There is no doubt that the internet is a useful gadget that holds a plethora of knowledge. However, it can also be a huge waste of time as you weed through incompetent information, bench racing, opinions, and cat memes. When it’s time to purchase a product for your vehicle, it’s always a good idea to call the product manufacturer if you have a question. They’re the expert in the field and should be able to answer any inquiries that you have, and maybe even some that didn’t come to mind.

When it was time for a new rear axle assembly in our 2000 Chevrolet Silverado, we knew who to call. Moser Engineering has been atop the competition since 1986 and continues to provide industry-leading products with axles, rear end components, and service. We had a good idea of what we wanted, but we didn’t know what we needed due to the truck’s weight and our horsepower goals.

After searching the web to see what was popular, it was evident that everyone had their own opinion and very few facts to back them up. Currently, the full-weight truck has a 6.0-liter with a stock bottom-end, 76mm Trick Turbo System, factory rear end with 3.73 gears, leaf springs, and Calvert Racing CalTrack bars. After a bit of research, we thought the best option for our needs was the Muscle Pak 12-bolt for the Silverado. This unit comes from Moser, ready to bolt in the factory location and uses all of the mounting points in the truck, making for a simple swap.

We reached out to Shane St Meyers, Sales and Tech at Moser Engineering to see if we were on the right track.

The first part of our conversation went as you might think. Shane asked us detailed questions about the truck and what our goals were. Our purpose is pretty simple for the Silverado. We want to make modest power with the turbo setup, for now, while maintaining street manners driving around town. On the weekends, we plan on heading out to our local dragstrip and have some fun.

We told Shane what we thought we needed, and right out of the gate, he shot down our idea. It wasn’t that the 12-bolt wouldn’t hold up to our current power level of the truck; it would with no problem. The predicament was, our current combination is good for 600 horsepower, and we intend to crank it up… A lot. Shane said, “For what you guys are doing with that kind of power potential in a heavy vehicle, I recommend the M9 Fabricated 9-inch Ford.”

If you are not familiar with Moser’s M9, you need to check it out. This rear end is a work of art that can take some severe abuse. Moser builds this 9-inch housing in house, which means they don’t use any remanufactured, refurbished, or rebuilt components with this assembly. The standard M9 Muscle Pak includes; a new heavy-duty (9-inch Ford) made in the USA fabricated housing, OEM located mounting provisions, seamless steel tubing, custom alloy 31-spline bolt-in axles, bearings, studs, seals, heavy-duty retainer plates, new housing ends, t-bolt kit, Trac-Loc clutch type posi, “1310” series pinion yoke, ring & pinion, Timken bearings, new drum brakes, brake lines, brake line clamps, and emergency brake cables. The best part is, it shows up to your door completely assembled and ready to install.

Due to the 4,400-pound weight of the truck and our expected future horsepower levels, it makes more sense to overbuild the rear end and not have to do it again later, saving us time and money in the long run. With these factors in mind, Shane suggested a few upgrades over the standard package. He said, “If your planning on keeping the leaf springs and CalTrack bars, we can actually box the perches in to make them more rigid. I would also recommend running the back brace as well.” Per Shane’s recommendation, we also upgraded to the more robust “1350” u-joint in place of the “1310” unit that comes standard with the Muscle-Pak. These modifications will allow the M9 to hold up to our needs effortlessly even in the heavy truck.

At this point in the conversation, we knew which housing we were going to utilize and the modifications needed for durability. Now we needed to figure out what axles to use and which posi unit. Luckily for us, Shane had the answers. Shane said, “I would recommend 35-spline axles and a Wavtrac posi unit.” Shane continues,” Wavetrac offers a lifetime warranty on their products, and it’s a great piece. The units don’t ratchet or click, they are very quiet and can hold up to 1,000 horsepower. Their products are awesome.” Wavetec is not the only manufacturer on this build that offers a warranty. Moser also has a warranty on its 35-spline axles that covers them from breakage up to 10-years when used for drag racing.

Now that we knew what we needed precisely, we also had a few requests on the build. If you are familiar with this body style truck, you know that one of the rear shocks faces forward while the other one faces backward. While this configuration works well for a stock vehicle, this type of placement is less than ideal for drag racing. Shane said they could make the shock mounts the same for us. We also wanted to narrow each side of the axle tubes 1.5-inches for a total of 3-inches, allowing us to tuck the rear tires. Shane told us to mark these changes on the build sheet, but more on that later.

All that was left was figuring out a gear ratio and brakes. For these items, we once again turned to Shane and his expertise. Since we’re now running a turbo setup instead of nitrous with a 28-inch tall tire, Shane recommended going with a 3.50 gear set in place of the 3.73 unit we previously ran. The new gear will be perfect for driving around town and drag racing with our turbocharged 6-liter powerplant.

