Over the years at Corvette Online, we’ve seen countless suspension upgrades, done more engine swaps than we can remember, and even taken part in more than a few complete chassis updates. But we must admit that this C2 project undertaken by Retro Designs Speed and Custom in Concord, NC, may just be the most thorough, turnkey, everything-swap we’ve ever seen.

The perimeter chassis is designed to be both lightweight and rigid thanks to mandrel-bent 2×4-inch tubing. As you can see, it is also designed to tuck the larger modern Corvette wheels into the 1967’s fenders.

When the customer brought his 1967 Corvette convertible to Retro Designs, he wanted the car to look period correct on the outside but update everything underneath so that it rides and handles like a fresh-off-the-line C7. While shop owner Daniel Valjevac and his crew can certainly pull off a build like this from scratch, this time they decided to work with Street Shop out of Athens, AL to build an all-new chassis, fully decked out with C7 components, engine, transmission – even a new fuel tank – and get it to slide right under the ’67 Corvette body.

Street Shop specializes in building complete chassis and drivetrain packages for Corvettes—and only Corvettes–from 1953 all the way up to 1982. The upgraded chassis is a perimeter frame, constructed from high-strength, mandrel-formed 2×4-inch, 0.120-wall tubing and designed to fit underneath the stock floor pan without requiring any cutting.

