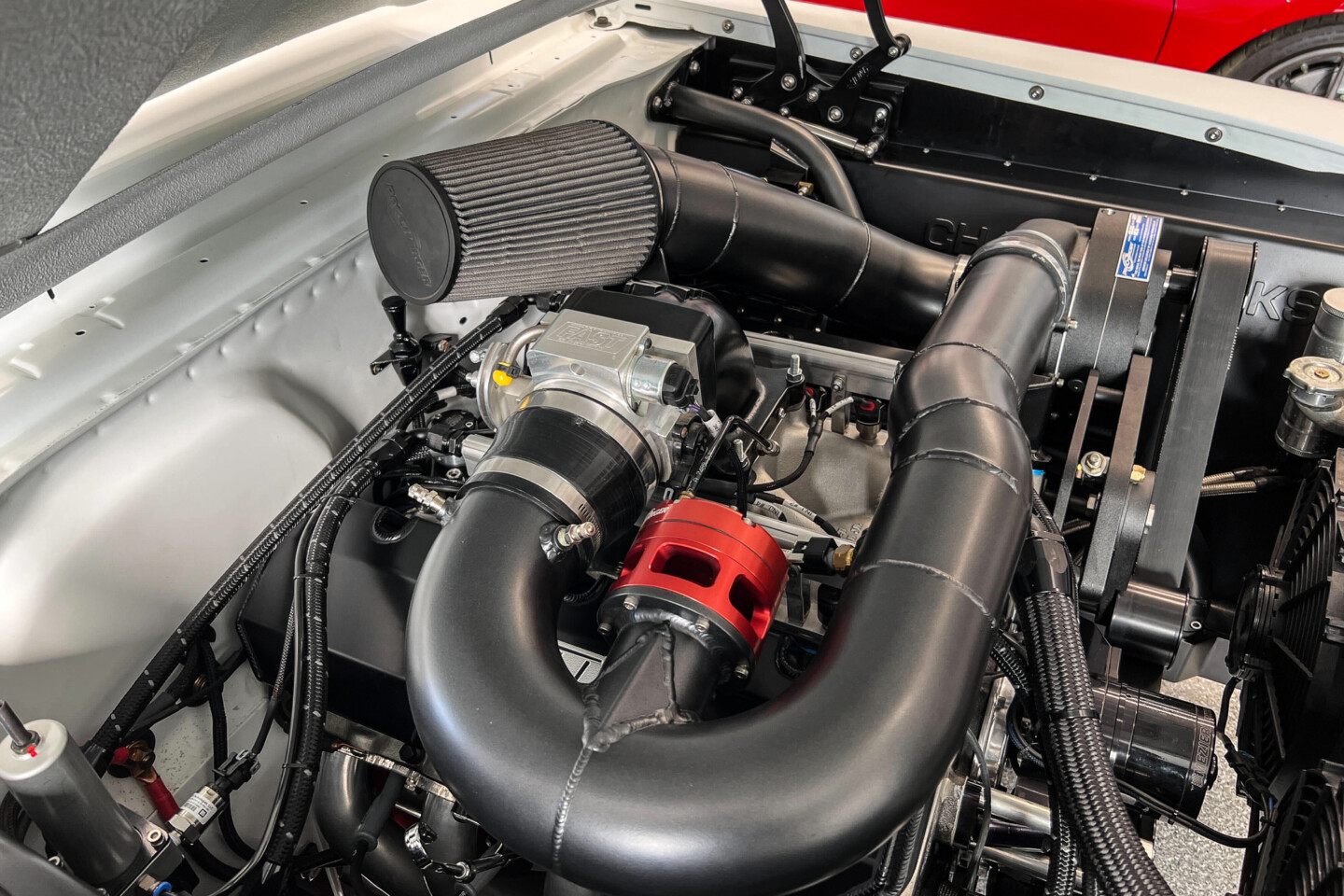

The blower belt tensioner is in the lower left corner of this image. On the 5.0 system pictured here, the blower has a dedicated drive, independent of the factory accessory drive and tensioner.

Tension Is A Good Thing, In The Right Amount

Supercharger belt tension, as well as belt condition, are very important to ensuring that the blower performs as expected.

“Most modern cars are tight on space, so we generally use the factory tensioners; this also helps to not add additional stress to the crank or factory FEAD system” says Vortech’s Martz. “The tensioner service life is the OEM service life, but if the user is racing or driving spiritedly on the weekends, the tensioners are going to wear out quicker. Just be sure they are operating in their appropriate range.”

