The expansion of polytetrafluoroethylene (PTFE, a synthetic polymer better known by its Chemours brand name Teflon) hose products into larger size options continues to be a trend. This has opened the door for such companies as Fragola Performance Systems to offer a reliable plumbing option for exposure to extreme fluids and plumbing pressure used at the dragstrip today.

There is a large difference between PTFE hose compared to traditional rubber or synthetic rubber hoses, especially with fuels known to cause issues—like E85 and other race fuels.

“I haven’t found a rubber that works well with those fuel applications. I have tested a couple different brands that didn’t hold up very well at all,” says Fragola’s Brint Mclellan.

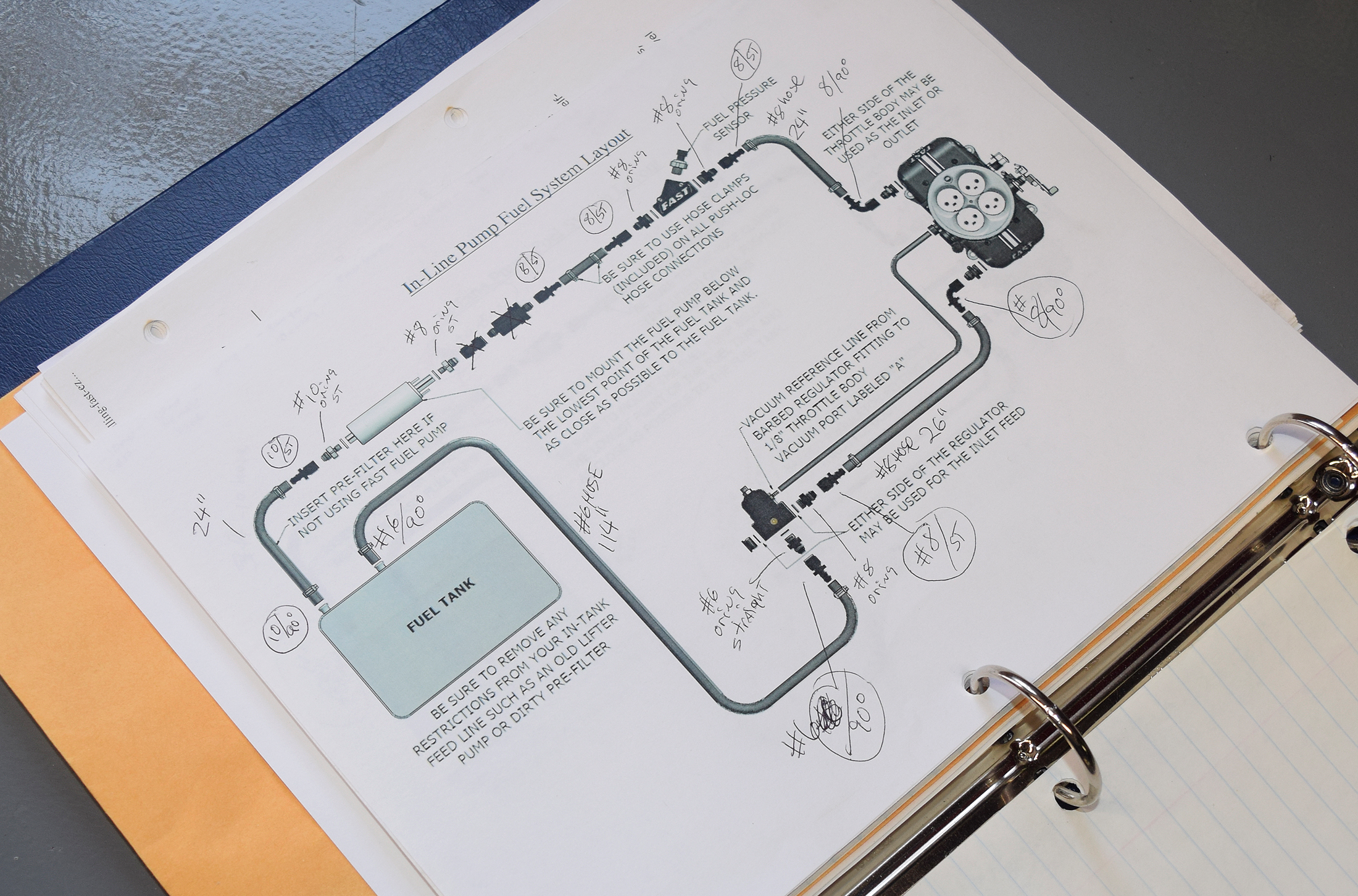

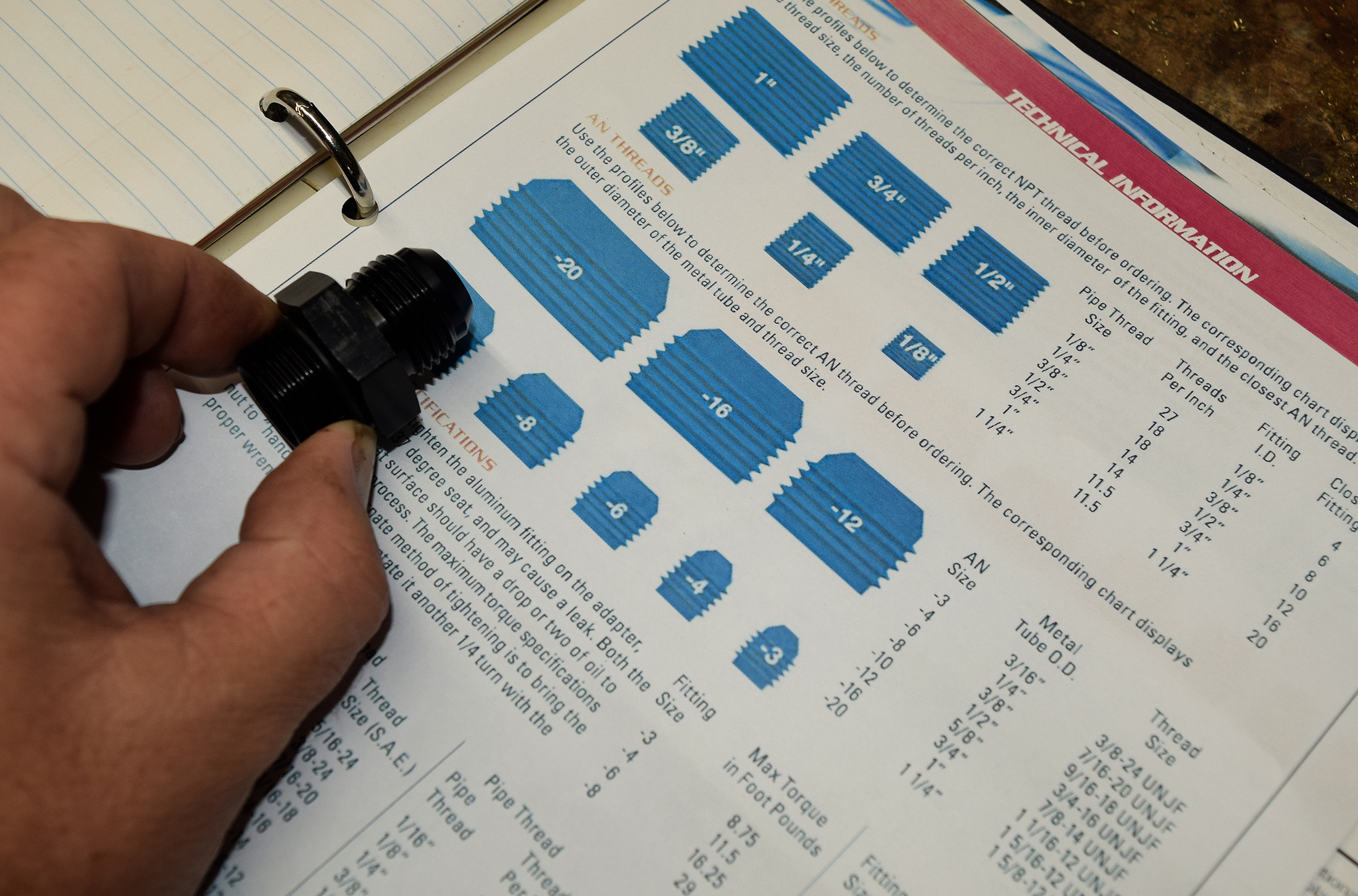

We reprinted a fuel system layout from the FAST EFI installation manual. Each fitting and hose length was logged on the sheet to make sure our hose and fitting order to Fragola was correct. If you do not deal with AN fittings on a regular basis, the Fragola catalog has a handy size chart that makes it easy to accurately double-check your fitting sizes.

