For decades, GM’s LS-series small-block V8 has been the go-to motor for engine swaps across the automotive landscape, finding its way into the engine bays of everything from vintage Chevys to Mazda MX-5s. Its compact packaging, light weight, and relative low cost – largely due to plentiful supply – makes these motors a compelling option for enthusiasts looking to add modern V8 power to their projects, and the fact that a garden variety LS3 makes about 430 horsepower right out of the box doesn’t hurt either.

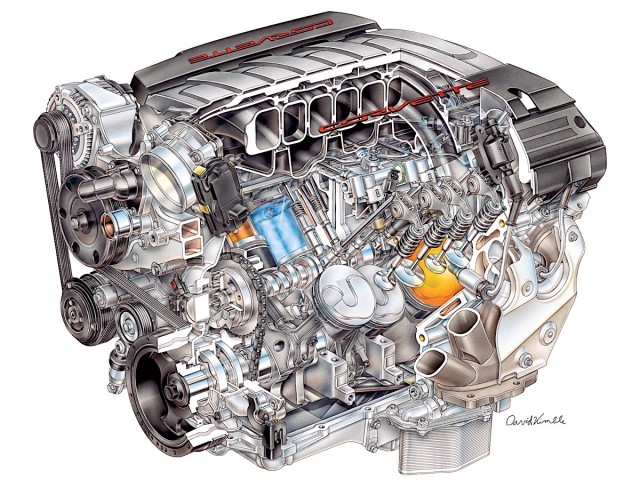

But the march of technology never stops, and GM’s newest small-block V8 family is further evidence that, more often than not, that’s a good thing. First introduced under the hood of the then-new seventh generation Corvette in 2014, the new pushrod LT series motors’ design may be old fashioned by some standards, but it also leverages some of the latest tech on the market today. Boasting features like direct injection and Active Fuel Management, these Gen V motors are more efficient than ever while delivering serious performance.

