When we started our journey to build a competitive 275 radial stock suspension car, we had a rough idea of where we wanted to be. We needed a machine that would be capable of competing with and outperforming some of the best that small-tire doorslammer racing has to offer. We also had to make sure we didn’t put together a combination so sensitive that it would only work under the best conditions on the stickiest tracks, as that’s not where we race.

The results?

- Low 1.1-second 60-foot times on 275 radials and leaf springs

- Consistent sub 4.5- second 1/8-mile passes at nearly 170 MPH

- Bringing home W’s and Wallys

- Securing a top position in the list of fastest leaf sprung cars on the planet

The build turned out to be wildly successful, but how did we get there? To briefly recap, our build started with a solid foundation in the form of a LS Next iron block from Dick Maskin and the team at Dart Machinery. To match the quality of the block, we engaged the likes of Total Seal, Winberg, GRP, Ross Racing, Peterson, Chris Alston’s Chassisworks, Vortech Superchargers, and ARP to pull together a mass of billet and iron splendor capable of containing the 2,000-plus horsepower we were expecting.

We then connected with Comp Cams, Ferrea, T&D Products, and Mast Motorsports to pull together the heart and lungs of the engine. From the onset of the project, we knew we would have to orient the major details of our build around the capabilities of Mast’s best-in-class Mozez head and matching tunnel ram intake. The supporting cast of characters did not disappoint and resulted in a valvetrain that’s seen 10,000-plus RPM without missing a beat. That kind of RPM, over 30-pounds of boost, and gobs of horsepower is no small feat.

“When we first hit the track, we would wind the engine out to a 9,800 shift point. It turned heads but did pick up e.t. We decided flogging the engine that hard wasn’t worth it.”

None of these awesome parts make a difference if we aren’t able to control them. On that front, we turned to Doug Flynn, Blane Burnett, and the rest of the fine folks at Holley Performance to talk about engine management. We spoke with them about the combination and our plans to understand if they had an electronic fuel injection system with a complete ignition strategy that would meet our needs. After a few rounds of discussion, we landed on the Dominator EFI computer. It was the top-of-the-line EFI unit that included must-have racer features like complete ignition control and adaptability with third-party systems, data logging, completely customizable inputs and outputs (I/O) and a really neat advanced table feature that allows experienced tuners to build their own custom features.

We also included Holley’s Coil-On-Plug (COP) system that came complete with a harness and eight Holley Smart Coils. Last, we picked up Holley’s touchscreen dash to show us everything going on in real time.

“Read the robust instructions provided by Holley from front to back before touching a wire.”

