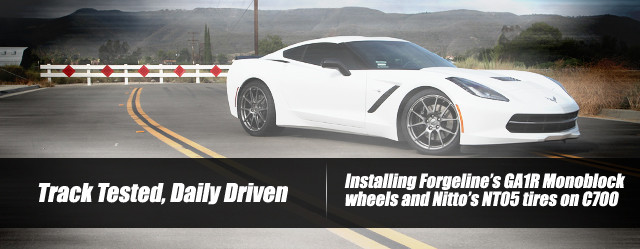

As you’re likely reminded every time you read the title ‘C700’, the end goal for our 2015 Stingray is to achieve 700 horsepower. However, we have a number of things that we’d like to maintain on that road to 700 ponies – such as the car’s clean, aggressive looks and ability to be driven on a daily basis.

As you’re likely reminded every time you read the title ‘C700’, the end goal for our 2015 Stingray is to achieve 700 horsepower. However, we have a number of things that we’d like to maintain on that road to 700 ponies – such as the car’s clean, aggressive looks and ability to be driven on a daily basis.

And while you might think that we set the bar a bit low at 700 horsepower (after all, late model builds pushing upwards 1000 horsepower are a dime a dozen these days), keep in mind that our vision for Project C700 is not that of a purpose-built race car. The end goal is for our ‘Vette to be more of a jack of all trades, able to hold its own in road racing, autocross, and drag racing.

In essence, the idea behind this project is balance – equipping all the right aftermarket products to improve performance while maintaining reliability, drivability, and aesthetics. And between the K&N full intake system and the Billy Boat headers and exhaust, we’ve already seen some respectable power gains over the Stingray’s stock output. But as the ever-insightful adage goes, ‘What good is all that power if you can’t get it to the ground?’.

What Chevy Gives You

The are a few key differences between the base-model Stingray and the Z51, but one of the most readily noticeable is, of course, the wheels. In both the front and rear, the Z51 wheels are an inch taller than the base model’s 18-inch by 8.5-inch fronts and 19-inch by 10-inch rears. To fit the larger wheels, the Z51’s factory Michelins are also sized larger than the base model’s (the base model comes with P245/40R18s in the front and P285/35R19s in the rear). Our Z51 came with the factory aluminum, split five-spoke wheels, sized at 19-inches by 8.5-inches in the front and 20-inches by 10-inches in the rear. For shoes, the ‘Vette came from the factory with P245/35ZR19-front and P285/30ZR20-rear Michelin Pilot Super Sports.

Our Z51 came with the factory aluminum, split five-spoke wheels, sized at 19-inches by 8.5-inches in the front and 20-inches by 10-inches in the rear. For shoes, the ‘Vette came from the factory with P245/35ZR19-front and P285/30ZR20-rear Michelin Pilot Super Sports.

These tires are at the tip of the spear when it comes to Michelin’s street-performance lineup. Improving upon some of their previous technology, the Pilot Super Sports maximize their contact patch and also utilize specific tread compounds to increase adherence – especially in cornering. The tire delivers admirable performance while still offering a smooth, quiet ride and great longevity. For an OE tire, it serves its purpose well.

What We Replaced It With

As we’ve mentioned before, C700 is going to see a lot of track time. So while the wheel-tire combination Chevy offers from the factory is certainly capable, our purposes will demand a bit more. As such, we got a hold of our friends at both Forgeline and Discount Tire to get C700 track-ready.

For the shoes, Discount Tire provided us with a set of Nitto’s high-performance NT05s. Plus-sized at 275/30ZR19 up front and 305/30ZR20 in the back, the tires let C700 have significantly more rubber on the ground versus the stock setup.

These tires are Nitto’s top of the line for passenger vehicles; they’re essentially a toned-down, streetable version of Nittos track-only NT01 road racing tire. Nitto boasts that the tire’s treadless center is the key to its incredible grip. This, coupled with the broad tread shoulder, offers what Nitto states as consistent contact and emphasized response, traction, handling, and high-speed capabilities.

To compliment these tires, we picked out a set of Forgeline’s monoblock GA1Rs for C700 – 19-inches by 9.5-inches in the front, 20-inches by 10.5-inches in the rear. The fully-forged one-piece wheel has a 10-spoke arrangement, utilizing Forgeline’s I-beam design to simultaneously reduce mass and improve strength. And with its deep-set cap and clean finish, the GA1Rs definitely serve the Stingray well in the aesthetics department.

