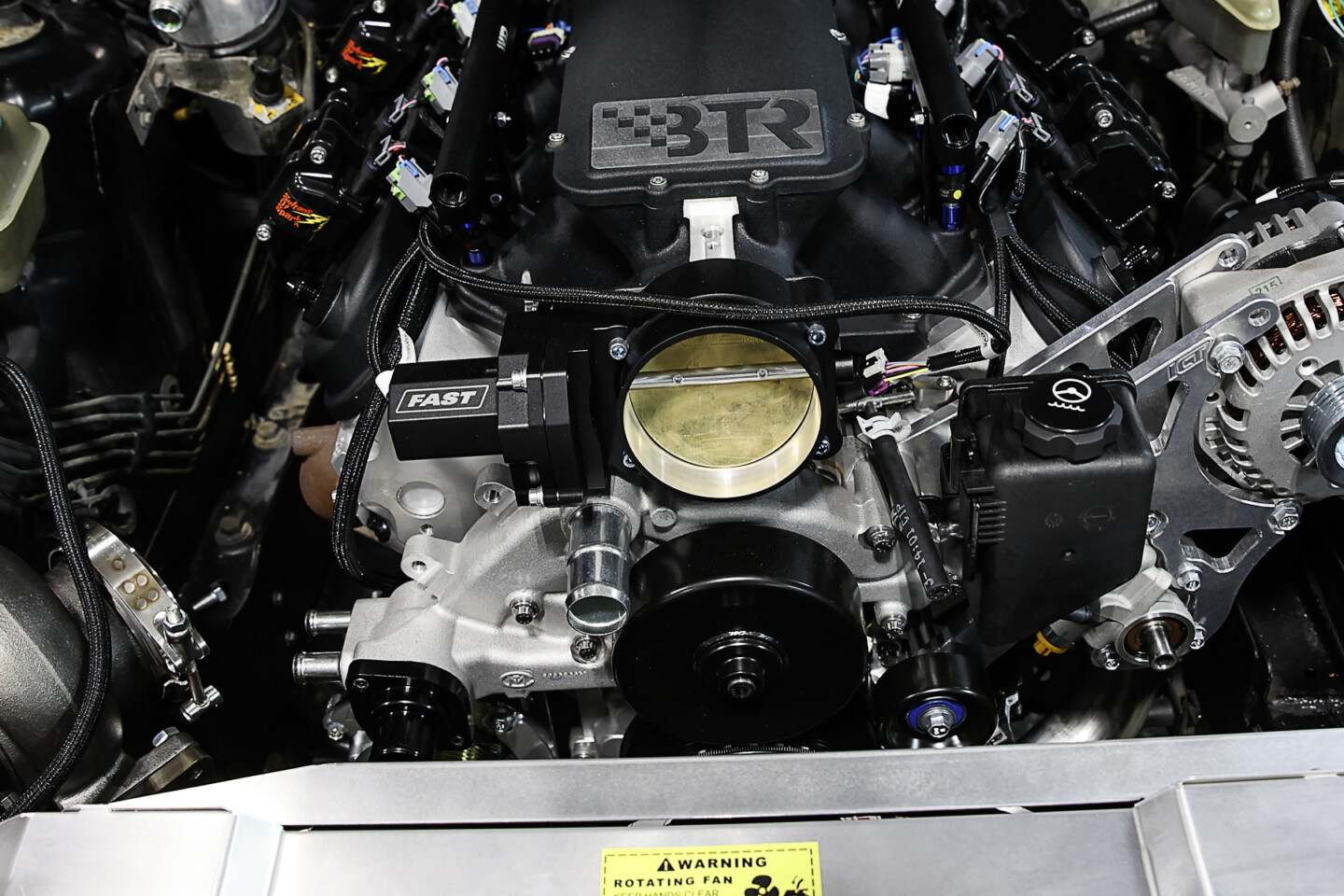

When you’re building an engine, there are countless options available for different parts you’ll need to finish the project. While it may be tempting to save a few dollars on some parts, skimping on quality may come back to bite you later. Melling is known for its high-quality oil pumps and valve train parts, but the company also offers other outstanding parts like water pumps and timing sets.