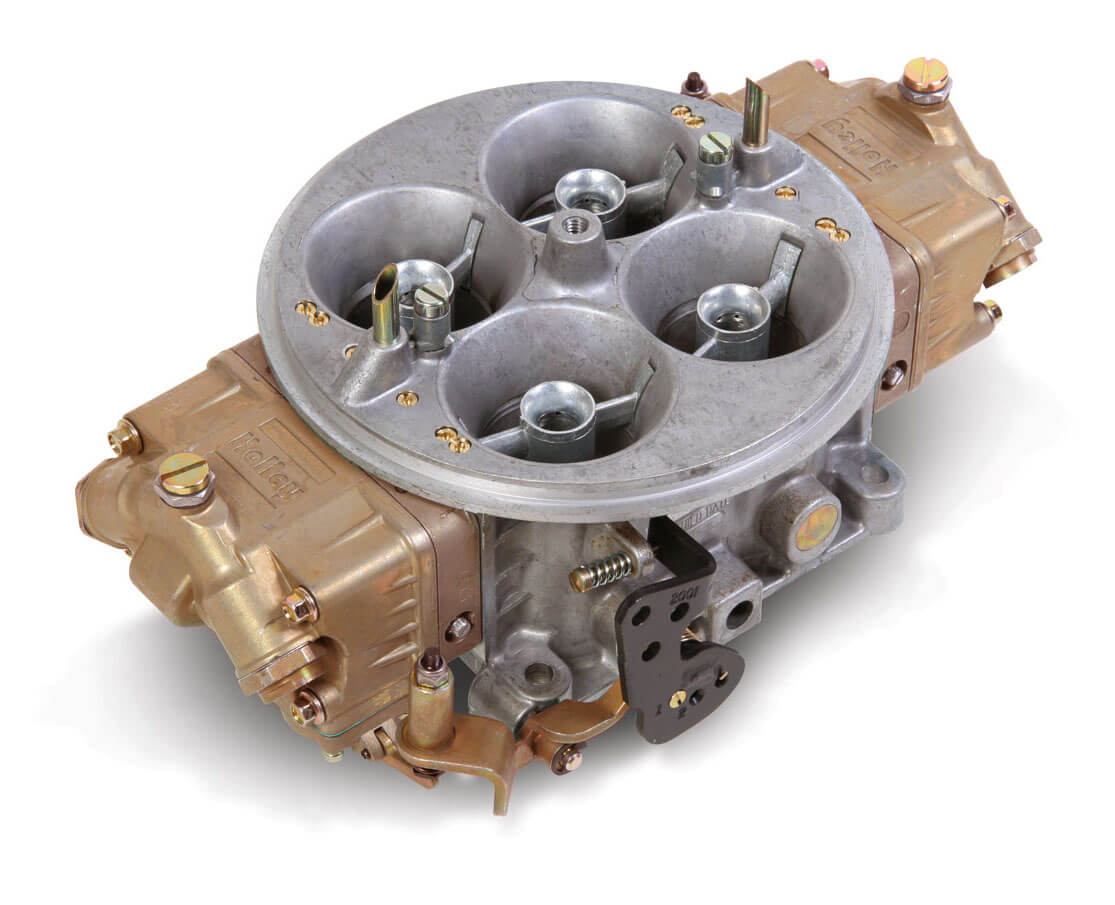

I was not a novice to EFI when I talked to the folks at Holley. We knew this project would be managed with an EFI computer, however, we wanted to understand if there were any reasons to consider the performance carburetors offered by Holley. As Blane explained, the reason to use EFI was two-fold.

Before going with EFI, we used units like the large Holley Dominator 1250 CFM carburetor on the left. To replace the carburetor, you'll need a throttle body for air. We used the Wilson 123mm V-Band unit shown in the center. You will also need fuel injectors like the billet pieces we used, shown on the right. To make it all work, the ECU will need some sensors to measure air pressure, temperature and other atmospheric variables.

“First, while carburetors are a great way to mix air and fuel, there is a reason why OEMs have utilized fuel injection as standard equipment for several decades: fuel injection allows you the benefit of atomizing fuel running into the engine better in most cases over a carbureted setup. That leads to a better burn of the fuel and oxygen mixture and as a result you can see more power.

“Second, the amount of things you can control with a standalone EFI system, and with ease, has changed drastically in the last ten years. There is a reason why numerous series are switching over to EFI as standard in their classes as well, (eg. ARCA, NHRA Pro Stock, Camping World Truck Series, standard equipment on COPO Camaro, etc). Holley EFI systems are great in that they allow you to control numerous stages of nitrous, progressively where desired, for up to eight stages in the case of our Dominator EFI computer. They also can control electronic transmissions, boost in forced induction applications, and they do it all from a single computer.”

He further explained, “A common misconception for many racers that are unfamiliar with electronic fuel injection is that it will increase horsepower. In truth, a well-tuned carburetor can be nearly as effective as a well-tuned EFI system, but there are still advantages to be had with an EFI system over a carbureted system. By the time a racer finishes putting everything in to their carbureted build, generally speaking, they could have purchased a single ECU, a harness, and sensors that would have granted all of the advantages that they ended up purchasing as add-on with the carburetor setup.

“For instance, AFR monitoring means you’ll want multiple O2 sensors, temperature probes, driveshaft sensors, shock travel, all of which add up to a lot of money when purchased as single units. A simple swap to Holley EFI and you have all those capabilities in one ECU.”

