Owning a car certainly has its ups and downs. When the vehicle is new, everything is excellent with the new car smell and the factory warranty. The only thing you need to worry about is the payment and making sure the insurance is up to date. However, there comes a time in a car owner’s life when maintenance is required. And if you own a C5 Corvette, things like brakes, an alternator, and even the water pump can be performed in any garage with the right tools. But when it comes to replacing the clutch in a C5, owners, even with a pretty good mechanical background, start to get a little squeamish.

Our C5 is a daily driver, which is mostly stock. The only performance modification to date is an exhaust system.

Over the years, engineers have never made the Corvette easy to work on. The independent rear suspension has always been a pain, but the lack of room in the interior and under the hood magnifies the problem. When Chevrolet moved to the transaxle design in 1997, it added even more complexity to the situation. Instead of unbolting the driveshaft and transmission like in years past, you have to dismantle the car’s rear to get to the clutch.

By now, you’ve probably figured out where this story is going. We know that the clutch on our C5 has seen better days, as it was getting up there in miles. So when the time came to replace the clutch in our Corvette, we made two phone calls: our first one was to JEP Autowerks in Hemet, California, because we had some questions about the installation; our second call was to SPEC Clutch to order a replacement for our worn out factory unit.

JEP Autowerks is a local performance shop and is very knowledgeable when it comes to late-model muscle cars. Since we’re gearheads, we decided to see what we were up against with this C5 clutch install. We reached out to Josh Epstein, the owner of JEP Autowerks, to see how difficult this installation would be.

“On a scale of 1-10 for an experienced tech, it’s a solid five. It’s a very time-consuming process that takes a copious amount of time, even with the best tools and equipment. As vehicles get newer, the difficulty level increases and some cars are far more challenging to replace a clutch on, believe it or not,” Epstein explained. “It typically takes 10-14 hours depending on the environment you’re doing the work. If you’re working on the car in your garage on jack stands would take considerably longer than on a vehicle lift.”

While we had Epstein on the phone, we asked if anything else needed to be addressed with the car torn down. Epstein said, “It’s all about preventative maintenance on all types of cars, especially on these higher-performance vehicles. You definitely want to check the fluids and throwout bearing at the bare minimum. We recommend flushing the system out entirely since you’re already in there, and also advise surfacing the flywheel, and replacing the pilot bearing and release bearing.”