Chances are, you’ve seen a vehicle on the street or at the track that had a Melling oil pump or valve train parts inside its engine. Hardcore performance enthusiasts have counted on these parts to keep their engine lubricated and making all the horsepower it can. When we had the chance to use a water pump and timing set from Melling on Project Swedish Meatball to go with our oil pump, we jumped at the opportunity to try these parts out.

Melling’s Water Pumps

Melling's water pumps and timing sets are built with the same quality as the oil pumps the company is famous for.

Water pumps and timing sets don’t get a lot of attention on a build sheet, but they are very important components. Since Project Swedish Meatball is going to be making 600+ horsepower, will be driven almost daily, and will see plenty of spirited driving, we needed high-quality parts. The last thing we want to deal with are the issues that can be associated with a water pump or timing set failure, so using the parts from Melling made sense.

“Melling has always been known for oil pumps. Melling started in the OEM water pump business back in 2009, and we currently produce around 375,000 water pumps annually for our various OEM customers. In 2018, we decided to release our line of aftermarket water pumps,” says Melling’s Cale Risinger.

Melling has a lot of history working on developing and manufacturing OEM parts, including water pumps. That led to Melling being able to create higher-quality aftermarket pumps for its customers. Along the way, Melling also worked to create an outstanding group of partner companies that supply them with the best components for their parts, including seals and bearings for the aftermarket water pumps.

The accuracy and quality of the water pump casting is very important. Melling spent a lot of time designing its pumps to fit just like an OEM part but with an improved casting.

A water pump is full of hot coolant and all of that coolant is under pressure. That means the water pump needs to be cast or machined correctly. If it isn’t, there could be leaks and even total pump failure.

“The casting is going to grow and shrink as the temperatures cycle, so the casting has to be spot on. The machining of the casting has to be right to ensure proper sealing to both the engine block and the water pump internal components, if the internal machining is incorrect, the flow can be negatively affected,” Risinger explains.

The Details Matter

To prevent issues like that, Melling has spent a lot of time reviewing and refining its water pump designs. Each pump is thoroughly tested to make sure it not only will flow enough coolant, but it will be durable and survive in the most extreme conditions. When we explained our build to Melling and how the car would be used, they said the LS water pump they produce could easily handle everything we planned on throwing at it.

The other parts besides the casting on a Melling water pump are high quality. This helps to prevent leaks and ensure the pump lasts a long time.

The body of the water pump is the main thing people see, but there’s a lot more to a water pump. There are other components inside the water pump that are just as critical to its ability to function.

“The seals and bearing are obviously very important as they are the most common failure point regarding the water pump. An out-of-round or out-of-balance pulley can lead to premature wear, and finally, the design and construction of the impeller is critical to both coolant flow and bearing life,” Risinger states.