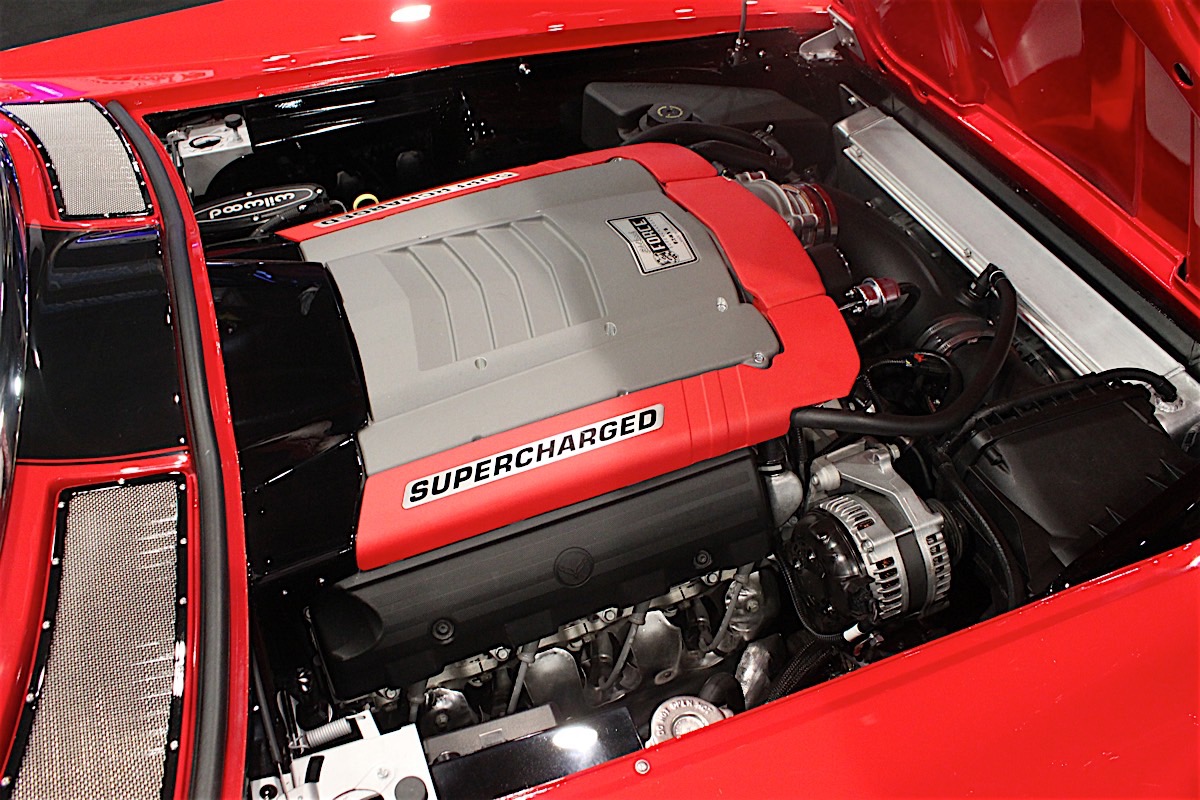

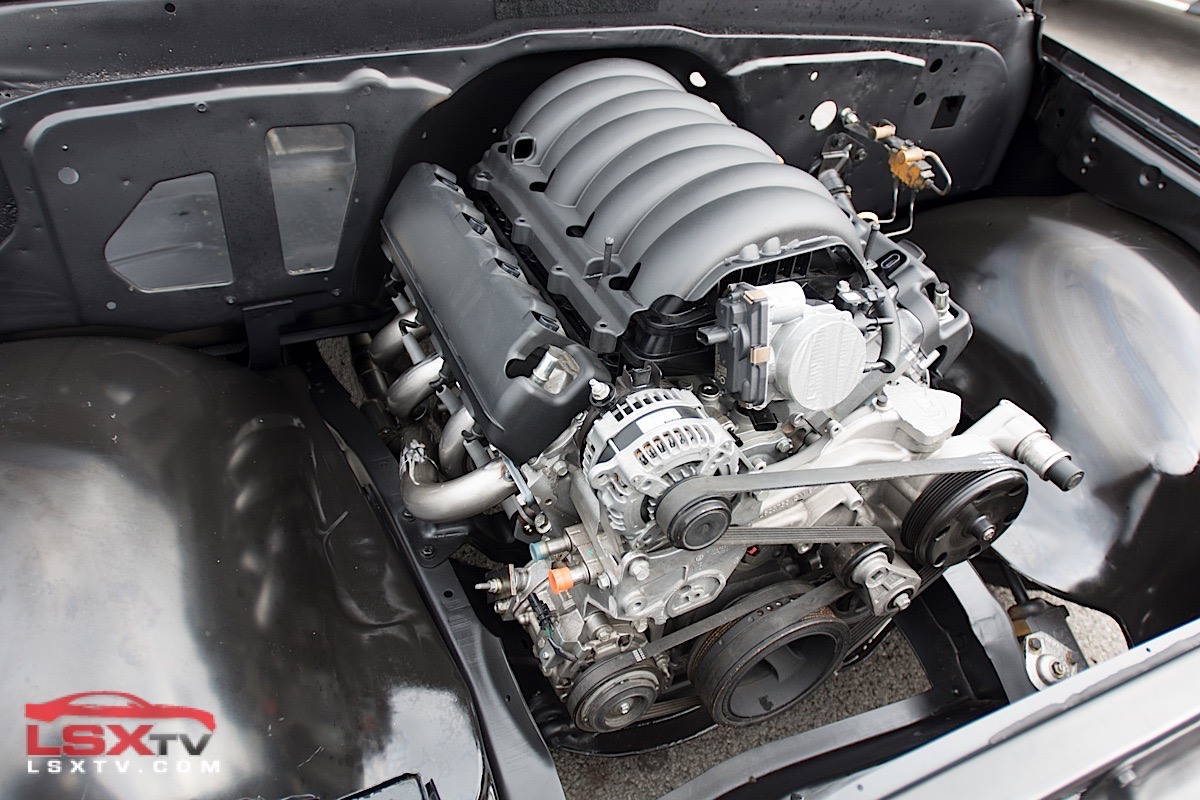

This '69 Chevelle recently got a new lease on life, courtesy of an LT1 transplant from Chevrolet Performance.

Accordingly, it comes as little surprise that folks are already starting to look to the LT engines as swap candidates into older vehicles. With Chevrolet Performance’s recent announcement at SEMA of the Connect & Cruise package, which includes not only a 460 horsepower LT1 or 640 horsepower LT4 crate engine, but all of the requisite wiring harnesses, controllers, and even a gearbox if you need it (as well as a hotter cam and heads package that’s good for 535 horsepower and 470 pound-feet of torque on an otherwise stock LT1), it’s clear that interest in these swaps is already in full swing.

