The feedback that a driver gets from the steering of a vehicle is an important part of defining the personality of your car. While it would be nice if it was as simple as the steering on a soapbox derby car, a classic or restomod project demands a lot more attention to specific details to ensure good handling and positive steering. In a time when the aftermarket can supply an abundance of parts to piece together a modernized steering system, it’s important to make sure those parts will get along together and perform as desired.

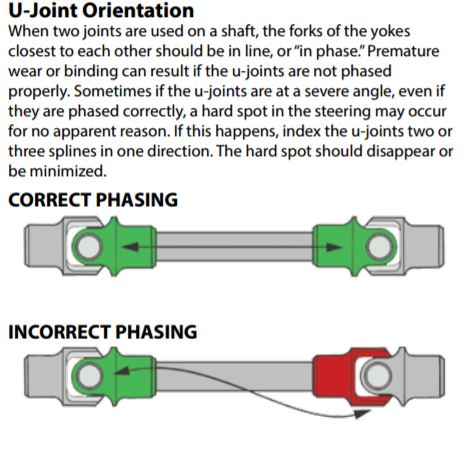

Universal joints are a great accessory for steering systems, but there are some rules that should be applied to their use.

Steering pumps, racks, geometry, bumpsteer, universal joints, and vibration dampers are areas of common concern or confusion when enthusiasts are tackling a project. Luckily, there are experts out there that are happy to steer you in the right direction to make your project a success. Jeff Grantmeyer of Borgeson, and John Jennings from Flaming River know their steering, and field technical concerns on a daily basis. We posed five of the most common questions to the experts, seeking tips for our loyal readers that may be designing a steering system for their own hot rod.

Flaming River Industries has built their company on providing quality steering components for hot rodders and street rodders. Many of the Flaming River’s employees have built their own rods with Flaming River components.

Can I use my GM power steering pump with my Mustang rack-and-pinion?

Jeff Grantmeyer: One of the most common questions asked of us relates to the compatibility of a GM power steering pump with a Ford Mustang rack-and-pinion. (Think small-block Chevy in a ’32 Ford with a Mustang II frontend.)

Most standard GM Saginaw self-contained power steering pumps have the pressure optimized to power an integral power steering gear box. This is a pressure ranging from 1,100 – 1,600 psi, depending on the OE vehicle application and gearbox used. Mustang rack-and-pinions are designed to be operated at only 800-900 psi. Using a standard GM power steering pump without altering the output pressure will result in very twitchy, sensitive power steering at highway speeds, and will make quick work of destroying the rack-and-pinion seals.

Borgeson offers both pressure reducing kits to adjust the output of your existing GM Saginaw pump or complete power steering pumps with the output pressure properly set to operate a Mustang rack-and-pinion.

John Jennings: The GM pump is designed to deliver high-flow with high-pressure. The Ford rack utilizes low-flow with low-pressure. At low speeds (engine RPM), that’s great. But as you get up to highway speeds (higher engine RPM), the pump is maxed out and putting out the same pressure. When you turn the wheel, it gives you that squirrelly feel. You can re-valve the pump, but that doesn’t always get you there. Best practice is to research flow rate and pressure with the manufacturer of the pump and then compare with your rack.

Another often overlooked consideration is whether you are running hydroboost brakes. If your brakes are taking all the boost and assist out of the system when you are not using them, you won’t have any left for the steering.

Do I need, and where do I place the vibration reducer in my steering system?

Multiple universal joints require some additional attention as Borgeson’s Jeff Grantmeyer points out.

JG: Using a vibration reducer in the steering system creates a break in the metal-on-metal contact, which eliminates the road vibrations and power steering hydraulic “noise” from coming through to the steering wheel. Whether you need one or not can be a matter of personal opinion, however, please note that production vehicles beginning in 1967, incorporated some type of vibration reducer in the steering system. When choosing where to place the vibration reducer, you must take into account the total quantity of universal joints used in the steering system.

In a steering system with only two joints (one at the column and one at the rack/box), the vibration reducing universal joint can be placed at either end. There is no difference in the function of the vibration reducer in a two joint system.

In a steering system with three or more universal joints and a steering shaft support, it is important to place the vibration-reducing universal joint on the steering column side of the steering shaft support bearing. This is done to prevent the steering shaft support from transmitting chassis vibrations back into the steering system, negating the effect of the vibration reducer.