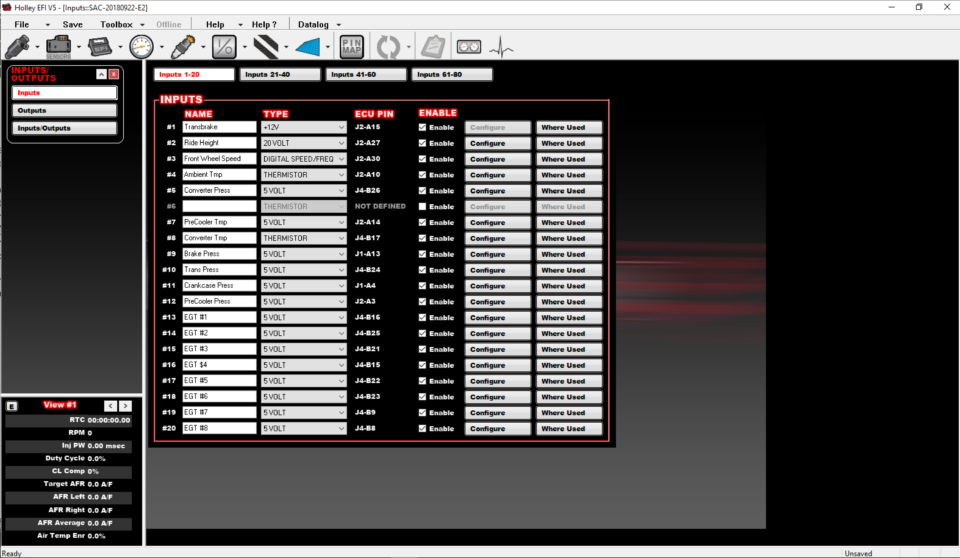

The Holley comes off the shelf with support for up to 60 I/O channels. Beyond that, there are provisions for adding more channels virtually or through the digital dash add-on.

And he was right. The Dominator ECU that we picked up for the Camaro included a need for all the sensors he mentioned, and more, even if we decided to go with a blow-through carburetor for our supercharged setup. Picking up those sensors for a stand-alone data logger would certainly raise the cost of the build and those sensors would not be able to interact with our carburetor for down-track, real-time adjustments. Further, Holley was on its fifth version of ECU updates where they provide software updates, additional features, tables, controls, and a number of other updates that carburetor technology just can’t keep up with.

“I’ve seen many builds where it appeared a racer spent over $150,000 on their build to then put the EFI system in with a $40 kit from Radio Shack.”

Wires…

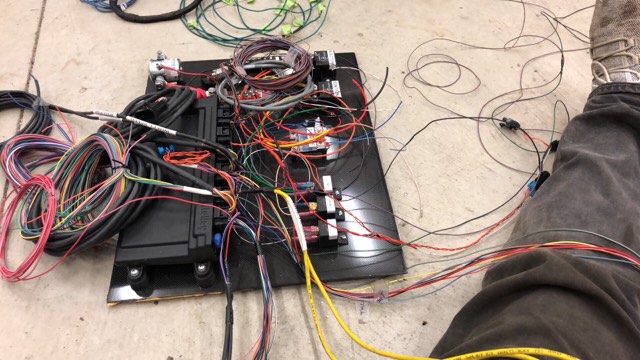

Before discussing tuning and features, there was a bit of an elephant in the room. A typical carburetor requires some fuel line, a screw-driver, and a 1/2-inch wrench to install. What about all those wires that come out of the EFI unit? Where do they go? While tuning EFI is fairly straightforward (once you get the hang of it), the installation can be intimidating to the uninitiated. Installing the unit, connecting the sensors, and grafting it into existing functions like the transbrake, water pumps, and logging switches involved patience and a willingness to engage in wiring.

Wires, wires, and more wires. Here is a shot of just a fraction of the wiring to make sure the sensors and components can talk to and be controlled by the EFI system. More complex installs are not for the faint of heart and can benefit from professional assistance. Holley offers a completely terminated (pre-wired) harness to make the task easier. We of course chose the harder path.

We took this task on directly but would recommend a professional installer for those unsure about their capabilities. If you were to decide to take on this task as a novice, it’s not the end of the world but do it right. I’ve seen many builds where it appeared a racer spent over $150,000 on their build to then put the EFI system in with a $40 kit from Radio Shack. Those builds almost always had intermittent problems that were nearly impossible to track down. The suggestion? Read the robust instructions provided by Holley from front to back before touching a wire, hone up on your wire routing and splicing skills, purchase the correct tools, test each connection upon completion, and most of all, take your time.

As Burnett explained, “The most critical part of an EFI system is the quality of the install itself. This means that the wiring and sensors need to be installed correctly. If the wiring process is skimped on in any way, you’re asking for trouble. The most expensive, capable EFI system on the market isn’t going to be able to get you down the track without breaking up or failing at that point. You may damage the ECU itself, along with other expensive components on the vehicle that you’re trying to run with it.”