“The PTFE hose products do not degrade with corrosive fuels like methanol, ethanol, E85, and nitromethane. Many racers also believe in the use of the PTFE hose for oxygenated fuels and exotic motorsport diesel blends,” Mclellan continues. “The rubber/synthetic rubber products will harden, crack, and leak in a short time. It will also degrade with rubber particles getting into your fuel pumps, carburetor, injection, etc.”

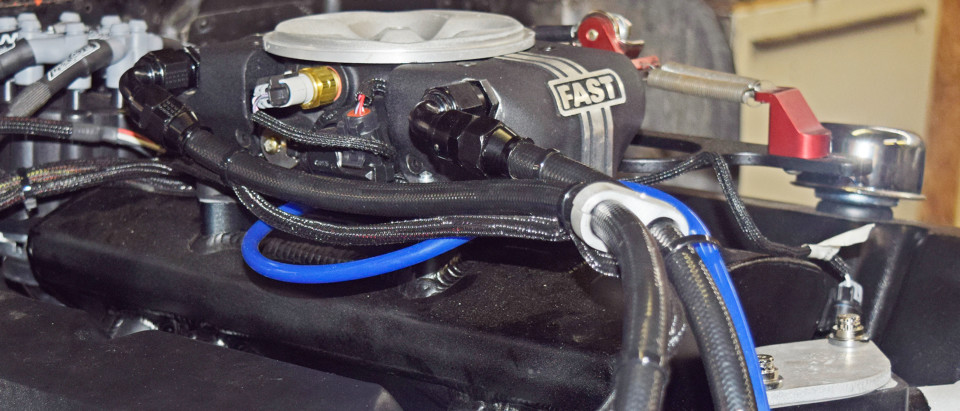

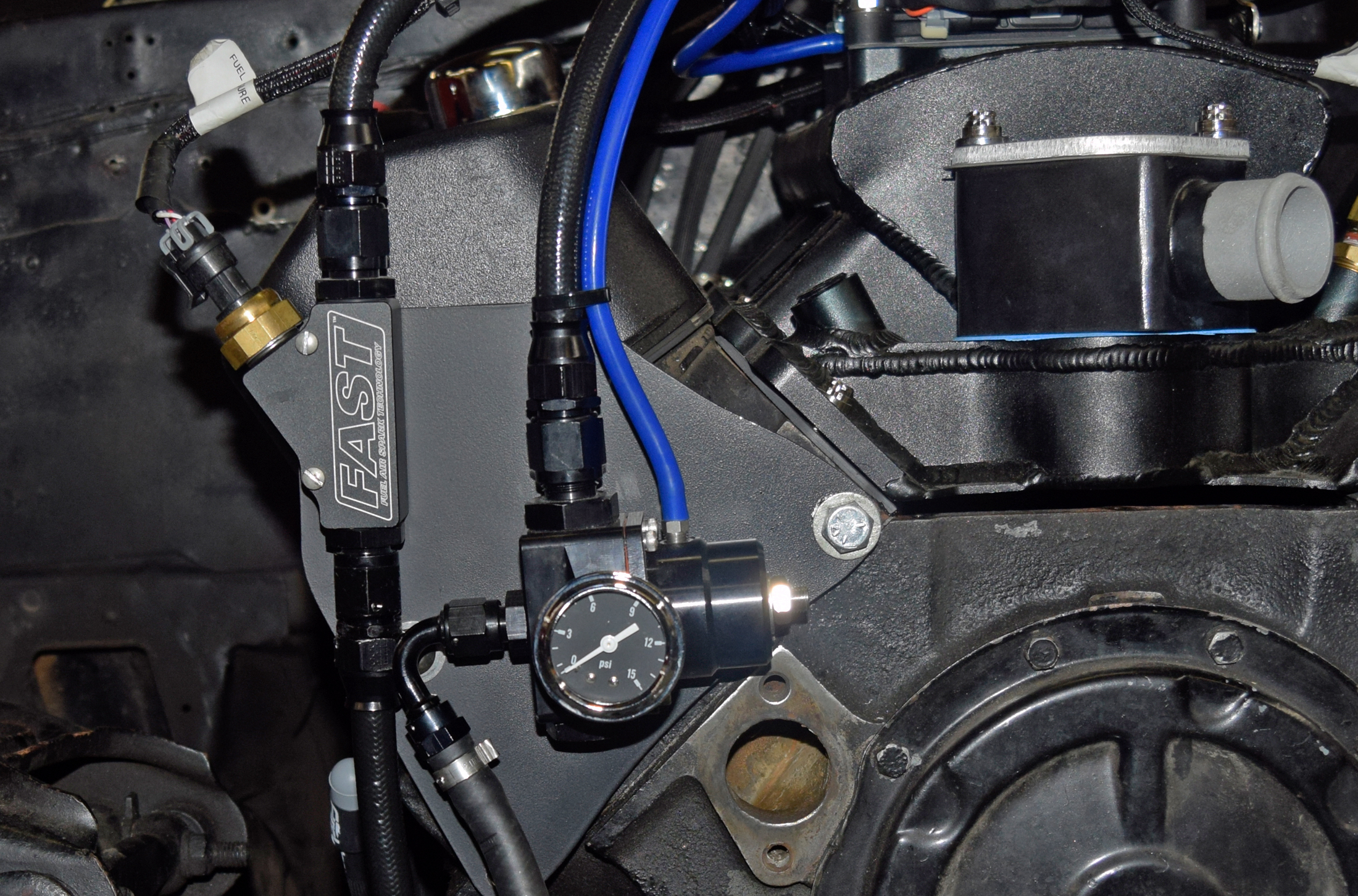

We are plumbing a FAST EZ EFI 2.0 system with the Fragola Series 6000 PTFE product. The FAST EFI system contains an E85 fuel program where a recirculating fuel system is an opportunity to try the fuel with the Project Rover, a 10-second Camaro application.

The PTFE hose cannot bend as easily as other hoses, mainly because of the PTFE inner hose liner. This -8AN PTFE hose has a bending radius of 5.25-inches as specified in their technical catalog. We installed our hose fittings securely at the related mounting points and with the most gentle of bends as possible, marked the hose for length to cut.

“Approximately five years ago, the PTFE hose product lines started to expand,” Mclellan says. “Hose and related fittings began to grow with larger size options. Now it is far beyond the -2 and -3AN sizes proven for use in flexible brake in past decades. Today we offer PTFE braided hose and related fittings for sizes ranging from 1/8-inch (-2AN) to 3/4-inch (-12AN) in diameter. Fragola fittings are specially coated to be durable in harsh conditions just like the PTFE line.”

