The Cadillac CTS-V is often thought of as the official racecar of the pragmatist. What we mean is, most people that start a build on one want it to be fast, but they also want it to be practical, so they make compromises on the build. Unfortunately, these two facets often sit in juxtaposition to one another. The more practical something is, the slower and vise versa.

Think about it this way: when you compromise with a significant other, is it really what you want? We didn’t think so. But what happens when someone decides to build a CTS-V that compromises on nothing? Well, you end up building something similar to Jeff Hagaman’s back-halfed 2011 Cadillac CTS-V, and your name is probably Hot Rod Dynamics.

All images via Patrick McGinnis and Mateusz Czarnocki

Getting Back-Halfed

You may be thinking “did they really just say back-halfed?” And the answer is a resounding yes. See what we mean about no compromises? When Hagaman first brought his CTS-V to the guys over at Hot Rod Dynamics, he told them he wanted to fit a Mickey Thompson 315 ET Street Radial Pro under it; oh, and enough horsepower to take the portly Caddy to 200 mph in the standing half-mile. Unfazed, Joe Lutz, the owner of Hot Rod Dynamics, told him “no sweat.”

Here you can see how much of the floorpan Hot Rod Dynamics removed to make way for the 4-link suspension.

You can see here that back halfing the Cadillac was no easy task, requiring virtually annihilating the back of the car.

The first order of business? Removing the entire rear of the car. After the stock suspension was stripped away, it was time for the guys to get cutting.

“We basically cut it from the bumper to the front seat mounting position, and fender to fender, then dropped it all out and then started all new.” Lutz said. “We built new frame rails and floor and trunk and all that stuff. It was the only way to get the tire Jeff wanted to fit under it, was to back half it.”

The rear wing, front splitter, and parachute are all put to good use as the V2 makes 200+ mph passes at half-mile events.

When the smoke cleared, the team at Hot Rod Dynamics were left with the perfect canvas on which to paint a masterpiece of drag racing tech. In place of the stock independent rear suspension, a solid rear axle from the guys at Mark Williams with a housing from Competition Engineerin now resides. It’s a 9-inch unit with 40 spline, gun-drilled axles and a spool—remember that no compromise thing? Yeah.

“Jeff’s main goal was to throw a big tire under it when he first came to us. We really couldn’t come up with a reasonable way to do that, other than to back-half it because of the way the rear suspension is made, you just don’t have enough room—no matter what you do with it—to get them to fit,” Lutz explained. “He really didn’t want to flare the fenders out anymore than stock and wanted to keep it looking kind of stock on the outside, so that’s really the only choice we had.”

The rear suspension and frame rails are tied into the Cadillac’s chassis so flawlessly that you would almost guess it left the factory like this.

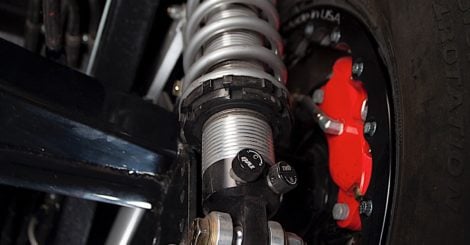

QA1 double adjustable coilovers help the Cadillac plant almost 2,000 horsepower to the ground.

The four-link suspension that now underpins the V2 was designed by the Hot Rod Dynamics team in house using computer aided design (CAD). All of the pieces were then cut out on the crew’s plasma table and welded into place. While that may seem pretty straightforward, getting the geometry right on a setup such as this is crucial. Luckily for Hagaman, the experts at Hot Rod Dynamics have been around the block a few times, to say the least.

After the four-link was sorted out, a custom floorpan was built to allow the interior to stay as stock as possible. This enables the car to retain its trunk and rear seat (more on that later). With the rear of the car buttoned up, the crew shifted their focus to the front of the car.

The CTS-V tucks the massive rear meat so well, you almost don't realize just how gigantic they really are.

The Powerplant

Since Hagaman had lofty goals for the 4,000+ pound Caddy, Lutz knew that they were going to have to go with something pretty potent under the hood. And by potent, we mean in the realm of 2,000+ horsepower potent. For that, he turned to Tim Lynch at Lynch Mob Racing to spec and assemble an engine suited to the task.

Lynch started things off with an LSX block and then stuffed it with a 4.00-inch forged crank from Callies. Combined with a 4.125-inch bore, the LS displaces 427 cubic inches. Forged slugs and connecting rods from Diamond and Callies respectively, along with a boost-friendly 9:1 compression ratio, allow the mill to take on some serious atmosphere.

Twin Precision 72/75 turbos feed the 427 cubic inch mill massive doses of atmosphere.

Feeding the mill fresh atmosphere is a custom intake designed and built by RCI Performance. Oddly enough, cathedral port AFR heads top off the mill. And while cathedral ports might seem like an odd choice on such a build, the heads were selected by Lynch, in conjunction with Brian Tooley, for a specific reason. The cathedral ports on the heads help improve air velocity down low and bring the turbos online sooner. Since the engine has no problem creating peak power, it was important for the powerband to be as wide as possible. And, with as advanced as cylinder head technology is these days, the difference between a cathedral and square port cylinder head can sometime be marginal, even at max lift.

Once the engine was assembled, it was back to the guys at Hot Rod Dynamics so they could fabricate the turbo kit. Using 304 stainless steel, the kit was designed to be used in conjunction with twin Precision Turbo 72/75 mm turbos. Dual 46 mm Precision wastegates keep boost from getting out of hand and twin blow off valves make sure all that boost has somewhere to go when the throttle blade slams shut.