At the 2016 SEMA show, Chevrolet Performance unveiled the LT376 crate engine. Like the LS376 before it, this version of the LT1 uses a hotter cam and CNC-ported cylinder heads. The new crate mill also ditches its variable valve timing and Active Fuel Management for the sake of performance and piston-to-valve clearance. Sold with a two-year, 50,000 mile warranty, the LT376 delivers 535 horsepower and 470 pound-feet of torque.

In this guide we’ll look at what it takes to get an LT-series mill into a vintage engine bay in terms of the what you’ll need to know for the swap and how to source the parts, and we’ll also get some insight from the folks who’re on the forefront of aftermarket development to help make these swaps a reality.

Blazing A Different Trail

Introduced back in the late 1990s, the LS-series engines have been powering high-performance street machines for decades. For GM-powered builders looking to stand out in the crowd, moving to the LT series presents an opportunity to do something new and unusual. “We’ve been pleasantly surprised by how many header requests we’ve had for the LT1 and LT4 motors,” says Jim Browning of Ultimate Headers.

“It definitely offers a certain level of “cool factor” when you pop the hood, and the motivating factor for many choosing to go LT right now is a desire to have the latest technology.”

Also seen at this year's SEMA show was this '63 split-window Corvette coupe built by Browns Classic Autos. That Edelbrock supercharger sitting on top of the engine adds some serious grunt to this LT1.

It’s a sentiment echoed by Keith Jessee of Holley Performance as well. “The current generation LT truly is the ‘latest and greatest’ in cam-in-block technology. From the direct injection to cylinder head design to oiling system technology and valvetrain technology, this new LT engine is the current pinnacle of small-block Chevy technology. Obviously, the potential for big horsepower is a great reason to choose an LT, but I think the main reason most people are doing it right now is simply to stand out in a sea of LS-powered rides.”

Jared Ochs of Current Performance Wiring agrees, and offers a bit of insight into the rationale behind the developing trend, which is more of a “heart over head” proposition at the moment for most builders. “Right now, I’d say the main thing that is really desirable about the LT engine is ‘to be different’. If you’re a shop who wants to make a name, or a company trying to develop parts, I can see the desire to try and do these so that you can support an eventual aftermarket group,” he explained.

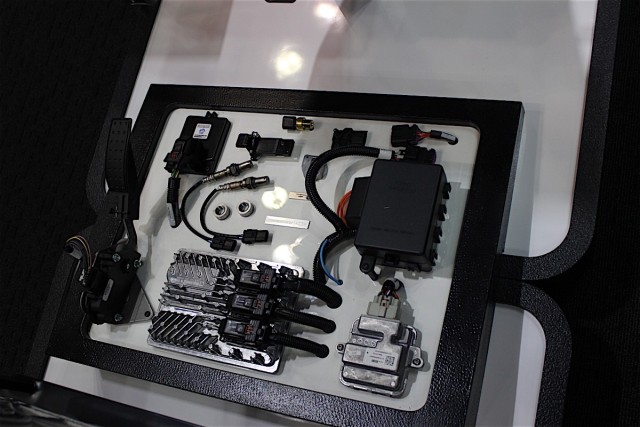

Chevrolet Performance’s Connect and Cruise package comes with almost everything a builder would need in order to get GM’s latest powerplants up and running in virtually any application. Although it doesn’t include the physical hardware to mount the drivetrain to a specific vehicle, it does come with all the essentials needed to get the LT engine talking to the rest of the car, including the ECM, TCM, oxygen sensors, pedal position sensor, MAP sensor, and fuse block.

“But for the end customer, unless you just have access to one of these engines at a great price and you have the ability to make everything mount up and work, I don’t really see a big advantage. We all know the power potential of the LS engines, so you can’t say that the LT platform is just going to make more power, and the engine isn’t really that much different dimensionally then an LS, so it’s not like it will just fit better in something.”

The Gen-V LT platform will one day overtake the LS swap just like the LS swap overtook the old LT1s – as they become more plentiful, cheaper, and gain more aftermarket support, the LS engines will become ‘old school.'” – Jared Ochs, Current Performance Wiring

“When a car takes 1-5 years to build, would you rather plan on using an older fuel injected engine or one with the latest technology already built into it?” muses Greg Was of Pace Performance.

