Making sure you have enough fuel to feed a nitrous application is essential to avoid issues–such as burning a hole in the pistons or hampering performance–and get the most out of the system in an efficient and reliable fashion. A great way to supplement the factory fuel system that’s already in place is adding a dedicated fuel system for your nitrous setup. Our Project Red Dragon Pontiac Trans Am received one of Nitrous Outlet’s dedicated fuel systems so we can run bigger jets and have more room for growth with the tune-up.

We previously looked at Nitrous Outlet’s Pro Wiring Harness and ProMax nitrous controller before they were installed in the Red Dragon. This was done in preparation for the Nitrous Outlet dedicated fuel system, the final piece of our power-adder puzzle. We wanted to run more nitrous and have the ability to adjust the tune more without hurting parts. The dedicated fuel system gives us everything we need to safely make a lot more horsepower without taxing the car’s fuel system.

What Is A Dedicated Fuel System?

The Red Dragon uses a wet shot of nitrous that’s injected into the intake via a Nitrous Outlet plate system. When the nitrous system is armed it sprays both the nitrous and fuel through the plate via jets. The nitrous and fuel atomize and mix into the air flowing into the intake to produce power. This system pulls fuel from the engine’s fuel rail that comes from the tank and the rest of the fuel system.

This plate system works great to a point, but it does have some limits, and that’s where a dedicated fuel system comes in. It’s an affordable way to take a plate system like what’s already on the Red Dragon to the next level. A dedicated fuel system works with a built or near-stock engine to help make nitrous horsepower safer to use.

Jonathan McDonald from Nitrous Outlet explains why they developed their own fuel system for nitrous users.

“Basically, the dedicated fuel cells were developed for customers who wanted to run a larger shot of nitrous but didn’t want to spend several thousand dollars to upgrade their vehicles’ current fuel system. For less than a thousand dollars you can get one of our dedicated systems that will support all the nitrous you need for most street cars. That’s helpful if you don’t plan on going any further with the engine package and the level of nitrous you’re going to run will be limited. It’s a cost-effective way to maximize the amount of nitrous you can run without pushing into race car territory.”

If you’re not wanting to totally upgrade the fuel system to support that power, the dedicated fuel system solves that issue.

According to McDonald, there is a threshold you need to be aware of and that’s when the dedicated fuel system starts to make sense for a nitrous system.

“Whenever you get to about a 200 horsepower shot of nitrous, that’s when you start to exceed the factory fuel system’s ability to support that level of nitrous. Let’s say you’re running a direct port nitrous system on an LS-based engine — those can handle a 300 horsepower shot or more stock. If you’re not wanting to totally upgrade the fuel system to support that power, the dedicated fuel system solves that issue. This was all designed with your typical street car in mind,” McDonald explains.

What Makes Up A Dedicated Fuel System For A Nitrous Application

The concept and execution of a dedicated fuel system is really simple, however, the right parts must be used to get the greatest benefit. Generally, a user will put a high octane fuel in the fuel cell so it can be pumped directly into the fuel solenoid of the nitrous system.