“Most of our late-model kits have our HD tensioner,” Sipp explains. “It’s self-tensioning for the supercharger belt, but we do make kits with static tensioners that require adjustment. Some kits use the stock tensioner in conjunction with our static, and if the stock one fails, no adjustment to the static tensioner will compensate for the stock one not working. It’s definitely important to keep track of the belt tension. Incorrect belt tension can yield premature wear or failure, but can also negatively affect boost level and performance. Check it every time you change the oil, or any time you’re under the hood. You’re there, so you might as well check it.” Sipp also notes that the belt’s condition is just as important.

“Check it regularly and check it for wear, fraying, and cracks,” Sipp continues. “Keep an eye on what the adjustment is supposed to be. See the install manual to make sure it matches the factory specs. We have videos online to cover a lot of this. If the belt needs to be replaced, make sure to use a quality replacement belt. Using a sub-par belt can cause loss of boost due to slip and potentially break prematurely.”

The Spark Of Life

Perhaps overlooked from a maintenance standpoint for a supercharger kit — as they are not so much a part of the kit but are directly affected by it — are the spark plugs.

“Adding a blower to your engine definitely changes the spark plug change interval,” notes Sipp. “You’re not going to get a 100,000-mile interval with boost. We generally recommend colder plugs anyway, and they are not designed for that longevity, getting maybe 25,000-30,000 miles or so. Always check that the gap is properly set for a supercharger application, rather than what the spark plug box says. You will almost always run a tighter gap than what the factory gap would be. Dirty, worn, or old spark plugs can cause detonation, poor performance, and other engine related issues. Forced induction adds more pressure to your engine cylinder, so it’s important to properly adjust and maintain your spark.”

“Using the incorrect spark plug or gap can also cause drive-ability issues,” notes Martz. “We have seen many customers have issues with misfires and rough idle that are easily fixed once the right plug and gap are used.”

A bypass valve that isn’t functioning properly can cause all sorts of issues, from basic drivability problems to damage to the supercharger itself. Ensuring they are working properly is a somewhat easy task to verify during service intervals.

Ensuring Proper Bypass Valve Function

Verifying bypass valve function is something Sipp said is relatively easy to check, and that a properly functioning bypass valve is essential.

“A bypass valve that is not operating properly can cause boost issues and poor performance. It can also cause harm to the supercharger, as well as drivability issues,” Sipp tells us. “If the valve is supposed to be open but it’s closed, it should see no additional airflow, so you might get lopey idle surges and low-speed drivability issues. “When we see customers chasing a boost issue, the bypass valve is one of the things we will have them look at. Sometimes, it’s as simple as a bad vacuum line going to it that is causing the issue.

With regard to bypass valve testing and maintenance, Martz said, “A simple test can also be performed using a hand vacuum pump. You can add vacuum to the port on the valve to test for operation. Make sure the valve opens fully and smoothly at the proper vacuum level. Most valves will open in the 3-8 “HG range. Also be sure the valve holds positive pressure. We have seen valves open under boost once it pushes past the spring pressure, this would cause lack of power and loss of boost pressure.”

Adds Sipp, “Our Pro-Flow valve has a filter on it for noise reduction, but most never look at it to clean it. Keep an eye on that and the functionality of the valve. Some of our valves have a linkage mechanism and you want to make sure that is working properly. You can smoke test it, and you might see that the valve isn’t shutting all the way, but that’s normal. Just make sure it’s actuating properly — that it is opening and closing, not binding. With our valve, it’s vacuum operated. We would tell a customer if you have it on the car or off, open the valve, and cover the vacuum port; if it stays open, that’s what it is supposed to do. If it starts to close, it may have an issue like a bad diaphragm. A bypass valve that isn’t opening causes surging in the system. It can cause throttle surge, boost/compressor surge, and can walk a belt off. Long term, it’s hard on the blower.”

You don’t want any of your valuable boost pressure to escape, so take a minute to check the fittings and couplings during regular service or even if you just happen to be looking under the hood in general.

Admire, But More Importantly, Inspect Your Supercharger

A supercharger is a working moving component made up of numerous other components, must like your engine, and it is good practice to take a look at these things any time you’re under the hood, whether you are performing routine maintenance, at a car show, or at your buddy’s house showing off your boost-making hardware.

“Anytime you’re under the hood, check the oil lines for kinks or cuts, check hoses and tubes for leaks, and check the clamps for tightness,” says Martz. “Check for impeller contact to the volute and/or debris, check the impeller for damage — visually inspect it any time you have the filter or inlet off. Typically, if you run a filter on it at all times, you won’t see any issues.”

All the Horsepowers

Keeping in mind the old saying that an engine is just an air pump, making sure it has the cleanest and most air available is key to ensuring it performs as well as it can, and the same can be said for your centrifugal supercharger. Following the tips we’ve talked about today will keep your blower operating as expected and for a long time to come. It’s a sizable investment in your vehicle, so why not take a few minutes to ensure that it is operating optimally so you can enjoy all of the performance benefits it has to offer.