“You don’t see many of the TPI engines in street rods anymore just because once the LS arrived it was known to be far superior and replaced many of them. Now the LT might not hit that status among builders, but it will be close in my opinion.”

New Technology, New Challenges

For builders who’re used to doing things the old school way, these modern powerplants and their requirements can be a bit of an unknown. Compounding that is the transition from the LS series’ use of fuel injection to the high pressure direct injection system of the LT engines, which seemingly adds a level of complexity that makes this a less attractive option versus an LS-series engine for some. But the truth of the matter is that this potential hassle is a bit of a misnomer.

“As of right now, the biggest item is the concern potential customers and builders have regarding the high pressure fuel system,” says Curt Collins of Chevrolet Performance. “But the reality is that the fuel system interface is very similar to our high performance engines like the LS7. The high pressure side of the engine is internal to the engine – and transparent to the installer.”

But for those that want to make tweaks to the fuel system, it presents an obstacle that the aftermarket is currently working to address. “The biggest hurdle in LT swaps has to be the direct injection,” explains Jessee. “This is unknown territory even for some of the more experienced EFI tuners and builders. Direct injection uses several thousand pounds of fuel pressure and there is very little aftermarket support for tuning this type of injection. We currently have a few of the LT-powered COPO Camaros running a Holley EFI direct injection box and hope to make this available to the masses in the near future.”

Ultimate Header's unique construction process allows their headers to use tighter bends than traditional header designs, allowing for better clearance. Their LT1/LT4 swap headers will fit a first-generation Camaro with a Detroit Speed subframe, ’68-’72 GM A-Body, and Tri-Five Chevys.

Packaging is another potential hurdle, but as it happens, there’s not too much to be concerned about here either. “It’s true there are some slight differences that could have an impact,” says Browning. “For instance, the LT4 has an oil cooler on the driver’s side of the block, and some guys are removing that and going to a remote filter. But we design around it, so there really isn’t much of an issue switching over to an LT motor.”

Aftermarket Development

The LT1 and LT4 motors may only be a few years old, but there’s no shortage of companies already offering components to help facilitate LT transplants. “We’ve created two unique castings – one for each of the new LT engines,” says Browning in regards to Ultimate Headers’ LT swap headers. “Compared to the LS series, where we had one casting across the entire lineup, the Gen-V engines are more costly in terms of tooling, but now that those castings have been developed, we can build LT swap headers for practically any application.”

But this early in the game, there’s still a lot of work to be done in order to support the vast range of different requirements that customers need.

Image courtesy of our friends over at The Block.