Insight From The Expert

We had the opportunity to speak with David Schardt – president of Forgeline Motorsports – about Forgeline’s wheels, their construction, and what stands them apart from others. He started off by explaining their general build process; he told us that Forgeline has “two types of wheels: one-piece monoblock wheels and three-piece wheels. The monoblock wheels start out with 110-pound 6061 aluminum, forging-heat treated to T6 specifications, and then have 85 to 90 pounds lathed and milled off to create a wheel. For the three piece wheels, we start with a 35 to 40-pound slab, forging-machining off 25 to 30 labs to create a center. We then bolt the center to an inner and outer rim shell also made of 6061-T6.”

We had the opportunity to speak with David Schardt – president of Forgeline Motorsports – about Forgeline’s wheels, their construction, and what stands them apart from others. He started off by explaining their general build process; he told us that Forgeline has “two types of wheels: one-piece monoblock wheels and three-piece wheels. The monoblock wheels start out with 110-pound 6061 aluminum, forging-heat treated to T6 specifications, and then have 85 to 90 pounds lathed and milled off to create a wheel. For the three piece wheels, we start with a 35 to 40-pound slab, forging-machining off 25 to 30 labs to create a center. We then bolt the center to an inner and outer rim shell also made of 6061-T6.”

Schardt continues, “The biggest benefit of a forged 6061-T6 wheel is its strength-to-weight ratio. Cast wheels and flow-formed wheels have porosity (are porous, or full of tiny holes) and have to be made thicker in order to maintain strength. We can machine our spokes and barrels considerably thinner, resulting in a wheel that is not only lighter but stiffer as well (there is less deflection under load).

Forgeline's manufacturing process allows for uniquely high-quality wheels every time.

“Another benefit of our manufacturing process is that we start with a blank canvas on every set of wheels. The customer can literally get any width, diameter, offset, bolt pattern, center bore and finish he desires.” This blank-canvas approach to constructing wheels also translates to initial cost benefits, typically in racing applications. Low-volume production of wheels can be extremely expensive when they are made by casting or flow-forming (due to the fact that a special mold would need to be made for the custom wheels). However, with the method of forging solid pieces of billet – starting from scratch with each wheel – most major mold and tooling costs are avoided.

One-Piece vs. Three-Piece

When it comes down to one- versus three-piece wheels, however, there are a few advantages each has over the other. As Schardt put it, “the main advantage of a 1-piece mono block wheel is stiffness. They offer improved stiffness and less deflection under rigorous racing conditions . If you look at the same design in a three-piece and a one-piece wheel, they have the same fatigue strength but the one-piece will be stiffer and provide better feedback through the steering wheel. Most casual enthusiasts and weekend warriors won’t notice a difference, but on a sophisticated prototype race car with aero, there is a measurable difference.”

Three-pieces, on the other hand, can easily fit the various needs of different drivers and engineers. Where it might be difficult to find the exact wheel you’re after off the shelf, three-pieces can have their inner and outer rim shells exchanged to change things like width and offset.

This feature also allows a damaged three-piece wheel to be repaired with incredible ease. In the instance that a wheel is damaged, the spun rim shells absorb the majority of the impact, saving the less-expendable center. A quick change of the shell, and the wheel is back in business.

This feature also allows a damaged three-piece wheel to be repaired with incredible ease. In the instance that a wheel is damaged, the spun rim shells absorb the majority of the impact, saving the less-expendable center. A quick change of the shell, and the wheel is back in business.

But while three-piece wheels are undoubtedly one of the best choices for someone like a Grand-Am race team or serious weekend warrior (and, of course, they’ll always score you a bit more cool-points), C700 won’t spend the entirety of its life solely at the track. We favored the style, increased strength, and better feedback of the monoblock, leading us to the GA1Rs.

Fitment And Applications

After getting the lowdown on Forgeline’s build methods and the advantages of their different wheel types, we consulted Schardt about how to determine the best setup for street and for the track. He told us that all of Forgeline’s wheels “Can be used on a street application, but we also make wheels specifically tailored for track use. The main difference in the wheels are the stiffness and fatigue strength. Another thing to keep in mind, as well, is that race tires will more than double the lateral load on a wheel under racing conditions.”