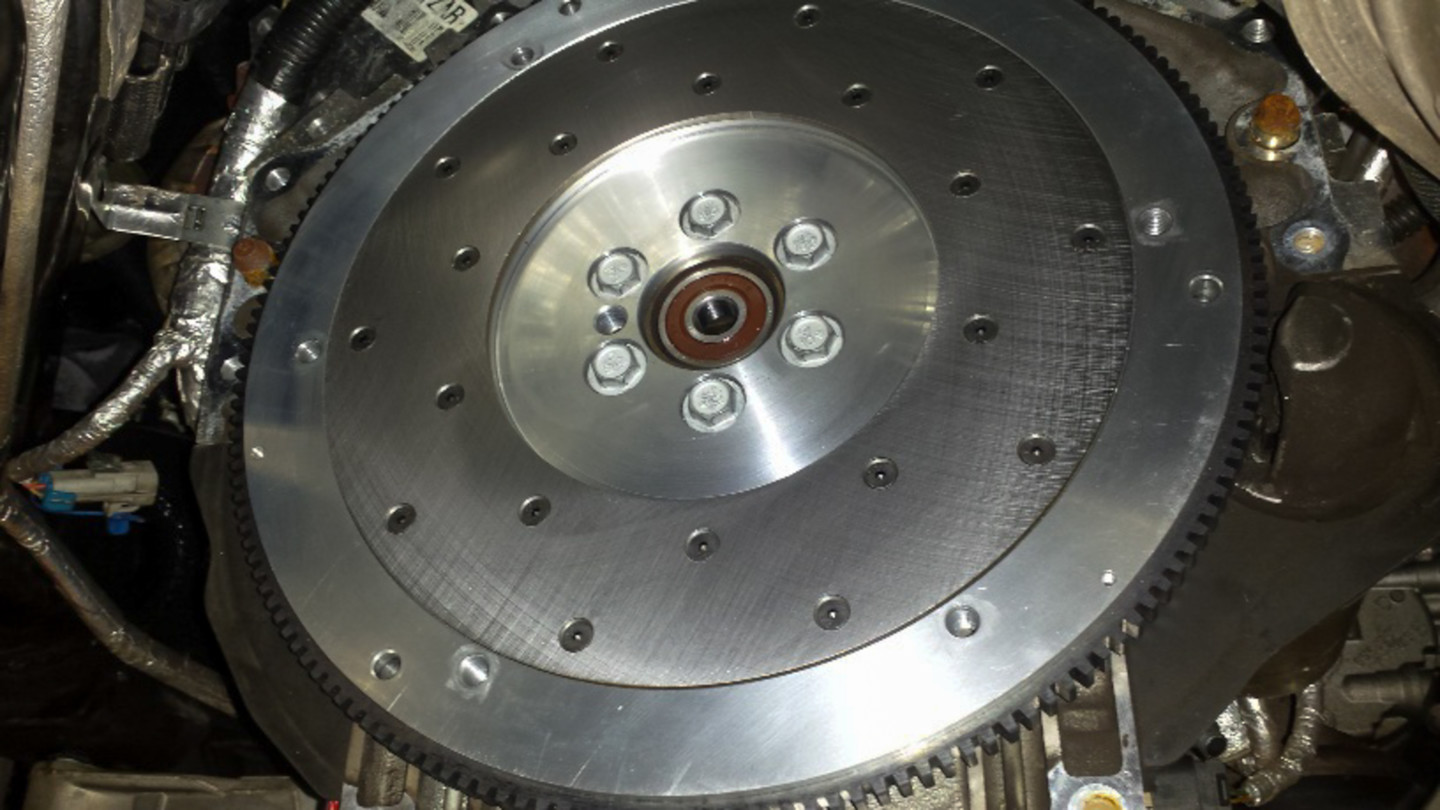

Basically everything you see in this picture needs to be removed to get to the clutch, which makes changing the old unit difficult.

Usually, a five on a scale of up to 10 would not deter us from tackling a project ,but since this Corvette is a daily driver and we depend on it, we didn’t want to take a chance of it winding up in jack stand jail. With our appointment made with JEP Autowerks, we turned our attention to the clutch and made a call to SPEC to find the perfect clutch for our relatively mild Corvette, because we were unsure of which unit to order.

“The SPEC Stage 1 clutch is an excellent choice for a daily driver and even a track rat that is within its torque capacity. The unit provides tremendous bang-for-the-buck value with an ability to hold just under 600 lb-ft of torque under the $400 price point,” Norton explained. He also informed us that the SPEC Stage 1 is SFI certified and will last longer in extreme environments than a factory clutch. “We offer a solid backplate disc carrier that eliminates the weak fin carrier of the OEM and other upgrade alternatives. Our lightweight double-sprung cage and treated splined hub can withstand 1500 lb-ft of torque, and our steel-backed woven organic lining provides the peace of mind that the abuse will not result in sheared friction material.”

After a few hours of work, the C5 drivetrain is finally on the ground and JEP Autowerks turned its attention to the installation of SPEC’s Stage 1 clutch.

While the Stage 1 clutch sounded like the perfect setup for our application, we had to inquire about the Stage 2. Norton said, “Our Stage 2 clutch has equal drivability to our Stage 1, with a capacity to hold just under 700 lb-ft of torque. If it’s within the budget, the Stage 2 is an exceptional alternative to the Stage 1 for a tad longer wear life. To maximize wear life, I would transition to the Stage 2 in the 580-680 lb-ft range.”

Since our C5 is pretty much stock other than a few bolt-ons the Stage 1 would work perfectly. The only other question we had was regarding driveability– how would the Stage 1 feel compared to the Corvette’s OEM clutch? Norton said, “The pedal requirement and engagement quality makes it pleasant to drive in traffic, and wear life is excellent, which is essential given the labor-intensive clutch swap on the C5.”

After talking to Norton about SPEC’s products, we ordered the Stage 1 clutch kit with the aluminum pressure plate option. The aluminum pressure plate is rebuildable and drops 9-pounds from the clutch assembly, adding about six horsepower to the rear wheels. We also opted for a new steel flywheel for our C5.

The clutch on our C5 looked pretty rough and needed to be replaced. It also showed signs of high milage as well as slippage.

The Stage 1 clutch and flywheel showed up on our doorstep a few days later. Excited, we immediately threw it in the car and headed down to JEP Autowerks so they could get to work. Within a couple of days, Epstein called and said the C5 was ready for pick up. Of course, we had to ask how bad the factory clutch was. Epstein said, “It definitely had some miles on it, and the previous drivers slipped it pretty good — it has signs of slipping, which is pretty standard. A lot of people drive these cars like a Honda Civic and slip the clutch.” We’re just going to assume Epstein was not talking about us in this case.

Anytime you install a new clutch, it’s crucial to break it in properly. We have always just put about 500 miles on a new unit for a safe measure in the past, but Epstein had some more details for us. “The best way to break in your new clutch is to drive in stop-and-go traffic for at least 400-500 miles — not highway miles, but stop-and-go traffic, city driving. You want to cycle that clutch as much as possible without putting too much heat into it and don’t apply full power; failure to do this will result in seeing me again for a new clutch.” While we like Epstein, we certainly don’t want to see him again for another clutch installation. So, we will make sure and break it in as advised.

SPEC’s aluminum pressure plate is rebuildable and drops 9-pounds from the clutch assembly, adding about six horsepower to the rear wheels.

With our new clutch job all buttoned up, it was time to hit the road for the first time. There was a noticeable difference in driveability immediately. The SPEC Stage 1 clutch kit is an excellent piece for the price. Even though there are more expensive options out there, this unit offers a great pedal feel and super smooth engagement compared to some of the others we have driven. The SPEC clutch engages more smoothly than the factory unit, and while it feels different, it’s not abrupt or grippy.

With the car back in our hands, it’s time to break in the clutch properly. The best way to accomplish this task is to drive the car 450-500 miles in stop-and-go traffic.

If you’re considering going with an OEM replacement clutch, don’t do it. A stock clutch can only hold so much power, but the SPEC Stage 1 offers superior holding power due to higher grade components and a higher level of engineering when compared to a factory clutch — or worse, the part store counter piece — and the driveability is superb. And while the SPEC unit is a little more of an investment, you certainly get what you pay for.