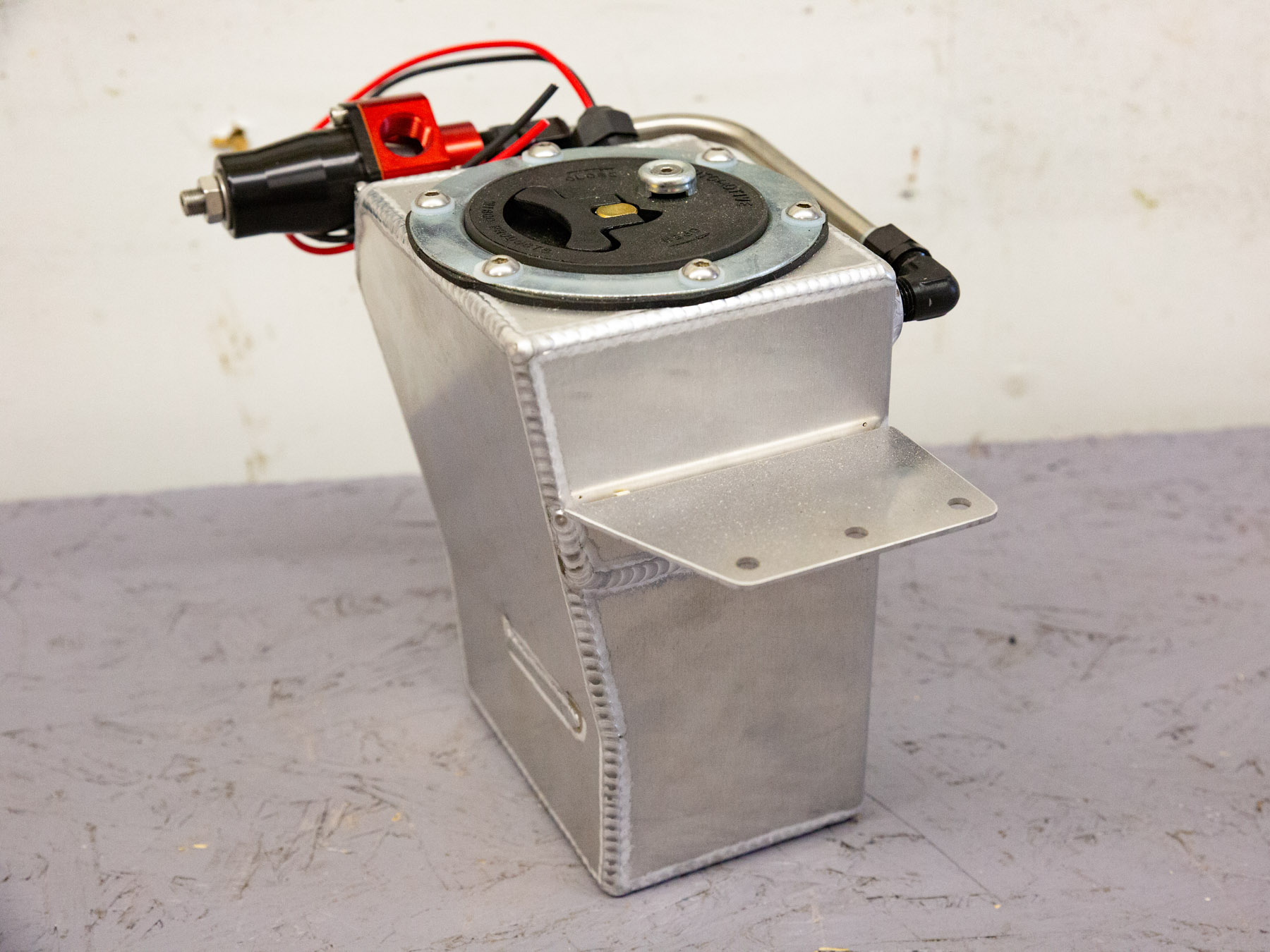

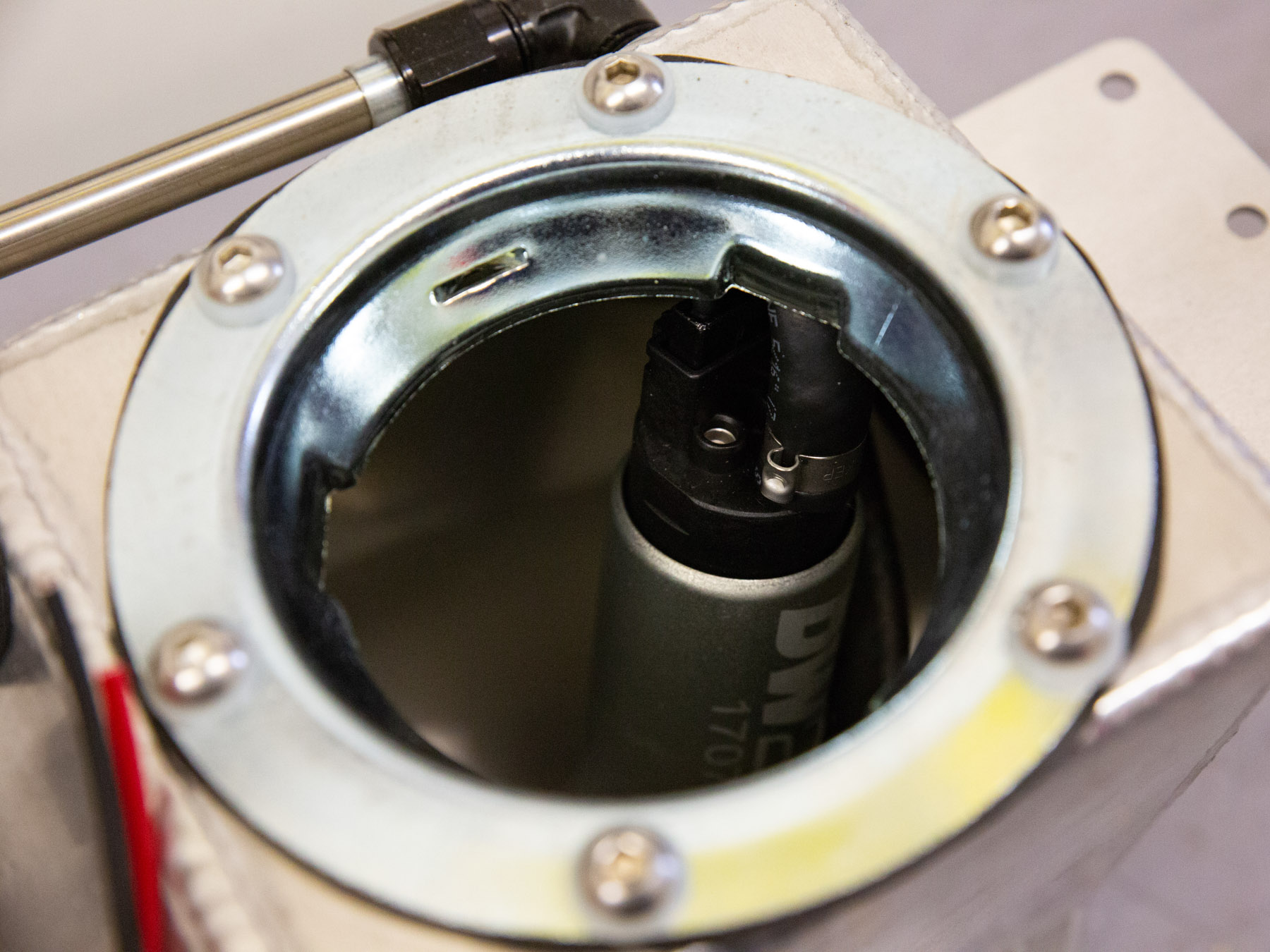

“We offer both custom and universal tanks with our dedicated fuel systems that will work with nearly any application. All of the universal tanks are plastic or aluminum, while all of the custom tanks are made of aluminum. The aluminum tanks are laser-cut, welded, and assembled in-house here at Nitrous Outlet. Inside the tank, there’s a Deatschwerks 255 liter-per-hour fuel pump capable of supporting up to 500 horsepower. We have an Aeromotive adjustable fuel pressure regulator that’s also included that you can run at either high- or low-pressure setting depending on your setup,” McDonald explains.

Nitrous Outlet put a lot of thought not only into the parts they selected to be used in its fuel systems, but also how the system would be designed. The placement of the tank and other parts inside the vehicle plays a big role in how it performs.