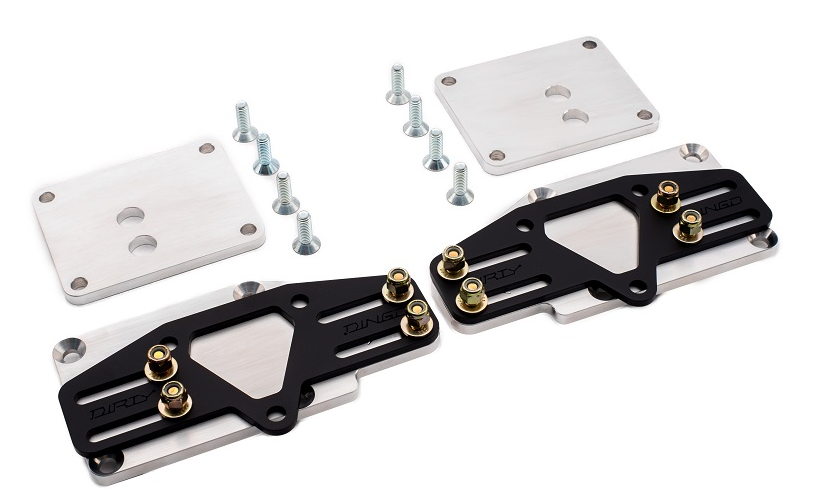

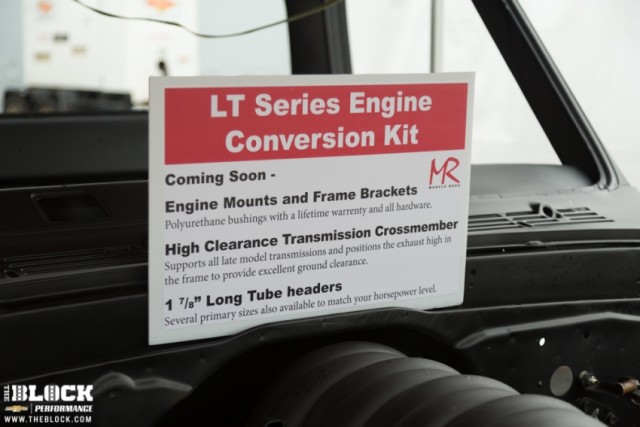

However, well known companies like Trans Dapt, in conjunction with their partner Muscle Rods, are already stepping up to the plate and offering engine swap mounts that allow you to bolt the Gen-V mill into any vehicle that previously came with standard Chevy small-block engine mounts. Their recent showings where in a ’60s C10 and headers from Hedman are said to be on their way as well. This eliminates the need to make custom mounts and headers just to get the newest technology around between your fenders.

Other less known companies such as DirtyDingo Motorsports and ICT Billet are also producing swap mounts for all sorts of Gen-V combos. In fact, DirtyDingo currently offers the only set of LS to Gen-V LT engine mounts we are aware of. Since most of the mounts are adjustable, they will fit a myraid of applications and allow you to custom tailor where the engine will be sitting in the chassis – which typically allows you to retain your stock, or conversion, transmission mounts.

“So far the largest hurdle for the new Gen-V engine swaps seems to be matching up combinations of parts,” says Ochs. “People always like to get that new engine, and then they want to put it on their 4L80e trans, or 700R4, or a T56 or something that isn’t what it originally came with. This can cause issues when the customer wants everything to be 100-percent functional at times. We can only do what the components and programming will allow, so if someone thinks they are going to have cruise control and traction control just because they are using the factory ECM, they sometimes have to have their expectations brought back to earth.”

Although complete solutions in terms of electronics are still a little out of reach, getting these motors to perform well in vintage chassis appears to be a done deal. “These engines seem to need just as little as the Gen III and IV engines in order to run well,” Ochs continued.

“Meaning, a proper wiring harness, MAF sensor, O2’s, 58-60 psi fuel, and that’s about it. So far, the CAN Bus seems to be compatible with the later years of the Gen-IV vehicles. We haven’t done a lot of testing yet to see, but looking at it in reverse, we put an LS3 in a 2015 Colorado and the CAN Bus all communicated with a 2013 and 2014 E38 ECU, so I would imagine that the same could be said for a newer CAN Bus vehicle – that it should be able to communicate fine with the E92 ECU. That doesn’t mean every OS will be compatible with every later vehicle, but over time, I’m sure we’ll figure out what talks to what and the right combinations to make it work in different applications.”