The engine bay and plumbing on the turbo setup is downright sanitary. The fit and finish on the engine bay is spot on.

An air-to-water intercooler is used to keep the incoming air charge frosty and is hidden under the dash where the A/C would normally sit. In the trunk, the Caddy sports an easy-to-access ice box that allows the team to keep the intake air temperatures even lower.

Handling fuel delivery duties are twin Holley EFI brushless fuel pumps controlled by a Holley EFI Dominator setup which delivers plenty of fresh Q16 to the bullet. One of many unique touches on the car is the fact that Hot Rod Dynamics has incorporated the Holley touchscreen right into the retractible display originally reserved for the V’s navigation system—adding to the factory looks of the car’s interior.

Here you can see how Hot Rod Dynamics integrated the Holley EFI system with the pop-up display where the old navigation system used to reside. It displays all of the pertinent information the Holley system is spitting out.

“It’s disgustingly powerful,” Lutz joked. “We made 1,450 horsepower to the rear tire on like 24 pounds of boost, and we’re at 36 now. It’s probably making 1,600-1,700 horsepower at the wheels. Turned all the way up, Tim says it should be good for roughly 2,000 horsepower.”

It’s About What’s On The Inside

“Jeff wanted us to basically leave the interior completely alone. He even wanted to use the factory front seats, but with the cage there’s just no way to do that, so we had to change them out,” Lutz told us. “But other than that, the radio and everything along with it are still in it. Stock gauges, carpet, headliner, even the rear seat is still in it. That was one of the main requirements, it had to have a back seat. We wanted someone to walk up to it, look in it, and basically not be able to tell the difference from stock—besides the cage.”

The shifter, seats, and cage are really the only giveaways in the cockpit that something beastly lurks beneath the surface.

In order to keep everything functioning as it did from the factory, Hot Rod Dynamics actually had to piggyback the stock computer with the new Holley EFI system. This allows all of the outputs from the Holley system to be displayed as if the factory computer was running the car.

Lutz tells us it was no easy feat to get the rear seat in the car after the tubs were in place. In order to facilitate the request, Lutz turned to the experts at Rick’s Auto Trim.

“We had a local interior guy named Rick Coffee, of Rick’s Auto Trim, he took the back seat and basically kept cutting away at it until we could get it to fit over the modified rear tubs and floor,” Lutz said. “It looks really good and it was amazing that he could get it to fit back in there, but it’s in there.”

As you can see, the rear seat is still fully intact and useable. It's hard to tell the two giant tubs sit right beneath them.

Where The Rubber Meets The Road

Since the aforementioned set of prerequisite Mickey Thompson ET Street Radial Pro 315s needed a home, Hot Rod Dynamics opted for a set of 15X12-inch Billet Specialties wheels with a stock set of CTS-V wheels handling duties up front.

The double beadlocker wheels from Billet Specialties really finish the car off. Matching front wheels were unavailable for the CTS-V so Hot Rod Dynamics decided to stick with a set of stock CTS-V wheels up front.

To keep the tires planted on terra firma, Hot Rod Dynamics designed and built a custom carbon fiber wing for the car that features an adjustable wicker bill design. Since the car will be seeing speeds in excess of 200 mph, the added stability was a must.

Two massive Wilwood calipers in the rear provide enough clearance for the 15-inch wheels while still providing enough stoping power to bring the car to a halt from 200+ mph speeds.

If You’re Not First

Once the car was up and running, Jeff and the Hot Rod Dynamics crew knew of only one way to test the cars mettle, so they headed to the nearest wannaGOFAST event to see what it would do. Not only would this give them a chance to see what the car was capable of, but sort out any bugs in the new setup.

“When we went to our first wannaGOFAST event, we set the record for the half-mile our first time out. That was with an RPM six-speed manual transmission TR6060,” Lutz said. “It had an RPS quad-disc clutch in it but we had some serious issues with the factory hydraulic system that caused a lot of issues for us and we actually ended up hurting the transmission going into Fourth gear. Long story short, we have switched it over to an automatic now.”

We don’t blame the guys for ditching the TR6060 in favor of an auto. While it’s awesome to row your own gears, at nearly 2,000 horsepower, coupling that kind of power while trying to go as fast as possible starts to become a game of diminishing returns.

For shifting duties, they installed a built Powerglide transmission from the guys over at PTC who also provided a billet bolt-together torque converter.

It turns out the change to the automatic was enough to do the trick. On May 20, 2017, the Caddy went 212.86 mph at a wannaGOFAST event in North Carolina, breaking their own previous record of 190 mph and officially making this the fastest half-mile CTS-V in the world. Not bad for a car that tips the scales at 4,300 pounds including the driver. Lutz says that quarter- and eighth-mile drag racing are next.

The "remove before flight" ribbon on the parachute is quite apropos.

“We’re shooting for low-5s in the eighth and eventually looking to go 4.90s,” Lutz said. “That should put us somewhere in the 7.50-7.70 range in the quarter.”

This back-halfed brute is a shinning example of just what can be accomplished when someone refuses to compromise. But, with a rear seat and all the modern refinements of the standard CTS-V, maybe you can have your cake and eat it too.

Photographers: Patrick McGinnis and Mateusz Czarnocki