A common question by enthusiasts is, “how long do drag radials last?” The question itself makes sense, as tires are the one thing racers and spirited drivers want to avoid buying frequently. Unfortunately, there are too many variables to give a mileage interval or timeframe before replacement, however, there are ways to increase the lifespan of drag radials.

Every racer wishes they could give their tires immortality, but the truth is these chambers of air take a severe beating by absorbing energy on different surfaces, being exposed to the elements, and even user error when maintaining tire pressures. Through all the torture drag radials face, it is amazing that they can still provide critical functions, such as enable a vehicle to hook off the line at launch and still manage to control and stabilize on the top end of the track.

Start With The Correct Tire

Before you can begin to look into how to prolong the life of your drag radials, you first need to make sure you’re purchasing the correct tire for the job. Although this step seems easy, especially if the term “drag radial” is a generic one in your vocabulary, there are major differences that are associated within specific selections.

“We are constantly asked about which is the right type of tire, even for DOT-legal tires,” says Jason Moulton, Motorsports Director at Mickey Thompson. “In these cases, we typically say the Mickey Thompson ET Street S/S is a tire you can take on the track, but is more geared for the guy still driving his car on the street. The ET Street R can be driven on the street, albeit only in dry conditions, but is more of a race tire that can be driven on the street.”

Although they share a similar name, the Mickey Thompson ET Street S/S and ET Street R cater to different crowds.

While the two different tires’ purposes are easily explained, it’s the compounds and construction technologies that make the tire capable of performing in the different scenarios. The ET Street S/S is set up for consistency at the track, but its steel-belted radial construction and tread pattern allow it to handle street and mildly wet conditions. The ET Street R takes the on-track performance up a notch, as it uses the same compound and construction technology used in the Mickey Thompson ET Street Radial Pro.

Inflate To The Proper Pressure

Aside from choosing the right tire model, another way to keep your drag radials lasting as long as possible is through proper inflation. Since a tire’s air pressure is meant to carry the weight of the vehicle, it is naturally a key component in longevity. However, there is more than making sure your tire pressure gauge’s indicator stays at a specific level, as multiple surfaces require different pressure settings to allow drag radials to grip.

“Running low pressure – proper low pressure– at the track does not have a large effect on tire longevity,” Moulton explains. This is why it’s common to see racers reducing their air pressure to create a good footprint. While this number hovers around the 15-20 psi mark for a baseline in most applications, it’s only kept there for when racing on track.

Tire pressure plays a major role in cutting a good 60-foot time. However, running the same pressure you used at the track on the street over longer distances may have adverse effects.

Although “track-based” tire pressure in shorter increments does not break down the tire compound as quickly, extending the same pressure settings to the street can have damaging effects. “If you don’t inflate the drag radials when driving longer distances on the street, the tires will generate internal heat and start to have a negative impact,” Moulton states. “The best practice is to air them back up to what the vehicle manufacturer states on the door tag.”

Finally, for those who have decided to utilize their sport utility, truck, or electric vehicle in drag racing, you’ll want to run higher tire pressures than seen on a lighter drag car. “We find radials are better for heavier vehicles than a bias-ply slick, but you’ll need to run more tire pressure,” Moulton explains. “We even used our drag radials on Ford Racing’s Cobra Jet EV, weighing nearly 5,000 pounds.”

Avoid Rough Surfaces

After selecting the correct tire and properly inflating it, the final step of lengthening a drag radial’s life during use is to understand which surfaces will have the most impact against it. This should come as no surprise that the rougher the surface is, the worse it is for your tire’s lifespan. After all, aside from when bad things are happening, the tire and the pavement are in constant connection with one another. However, this is more than just avoiding potholes and poorly paved streets to give your tires a longer life.

One of the hottest segments of the drag racing community currently can be found in the form of no-prep racing. While these cars scurry in eighth-mile increments, the surface has usually been scraped clean and the asphalt has little to no prep applied. You might think these surfaces are smooth enough, but according to Moulton, that’s far from the truth.

“Racing on variable track conditions (read: no-prep) tends to be harder on the tires, since the surfaces are not as smooth. In these environments, you’re working the compound of the sidewall and breaking it down much faster,” Moulton explains. “In most cases, switching to a bias-ply slick with very soft sidewalls, soft compound, and accommodating to lower tire pressures to absorb that energy might be a better option.”

Simply put, the smoother the surface is, the less absorption of energy the tire will have to take on, therefore your tire will live a longer lifespan. This is why most tracks use a concrete surface that is smooth and does not work the tire as hard, but still provides a sticky surface for faster times. Although having a concrete track nearby is not always an option, the ability to know where your tire wear is most coming from can be extremely valuable.

Properly Storing

Outside of usage, there are ways to extend the life of your drag radials. Like any tire, Mickey Thompson drag radials also have a proper storage process meant for extended storage intervals during the off season. The techniques are to prevent any flat spots or premature wear in the tires’ compound that would hinder their life, or your safety in the following season.

Sometimes mother nature has different plans and throws a random ice storm your direction. While these circumstances are often times unavoidable, its best to keep the car off the ground or remove your drag radials during the off-season for maximum lifespan.

The best way to store your Mickey Thompson drag radials is by removing them from the car or jacking the car off the ground to remove the load. Next you’ll keep the tires away from direct light, including sunlight and fluorescent lighting. You’ll want to store the tires away from any electric motors, such as those found in a furnace or air compressor, and avoid storing the drag radials in places that have extreme high and low temperatures. Most importantly, do not use any chemicals on the tires! If you can persuade your significant other that they require a special spot in the house when not in use, go for it. Remember, if you’re cold, they’re cold.