PTFE hose is also beneficial for use with racing oils, brake fluid, and coolant applications. Its durability when exposed to extreme burst pressures makes it applicable for dry sump oiling systems on severe pressure applications like Top Fuel and Pro Modifieds. For example, a -8AN Series 6000 hose from Fragola handles a working pressure of 2,000 psi and a burst pressure rating of 8,000 psi. This pressure durability also makes it a flexible plumbing option for nitrous oxide systems.

If you do a little research into PTFE hose, in general, you will notice there are “conductive” and “non-conductive” versions of the product.

“We only sell the conductive version of the hose,” Mclellan says. “This allows for fuel, oils, brake fluid, etc to pass through it without generating static electricity. This extends the life of a PTFE hose in racing by eliminating the chance of leaks due to damage resulting from an electrical charge.”

When mapping out PTFE plumbing, you need to recognize that the bending radius of solid PTFE hose is more restricted than other hose types. We carefully routed our system and thought out angled hose end fittings as to not force any extreme bends.

Our two big applications for PTFE hose are use with exotic fuels and then on the other side of the spectrum would be high pressure external oil lines because of their high burst strength capabilities – Brint Mclellan

We deliberately mapped out and ordered our PTFE hose and fittings from Fragola. We are using -10AN line and fittings from the fuel tank to the inline fuel pump, an -8AN system to the FAST fuel flow sensor and EFI throttle body, and back to the fuel pressure regulator. From the regulator, we plumbed the low-pressure return back to the fuel tank with the Fragola EZ Street hose, and hose ends.