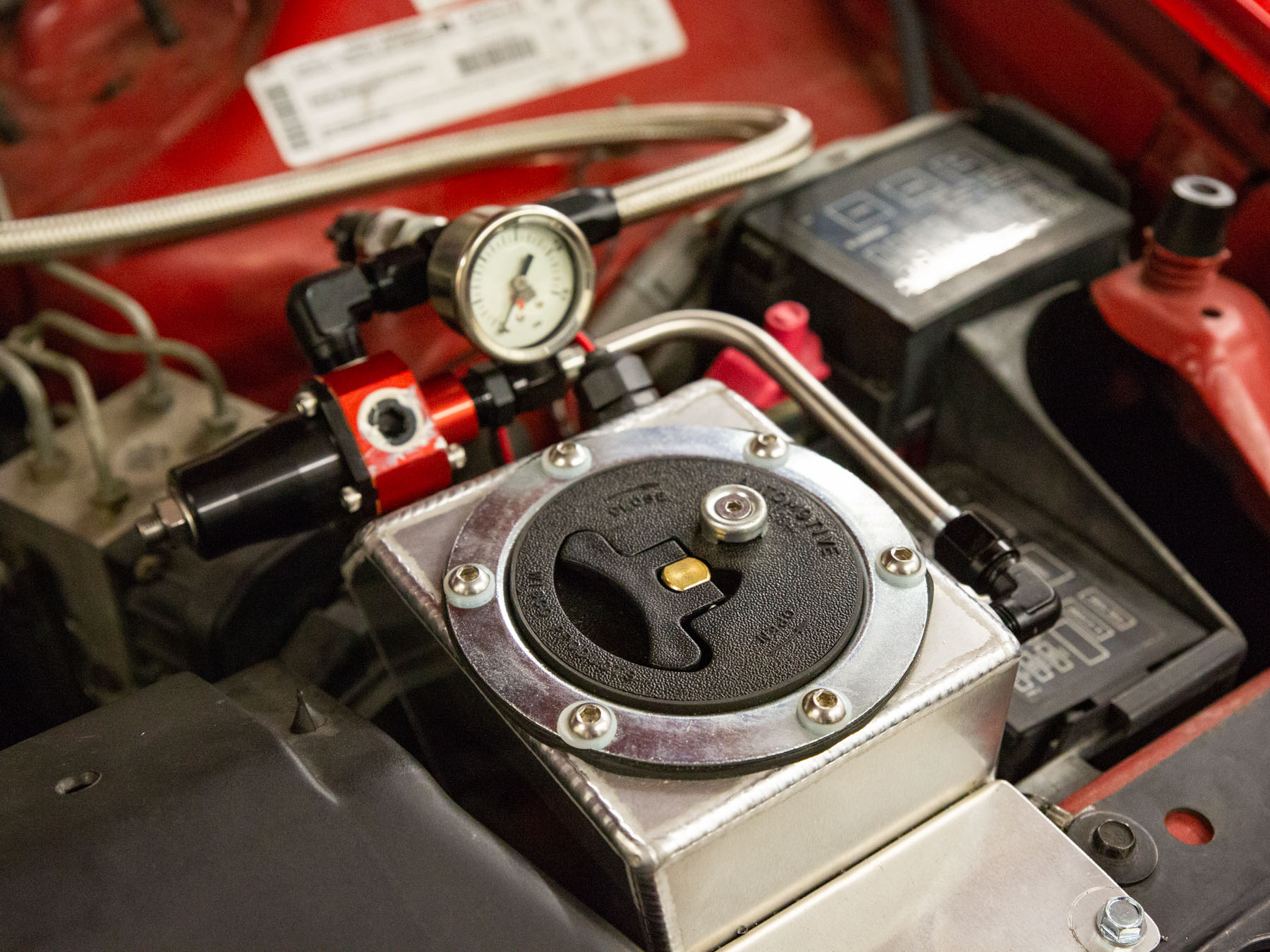

“We wanted to keep the fuel pressure regulator under the hood because all of the fuel pressure changes happen to the engine quickly — this way you’re not getting a delay in fuel delivery. Systems that have the regulator away from the engine experience a delayed response to the engine because you have all that line that has to change pressure when there are changes based on boost or vacuum. By keeping the amount of pressurized line short and the regulator under the hood, that allows any pressure changes that occur to affect the engine much quicker. That will affect the nitrous system quicker so you’re not dipping either lean or rich depending on the type of pressure change. The regulator is boost reference compatible, so if you’re running boost they will adjust pressure accordingly,” McDonald says.

The correct fuel pressure provided by the Aeromotive fuel pressure regulator used in the dedicated fuel system plays a critical role in how it functions, but there has to be a solid pump behind it making sure the fuel flows. McDonald explains why the Deatschwerks fuel pump was selected to be a part of the Nitrous Outlet fuel system.

“We went with this pump setup because typically you’re not going to need more than 500 horsepower of fuel for nitrous in a street car. These pumps have proven to be very reliable, the pumps are widely available, they’re affordable, and they work with E85. The different fuel compatibility and ability to swap pumps if there is an issue gives our users a lot of options.”

How A Dedicated Fuel System Functions

As we mentioned earlier, the dedicated fuel system delivers a dose of high octane fuel directly into the nitrous system’s fuel solenoid. Introducing the fuel at the same time the nitrous is flowing is vital to ensure there aren’t any issues in the combustion chamber. Nitrous Outlet has made getting the system online an easy task with how it has everything wired up.