How To Tell If A Drag Radial Is Still Good

Aside from your drag radial being worn down to the minimum depth, showing signs of abuse, weather cracking, or any other visually obvious reasons, there are also other ways to determine if your ET Street S/S or ET Street Rs are still in race shape. Another way to determine the condition of your drag radials actually comes from use and what better place to do it than in the first 60 feet at the drag strip.

The Mickey Thompson ET Street S/S and ET Street R both have an embossed date of manufacture. This four digit code will show two-digit week and two-digit year when the drag radial left the factory. However, the best way to determine what condition your drag radials are in is to monitor your 60- and 330-foot times.

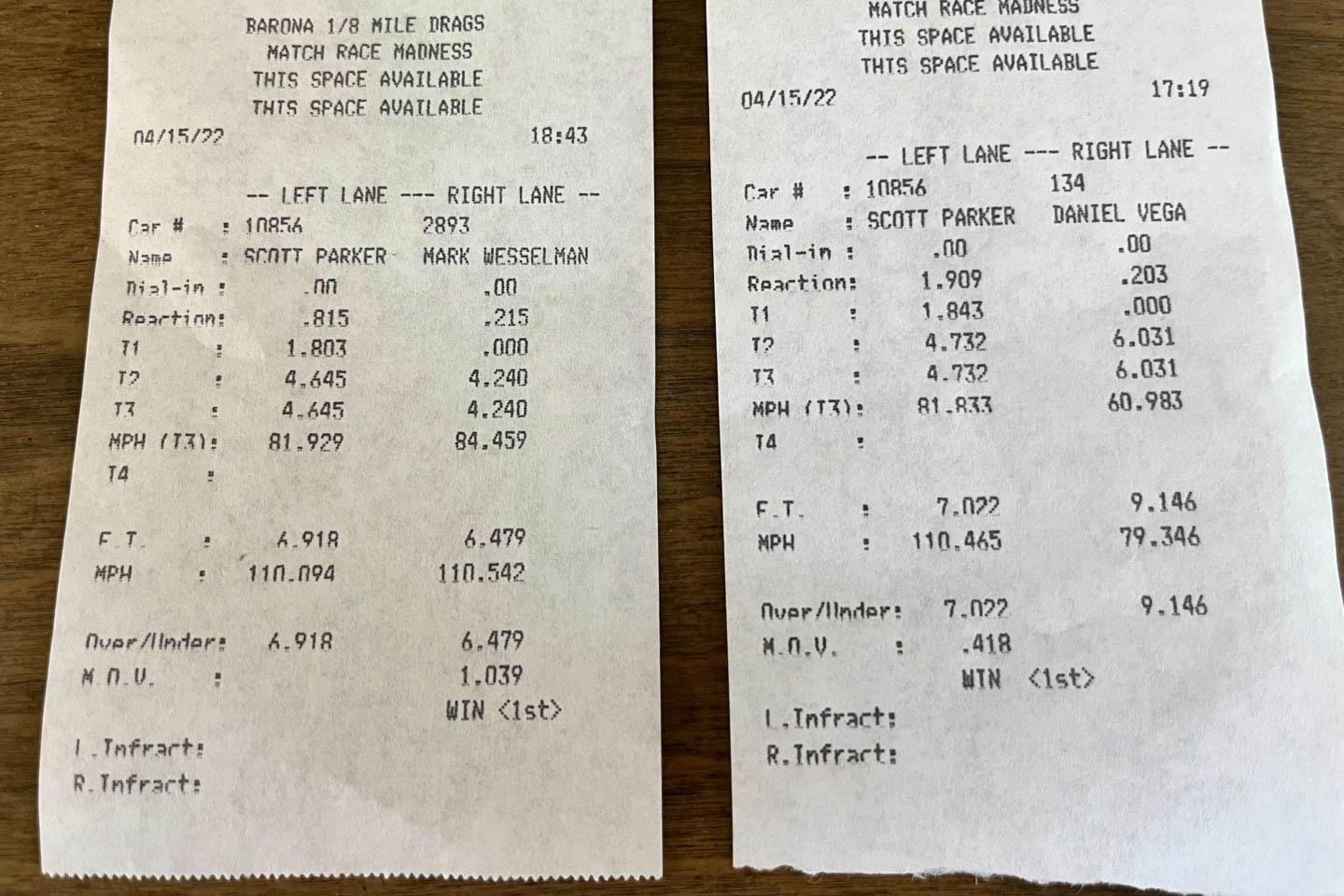

While Mickey Thompson drag radials come equipped with a “born-on date” embossed on the side of the DOT-legal tire, it should be noted that there are too many variables for this to offer a guaranteed full service life. Instead owners should pay attention to their 60- and 330-foot times. “You’ll see your 60-foot times drop off quickly, however you have to be careful and take into consideration track conditions, weather, and vehicle performance,” Moulton says .

If you begin to see your 60-foot times dropping off, it might be time to replace your current drag radials. After all, being safer and quicker sounds a lot better than the alternative option.

The Final Verdict

While neither Mickey Thompson, your faithful scribe, nor a tarot reader could predict the exact time you’ll need to replace your Mickey Thompson S/S or ET Street R drag radials, these tips should come in handy at extending their lifespan. So remember, to get the longest life out of your drag radials, choose correctly, inflate properly, race on smooth surfaces if possible, and store indoors or off the ground. Best of all, monitoring your drag radials involves actually using them!