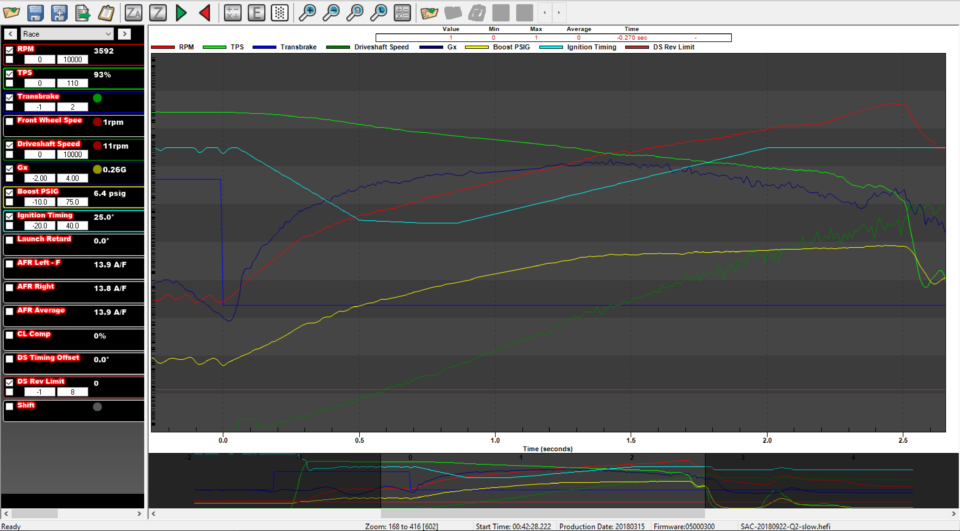

A data logger is critical if you want to get anywhere in drag racing. Holley’s EFI unit comes with a fully capable data logger, built in. This means no additional boxes are needed to log every aspect of every pass down the track.

In addition to solid wiring principles, the job could be made easier by picking up a harness terminated with all the sensor connections from Holley. However, we wanted to custom-fit the harness to our specific vehicle and opted to pick up several unterminated harnesses from Holley. Sourcing the harnesses from Holley meant we would have an easier time wiring the car but would still have to get our hands a little dirty in routing, splicing, and properly terminating the wires to their assigned components.

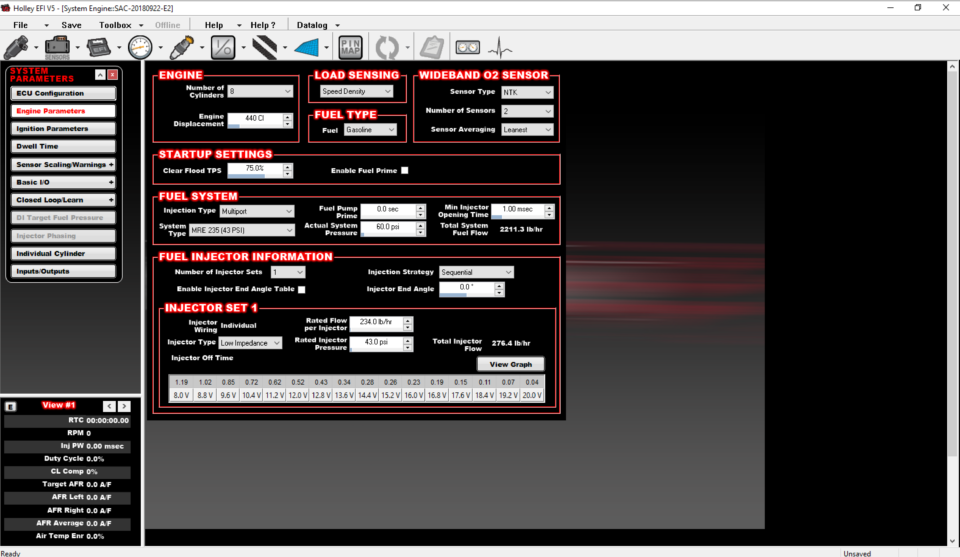

Once installed, we powered up the unit and began the work of configuring the computer to the specific details of our leaf-sprung, 275 radial, track smasher.

Car Configuration

Holley’s software allows the tuner to specify everything about the engine. This makes the system versatile enough to power a car show cruiser or a 3-second 1/8-mile doorslammer.