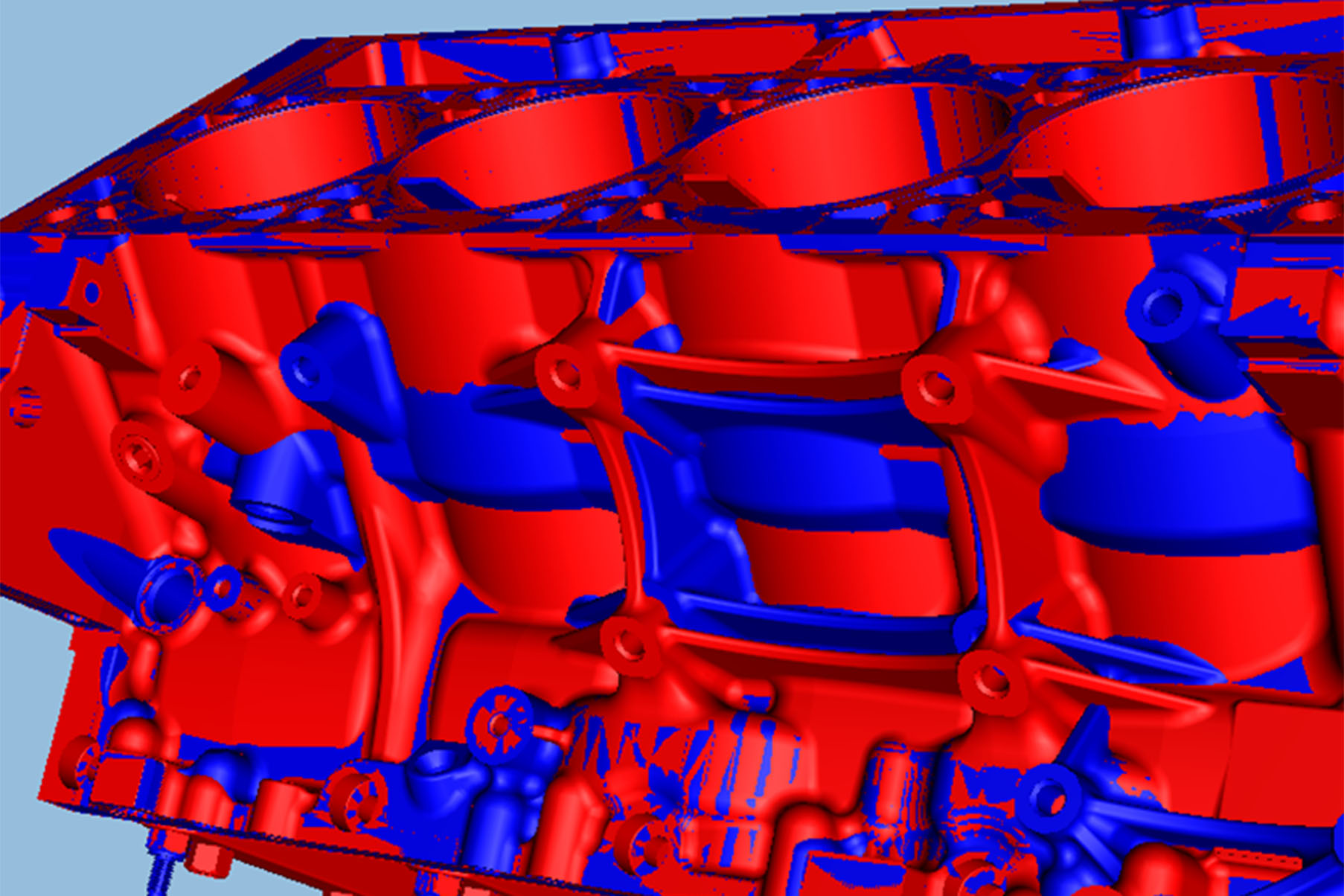

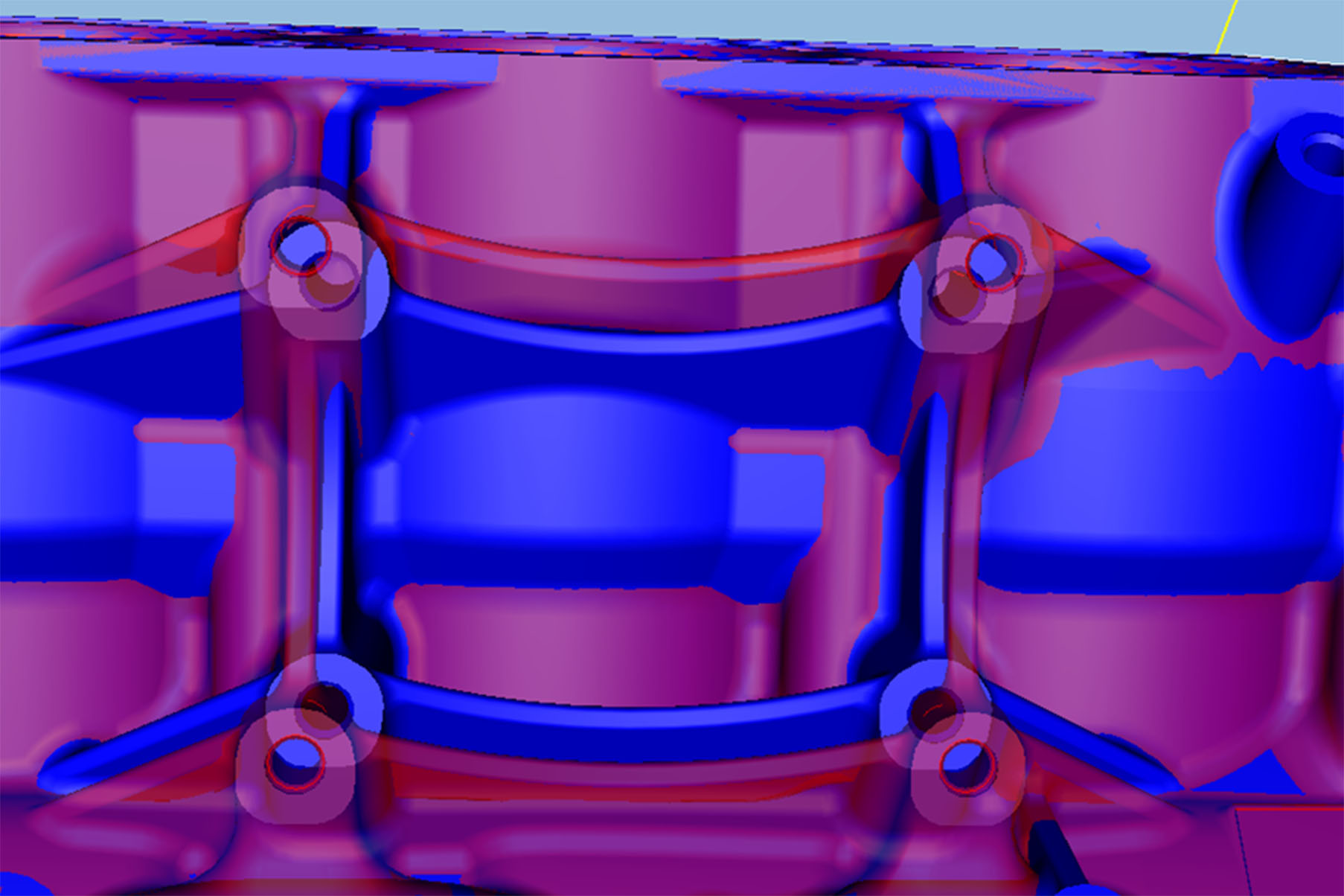

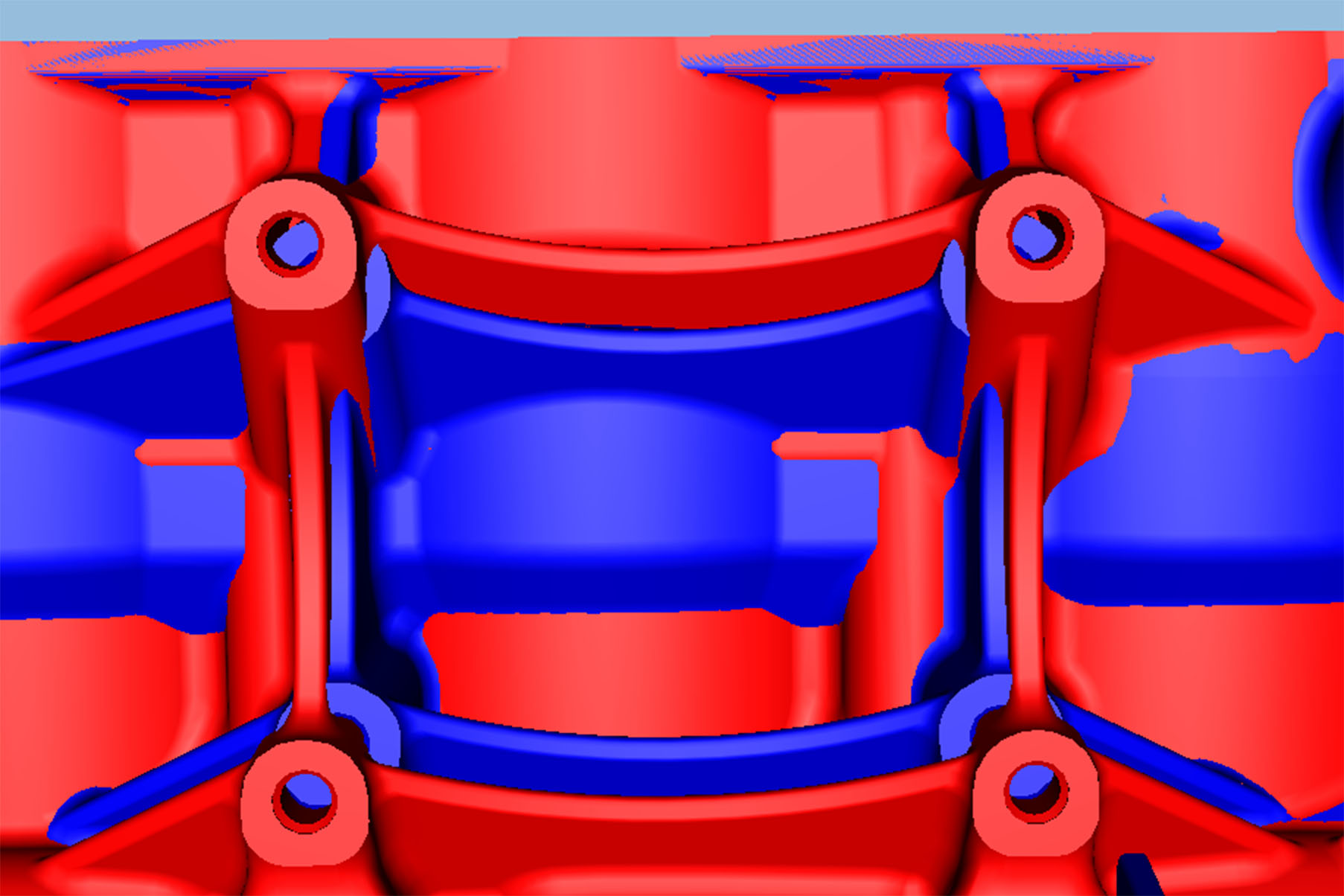

These renderings show the mounting differences between the LS3 (blue) and the LT1 (red). Although very similar, the mounting does differ between Gen IV and Gen V motors, so don't expect to be able to use LS series mounts on Gen V motors.

Holley Performance recently announced a number of LT swap parts and performance components as well, and they’re currently developing parts to allow builders to adapt previous generation hardware to these Gen-V engines. “We’re currently developing an adapter that will allow you to use our pre-existing LS accessory drive kits, Ex: 20-136, 20-137, 20-138,” Jessee told us. “And we’re going to be offering a front drive kit that allows you to use a hydraulic power-steering pump on an LT engine, which should be available within the next few months.”

“The new Holley LT accessory-drive adapter brackets are a step in that direction already,” Pace Performance’s Greg Was pointed out. “They will be perfect for the guy that has the LS engine with the Holley