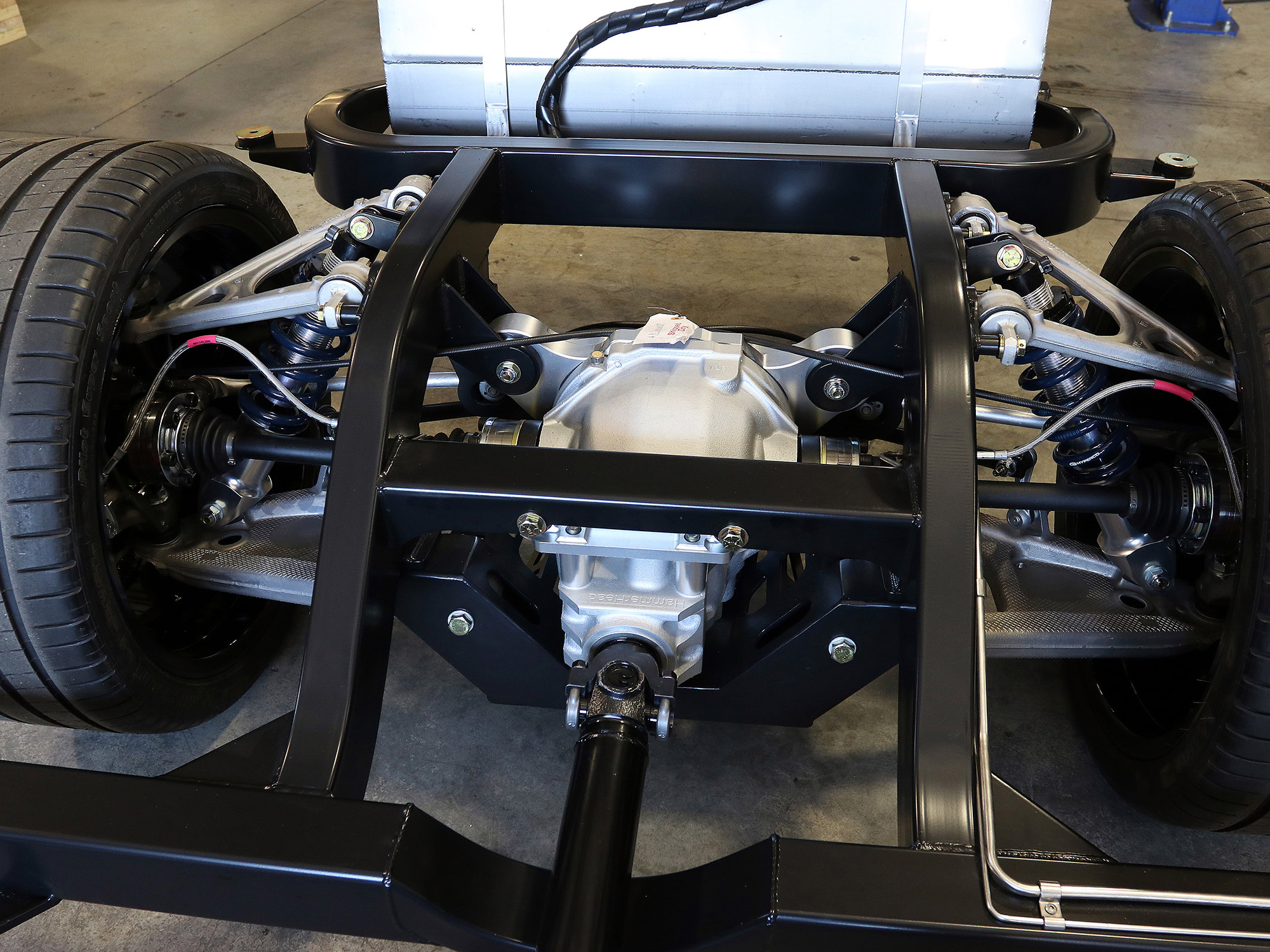

This view gives a little better idea of the front-end geometry using mostly OEM C7 Corvette components. Notice also the hydraulic power-steering rack sourced from Detroit Speed and Engineering. The more traditional hydraulic rack helps simplify the steering system versus the C7’s electric power steering setup. You can also see the independent rear suspension, which is a hybrid of C7 and aftermarket components. The coilover shocks at all four corners are supplied by QA1 and are wrapped in HyperCo springs.

That, however, is the version using C4 suspension components. Street Shop has been doing that for years with a variety of engines. For this build, however, Retro Designs chose to go with Street Shop’s upgraded chassis using all-new C7 suspension components and even Chevrolet’s new, direct-injection LT1 engine. Unlike the C4 setup, the Street Shop chassis that’s been fully outfitted with C7 suspension and driveline does require one alteration to the body.

The Street Shop kit includes a replacement rear floor section that raises the rear floor behind the seats approximately four inches. This allows the larger wheels and tires found on the C7 to fit inside the rear fenders as well as Street Shop’s independent rear suspension with coilover shocks—instead of the stock C7’s transverse leaf spring setup. Retro Designs’ Valjevac says he believes the extra work is worth it to get the upgraded components from the C7 in the car. Plus, as you can see, the 19-inch rear wheels look fantastic tucked underneath the C2’s fenders.