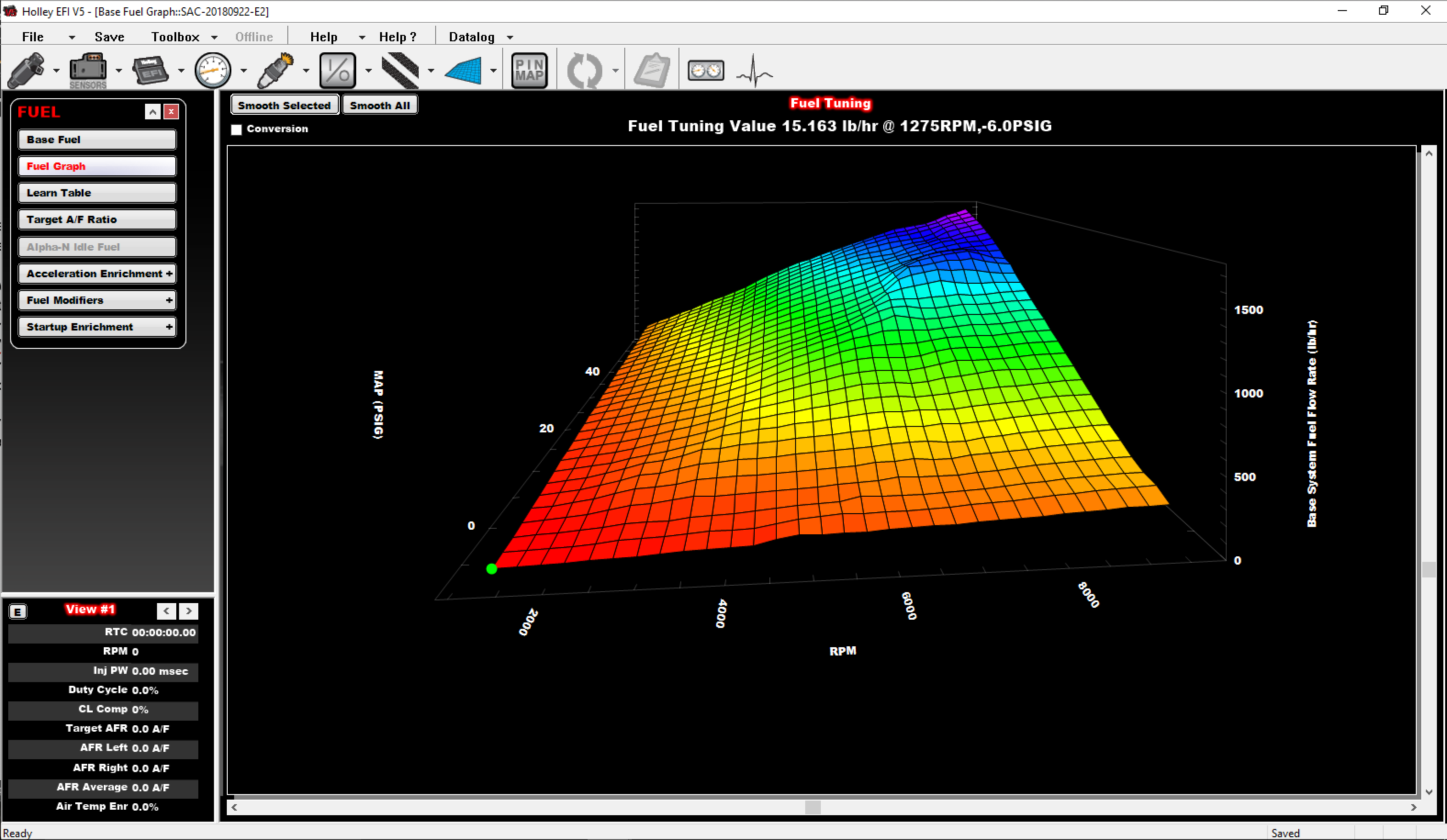

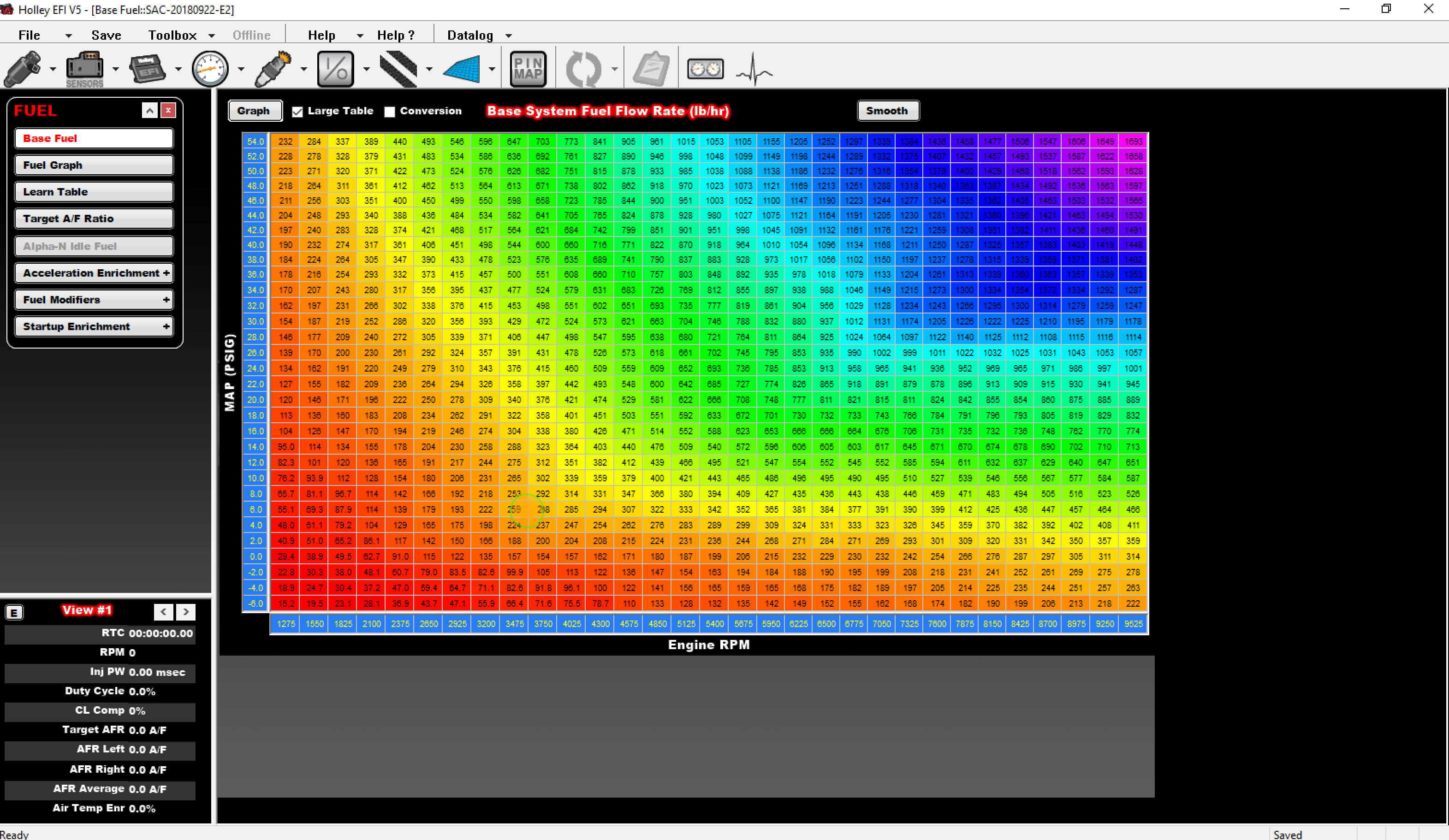

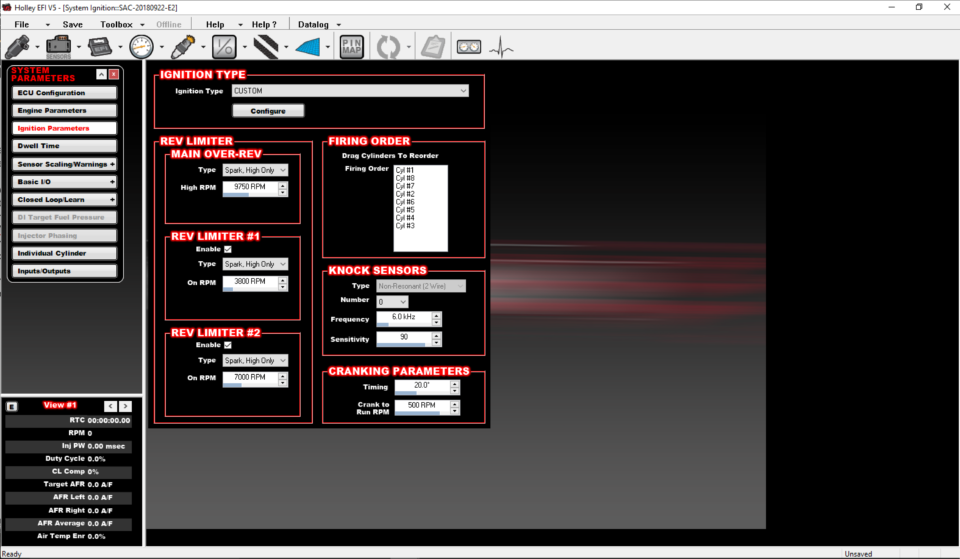

One of the first tasks we confronted when configuring the computer was telling it what kind of engine it would be controlling. Most of this configuration is handled in the “Engine Parameters” screen, and the interface of the software really did make this relatively simple. Some of the more complex settings, like “Load Sensing” relate to how the car will be tuned. This is primarily based on tuner preference. In this case, we chose “Speed Density” to tune the car based on our MAP (Mass Air Pressure) readings in relation to engine RPM. Tuning this way would allow us to set a desired fuel number (in pounds-per-hour or volumetric efficiency) at any point in the engine RPM curve.