accessory-drive currently able to swap to the LT engine and not have to buy all new accessories. That kit is 21-5, and I’m keeping an eye on availability for our customers.”

Holley Performance unveiled new LT swap parts at this year's PRI show. Their GM Gen-V LT-Engine Swap Oil Pans are designed to solve clearance issues for F-bodies, 68-74 Novas, 78-97 G-body, and 64-72 A-body vehicles, while those looking to add power will soon be able to bolt up Holley's Hi-Ram Intake to a Gen-V engine.

The Road Ahead

With aftermarket development and support already churning out swap components, it’s clear that the LT transplant era is already upon us. But, with literally millions of LS mills currently in circulation, the Gen V engines are likely to live alongside the LS-series engines rather than replacing them entirely, at least for the foreseeable future.

Current Performance Wiring is using this 2014 C7 Corvette Stingray chassis and drive train as a test bed for the development of stand alone, direct fit, and modified harnesses for Gen V engines to be used in all types of engine swap environments.

In time, the LT popularity will continue to grow. Without getting into any specifics, both the LT1and LT4 have far exceeded any launch sales goals we set.”–Curt Collins, Chevrolet Performance

But on the other hand, the tide is bound to change as time goes on, though everyone seems to agree that a changing of the guard is still expected in the relatively distant future.

“In time, the LT popularity will continue to grow. Without getting into any specifics, both the LT1 and LT4 have far exceeded any launch sales goals we set,” Chevrolet Performance’s Curt Collins said.

Seen at last year's LS Fest, this C10 was among the first to get an LT1 swap.

“When we launched the first LS engines, there were concerns at that time regarding a ‘new direction’ for Chevrolet Performance. If you look at the LS today, I think those concerns were put aside. The explosion of LT is coming. The direct injection technology in our LT1 and LT4 engines provides increased fuel economy, increased horsepower/torque, and also reduces cold start emissions. On the other side, the LS market continues to grow, and we don’t see that slowing down anytime soon.”