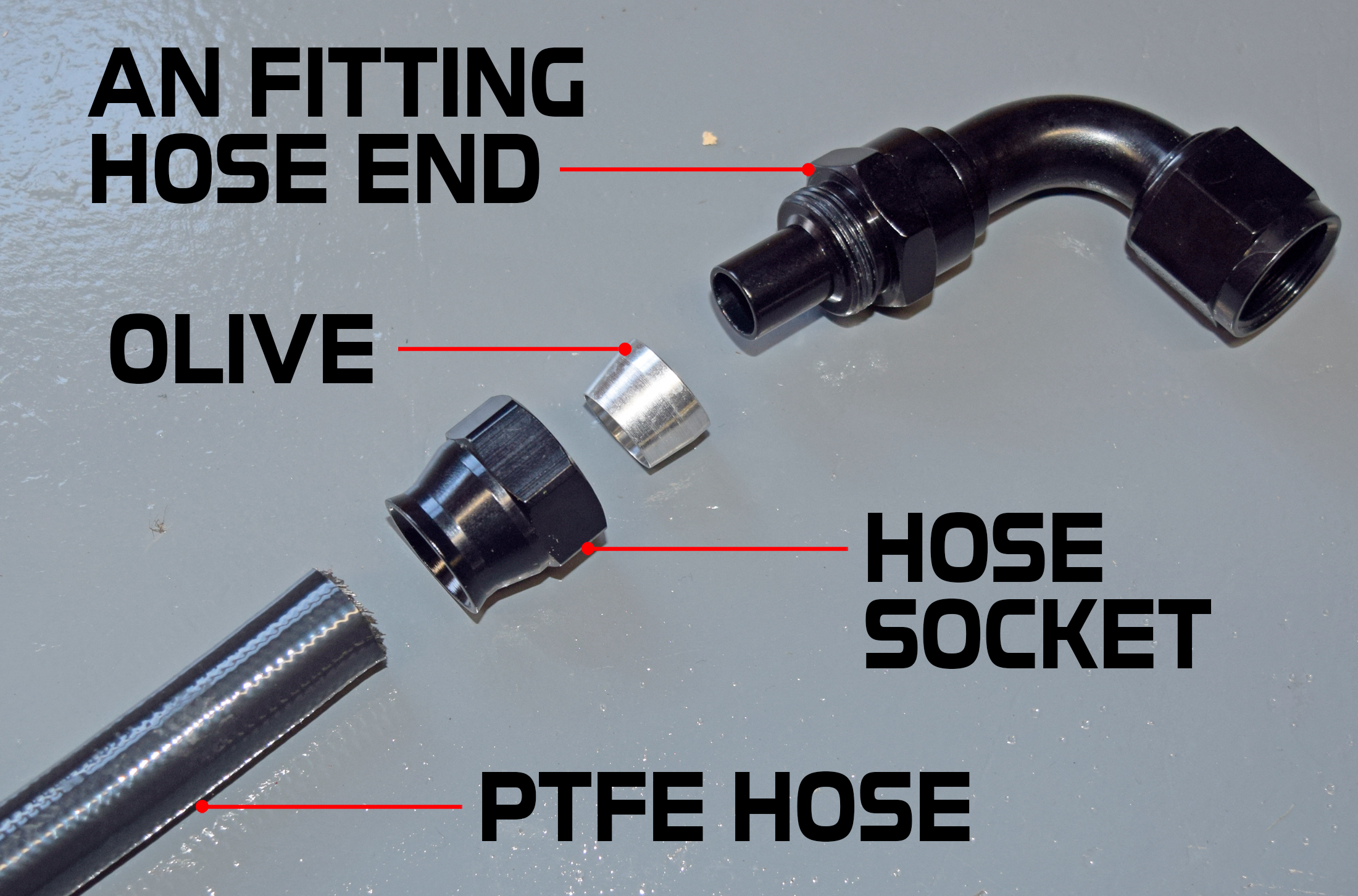

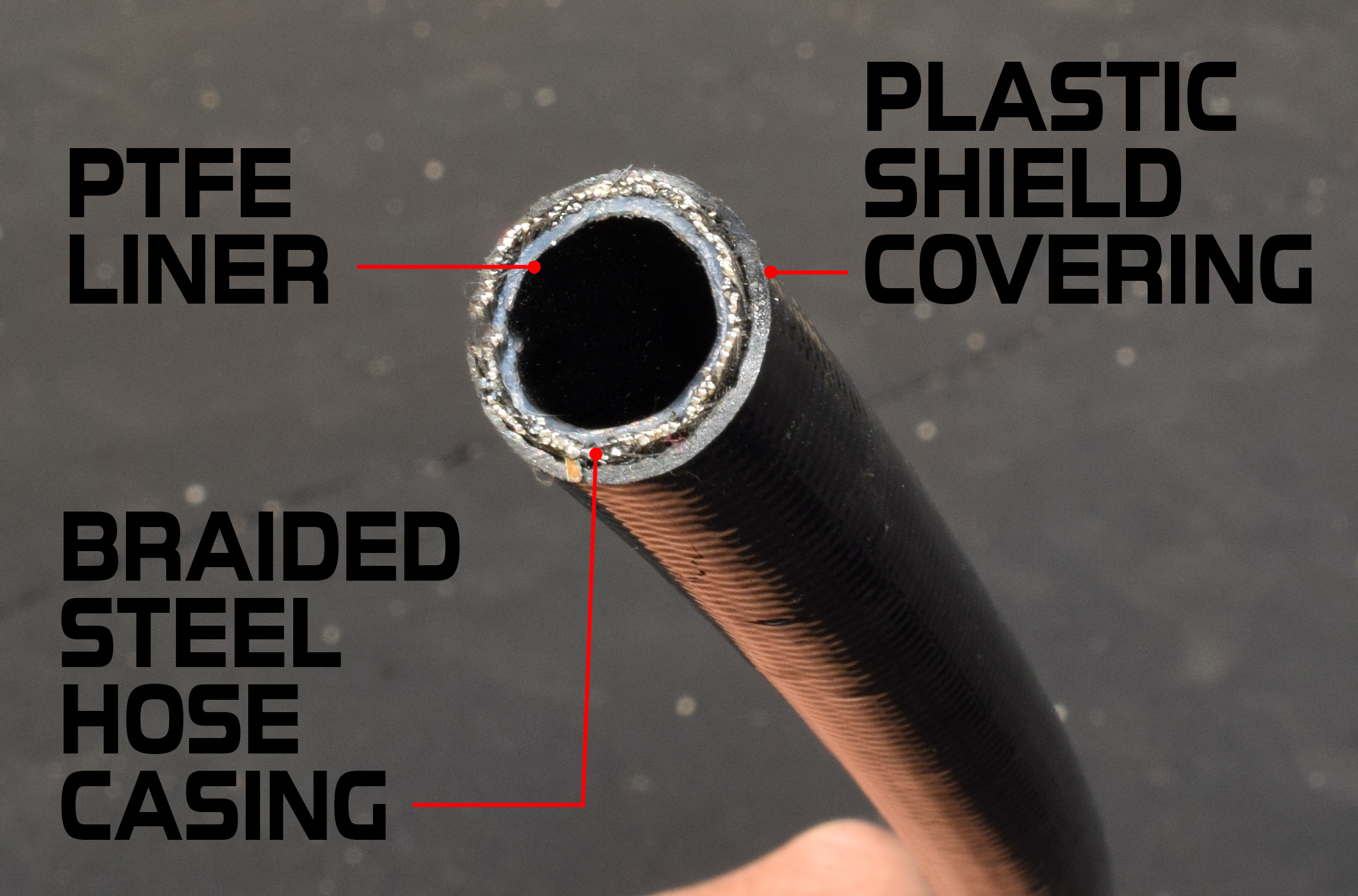

The Fragola PTFE hose is made up of a braided stainless steel casing that is covered by a plastic cover sheath and an internal liner made of PTFE material. A small aluminum "olive" ferrule is sandwiched between the PTFE liner and stainless braid. The AN fitting hose end and hose socket are threaded together surrounding the olive.

Fragola’s EZ Street hose product is a low-permeation fuel hose with the outward appearance of a standard rubber-style fuel hose, but is also impervious to gasoline, methanol, ethanol and extreme diesel blends. The EZ Street hose uses an aramid reinforcing braid inside of the hose that prevents collapsing while handling pressures up to 175 psi.