Advanced ICF

A unique feature offered in the Holley software are what they call advanced tables. The Advanced ICF came for free with the V4 software update and provides the Holley EFI with unparalleled configurability. The advanced tables allows the tuner to use conditional operators to play any one or two values against each other to trigger a new action by the ECU. With advanced tables, the rabbit hole can get very deep.

- Want to drop timing after a certain time threshold but only if ride height is above X inches and the TPS is above Y%? Advanced tables have got your back.

- Want to compare front wheel speed to rear wheel speed and change a setting based on the divergence of the two? Yep, put it in an advanced table.

- Have an off-idle stumble that can’t be ironed out in the idle ICF? Got ‘ya covered.

An advanced table can look at EGT, O2, temp, RPM, TPS, or anything and then modify timing or fuel based on custom defined conditions. You can even play advanced tables off other advanced tables.

On the fuel side, a camshaft position sensor is key to “Sequential Injection,” which allows the computer to target a specific cylinder when fueling. This allows the tuner to change fuel values per cylinder, which is critical when equalizing cylinders for maximum power. As air routes through the intercooler, piping, and intake, it doesn’t always take a uniform path. As a result, some cylinders will naturally end up with more air than others. More air needs more fuel to burn. When pushing the engine hard, providing each cylinder with what it needs prevents engine damage and provides more power. Like fuel, the cam sync sensor allowed us to target individual cylinders for spark timing as well.

The Benefits of Coil-On-Plug

Coil-On-Plug setups allow the builder to place eight coils, one per cylinder, closer to the cylinder it is supposed to support. Instead of a single coil, eight coils perform the task and use the ECU, not a distributor, to fire based on the individual cylinder timing settings. Here, you can see four coils, below the passenger header, hiding behind the front wheel.

One of the neatest changes we made when switching to the Holley EFI was going to a coil-on-plug,” or more accurately, “coil-near-plug,” ignition setup. When making fire, the Holley can accommodate a number of ignition setups, including most popular CDI/digital ignition controllers like the well-known MSD spark boxes. We opted to forgo the MSD and skip the mechanical parts like the distributors more commonly found in race cars. Coil-On-Plug (COP), or in our case, coil near plug (CNP), is just as it sounds.

The software allows the tuner to specify ignition parameters. Any type of ignition from popular MSD distributors to the latest in Coil-On-Plug hardware.

Instead of installing a single coil and then using a distributor to route the spark, the coil-near-plug setup uses eight individual coils. One coil per cylinder fires individually based on the timing parameters in the computer. It’s the same strategy used for firing the fuel injectors and allows fine tuning the spark lead per cylinder. Another core benefit is each coil is fired less often than a single coil.

A quick view under the engine shows the coils hidden away in a safe space. They are under the header and just above the A-arm. Note the very short spark plug wires that help reduce unwanted resistance.

The result is increased dwell time, as eight coils split the function of what was previously a single coil. Dwell is also configurable in the Holley software. Last, the entire setup is digital and eliminates mechanical parts. This meant no clocking distributors, no cap and rotor replacements, and no mechanical failures. As a bonus, we were able to shorten the spark plug wires.

Fuel And Spark Configuration

Base fuel tuning takes place in a 32x32 grid that allows the tuner to specify a fuel number for each MAP and RPM value pair. Depending on the tuners preference, the data can be entered using pounds of fuel per hour or volumetric efficiency.

At their core, every EFI system performs the same function. They tell the fuel injectors when and for how long they should be open. It seems simple but when digging deeper into the details, the story becomes more complicated. Most modern-day EFI units have the processing power needed to keep up with the complicated calculations. This includes converting high RPM and interdependent engine management tables into the fuel injector and coil firing timing. That is, if the person behind the keyboard enters the correct values in the first place.

“Holley EFI products and software were created, are maintained, and improved upon by actual gearheads. They spend time out on the track when they’re not in the office, which is a perfect storm for us for continuous development of our products.”