“When it comes to choosing the perfect wheel and tire setups for performance-minded street cars and track/road-racing cars, this is a tough question to answer. When you’re talking about Corvettes, on the street it’s good to stay within a plus 1 to 2-inch diameter of stock (22-inch wheels on a Corvette, no matter what year, is not a good idea for performance). Typically, we can add at least an inch to wheel-width on a street car and gain performance without losing any drivability. On track applications, we often can go up to 2-inches wider per axle, but that can come with rubbing or steering lock issues that are not desirable for the street. We always try to stay with 18-inch diameter wheels for the track, as they are the lightest and offer the most availability in ‘track’ or R-Compound tires.”

The issue of finding track-tires for wheels larger than 18-inches is something we experienced firsthand, as tire options and availability rapidly thin as your wheels get larger and larger. Discount Tire was one of the few sources we found that offered shoes big enough for our large 19 and 20-inch wheels on C700.

Shakedown And Driving Impressions

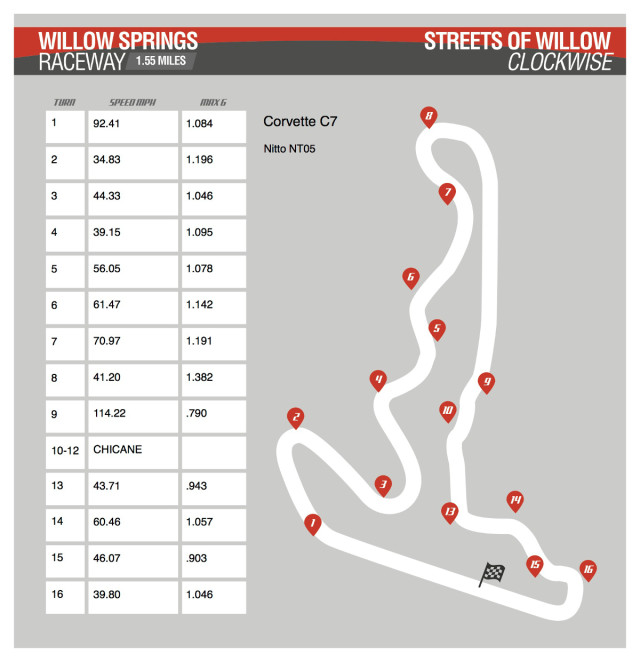

As sexy as our setup looks on C700, we didn’t throw this high-grade setup on the car just to stare at it. Itching to stretch the Stingray’s legs, we headed out for Willow Springs Raceway in Rosamond, California.

There’s no doubt that we put the Nitto-Forgeline combo through its paces; however, we weren’t gunning for ET’s. Our track-day with C700 was a run to get some impressions on drivability, road feel, cornering feel, and durability under performance driving.

There’s no doubt that we put the Nitto-Forgeline combo through its paces; however, we weren’t gunning for ET’s. Our track-day with C700 was a run to get some impressions on drivability, road feel, cornering feel, and durability under performance driving.

We had professional driver Conrad Grunewald test our setup on C700, and he told us “It was a treat to drive. It’s a very well balanced car – it’s very predictable. The C7 is very easy to drive and flick around, and that’s what makes it fun. It communicates to the driver extremely well, allowing you to drive it very aggressively without ever feeling out of control. I’ve driven hundreds – if not thousands – of different cars, and the C7 is one of the select few that you can feel very at home in.”

Conrad went on to state that the NT05’s themselves were also “Very predictable. The performance stayed consistent throughout my laps around Willow Springs. It isn’t a purpose-built, ultra-high grip, sticky slick tire, but it is a very good track tire. The car was very well behaved on it, and it could handle all the horsepower just fine.

“Overall, I had an absolute blast in the C7 with these tires. It is a great tire, but I don’t think it’s going to be the one you’ll go out and set the track record with – that’s not what it was designed to do. It’s reliable and communicates well with the driver, and it ultimately contributed to the great time I had taking the Corvette around the track.”

The Nitto tires allowed us to take each turn aggressively and confidently.

The Bottom Line

As you might’ve guessed, we’re pretty happy with the way C700 is turning out. Our Forgeline wheels look fantastic, offer great stiffness and response, and the Nitto tires do well to compliment that. As Conrad put it, the Nitto tires are not purpose-built for dominating the road course. They provide a great balance as a street and track tire, and offer a seriously fun driving experience. All in all, our wheel and tire setup fits the theme of Project C700: superb looks, great reliability, and a kickass driving experience.