“Basically the way we wire them up is that we wire the pump relay to the arm switch for the nitrous system; this causes the pump to kick on as soon as the nitrous system is armed to make sure you have everything pressurized. This way there’s no delay when the nitrous starts to flow…the nitrous system is getting all of the high-grade fuel directly from the fuel tank with consistent pressure,” McDonald says.

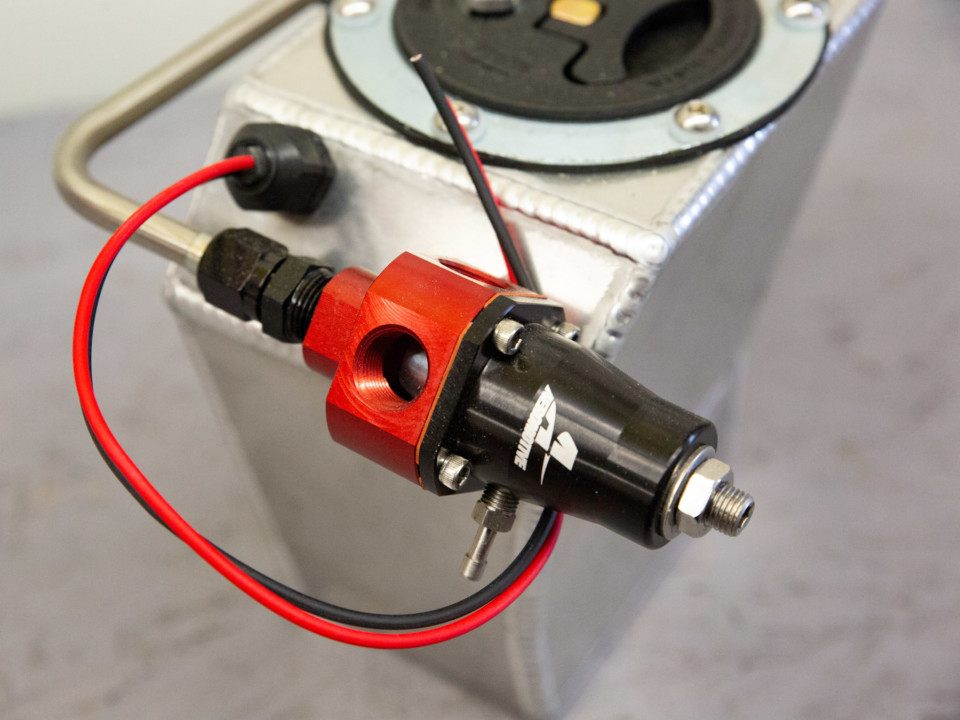

Part of what makes the entire system work so well is the Aeromotive fuel pressure regulator that is attached to the fuel cell. Tuning the fuel pressure via a spring is how you can use different jets in your nitrous system. To make this easier Nitrous Outlet offers both high and lower pressure spring options with the dedicated fuel system.

“There’s a couple of bolts on the regulator that you can remove to take it apart and add either the high- or low-pressure spring. Low pressure is around 10-12 psi, and high pressure is up to around 65 psi. Most of your EFI cars are a high-pressure system from the factory, so to keep your tuning simple you would just keep the high-pressure spring in there and follow the jet chart,” McDonald explains.

Depending on your application, the low-pressure spring might actually be a better option. Going with a lower pressure from the dedicated fuel system will give you more options for tuning and pushing your nitrous usage.

“Going with the low-pressure spring changes your fuel side jetting. Running the low-pressure spring allows you to make smaller fuel adjustments without changing the fuel jet. That’s one of the reasons some like to go with that option, because they’re trying to chase that absolute edge of their tune so they have more options. That’s getting into max effort race car territory where you’re just making the smallest of pressure changes,” McDonald says.

For the Red Dragon, we opted to go with the low-pressure spring setup. This gives us a bit more room to tune on the car so we can get more aggressive if we want. Since there could be some additional changes to the car’s engine package in the future we can grow into using the full potential of the dedicated fuel system using the low-pressure spring.

The only real limitation with this dedicated fuel system is the horsepower level you’re trying to achieve.

A dedicated fuel system isn’t a magic wand for every nitrous setup; there are some applications where the dedicated fuel system will be limited in how it can be used. Even with those limits in play, there are ways to expand the system.