JJ: It varies from application to application. If you’re running aggressive street tires with a manual rack, then I would say you’re definitely going to want to run a vibration damper, and you should put that damper right at the end of the steering column itself, so your shaft will help pickup and get rid of vibration.

A lot of guys will put their vibration damper on the rack, and wonder why they’re still getting that hum in the steering wheel. Your steering shaft (especially if you’re running three u-joints) is tied to the chassis, and you’ll pick up motor vibration and whatnot.

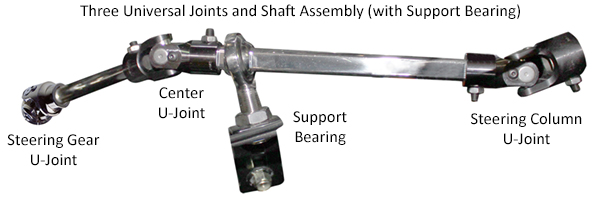

There’s no limit on how many universal joints can be used in a steering system, but three is common with today’s engine/chassis layout.

How many universal joints can I use in my steering system?

JG: There is no limit to the quantity of universal joints that can be used in a steering system, provided that the universal joints are properly supported and properly phased. You can use two universal joints with no steering shaft support, but for each additional joint over two, you will need to add a shaft support bearing to prevent the steering shaft from looping over on itself.

JJ: Three u-joints is what most of today’s engines commonly require, and that’s fine. When you start adding more than that, you have to keep in mind that every time you add a u-joint, there’s going to be some lash – no matter how tight they are.

JJ: Three u-joints is what most of today’s engines commonly require, and that’s fine. When you start adding more than that, you have to keep in mind that every time you add a u-joint, there’s going to be some lash – no matter how tight they are.

With any type of universal joint, you have to phase them correctly, because if they’re not turning at the same bend at the same time, they will bind. I recommend using Double-D shaft, because it automatically phases the u-joints, you can never get them out of phase.

How do I measure and count the splines on my box, rack, or column?

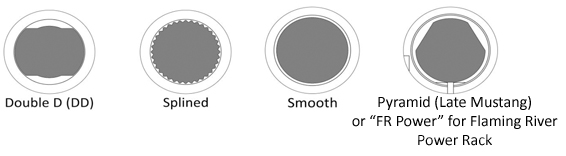

JG: We have over 3,000 different combinations of single, double, and vibration reducing universal joints in just about any spline or Double-D configuration (A Double-D is a round shaft with two opposing flat sides). In order to choose the right size, it is important to know how to measure/count splines.

To determine the size of a Double-D shaft, we use the outside measurement from round side to round side. The most common sizes are 1-inch, 3/4-inch, 17 mm, and 18 mm. To determine the proper spline size of a shaft, we need the diameter of the steering shaft itself, not the old coupling since they are prone to wear. Be sure to measure the major diameter over the peaks of the splines (It is best to use a dial caliper for this measurement).

When counting the splines, it is important to obtain a count around a full circle. It is very common for steering box/rack shafts to have a flat machined on them with no spline. If this is the case, count the splines around half of the diameter and double that number.

JJ: The easiest way to measure is with a pair of calipers. Measure on the outside diameter of the splines themselves. Because all the modern steering-box shafts have flat spots on them, divide that shaft in half and count that number of splines that are there, then double the number. That will give you an accurate spline count, even going across that flat without having to guess.

Where Can I Find A Power Steering Conversion For My Vehicle?

JG: Our line of power steering conversions for classic cars and trucks has grown exponentially over the last couple of years. 2010 and ’11 alone saw five new conversion boxes offered. With new projects already in development, the best way to answer this question is to check our website or our Facebook page for the most “up to the minute” updates.

JJ: We do bolt-in kits for Chevelles, Camaros, Impalas, Mustangs, and some other early ‘60s cars, and ’67-’87 GM trucks. These are already dialed in, they bolt-in, and you’re ready to go. When it comes to doing something custom, we have to be able to get the geometry from the front end – where the steering pivot points are located. If the pivot points of your suspension don’t match the pivot points of your steering rack, then all you’ll be doing is creating a bunch of bumpsteer, and the car is never going to handle correctly.

There are worksheets that we have to tell you what dimensions we need on the rack. Measuring it is a little more difficult. If you’re unsure, we recommend you go to a qualified chassis shop and have them measure it for you.

In Summary

With something as important as the steering system, no one should just “wing it” and go with gut feel. Call the experts at Borgeson Universal or Flaming Rivers Industries for some solid advice. Getting help from the professionals will get you going in the right direction when it comes to steering control.