This is where the Holley EFI really shined. The software layout is robust but extremely simple to navigate. As Blane mentioned, “EFI software can appear daunting at first; spend some time with other brands of EFI software and you’ll find yourself missing the easy-to-read interface of Holley EFI and simplicity of making changes.”

He was right — prior systems we had used were extremely hard to navigate. Shuffling through drop-downs, trying to remember where fueling cells where, how to swap to a smoothing map, and making sure the computer actually saved the new values – all while trying to make the next round call introduces unnecessary stress into a racing weekend.

Holley uses a simple set of configuration clusterings in Individual Configuration Files, or ICF for short. We are able to swap the configurations files, independently of the global file, across tune-ups. This provides the ultimate in portability.

The Holley software broke out engine management into what they call Individual Configuration Files, of ICFs for short. These ICFs group related parameters in sections that allow adjustment of the parameters in a single location. For example, we modified how the engine is fueled, directly in the fuel ICF. Spark? There is an ICF for that, as well. Some of the more common ICFs include fuel, sensor, system, idle, spark, inputs & outputs (I/O), and the very unique to Holley, advanced ICF. The ICFs are also modular, meaning we could save them individually and load them into other tune-up files as desired.

The Holley Dominator EFI system is one of the most robust systems we have used to date. It packed enough punch to grunt our hot rod to sub 4.5-second e.t.’s and sports a larger street/strip online following. It literally has everything a racer or weekend warrior could want.

Got Coils?

We sat down with Blane Burnett from Holley and asked him a few questions. One of those was around the advantages of Coil-On-Plug.

Dragzine (DZ): You recommended we run your Coil-On-Plug setup instead of a traditional distributor. Why?

Blane Burnett (BB): There are three universal components to making power: air, fuel, and spark. You have to have the right combination of air and fuel, which is what Holley EFI gives you. Now, what do you do with that combustive mixture? Light it off and drive that piston down hard. While distributors have always been a staple of the internal combustion engine, they are also a bit antiquated at finding and extracting those gains. A Coil-On-Plug system give multiple advantages.

It allows you to control when and how the spark arcs. Imagine having the ability to control when you set the flame in relation to when your compression is. You can then ignite your peak energy and performance cycle, and you can do it repeatedly. In addition, you now have the benefit of controlling how much saturation your coils will release. Imagine having the ability to control the power output needed at a whim. It does not matter if you’re running N/A, boosted, E85, or methanol, you can have the proper burn. Finally, your spark potential per cylinder increase. A traditional setup limits you to the capabilities of a single coil. If you transition that to a coil per cylinder, you now have that same potential energy but as opposed to one coil, you now have the power per cube.

DZ: Cool. Why would I go with Coil-On-Plug over a mag? Isn’t that the ultimate setup?

BB: They both have their place. Your small-tire LS or SBC block making 2,200 horsepower, cool. Coil-On-Plug. That’s because you have the energy there and the capacity needed to produce an effective spark. However, your blown big-block HEMI motor running alcohol with a twin screw on top is going to require some energy you won’t be able to match with anything else. While Coil-On-Plug is an effective tool, they are no match to the firestorm tornado a Mag is going to produce.

Holley Smart Coils feature:

- Peak Voltage – 44,000 Volts

- Peak Output – 102 Mj

- Maximum Battery Voltage 17.0 Volts

The system made it easy to get the car up and running. However, we retained the sophistication needed to use features like Coil-On-Plug, 16 injectors, and advanced tuning tables. Last, unlike most EFI systems, Holley is constantly working on its software. The team frequently adds new features and releases them in major versions for free. These updates do not require hardware modifications…only simple updates to the ECU that are downloaded over the internet. The current version, V5, includes options to incorporate some of the latest traction control technologies used in drag racing.

In Conclusion

Making fire has progressed significantly since the days of gapping points, jet changes, vacuum gauges, and other common techniques for achieving performance and drivability. Today’s EFI and non-mechanical, coil-near-plug systems have turned a traditionally dirty job into a simple set of keystrokes.

With the journey of the build concluded, the journey for performance is well on its way. In the first few outings, the Mast Motorsports-inspired beast has posted impressive numbers that reveal its 2,000-plus horsepower potential. When we first embarked on this LSX project, we anticipated mid 4-second performance. The numbers are in the bag and there is clear potential for more. So far, we’re more than pleased with this top notch, stock suspension, 275 radial tire doorslammer.

Until next time.