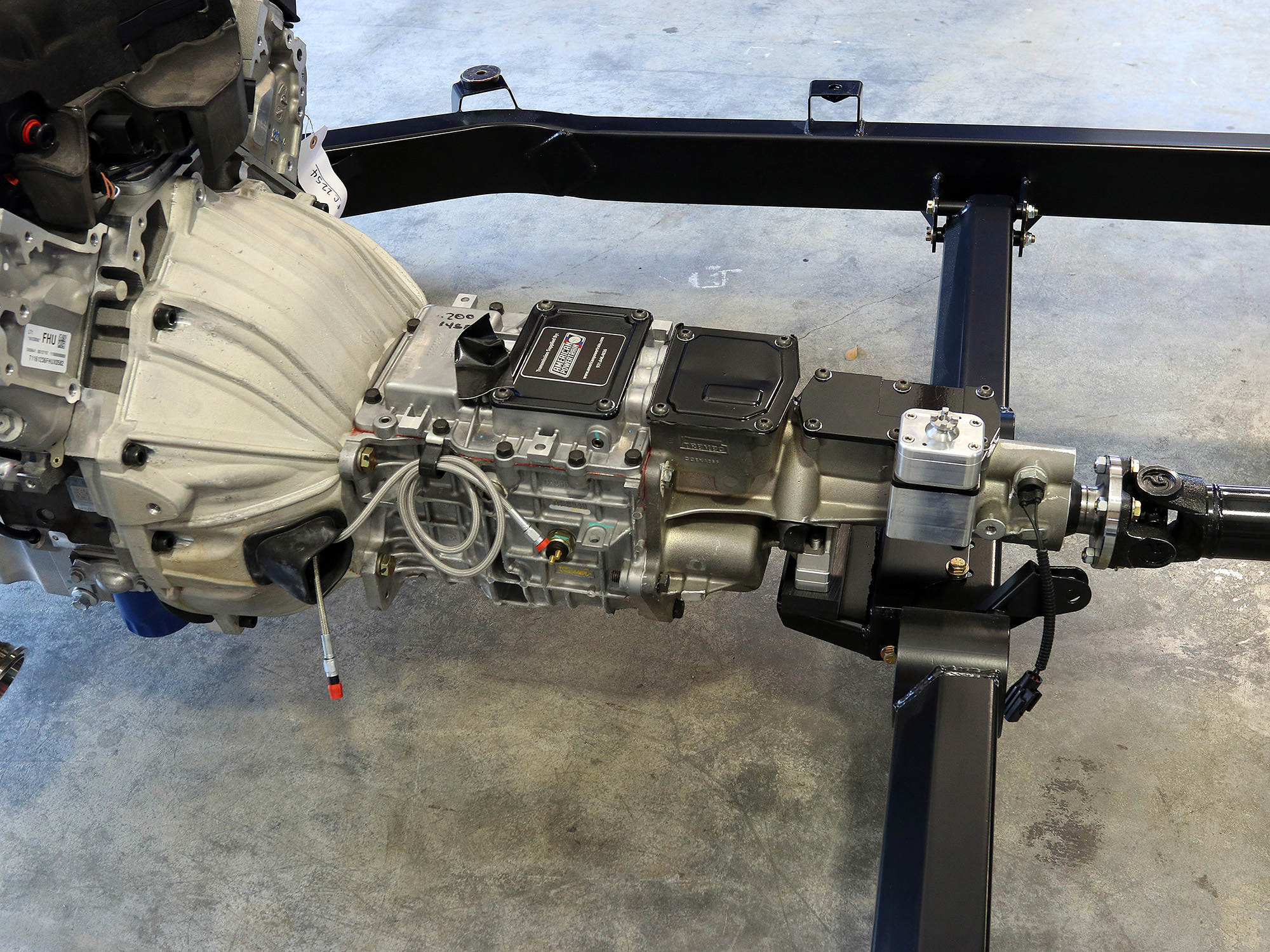

Street Shop is a Chevrolet Performance dealer, so it sourced an all-new LT1 as part of GM’s Connect & Cruise crate package. The LT1 is GM’s fifth-generation small-block, and in its naturally aspirated form, packs an impressive 460 horsepower and 465 lb-ft of torque. That should be more than plenty to make this C2 a ton of fun to drive, and the updated tech should help make it a daily driver that is just as dependable as any modern Corvette. Of course, it’s not as simple as just dropping a new LT1 in between the frame rails and wiring it to a battery. Street Shop solves a lot of those issues by machining its own accessory brackets and other similar components.

Retro Designs is a top-flight custom shop that regularly turns out eye-popping work, so this Corvette project involves a lot more than a simple chassis swap. The plan was for Retro Designs to provide a complete, finished car to the customer. Obviously, we didn’t hang around for all of it, but we did want to pass along some pretty cool tricks that the crew at Retro Designs did along with the chassis and driveline swap.

Instead of the torque tube setup that moves the transmission to the rear of the car, the Street Shop design utilizes a Tremec TKO five-speed from American Powertrain that keeps the shifter in the stock location. The crew at Retro Designs fabricated these body hooks to lift the ’67 body off the chassis with a two-post lift. This way the body can be lifted off the car without twisting the body or doing any damage to the relatively fragile fiberglass. Finally, Vintage Air has retrofit AC systems specifically for the 1967 Corvette, and it installed on this hybrid build with no issues.

Besides the LT1, the rest of the Connect & Cruise package includes a complete wiring harness, an engine control module, a throttle pedal, a controller for the drive-by-wire system and a fuse box. That list makes it sound a lot worse than it really is. The good news is almost all the plugs are unique, so there is practically only one way the wiring harness will hook up.

Modern fuel-injected engines work best with in-tank fuel pumps that can provide a steady stream of fuel at the same pressure. This is especially critical for the new LT1’s high-pressure, direct-injection system. Electric in-tank pumps can be hard to retrofit into a ‘60s-era tank, so Street Shop uses fabricated stainless steel fuel tanks with an in-tank fuel pump already plumbed and ready. Thankfully, the correct pump already arrives installed in the tank as well as the high-pressure pump on the engine that is activated by a lobe on the camshaft.

Another seemingly incompatible issue is mating the old braking system with the new C7 stock. But it turns out the solution is as easy as installing a hydro-boost system which will provide plenty of clamping force to the large rotors and calipers.

When it came time to drop the C2 body onto the new frame, the crew at Retro Designs discovered the seat belt anchors underneath the body interfered with the chassis. The simple solution was to cut them off, and then new anchors were fabricated. The lesson is when you are working with a 50-year-old automobile, things get moved or bent from previous modifications or repairs. Always expect the unexpected.

Retro Designs will be installing a full gauge cluster from Dakota Digital to help monitor the engine’s health. It isn’t in place yet, but here you can see the very interesting setup that will be controlling everything behind the scenes. The box just above the steering shaft connects to all the gauges, but notice the black box just to the right of it. That’s Dakota Digital’s CAN interface that allows the gauges to read directly from the engine’s diagnostic port to provide critical data like RPM, engine temp, etc., back to the main box. The 21st-century powerplant fits in the ‘67’s engine bay quite nicely. Despite a hand-fabricated top to spruce things up, that’s the original radiator bracket holding a new DeWitts’ aluminum radiator in place. Retro Designs fabricated hard lines to carry the coolant between the radiator and water pump, but you can also make it work with flexible lines.

Besides the body-mount locations, two other spots that are important to check are the shifter and fuel tank fill hole to make sure they match up with the body. Those can be difficult to correct later on. Fortunately, on this particular body, everything was still where it should be and it all lined up well. And with the engine in the bay, it looked like it should have been there all along. Check out this quick video clip so you can hear and see it for yourself. Because the Corvette still had to go to paint, the side exhausts weren’t installed yet. So the exhaust is dumping right out of the headers. Still, it’s hard to beat that sound.

We swung by after the car came out of the paint booth to give you a look at the nearly finished machine, and we think the results look fantastic.

Here’s the Corvette fresh out of the paint shop and looking absolutely fantastic. At this point the engine and driveline are completely functional, and there are just a few issues left to button up before this updated C2 is ready to hit the road again.