We used a large hose cutter designed to cut through stainless steel braiding. This is by far the cleanest method compared to a hacksaw or grinder-cutoff wheel that leave debris that must be thoroughly cleaned. With the hose cut to length, the outer black sheath is cut back 3/8-inch to expose the stainless braid. A pick is used to carefully work the stainless braid from the liner down to the point of the plastic cover.

Once the package arrived, assembly of our fuel system was relatively straightforward. AN hose ends are installed onto your standard braided steel hose with just a few additional steps. Cutting the hose to length is similar to a standard braided hose. Electrical or duct tape is used at the point of cutting to prevent fraying of the braided stainless steel.

There are a number of ways to properly cut hose to length. A very fine tooth hacksaw or abrasive cutoff wheel can be used. Great care must be taken to make sure the line is very clean following each cut. We prefer using a specific hose cutter for use with the braided steel line. This cutter leaves a clean cut compared to the PTFE material dust and stainless fragments left behind by other methods.

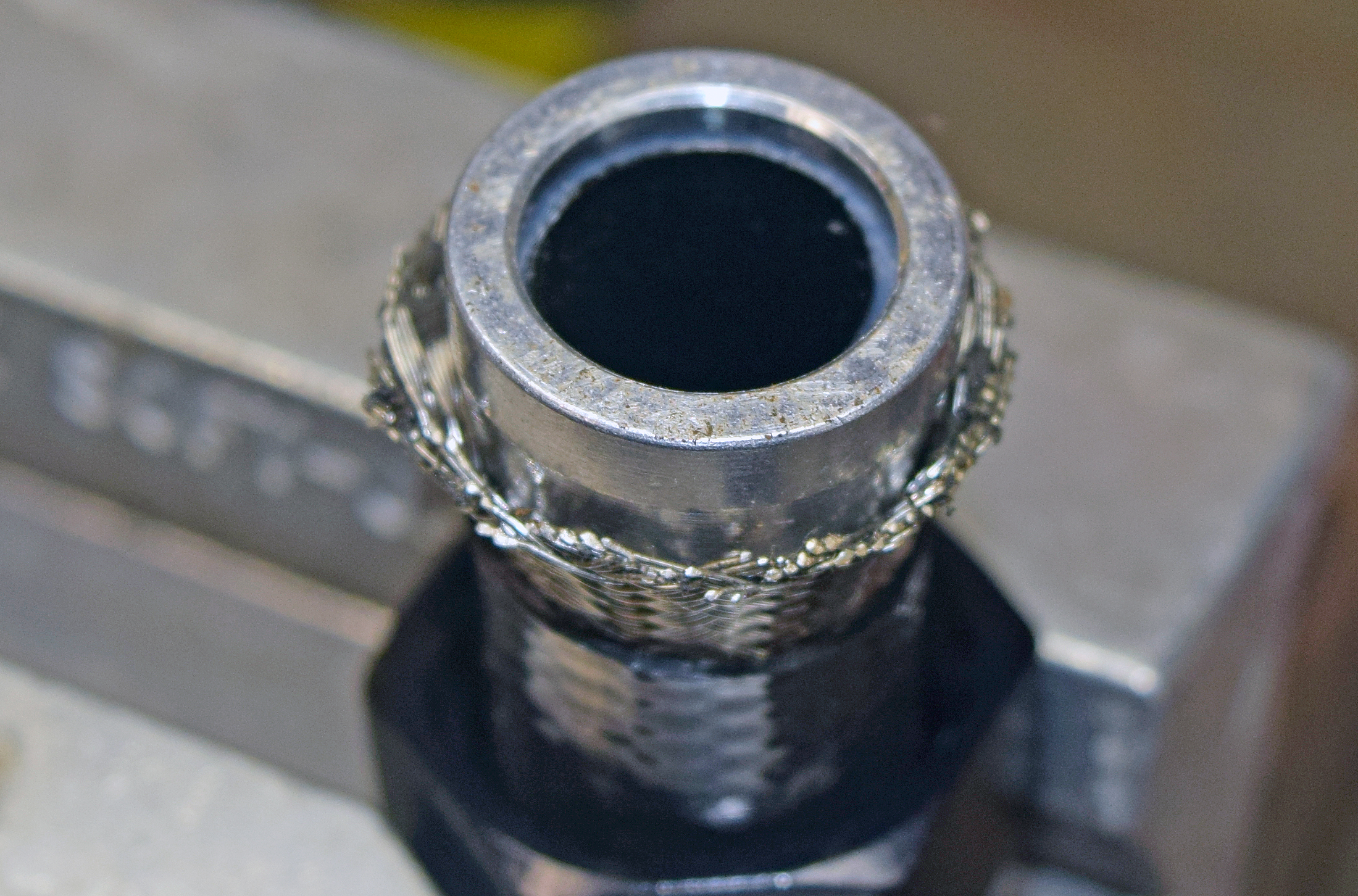

The PTFE liner is carefully pushed into the olive until it reaches a shoulder stop. This results in the braided steel portion around the outside of the olive. The two outer fittings are pushed together and threaded. It is critical to lubricate with a light oil during each step of the assembly process.

There are three parts to a PTFE hose fitting compared to the typical two on a standard -AN hose end. The “socket” slides over the line before cutting the line to length. There is also the AN Fitting hose end that will install within the hose and thread to the socket. The third component is called a ferrule or “olive” that, in the case of a PTFE hose end, installs between the two standard hose end components.

One of the critical additions to the assembly steps is the removal of some of the black covering from the outside face of the hose. Fragola recommends 1/4- to 3/8-inch to be cut away from the end. We found it best to cut 1/4-inch away from the smaller diameter hoses and 3/8-inch away from the larger -10AN line. We used a heavy-duty utility knife to cut around the circumference of the sheath and expose the stainless braid.

It takes a little muscle to wrench the olive/fitting assembly together. We recommend using quality steel wrenches in lieu of aluminum AN wrenches as not to round off the fittings. The tape on the hose shows if hose pushes out during assembly. To avoid leaking, the hose should not back out more than 1/16-inch. Throughout the entire assembly process, we gently work a round chisel into the hose to keep the PTFE liner round.