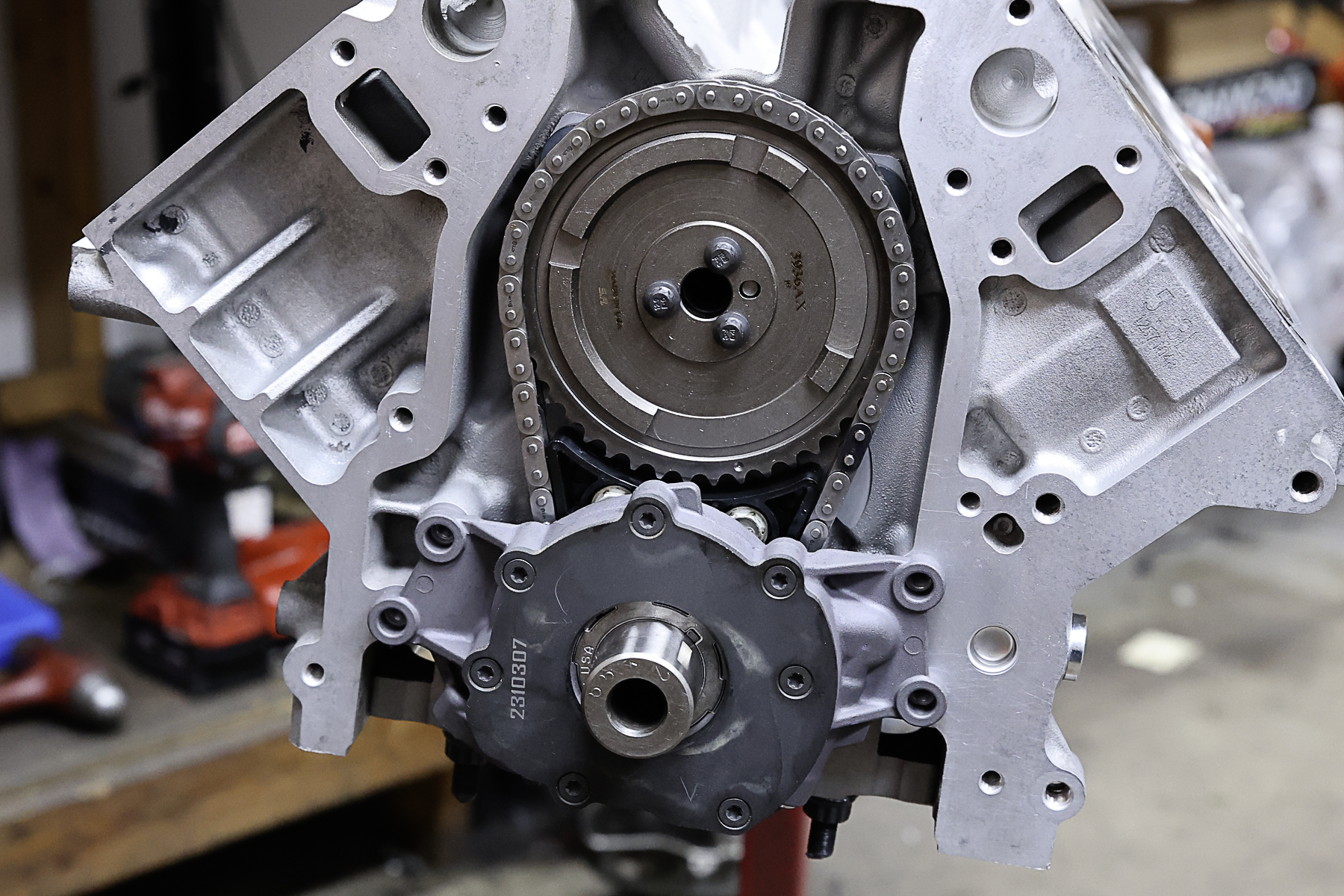

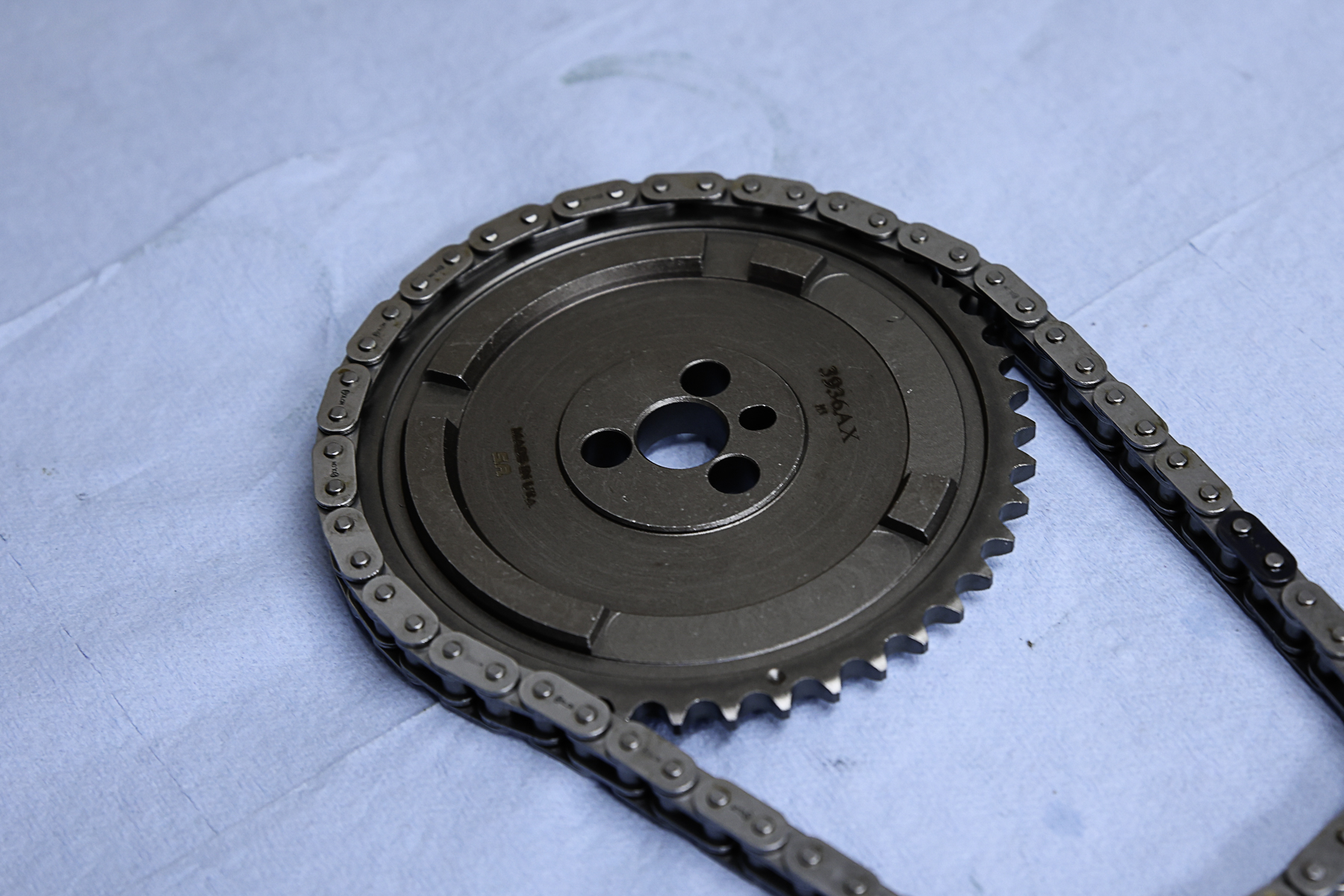

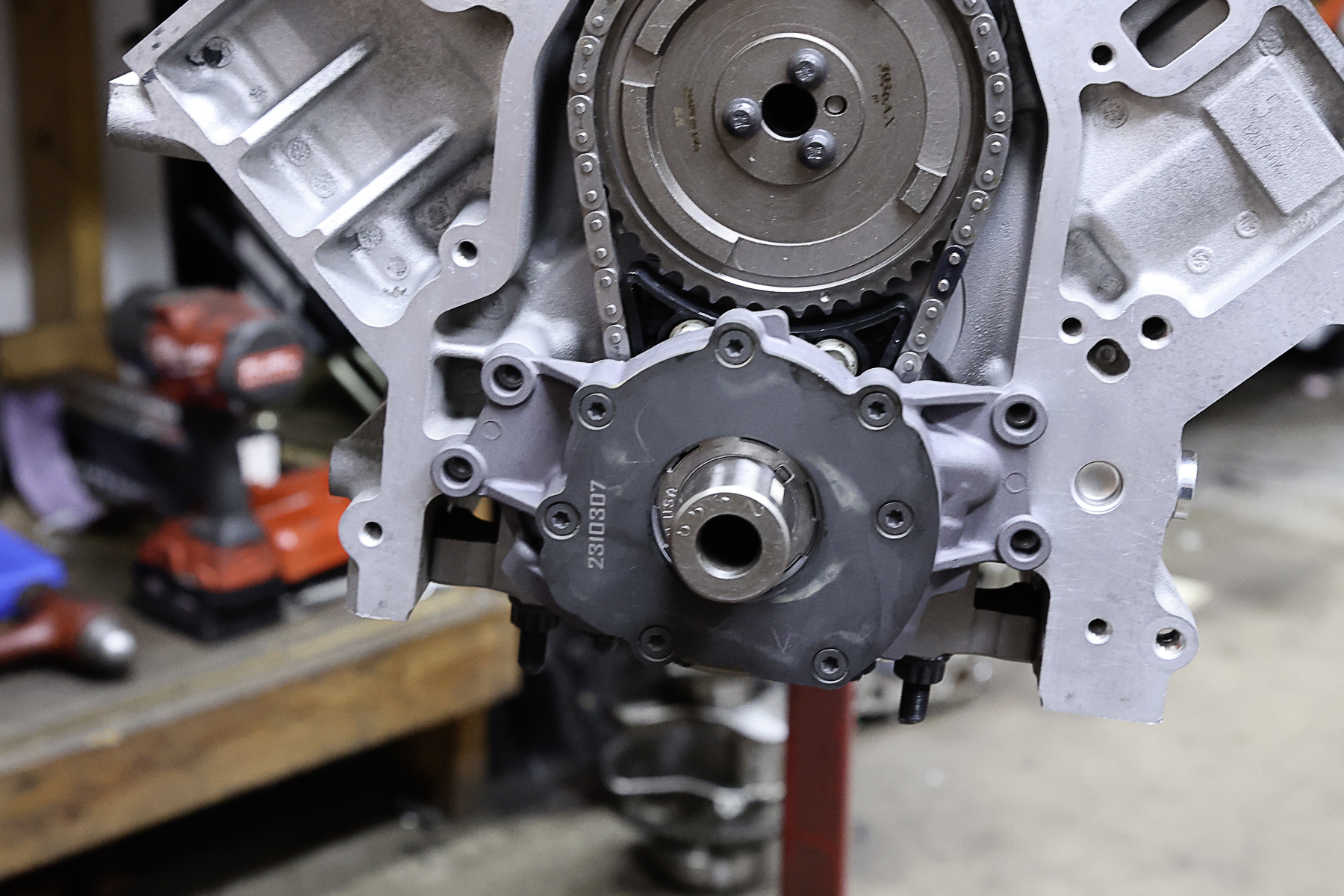

Melling Timing Sets

Melling worked with is supply network to ensure the timing sets that it sells are high quality parts.

Melling works with one of its partners to offer up the timing sets they manufacture. These timing sets must meet Melling’s high standards before they put their name on the box. That means each timing set goes through Melling’s own testing and evaluation process to ensure they are of the highest quality.

A timing set like the one we are using from Melling on our boosted LS engine is packed with features that make it a great choice for high-performance applications. A build that’s making substantial horsepower and being run at the track must have a timing set that’s going to be durable.

Melling worked with its timing set manufacturer to add the right features to each unit. Things like hardened gear teeth and single roller chains come standard on each Melling timing set.

“The timing sets have a billet steel cam sprocket and heat-treated teeth. This is a very strong combination. These kits will have a single-row roller timing chain and a timing chain damper to improve longevity. The one-piece pump drive and cam sprocket also use heat-treated teeth, another durability item that helps these timing sets perform in high-performance applications,” Risinger says.

Your water pump and timing set should never be overlooked and treated as low-value components of your engine build. Investing in the right parts will prevent bigger issues from developing later on down the line.