“The system isn’t compatible with methanol, so if you thought you were going to run methanol, it won’t do it. The only real limitation with this fuel system is the horsepower level you’re trying to achieve. This is geared more toward the street car market, so that dictates the amount of nitrous you’re trying to spray. You could put a bigger pump in the tank but then the line feeding the fuel into the nitrous system would become the limiting factor,” McDonald explains.

The best way to get the most out of a fuel system for a nitrous application is to understand what it’s capable of.

“This system really allows a user to get the most out of it via tuning. You get the most out of it by reading your plugs, looking at your fuel coloration, and checking the timing mark on your spark plug strap. It allows you to make fuel pressure changes, jet changes, or adjust your flow to get your tune up as spot-on as you can get it. Ultimately, you’re limited by what the engine can handle within reason,” McDonald says.

GM World Class Technician Scott Cordell led the charge on getting the Nitrous Outlet Pro Wiring Harness, ProMax, and dedicated fuel system installed on the Red Dragon. One of the things that stuck out during this process was the level of quality the Nitrous Outlet parts have.

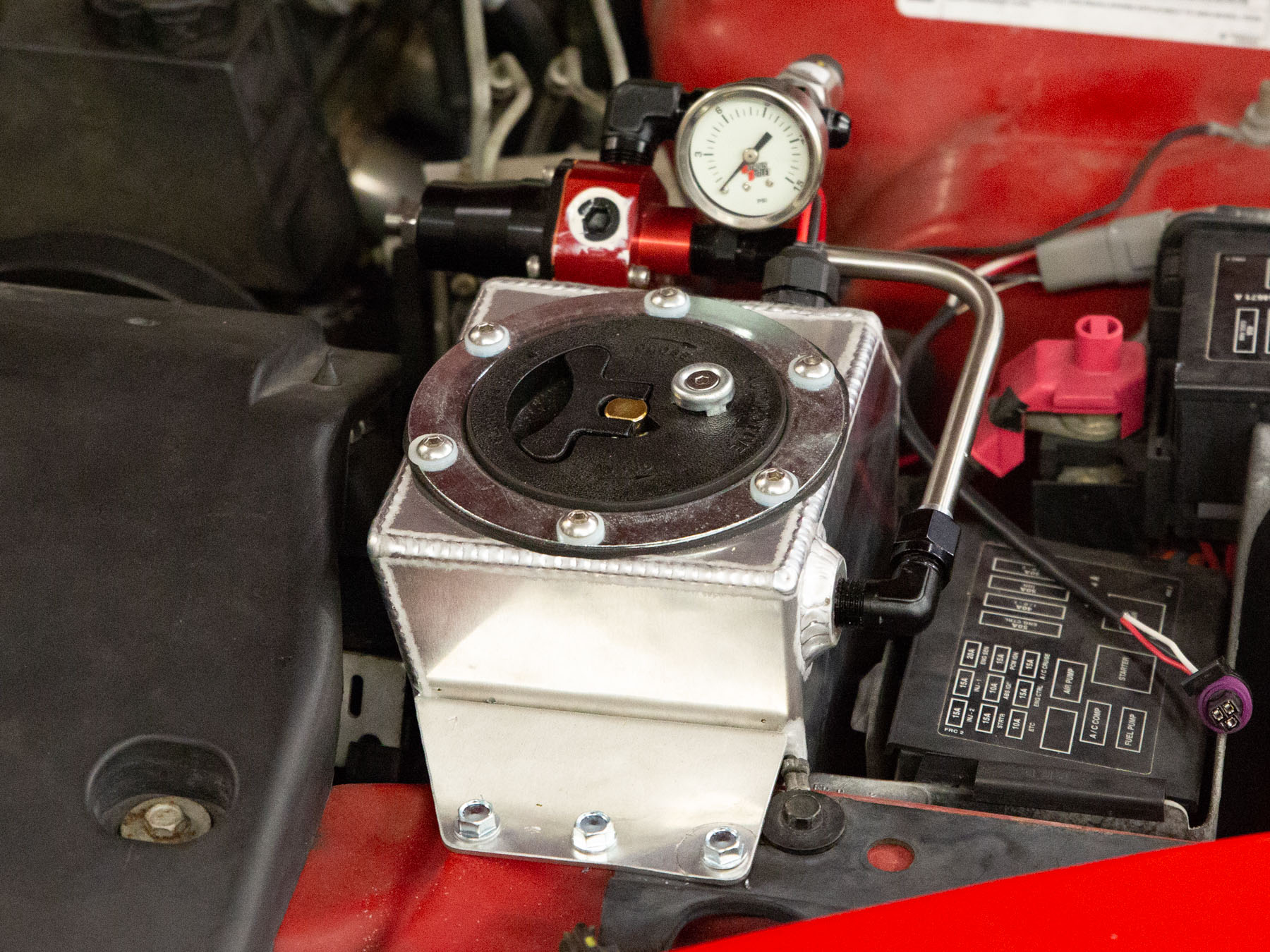

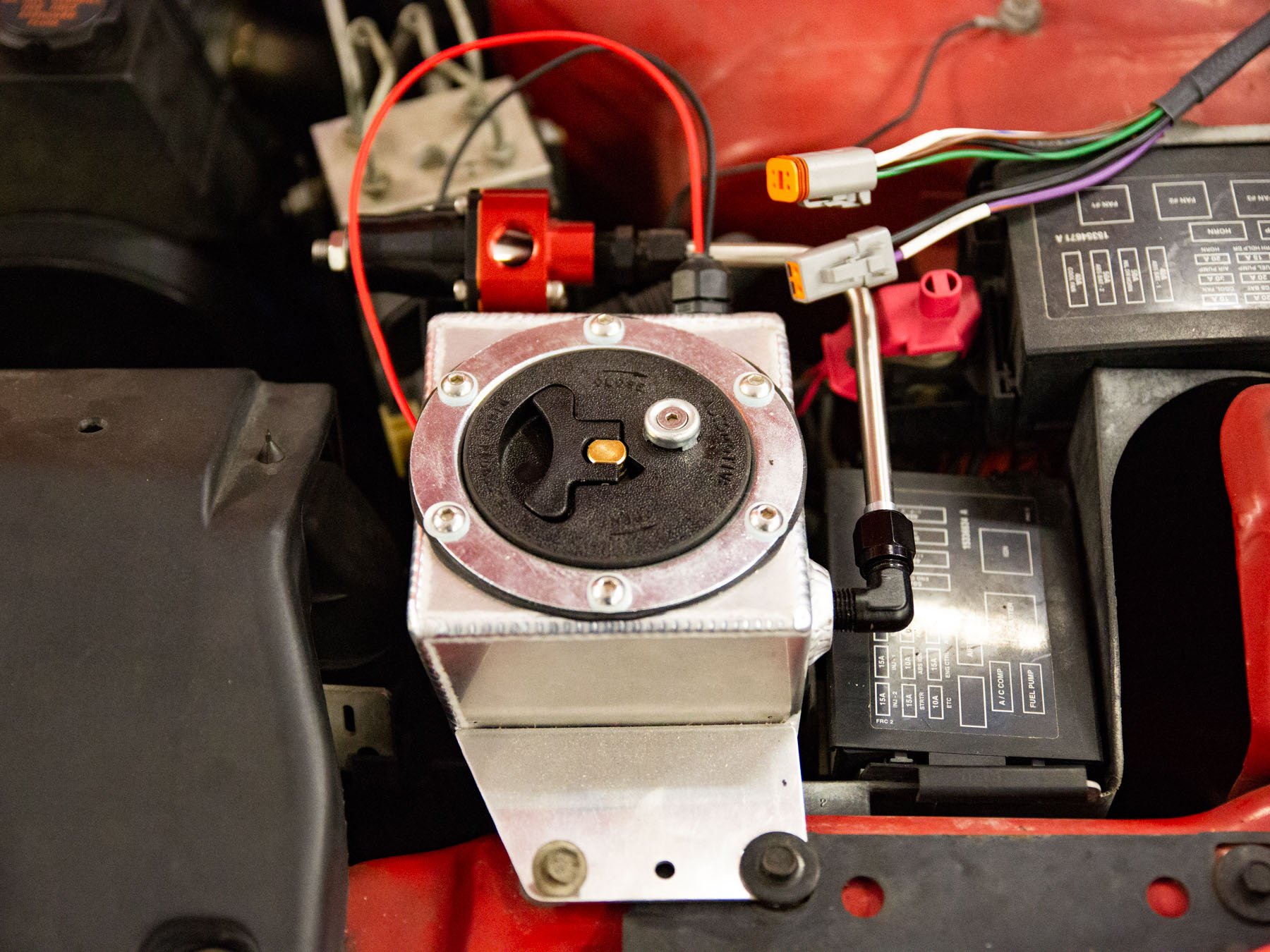

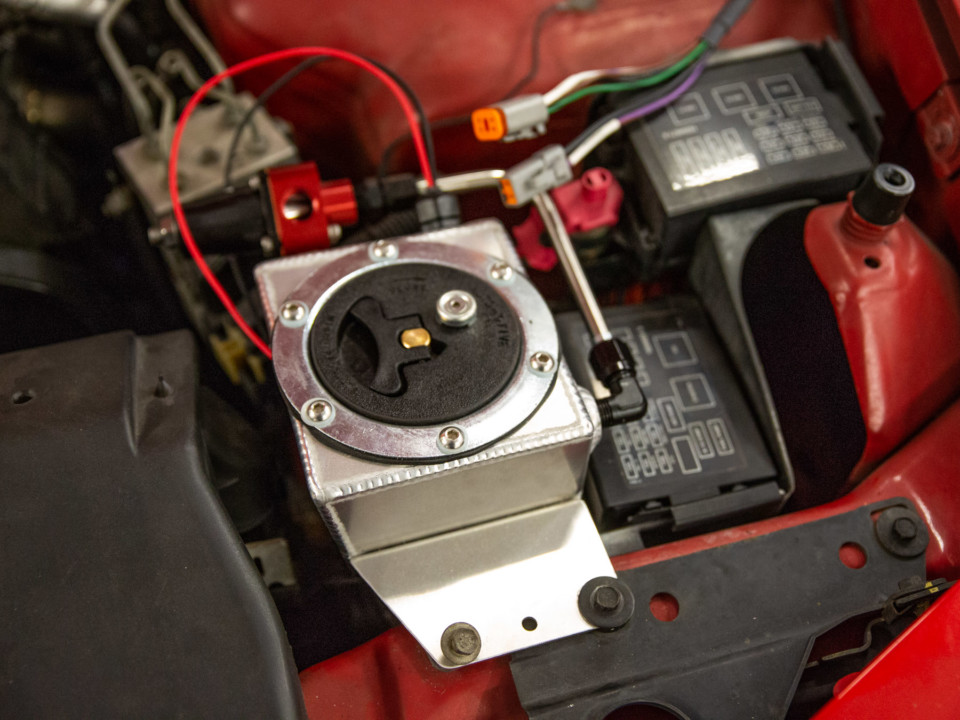

The fuel cell is mounted on the driver’s side toward the front on the car’s core support. Nitrous Outlet included mounting hardware to use and the tab on the fuel cell lines up nicely with three holes already in the core support. If you have a Camaro, the fuel cell bolts right in; for Trans Am owners you need to relocate the headlight control. After the fuel cell is mounted you just need to wire in the fuel pump per the directions with the ground and power wires. After the wiring is done you run the fuel line from the regulator to your fuel solenoid with the supplied hose and AN fittings. This is where you can also add a fuel pressure sensor if you have one and you add the fuel pressure gauge to the standalone fuel system. This is used to monitor and adjust the system’s fuel pressure. Finally, you block off the unused port on the fuel regulator.

After getting everything installed and tested we took the Red Dragon to Dynotune Motorsports where we strapped it to the rollers to see what gains were possible. After Scott worked his magic and did some baseline tunes with the system, the 200 horsepower jetting was added to the plate. The Red Dragon spun on the rollers several times and after adjusting the progressive controller the car put down over 650 horsepower and nearly 700 foot-pounds of torque. So far we have only been able to go to the track one time due to inclement weather, at which time the car laid down a 10.89 at 127 with a lot of tire spin. This was a new best run for the Red Dragon, but there is obviously plenty left in the combination.

The Nitrous Outlet dedicated fuel system gives users a larger tuning window to maximize the amount of horsepower they can make. By understanding how the system works there is a lot of potential to safely increase your nitrous-assisted horsepower that’s available. Stay tuned as we put the Red Dragon through its paces with the Nitrous Outlet dedicated fuel system.