Cutting away that black sheathing in our case exposed the braided stainless steel. With a small screwdriver or pick, we carefully worked the stainless braid outward without damaging the PTFE liner. The liner can become out of round during the cutting process or while working out the stainless braid. We carefully used a round chisel gently pushed into the liner to keep it rounded.

The “olive” is now installed over the PTFE line and under the expanded braided layer. The hose end is then pushed into the inside of the PTFE layer and the socket and fitting parts are then threaded together.

“Some customers try to cut the braided steel portion back from the PTFE liner to make the olive easier to install,” Mclellan says. “They’ll go to screw the socket on the hose end and you can literally pull the hose out and get a leak there. So we make sure the stainless is all the way to the top of the olive.”

We are using Fragola's EZ Street hose for the low pressure return line of our EFI fuel system. Though it may appear as a typical fuel line from the outside, it is impermeable to extreme fuels such as ethanol and methanol.

Constant lubrication during assembly makes the entire process far easier. Fragola frowns upon the use of a “WD-40” style penetrating oil as a lubricant. We used a light assembly oil found at local auto parts stores to lubricate during all assembly steps.

Adding in the return line hose and fittings is an easy step in the installation process. The Fragola EZ Street hose is a nitrile tubing that uses an internal reinforcing braid making it durable up to 175 psi.

The high pressure side of the -8AN Fragola Series 6000 plumbing travels through a fuel flow sensor, through the throttle body, and returns to the pressure regulator. The Fragola -6AN EZ Street hose exits the regulator as a tank return. We carefully clamped the PTFE hose at any loose points to prevent vibration that can cause the liner to leak.

We were given some preventative advice about the nature of PTFE plumbing.

“Do not allow the line to shake or vibrate,” Mclellan explains. “Keep it well fastened down where longer lengths of the hose cannot move around in a racing environment. If the liner is allowed to move around in a racing environment the liner can leak with time. Really keep it fastened down well at many points within your race car.”

Our new fuel system is the poster child of durable race car plumbing. The PTFE option is the answer to degradation due to extreme fluids and keeping a race car plumbing trouble-free in a high pressure environment.