Selecting a set of brakes was not a difficult task, either. We knew that we needed something that would work at the track as well as on the street. Wilwoods were the logical choice, but we needed to do some measuring to figure out what would work. Shane fired off an email with the dimensions we needed to figure out which brakes we could use. After a quick measurement of the 15-inch Bogart Racing Wheels, it was apparent that we needed to run the DynaPro Low-Profile series from Wilwood on this package. We simply didn’t have the real estate required for the other combinations.

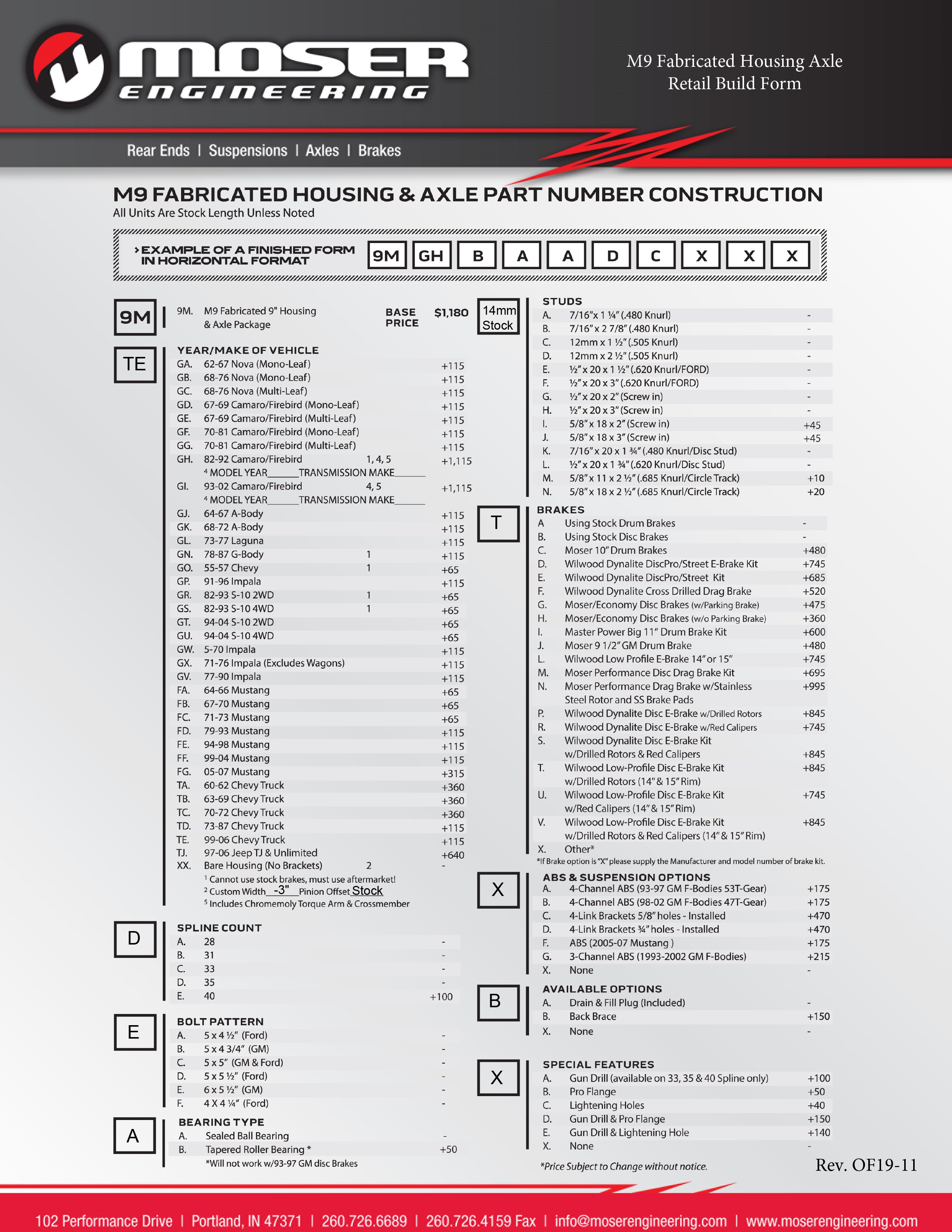

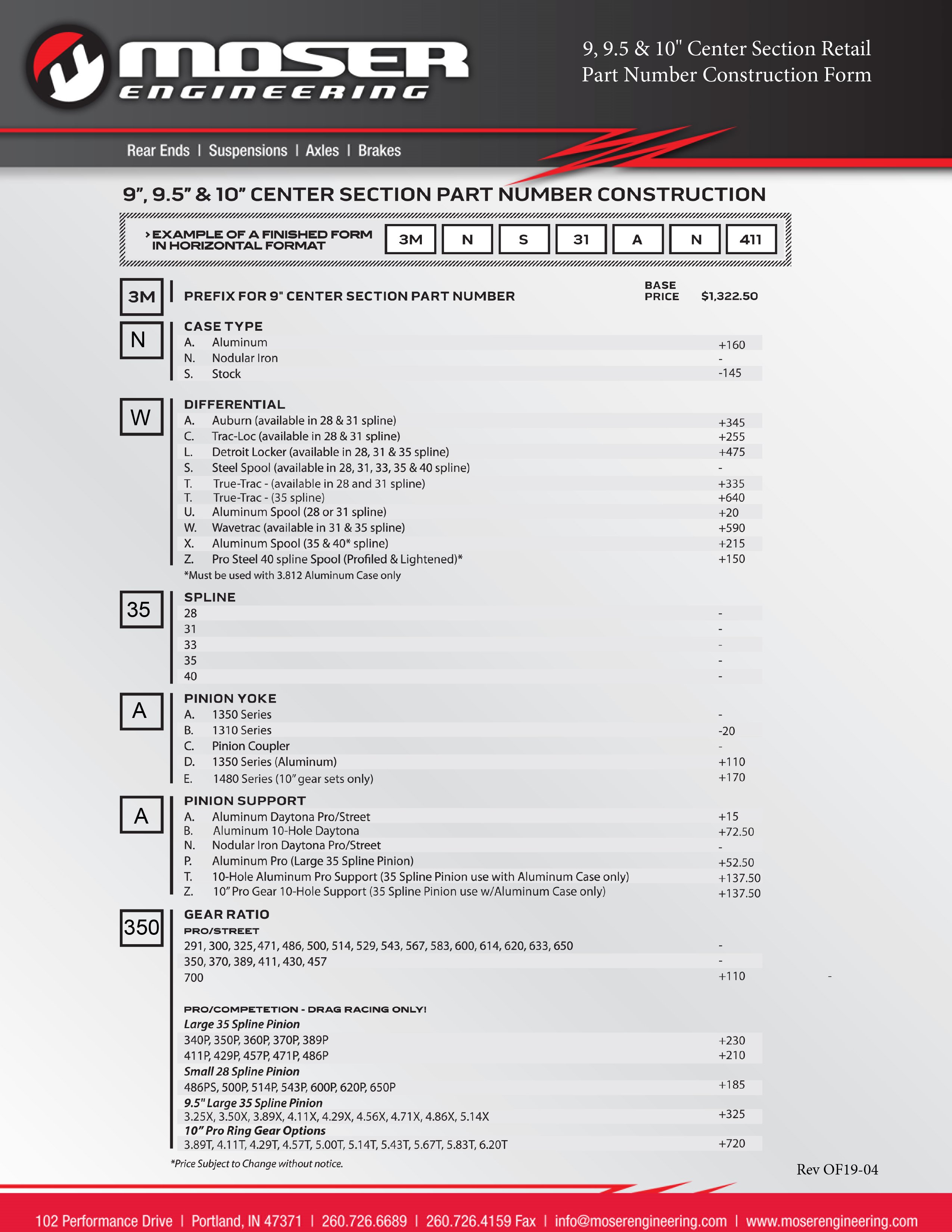

It was now time to fill out the order forms and get the rear axle into production. Shane was kind enough to show us which ones we needed and even helped us complete them while on the phone. For the M9 build, you will need to fill out two forms, one for the housing, and another for the center section. You can see the build sheets that we filled out below, and Moser would prefer that you fill them out over the phone with one of their techs. That way, if any questions come up, a technician can talk to you about the advantages or disadvantages of each option listed. Even though we had talked to Shane extensively about what we needed, we still had a few more questions as we completed the paperwork. When we were done with this process, we submitted them to Moser for review. After Moser receives the order, it only takes a couple of days before they build and ship it to your door.

By the end of our highly detailed conversation, it is evident that we were not experts in the axle world. What we thought we needed, in the beginning, was vastly different than what was ordered. While our initial choice would have worked, it would not have been ideal for what we want to do in the future. Thankfully, Moser has a team of experts in place that can answer any questions that you may have and can walk you through the process so you get what you need.

While the internet may be a good source of information, Shane at Moser served us much better for our rear end selection process. We were able to cut to the chase and find out exactly what we needed thanks to their experienced staff. Best of all, we avoided getting sidetracked with another ridiculous internet cat meme during this process, well almost.